Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

184 results about "Phase change enthalpy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

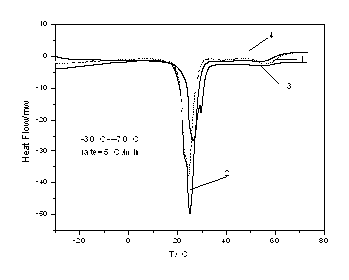

Composite phase-change heat-storing material using gel as carrier and method for making same

InactiveCN101117572AImprove stabilityPromote recombinationHeat-exchange elementsTemperature controlThermal stability

The present invention provides composite phase transition heat accumulation material used gel as carrier, and the preparation method and the application of the material. The material of the present invention is formed by compositing the phase transition heat accumulation material accounted for 60 percent to 80 percent of the total mass into a macromolecule gel carrier accounted for 20 percent to 40 percent of the total mass, the material has thermo-plasticity and better thermo stability, compared with the same kind of macromolecule heat accumulation material, the material has higher phase transition enthalpy. The material can be used in temperature control and energy saving for buildings, and can also be used in heat preservation and energy saving fields for daily articles, thereby the present invention has wide application prospect.

Owner:CENT SOUTH UNIV

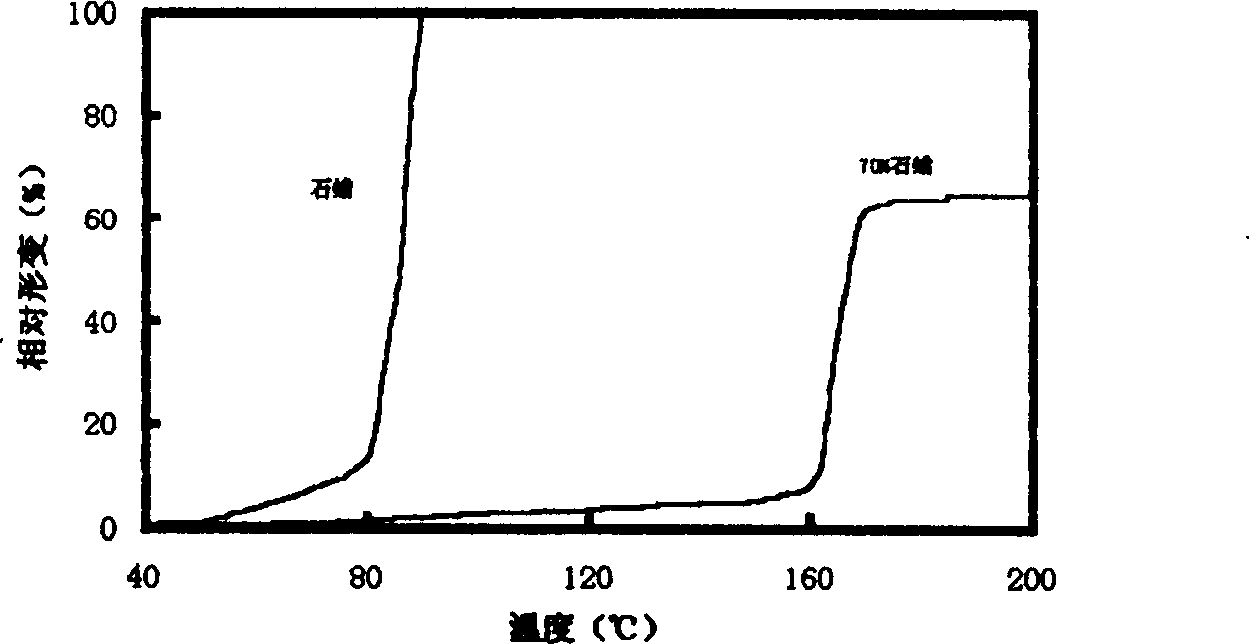

Process for preparing shaped phase change material

InactiveCN1369537ANo leaksThe phase transition process is reversibleHeat-exchange elementsParaffin waxPhase change enthalpy

A process for preparing a form-fixed phase change material includes plasticizing olefine polymer (10-50 wt.%) to become chips, gradually adding paraffine until its content is 90-50 wt%, breaking, smelting-extruding out, water cooling and baking. The said polymer may be at least one of polyethene, polypropene, polybutene, etc. The resultant material features 25-70 deg.c for phase-changing temp, high phase-changing enthalpy up to 175 KJ / kg and no molecular leakage.

