Novel shaped phase-change material and preparation method