Owner:TSINGHUA UNIV

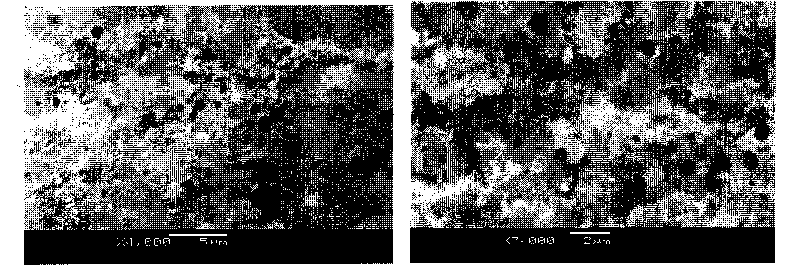

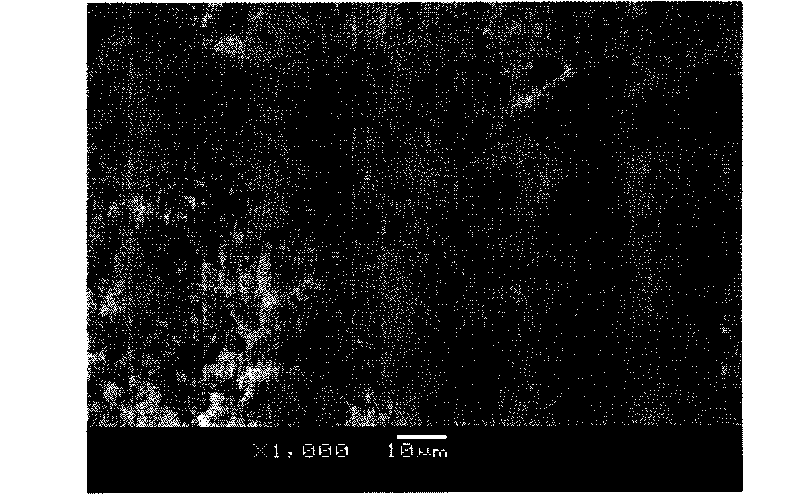

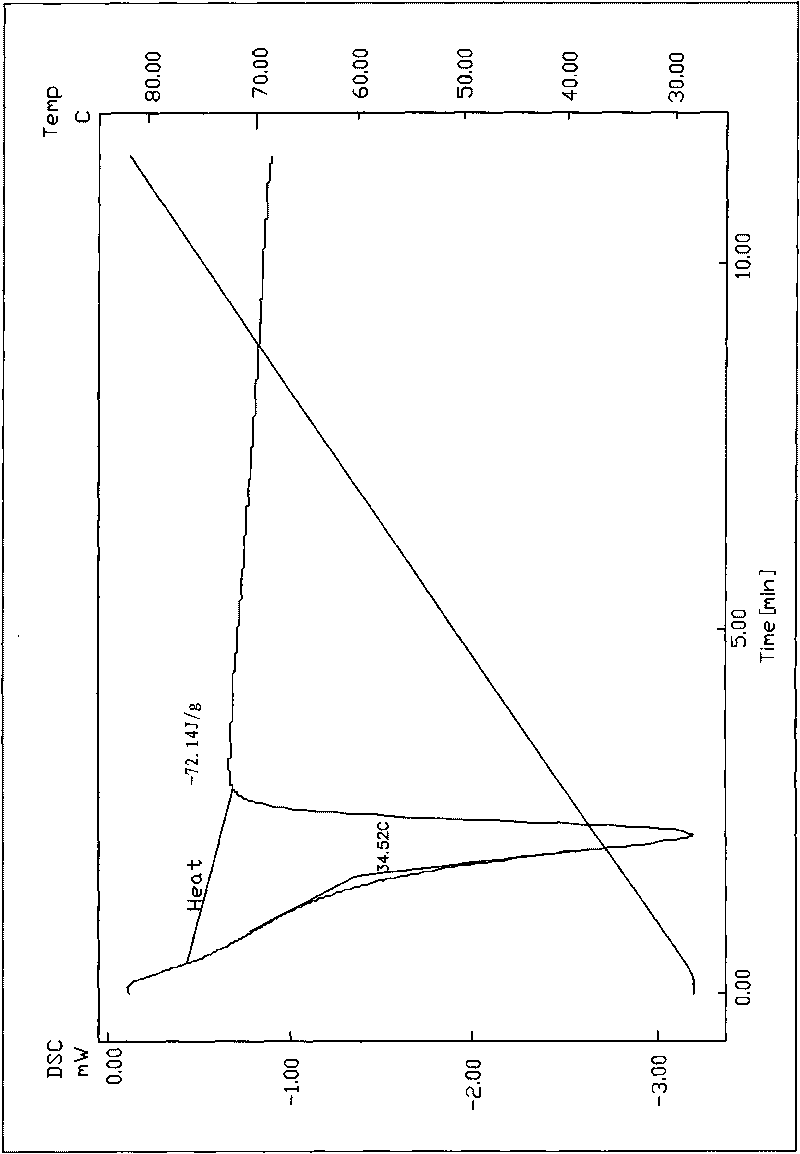

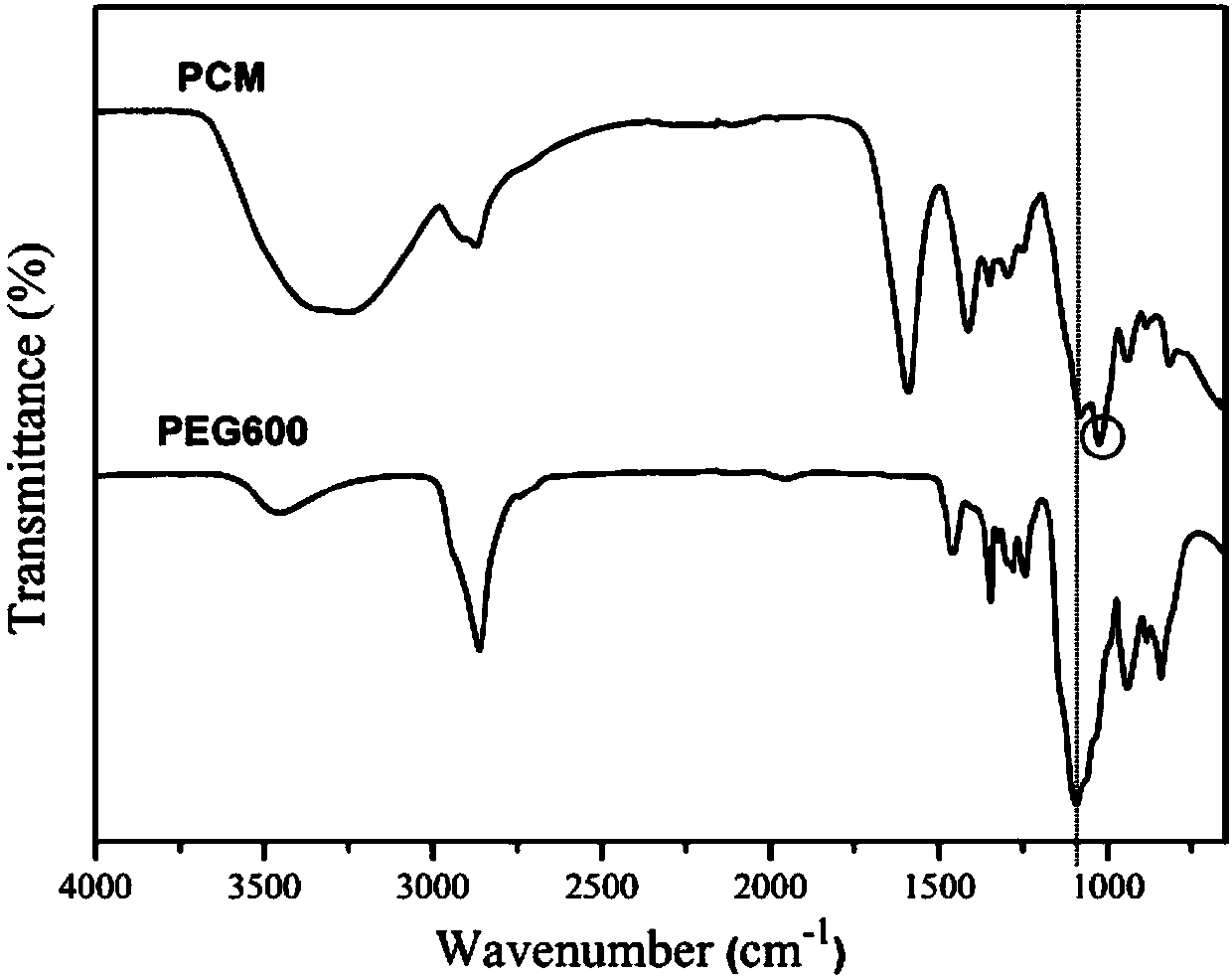

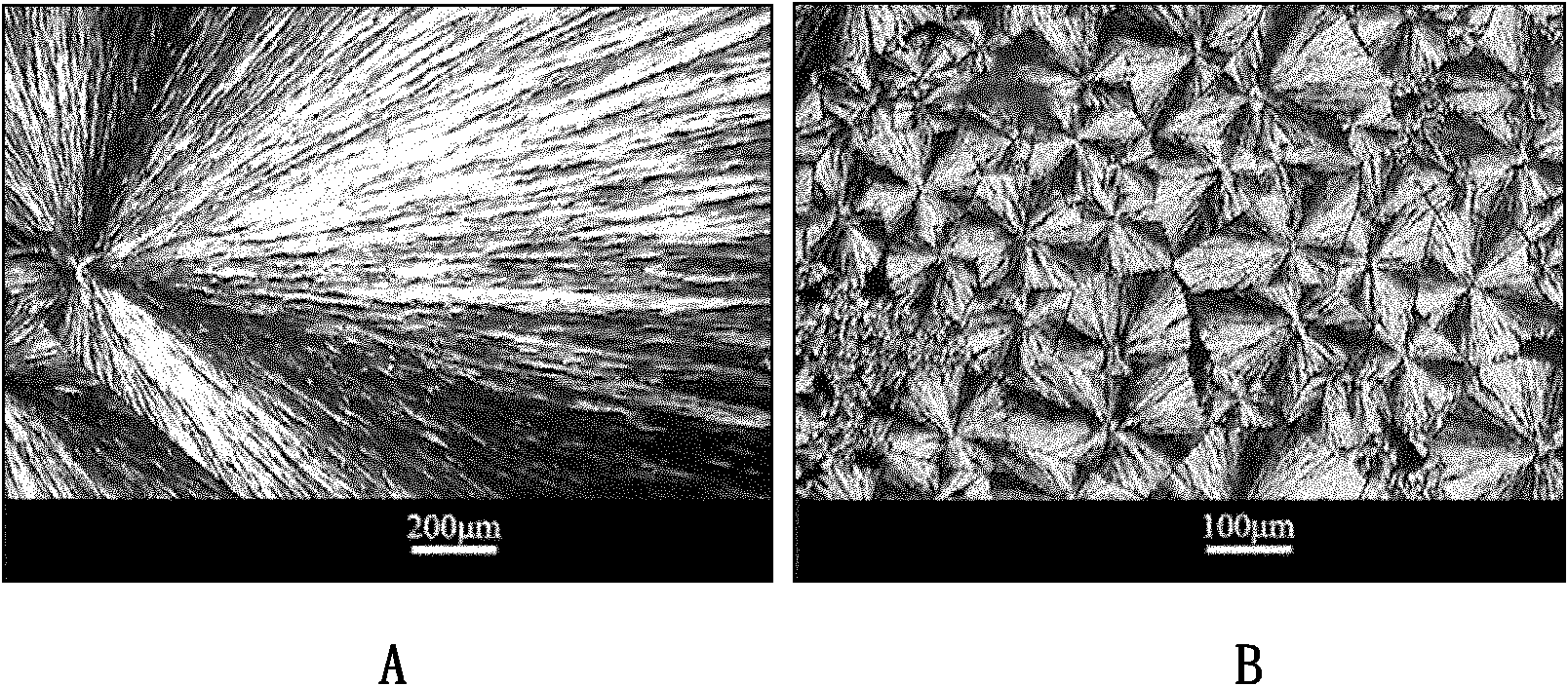

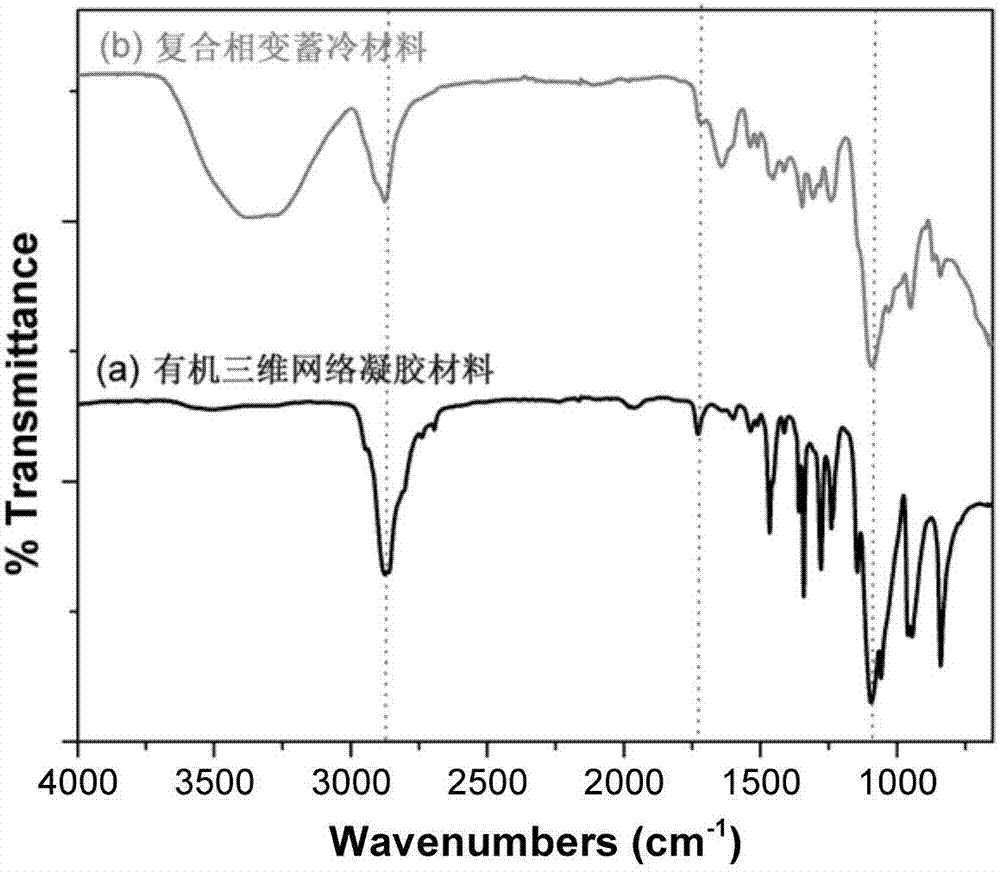

Three-dimensional gel network carrier and form-stable phase change composite material

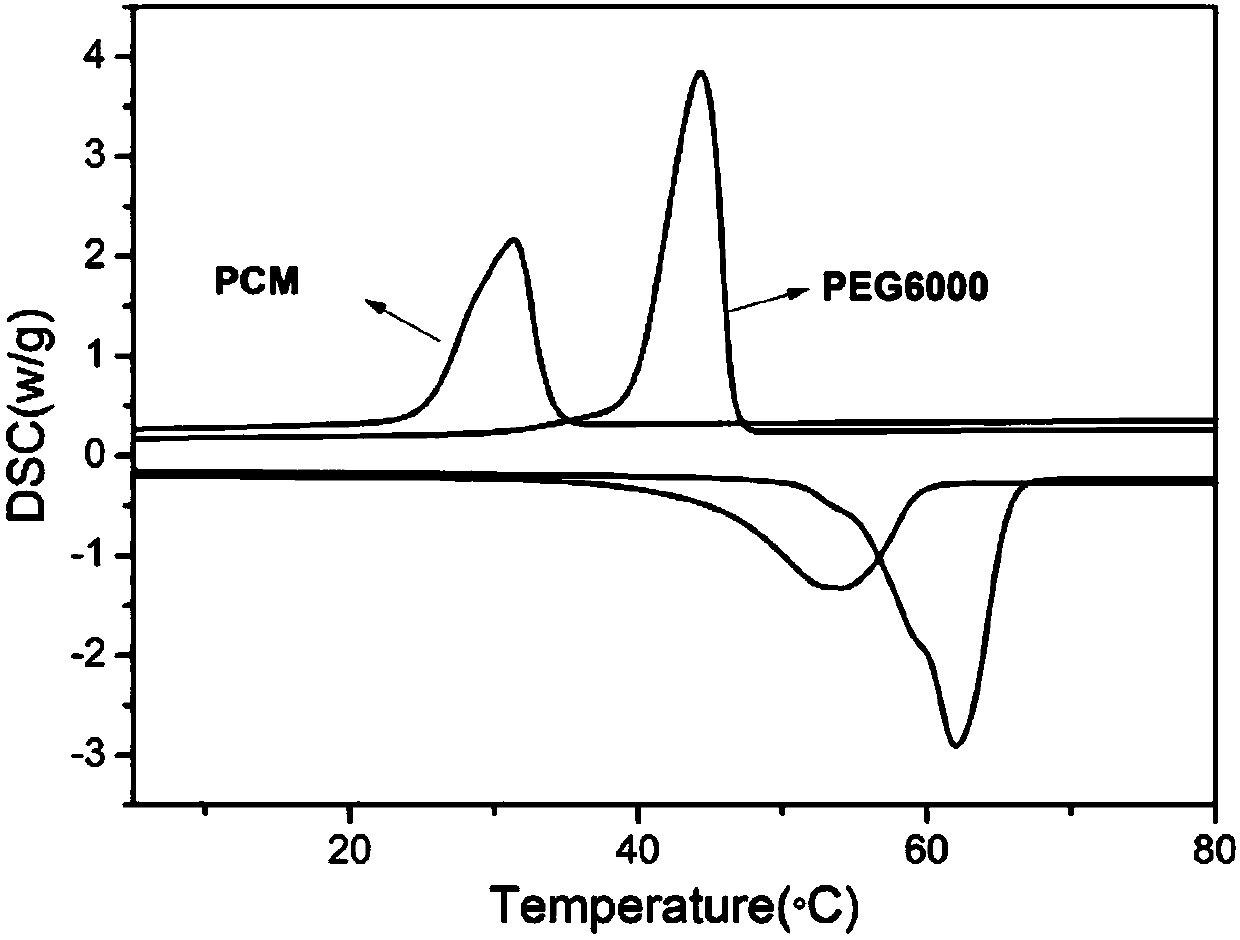

InactiveCN101709104AReduce lossesNo lossHeat-exchange elementsPhase change enthalpyPolyethylene glycol

The invention relates to a three-dimensional gel network carrier and a form-stable phase change composite material which adopt fatty acid (hydrocarbon), polyethylene glycol and other organic phase change materials as work material and use poly-(N-hydroxymethyl)-acrylamide heat-shrinkable interpenetration network as form-stable carrier. The preparation method of the phase change composite material comprises the following steps: firstly adopting low temperature eutectic method to select multiple components composite phase change material with proper phase change temperature, high phase change enthalpy and low cost, designing and determining the preparation method of the interpenetration network carrier and the addition mode of the composite phase change material and the combination mode of the carrier, preparing the form-stable phase change composite material based on multiple actions of bonding, physical adsorption and network confinement, cooling and grinding to obtain the form-stable heat storage functional particles. The form-stable phase change composite material containing 50%-75% of material can be prepared by the method, the maximum phase change enthalpy can be up to 110J / g, and the form-stable phase change composite material prepared by the method can be directly applied in the textile field, building field, military field, etc.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Thermal conductivity enhanced organic composite shaped phase change material and preparation method thereof

ActiveCN108048045AImprove thermal conductivityHigh phase change enthalpyHeat-exchange elementsThermal energyCross-link

The invention relates to a thermal conductivity enhanced organic composite shaped phase change material and a preparation method thereof, and belongs to the technical field of new materials. The thermal conductivity enhanced organic composite shaped phase change material is characterized in that the composite shaped phase change material is prepared from, by mass, 1-50% of coordination cross-linking network polymer, 40-98.9% of organic solid liquid phase change material and 0.1-10% of thermal conductivity enhancer, wherein the coordination cross-linking network polymer is prepared by coordination complexation of a polymer compound with metal ions. The material has a simple synthesis process, convenient application, a large phase change enthalpy value and an excellent shaping effect, and liquid leakage does not occur during operation. The material has a simple synthesis process, convenient application and broad application prospects in the field of thermal energy storage and management.

Owner:DALIAN UNIV OF TECH

High molecular solid/solid phase changing material with net type and comb type mixed structure and its preparing method

InactiveCN1616588APhase transition temperature is suitableSolid state goodHeat-exchange elementsPhase change enthalpyPolyethylene glycol

The present invention relates to a kind of high molecular solid / solid phase changing material with mixed net and comb structure, and features that polyglycol with two active end radical and polyglycol with one active end radical are fixed onto the high molecular skeleton material to form 3D mixed net and comb structure. The material of the present invention has relatively great phase change enthalpy up to 120 J / g, proper phase change temperature capable of being altered in 0-65 deg.c, stable solid state before and after phase change without supercooling, separating and other unstable phenomenon, high mechanical strength, high solvent resistance, good machining performance, no toxicity, no leakage, no corrosion, no pollution, long service life and other advantages. The present invention may be used widely in solar energy utilization, afterheat recovering, intelligent air conditioner and other fields.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

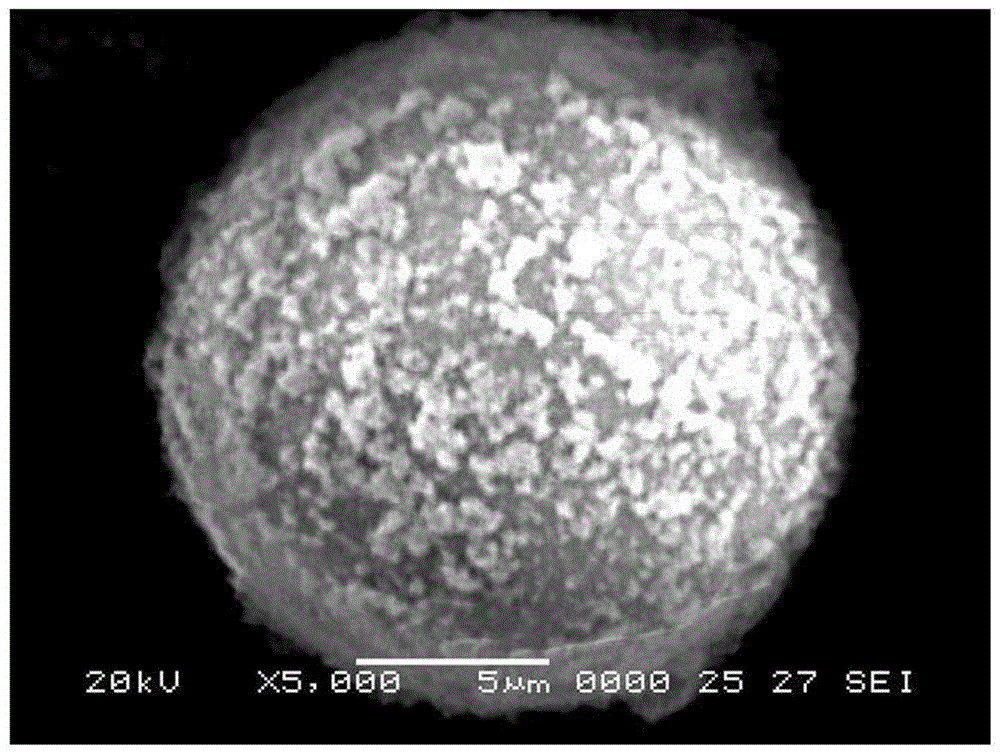

Preparation method of phase transformation material for microcapsult packing and forming

InactiveCN1657587AHigh mechanical strengthImprove hydrophilicityHeat-exchange elementsMicroballoon preparationParaffin waxPhase change enthalpy

A phase-changing material in the form of micro capsule is prepared from the phase-changing material (paraffin wax) and basic supporting material (polystyrene and polyethene) through heating for fusing, mixing for coating, and microcapsule packing by in-situ polymerizing by melamine modified urea-aldehyde resin. It has adjustable phase-changing temp (0-70 deg.C) and high phase-changing enthalpy (138 KJ / kg).

Owner:北京巨龙博方科学技术研究院 +1

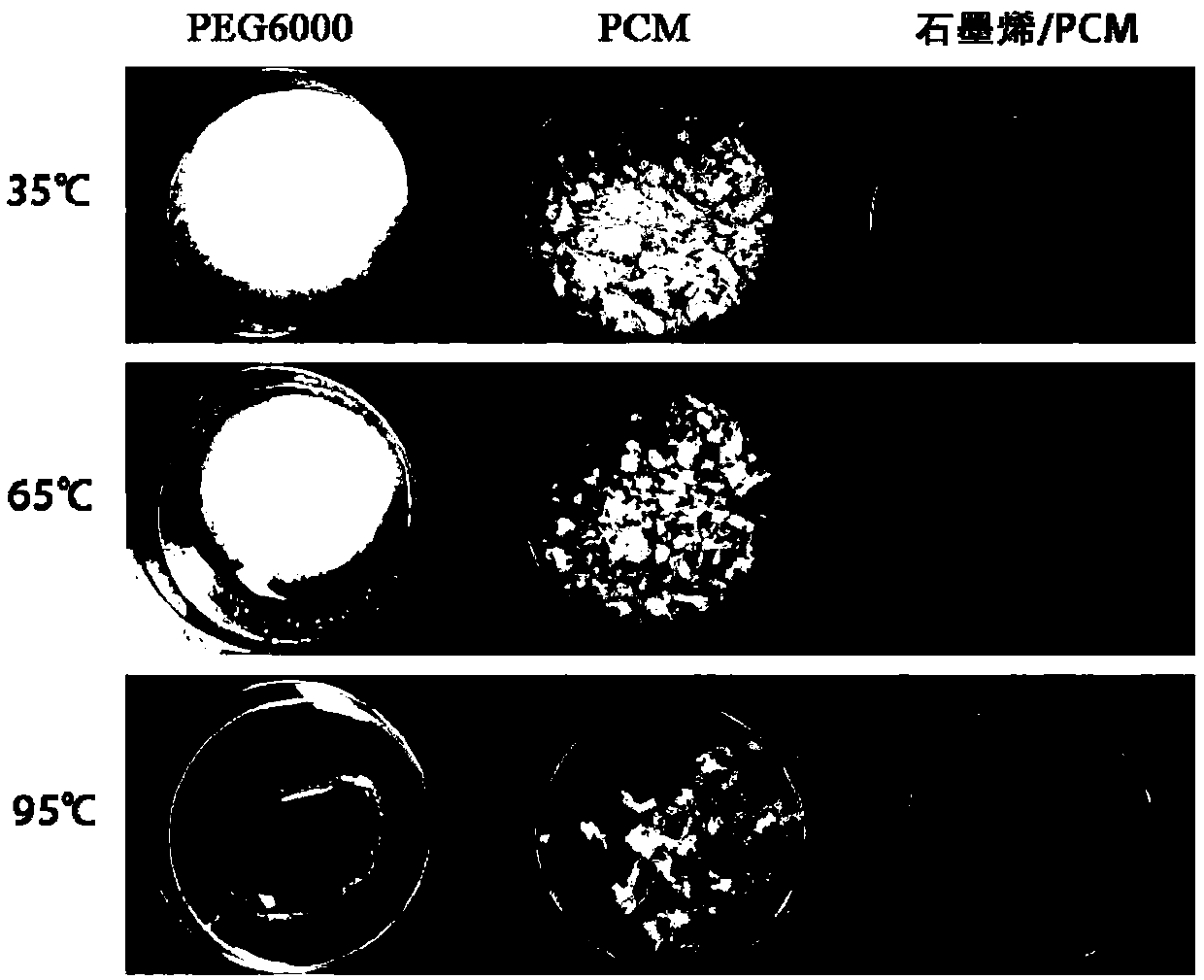

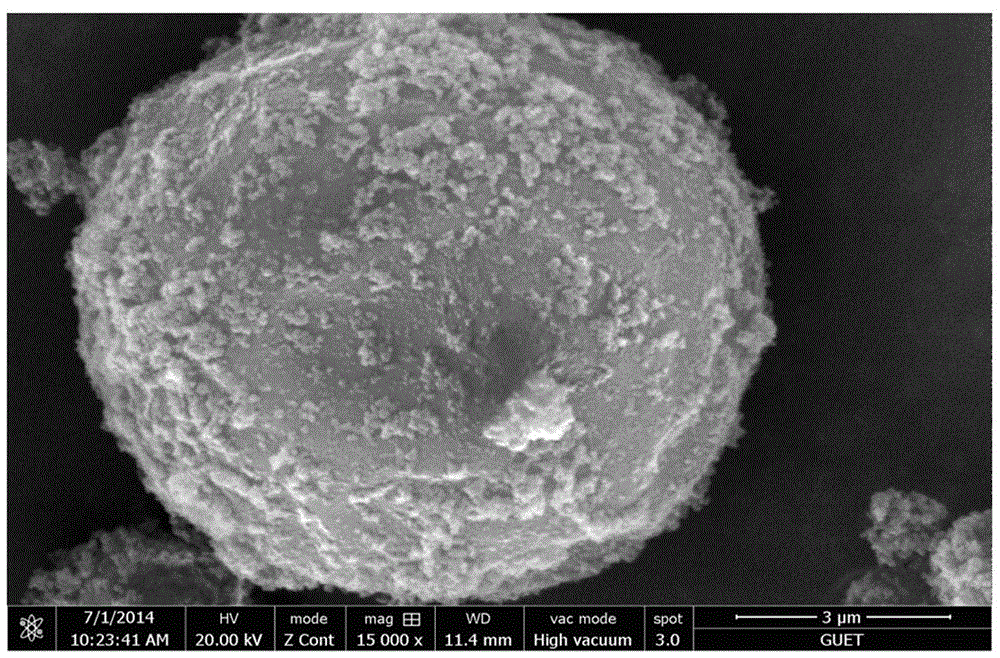

Nano thermal conductivity enhanced microcapsule composite phase change material and preparation method thereof

ActiveCN106085368AImprove efficiencyImprove thermal conductivityHeat-exchange elementsMicroballoon preparationPhase change enthalpyNanoparticle

The present invention discloses nano thermal conductivity enhanced microcapsule composite phase change material and a preparation method thereof, nano thermal conductivity enhancing material is high thermal conductivity nanoparticles such as boron nitride (BN), carbon nanotubes (CNTs) or graphene oxide (GO), and a microcapsule core material is organic phase change material. The phase change material, an emulsifier and a solvent are mixed and prepared according the preparation method of the invention to obtain thermal conductivity enhanced microcapsule composite phase change material based on nanoparticles such as BN, CNTs and GO, wherein all the added BN, CNTs and GO are modified to comprise hydroxyl groups. In addition, it is possible to add the nano thermal conductivity enhancing particles such as BN, CTNs or GR into the core material of the microcapsule core material according to actual needs. The composite phase change material prepared herein has high phase change enthalpy, good thermal cycle stability, excellent thermal conductivity and the like, has a simple preparation process, stable structure and high encapsulation rate and is widely applicable.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Energy-accumulating temp-controlled thermoplastic cross-link high-molecular composite material with solid-solid phase change and its preparing process

InactiveCN1482204AHigh energy storage densityImprove thermal stabilityHeat-exchange elementsCross-linkThermoplastic

The present invention features that the material has crosslinked crystalline polyolefin as base body and crystalline alkyl hydrocarbon dispersed inside the crosslinked net as the composite material for phase change energy accumulation. In the composite material, the phase change energy accumulating component accounting for 40-80 % has solid-solid phase conversion at phase change temperature of 20-80 deg.c and phase change enthalpy greater than 80 J / g. The composite phase change material has relatively high energy accumulating density and excellent heat stability, may be used as energy accumulating material for the accumulation of solar energy and industrial afterheat, constant temperature in building and energy saving in air conditioner and as temperature control material in electronic instrument, machinery, etc. widely.

Owner:云南玮昊能源发展有限公司

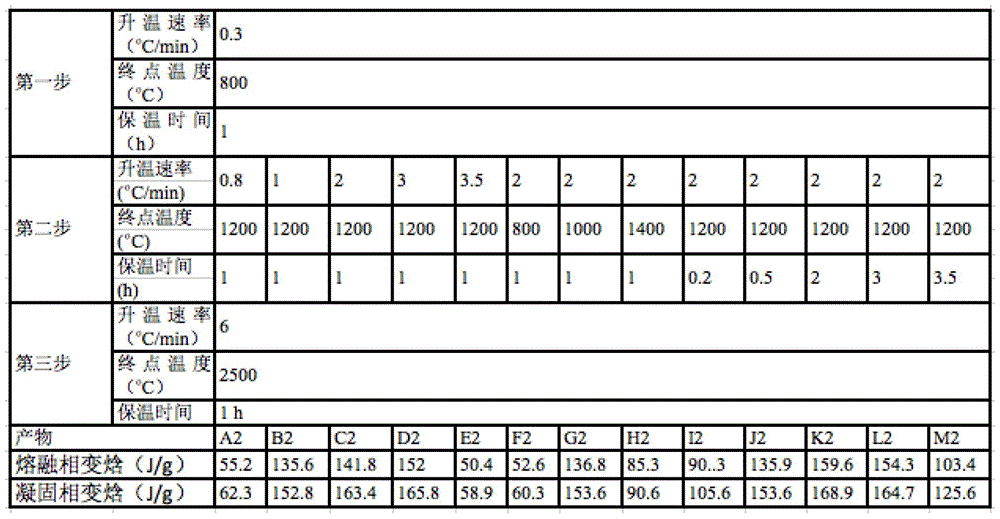

Three-dimensional phase-change material based on graphene and preparing method of three-dimensional phase-change material

ActiveCN105505330AEasy to fillChemical industryHeat-exchange elementsPhase change enthalpyFreeze-drying

The invention relates to a three-dimensional phase-change material based on graphene and a preparing method of the three-dimensional phase-change material. A graphene oxide aqueous solution with certain concentration is added into liquid nitrogen to be quickly frozen, then graphene oxide aerogel is obtained through freezing drying and is fed into a high-temperature furnace to be subjected to high-temperature heat treatment at 500-3000 DEG C in the inert atmosphere, the treated graphene oxide aerogel is then soaked in dichloromethane solutions with different paraffin concentrations, the product is put into a 30 DEG C vacuum oven to be dried after sufficient absorption, and then the three-dimensional phase-change material based on graphene is obtained. The three-dimensional phase-change material based on graphene is good in paraffin encapsulation effect, the filling amount of paraffin ranges from 0.1% to 99.9%, films and paraffin are uniformly compounded, the melt phase change enthalpy and the solidification phase change enthalpy of the material are basically maintained unchanged after multiple times of heating and cooling circulation, and thus efficient heat energy storage is achieved.

Owner:ZHEJIANG TANGUSHANGXI MATERIAL SCI & TECH

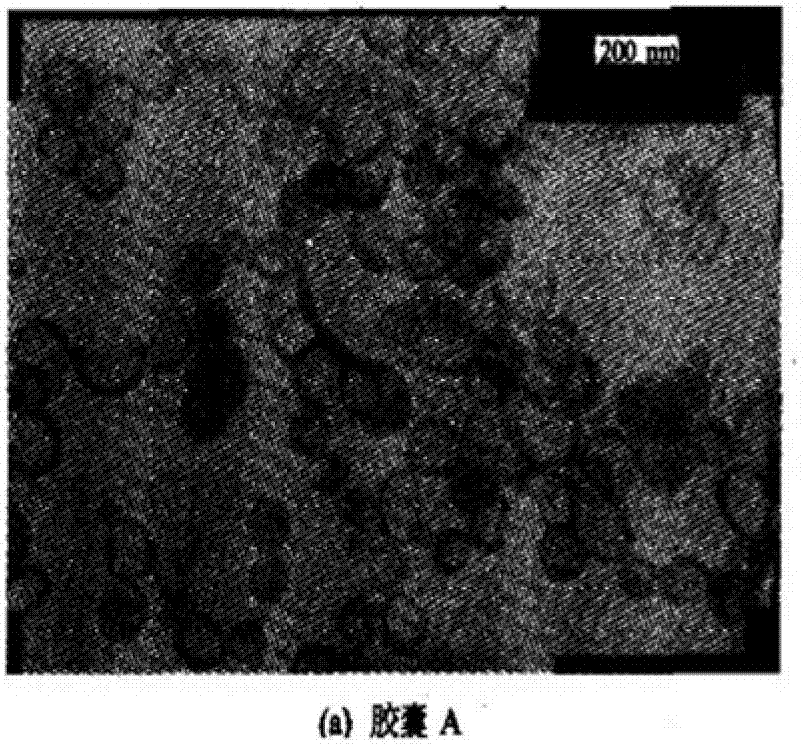

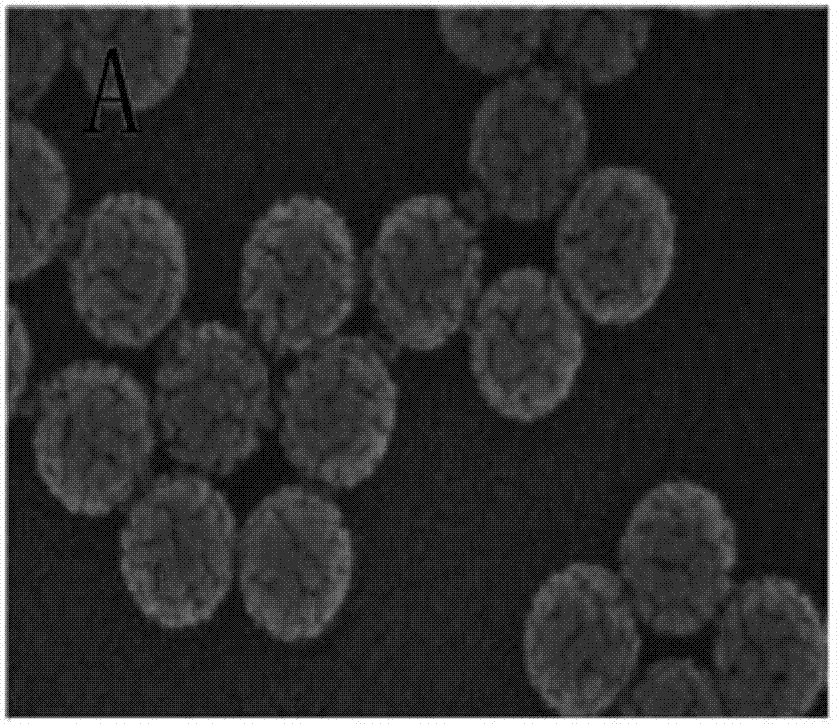

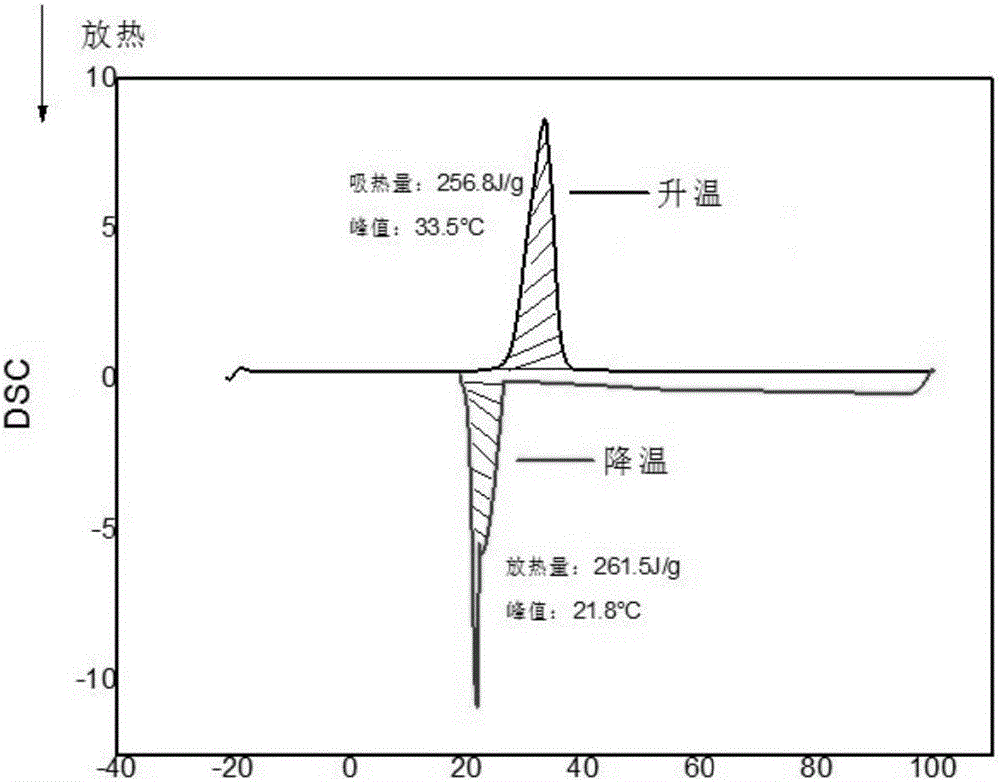

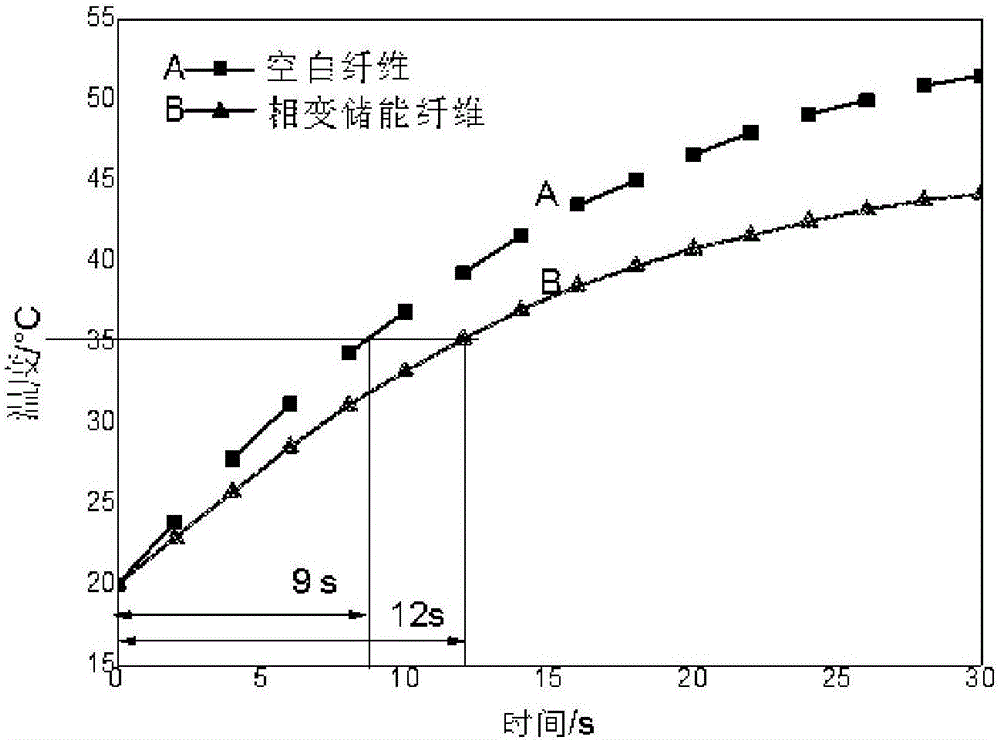

Finishing technology of nano-grade phase-change microcapsule heat-accumulation temperature-adjustment intelligent textile fabric printed cloth

InactiveCN102733192AGood effectFibre treatmentMicroballoon preparationPolyesterPhase change enthalpy

The invention discloses a finishing technology of nano-grade phase-change microcapsule heat-accumulation temperature-adjustment intelligent textile fabric printed cloth. The nano-grade phase-change microcapsules are prepared according to certain steps and process conditions. The nano-grade phase-change microcapsules and the textile fabric printed cloth are cross-linked and finished, such that a finished product is obtained. The textile fabric is printed cloth of cotton, tencel, modal, blended cotton (viscose cotton, polyester cotton, polyamide cotton), silk, wool cotton, and the like. According to the finished nano-grade phase-change microcapsule heat-accumulation temperature-adjustment intelligent printed cloth, the encapsulation appearance of the nano-grade microcapsules is complete, an average particle size is 150nm, a shell thickness is 15nm, a core-shell volume ratio is approximately 1:1, peak phase-change temperatures are respectively 18-40 DEG C, and phase-change enthalpies are respectively 57-60J / g. The heating or cooling rate of the finished nano-grade phase-change microcapsule printed cloth is substantially retarded, such that the cloth has an intelligent temperature-adjustment function. Therefore, the cloth can be widely applied in outdoor clothes, underwear, sweaters, shirts, hats, gloves, and bedclothes, and provides a good effect.

Owner:FUJIAN ZHONGHE

Phase-change energy-storing fiber and preparation method thereof

InactiveCN106801266AIncrease contentAvoid liquidityFilament/thread formingHeat-exchange elementsPhase change enthalpyClay minerals

The invention discloses a phase-change energy-storing fiber. The phase-change energy-storing fiber is of a skin-core structure which comprises a skin layer and a core layer, wherein a skin layer raw material is a thermoplastic polymer; and a core layer raw material is a mixture of the thermoplastic polymer, clay mineral powder and a phase-change material. A preparation method of the phase-change energy-storing fiber comprises the following steps: (1) weighing 2-20 parts of the phase-change material and 5-20 parts of the clay mineral powder in parts by weight, uniformly mixing the weighed phase-change material and clay mineral powder by virtue of ultrasonic oscillation under a vacuum condition, putting the mixture into a vacuum oven so as to obtain a composite phase-change material, and uniformly mixing 60-90 parts of thermoplastic polymer with the prepared composite phase-change material, so as to obtain the core layer raw material; and (2) carrying out melt spinning on the thermoplastic polymer, as skin layer raw material, and the core layer raw material by virtue of a compound spinning machine, so as to obtain the phase-change energy-storing fiber being of the skin-core structure. The preparation method is simple and low in cost, and the prepared phase-change energy-storing fiber has large phase-change enthalpy and a uniform temperature regulation effect.

Owner:WUHAN TEXTILE UNIV

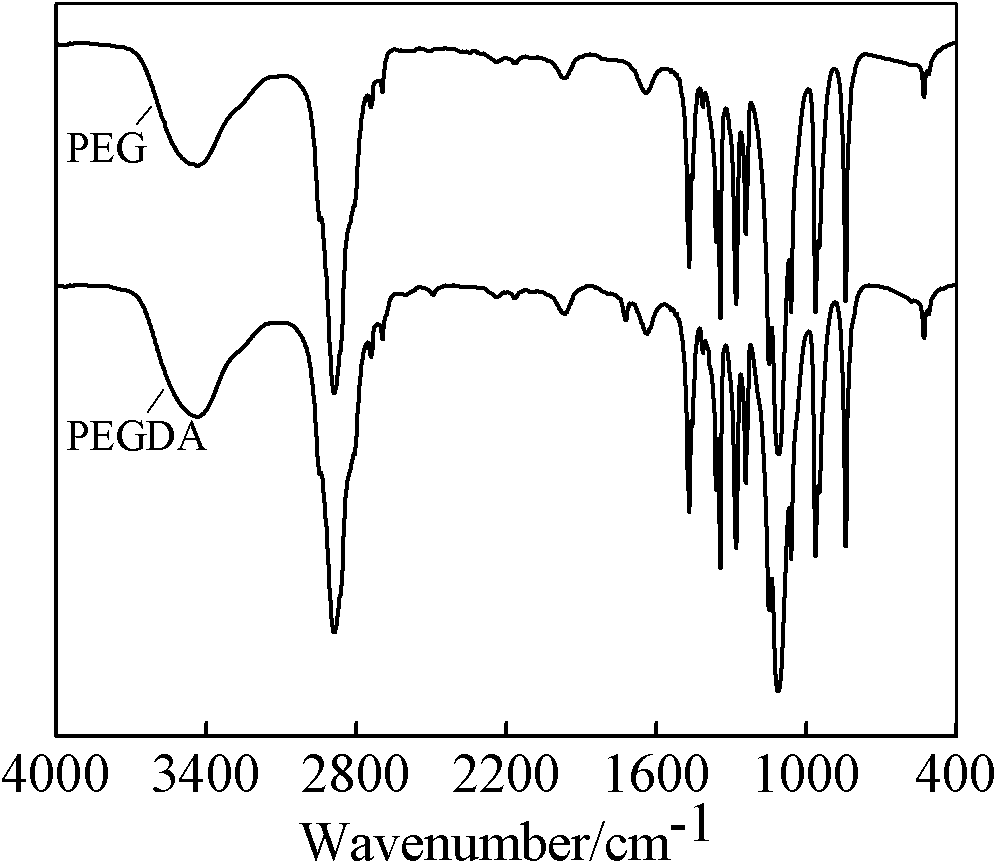

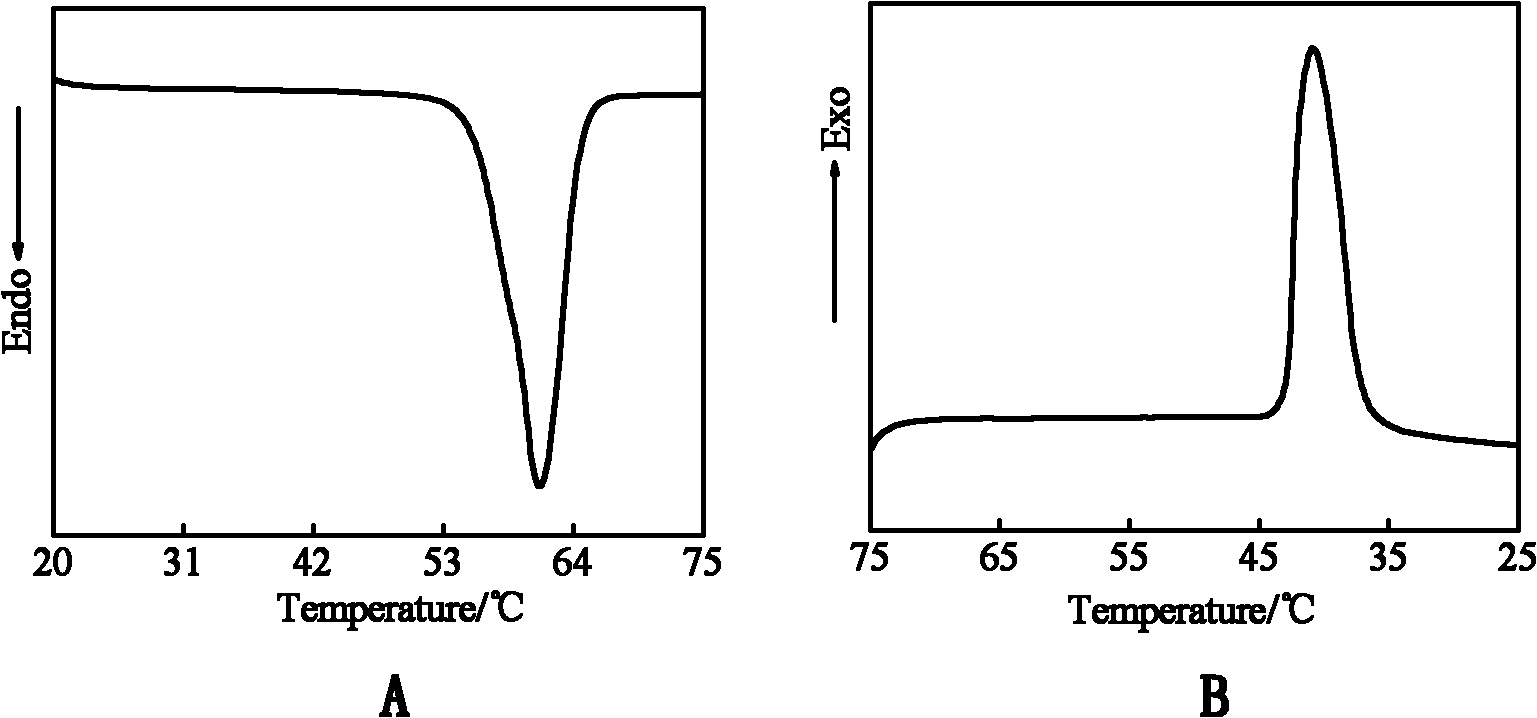

Preparation method of phase change monomer with double-bond end groups

InactiveCN102093552AHigh reactivityImprove high temperature resistanceHeat-exchange elementsPhase change enthalpyIce water

The invention provides a preparation method of a phase change monomer with double-bond end groups, which comprises the following steps of: in an ice water bath, dissolving PEG (Polyethane Glycol MW2000-10000) in dichloromethane, and then adding an acid binding agent (triethylamine or N,N-dimethylacetylamide) and acryloyl chloride; reacting at a temperature of 25-35 DEG C for 4-8h under the protection of nitrogen; adding a precipitant (n-hexane or diethyl ether) in reacting liquid in the ice water bath, settling for 10-15 minutes and leaching to obtain a finished product, wherein the molar ratio of the PEG to the acryloyl chloride is 1:(1-3), the molar ratio of the PEG to the acid binding agent is 1:(1-3), and the molar ratio of the PEG to the dichloromethane is 1:(0.312-0.546). The monomer has high activity and is easy to carry out copolymerization or grafting reaction with other monomers or polymers to prepare solid-solid phase change materials. The monomer has higher phase change enthalpy (163.21J / g), proper phase change temperature (46.53 DEG C) and higher thermal tolerance (320 DEG C). The preparation technology is simple, and the production cost is low.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Graphene-based composite phase-change membrane and preparation method thereof

ActiveCN105733516AMaintain the pore structureEasy to fillChemical industryHeat-exchange elementsPhase change enthalpyFreeze-drying

The invention relates to a graphene-based composite phase-change membrane and a preparation method thereof. The preparation method comprises the following steps: continuously and uniformly extruding a graphene oxide water solution with a certain concentration out of a preparation device with a slotted opening into a solidification solution, and quickly refrigerating in liquid nitrogen; and carrying out freeze-drying to obtain a graphene oxide aerogel membrane, sending the graphene oxide aerogel membrane into a high-temperature furnace, carrying out high temperature 1300-3000-DEG C heat treatment in an inert atmosphere, immersing the graphene oxide aerogel membrane in paraffin dichloromethane solutions with different concentrations, and sufficiently absorbing, thereby obtaining the composite phase-change membrane material. The graphene composite phase-change membrane material has excellent packaging effect on paraffin, and the paraffin loadability is 0.1-99.9%; the membrane and paraffin are compounded uniformly; and after repeated heating-cooling circulations, the melt phase-change enthalpy and solidifying phase-change enthalpy of the material are basically kept unchanged, thereby implementing high-efficiency heat energy storage.

Owner:杭州德烯科技集团有限公司

Microencapsulated multi-component inorganic phase-change material and preparation method thereof

InactiveCN102477285AFulfil requirementsImprove thermal stabilityHeat-exchange elementsMicroballoon preparationPhase change enthalpyFreeze-drying

The invention relates to a microencapsulated multi-component inorganic phase-change material which comprises polymethyl methacrylate as a shell material and a multi-component crystalline sodium sulfate-based phase-change material as a core material. The material is prepared by the following steps: stirring the shell material at 0-4 DEG C to make a shell material solution; mixing the shell material solution with a core material solution composed of core material, deionized water and emulsifiers; emulsifying; adding dropwise deionized water into the resulting emulsion and mixing to form a white viscous emulsion; standing in an ice bath to allow complete volatilization of ethyl acetate; washing and separating the resulting microcapsule-containing emulsion with petroleum ether; and freeze-drying to obtain the microencapsulated multi-component inorganic phase-change material product. The product is innoxious and non-corrosive. The phase change temperature of the product is 11-20 DEG C and the phase change enthalpy is 62-65 kJ / kg. The product is good in heat stability and has the advantages and benefits of simple preparation method, easily-accessible raw material and low cost.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Preparation method of solid-solid phase-change material immobilized by chemical cross-linking method

InactiveCN102391441AImprove thermal stabilityChange the degree of crosslinkingHeat-exchange elementsArtifical filament manufactureCross-linkChemical structure

The invention relates to a preparation method of a solid-solid phase-change material immobilized by a chemical cross-linking method. The method comprises the following steps: dissolving polyethylene glycol acrylate into deionized water, adding a cross-linking agent and an initiator, increasing the temperature of a system to 70-80 DEG C, reacting for 2-5 hours to form hydrogel with a crosslinked network structure, and drying the hydrogel at the temperature of 35 DEG C for 24 hours to get the solid-solid phase-change material, namely polyethylene glycol acrylate gel, wherein the weight ratio ofthe cross-linking agent to the polyethylene glycol acrylate is 1:(200-7):20, the weight ratio of the initiator to the polyethylene glycol acrylate is 1:(200-1):50, and the volume ratio of the deionized water to the polyethylene glycol acrylate is 6:(1-10):1. In the preparation method, the original chemical structure of the polyethylene glycol acrylate is changed through chemical reaction, the solid-solid phase change at the different temperatures can be realized, the cross-linking degree of a product is changed by controlling the reaction conditions, and the phase change temperature and the phase change enthalpy are further regulated so as to meet the different actual requirements.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Preparation method of phase-change energy-storage microcapsule

ActiveCN101947423AHigh Phase Transition EnthalpyEase of industrial productionMicroballoon preparationMicrocapsule preparationCross-linkPhase change enthalpy

The embodiment of the invention discloses a preparation method of a phase-change energy-storage microcapsule, which comprises the following steps: providing a preemulsion, wherein the preemulsion uses paraffin as the dispersed phase and uses a chitosan water solution as the continuous phase; dispersing the preemulsion in an outer oil phase to obtain a compound emulsion, wherein the outer oil phase is liquid paraffin; and adding glutaric dialdehyde into the compound emulsion to carry out cross-linking reaction, thereby obtaining the phase-change energy-storage microcapsule. The invention uses paraffin as the core material, uses chitosan as the shell material, and enables the chitosan to be crosslinked by adding the cross-linking agent glutaric dialdehyde, thereby obtaining the microcapsule. The invention uses chitosan as the shell polymer material, which has the advantages of no toxicity and easy preparation, thereby being beneficial to industrial production. In addition, compared with the prior art, the invention does not need to add an initiator or a surfactant, thereby having the advantage of simple preparation method. The experimental result indicates that the microcapsule can remain the structure and high phase-change enthalpy value after repeated heating and cooling, thereby having the function of phase-change energy-storage.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Double-layer coating solid inorganic phase change material micro-capsule and preparation method thereof

InactiveCN103087681ADoes not affect phase change energy storage performanceHigh strengthHeat-exchange elementsMicroballoon preparationPhase change enthalpyBi layer

The invention discloses a double-layer coating solid inorganic phase change material micro-capsule and a preparation method thereof. The double-layer coating solid inorganic phase change material micro-capsule is prepared from the following methods of: firstly, with polymethyl methacrylate as an inner layer wall material and the solid inorganic phase change material as a core material, preparing a single-layer coating solid inorganic phase change material micro-capsule by a phase separation method; and then with polystyrene as an outer layer wall material and the prepared single coating solid inorganic phase change material micro-capsule as the core material, preparing the double-layer coating solid inorganic phase change material micro-capsule by the phase separation or a solvent evaporation method. The double-layer coating solid inorganic phase change material micro-capsule is simple in preparation method, the phase change temperature can be adjusted between 30 DEG C and 60 DEG C, and the enthalpy of phase change is up to 150kJ / kg at the most; by the double-layer coating, the strength of the solid inorganic phase change material micro-capsule is effectively enhanced and the problems of percolation and corrosion of the core material solid inorganic phase change material are solved.

Owner:SHANGHAI INST OF TECH

Method for preparing cross-linked solid-solid phase change energy storage material

InactiveCN102321452APossesses solid-liquid phase transition propertiesHigh degree of substitutionHeat-exchange elementsPhase change enthalpyCellulose

The invention provides a method for preparing a cross-linked solid-solid phase change energy storage material, which relates to a method for, after homogeneous preparing laurel acid cellulose ester with high substitution by using a cellulose / LiCl / DMAc solution system, synthesizing a cross-linked polyethylene glycol / laurel acid cellulose ester phase change energy storage material by using laurel acid cellulose ester and polyethylene glycol as main materials through solution grafted polymerization in the presence of cross-linking agent. Although both polyethylene glycol and laurel acid cellulose ester are solid-liquid phase change materials, polyethylene glycol and laurel acid cellulose ester are mutually dissolved and cross-linked in the process of grafted cross-linked polymerization to have typical polyether type segmented cross-linking network structures, thereby containing and restricting their respective microflow mutually. The phase change enthalpies of two components are overlapped mutually, thus final product has higher phase change enthalpy up to 194.7J / g. The obtained material has proper phase change temperature at 19 to 60 DEG C, stable heat performance, no liquid produced in phase change process and completely invertible phase change process, is a polymer solid-solid phase change energy storage material with bigger use valve and development prospect.

Owner:XINJIANG UNIVERSITY

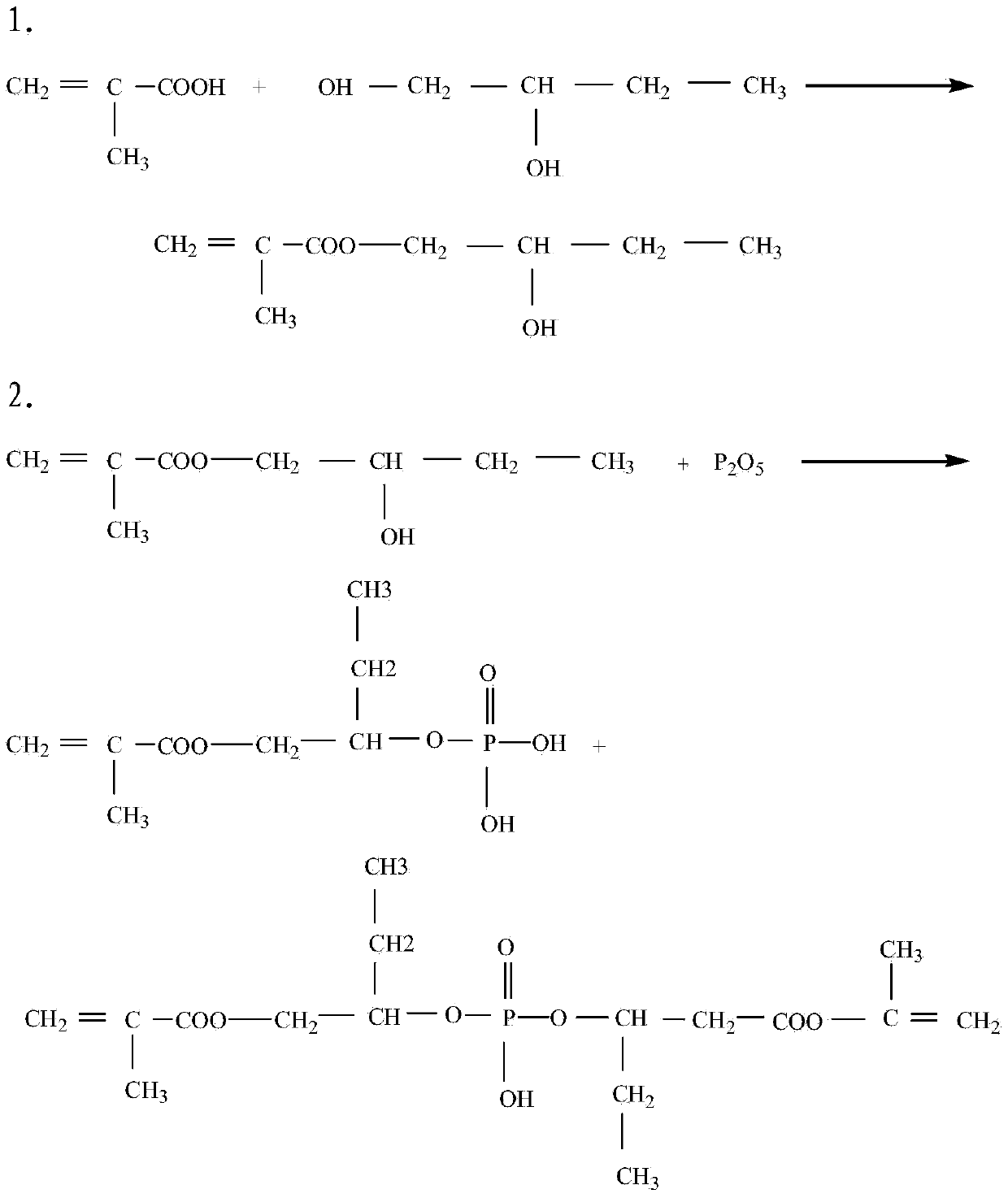

Novel shaped phase-change material and preparation method thereof

ActiveCN103740337AImprove performanceImprove flame retardant performanceHeat-exchange elementsMicroballoon preparationPhase change enthalpyMasterbatch

The invention relates to a novel shaped phase-change material and a preparation method thereof. The novel shaped phase-change material is prepared from the following raw materials in parts by weight: 1-10 parts of acrylic monomers, 1-10 parts of phosphate ester functional monomer, 0.005-0.03 parts of initiator, 10-40 parts of organic phase-change materials, 50-90 parts of deionized water and 0.1-1 part of emulsifier. The novel shaped phase-change material is excellent in performance, safe and environment-friendly, not only can play good fire retardation by modification on a capsule wall through phosphate, but also compensates the defects of inflammable performance of the organic phase-change material, as a phosphate ester group is led to the capsule wall, the flame retardant property of the phase-change material is greatly improved, application of the phase-change material in the energy-saving field is expanded, direct mixing of the fire retardant and a phase-change master batch also can be avoided, high phase-change enthalpy of the phase-change material is ensured, and negative effects caused by the heat storage performance of the phase-change material is avoided.

Owner:江苏丰彩建材(集团)有限公司 +2

Preparation method of paraffin-SEBS thermoplastic elastomer composite phase change material

PendingCN110713728AImprove adsorption capacityHigh phase change enthalpyHeat-exchange elementsElastomerPhase change enthalpy

The invention discloses a preparation method of a paraffin-SEBS thermoplastic elastomer composite phase change material. The paraffin-SEBS thermoplastic elastomer composite phase change material comprises the following components in parts by weight: 30-80 parts of phase change paraffin and 20-70 parts of SEBS elastic plastic. The flexible composite phase-change material has the beneficial effectsthat the blank of the current flexible composite phase-change material in the market is solved, the adsorption capacity is high, and the phase-change enthalpy value is large. Besides, the phase-changematerial with controllable phase-change temperature can be obtained by adjusting the mass ratio of the phase-change materials with different marks, so that the application field of the paraffin-basedcomposite phase-change material is further widened, and good economic benefits are achieved.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Preparation method of microencapsulated stabilized phase-change material

InactiveCN106746893AImprove thermal conductivityGood compatibilityHeat-exchange elementsPolymeric surfaceParaffin wax

The invention relates to a preparation method of a microencapsulated stabilized phase-change material and belongs to the technical field of phase-change materials. The preparation method comprises the following steps: firstly, taking soap stock as a raw material; carrying out saponification and acidolysis to obtain fatty acid; mixing the fatty acid with paraffin wax to obtain a phase-change material, wherein the fatty acid can be used for reducing the melting point of the paraffin wax; inserting an ethylene monomer into a graphite flake layer; polymerizing to separate the graphite flake layer; doping graphite into a polymer so as to increase the thermal conductivity of the polymer; carrying out emulsion reaction to coat the phase-change material with the polymer; taking tetraethyl orthosilicate as a raw material and depositing silicon dioxide on the surface of the polymer under the action of alkali to form a coating film; finally, drying to obtain the microencapsulated stabilized phase-change material. The microencapsulated stabilized phase-change material prepared by the preparation method has an excellent heat-conducting performance, the phase change enthalpy reaches 130.14kJ / kg to 135.25kJ / kg and the phase change temperature is 20 DEG C to 40 DEG C; the microencapsulated stabilized phase-change material has good compatibility with a building material and related mechanical properties of the building material are not influenced; the microencapsulated stabilized phase-change material has wide application prospect.

Owner:闫博文

Urea resin paraffin microcapsule material with high thermal conductivity and high enthalpy value and preparation method

ActiveCN105969317AParticle size has little effectImprove thermal conductivityHeat-exchange elementsPhase change enthalpyUltrasonic dispersion

The invention relates to a urea resin paraffin microcapsule material with high thermal conductivity and high enthalpy value and a preparation method. The urea resin paraffin microcapsule material is covered by graphene oxide. Graphene oxide serves as a covering layer, thermal conductivity of microcapsules is improved, and the phase change enthalpy value of the microcapsules is not reduced. The material is of a double-layer core-shell structure, the outermost layer is graphene oxide, the inner layer is urea resin, and a core is paraffin. The preparation method includes the steps that firstly, urea resin paraffin microcapsules are prepared, and the obtained microcapsules are washed and dried; secondly, graphene oxide and positive ion surfactant are added into deionized water for ultrasonic dispersion, and graphene oxide dispersion liquid is obtained; thirdly, the microcapsules obtained in the first step and a negative ion surfactant are added into water for ultrasonic dispersion, the dispersion liquid obtained in the second step is added to be stirred, and a final product is obtained through filtering, washing and drying. The microcapsules prepared through the method are uniform in particle size distribution, and thermal performance of paraffin microcapsules can be effectively improved.

Owner:SICHUAN UNIV

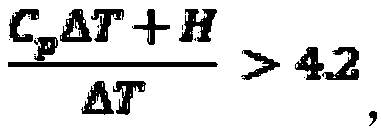

Phase change micro-emulsion as cooling working substance, and applications thereof

InactiveCN107841291ASmall temperature changeImprove liquidityHeat-exchange elementsInorganic saltsPhase change enthalpy

The invention discloses a phase change micro-emulsion as a cooling working substance. The phase change micro-emulsion comprises a phase change material, a surfactant, water and an inorganic salt, wherein the phase change material is a mixture formed from one or a variety of paraffins. According to the present invention, the phase change micro-emulsion has good fluidity, can reduce the temperaturechange of the cooling liquid during heat absorbing, and can greatly improve the heat dissipation efficiency and increase the system stability; and the phase change material meets the following conditions that (Cp[delta]T+H) / [delta]T is more than 4.2, [delta]T is T2-T1, and T is more than T1+{(4.2*[delta]T-Hx)} / {4.2(1-x)+Cpx}, wherein where Cp (kJ / kg / K) is the specific heat of the phase change material, H (kJ / kg) is the phase change enthalpy of the phase change material, T2 (DEG C) is the maximum temperature of the cooling liquid at the outlet position when the cooling liquid is water after theheat exchange work is completed, T1(DEG C) is the temperature of the cooling liquid at the inlet position when the cooling liquid is water, T (DEG C) is the phase change temperature of the phase change material, and X is the mass fraction of the phase change material accounting for the phase change micro-emulsion.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

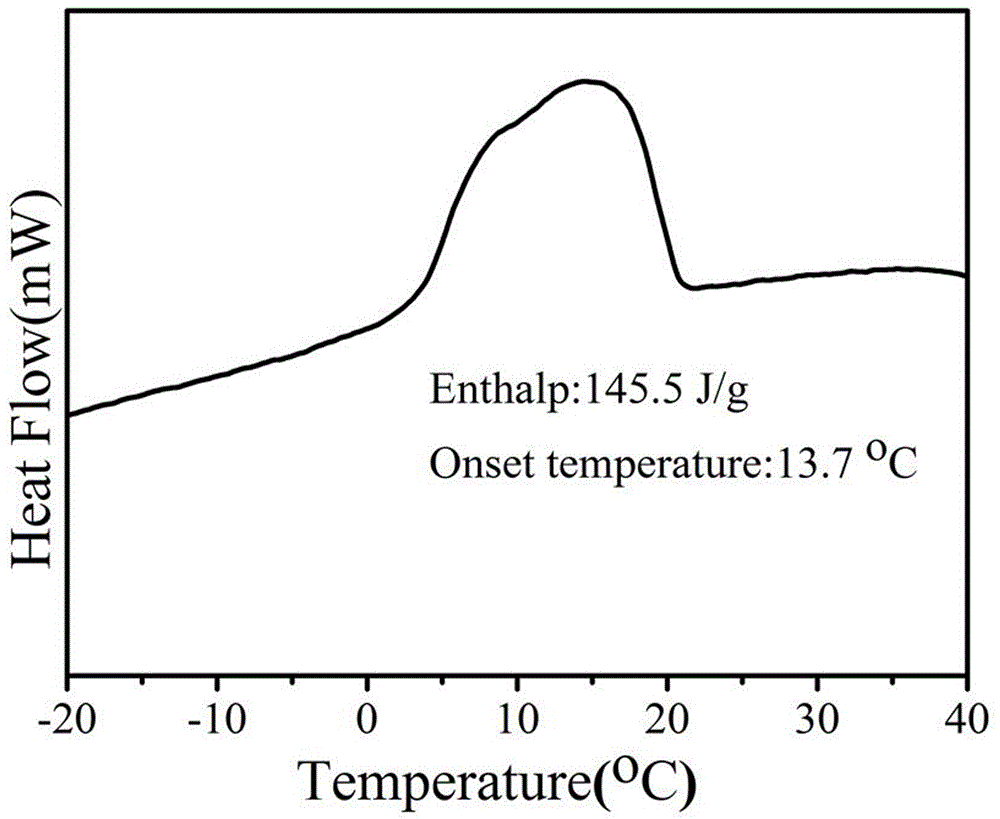

Preparation method of alkanol self-temperature control phase change material

InactiveCN103194183ALarge latent heat of phase changeLow costHeat-exchange elementsPhase change enthalpyParaffin wax

The invention discloses a preparation method of a phase change material. The preparation method is that dodecanol serving as a main phase change agent and paraffin serving as a secondary phase change agent are adopted for preparing a low-temperature phase change material. The low-temperature phase change material has phase change temperature about 22 DEG C, is relatively high in phase change enthalpy value which is about 180J / g, has stable performance, excellent phase change reversibility and little change in size during the phase change, and is safe, nontoxic and non-corrosive.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Inorganic hydrated salt porous carbon composite phase change material and preparation method thereof

ActiveCN108676550AReduce overflowReduce precipitationHeat-exchange elementsHydration reactionPhase change enthalpy

The invention discloses an inorganic hydrated salt porous carbon composite phase change material and a preparation method thereof, wherein the preparation method comprises the following steps: firstly, preparing biomass-based porous carbon subjected to activation treatment, and weighing an inorganic hydrated salt phase change material, the biomass-based porous carbon and a pore sealing agent in proportion; and then preparing a saturated solution from the inorganic hydrated salt phase change material, adding biomass-based porous carbon, impregnating, carrying out vacuum pressurization and adsorbing; and finally, adding the pore sealing agent, stirring, wind-drying, and grinding and pulverizing, to obtain the inorganic hydrated salt porous carbon composite phase change material. The composite phase change material prepared by the method has the advantages of difficult liquid leakage, no phase separation, small supercooling degree, high phase change enthalpy, no toxicity, no corrosion, good thermal stability, good durability, low preparation cost and the like, and has broad market prospects in the fields of building and energy-storage materials.

Owner:SHANDONG JIANZHU UNIV

Preparing method for polyethylene glycol/nano-silicon dioxide composite phase change material

InactiveCN106554754AImprove thermal conductivityLower phase change enthalpyHeat-exchange elementsPhase change enthalpyEnd-group

The invention provides a preparing method for a polyethylene glycol / nano-silicon dioxide composite phase change material. Firstly, polyethylene glycol and a silane coupling agent are subjected to the reaction, prepolymer with a siloxane end group is generated; after the prepolymer and ethyl orthosilicate are mixed uniformly, the PEG-SiO2 sol system is prepared through the acid catalysis hydrolysis-condensation reaction, gel is obtained through volatilization of a solvent, and the polyethylene glycol / nano-silicon dioxide composite phase change material is obtained through drying. By means of the polyethylene glycol / nano-silicon dioxide composite phase change material prepared through the method, the heat conductivity of a compound system can be greatly improved, and the phase change enthalpy and the phase change temperature are obviously reduced.

Owner:李博琪

Preparation method of polyurethane solid-solid phase-change material with high enthalpy of phase change

InactiveCN103159910AEasy to getThe preparation method is simple and easy to controlHeat-exchange elementsPhase change enthalpyPolymer science

The invention provides a preparation method of a polyurethane solid-solid phase-change material with high enthalpy of phase change. The formulation of the polyurethane solid-solid phase-change material comprises the following components in percentage by weight: 65-96% of polyhydric alcohol I, 1-30% of polyhydric alcohol II, 3-20% of diisocyanate and 0-3% of catalysts. The preparation method provided by the invention comprises the steps of: carrying out a reaction on the polyhydric alcohol I (or the polyhydric alcohol I) and the diisocyanate, so as to synthesize a prepolymer; uniformly mixing the prepolymer with the polyhydric alcohol I (or the polyhydric alcohol I), and carrying out defoaming after adding the catalysts; and pouring the mixture into a mold, and carrying out solidifying, cooling and demolding, so as to obtain the polyurethane solid-solid phase-change material. According to the preparation method, the raw materials are easily available, the preparation method is simple and convenient and is easy to control, and organic solvents harmful to an environment or a human body are avoided in the preparation process.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Compound phase-change cold accumulation material and preparation method thereof

ActiveCN107880854AThe synthesis process is simpleNo leakage will occurHeat-exchange elementsPhase change enthalpyInorganic salts

The invention relates to a compound phase-change cold accumulation material and a preparation method thereof and belongs to the technical field of novel materials. The compound phase-change cold accumulation material is characterized in that the material is prepared by compounding an organic three-dimensional network gel material with a low-temperature phase-change material through a solvent displacement method, wherein the mass ratio of the organic three-dimensional network gel material to the low-temperature phase-change material is 1 to (5 to 10); the organic three-dimensional network gel material is prepared by crossly linking and polymerizing polyisocyanate and a polybasic alcohol polymer; the low-temperature phase-change material is water, N,N-dimethyl sulfoxide, ethylene glycol or awater solution of inorganic salt; the mass concentration of the water solution of the inorganic salt is 0.1 percent to 10 percent. The compound phase-change cold accumulation material and the preparation method thereof have the advantages of simple synthesis technology and convenience for application; the material has great phase-change enthalpy and long cold-keeping time; no liquid is leaked ina working process and the material can be repeatedly used and has a wide application prospect in the aspect of cold accumulation and cooling.

Owner:DALIAN UNIV OF TECH

Phase change energy storage material with skin-core fiber structure and preparation method thereof

ActiveCN109576823AReduce inconvenienceImprove production efficiencyHollow filament manufactureArtificial filament washing/dryingPhase change enthalpyFreeze-drying

The invention belongs to the field of phase change energy storage materials, and discloses a phase change energy storage material with a skin-core fiber structure and a preparation method thereof. Polyacrylonitrile is dissolved in an organic solvent, the phase change energy storage materials are added into the solvent and uniformly mixed, and an oil phase solution is obtained. Water-soluble phasechange materials are dissolved in deionized water or the deionized water is directly used as an aqueous phase solution; the aqueous phase solution is added into the oil phase solution, an emulsifyingagent is added for homogenization and dispersion, oil in water emulsion is obtained, and a composite fiber material with the skin-core structure is obtained through electrostatic spinning; a hollow fiber material is obtained through freeze-drying; finally pre-oxidation and carbonization treatment are performed in an inert atmosphere, and the phase change energy storage material with the skin-corefiber structure is obtained. The fiber preparation technology is combined with the high-performance phase change material, the phase change energy storage material has higher phase change enthalpy and reversible capacity, and multi-scene application of the phase change energy storage material is achieved.

Owner:SOUTH CHINA UNIV OF TECH

Phase-change paraffin preparation method

InactiveCN105505331AEfficient steam outReduce pollutionPetroleum wax refiningHeat-exchange elementsPhase change enthalpyHydrogenation reaction

The invention relates to a phase-change paraffin preparation method, and belongs to the technical field of pharmaceutical and chemical engineering. The phase-change paraffin preparation method is simple in technology; by means of the method, demand-based customized production can be achieved, waste can be reduced, cost can be lowered, and economic benefits can be effectively increased. According to the technical scheme, the phase-change paraffin preparation method includes the following steps that coal is subjected to gasification production to obtain synthesis feed gas, the feed gas is subjected to a Fischer-Tropsch synthesis reaction to obtain Fischer-Tropsch synthesis products, the Fischer-Tropsch synthesis products are subjected to a hydrogenation reaction to obtain a wide-fraction mixture, namely, Fischer-Tropsch synthesis paraffin, the Fischer-Tropsch synthesis paraffin is subjected to molecular short steaming and rectification to obtain refined paraffin products with different phase change enthalpy values, and NNO is added to obtain stable phase-change paraffin.

Owner:SHANXI LUAN COAL BASED SYNTHETIC OIL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com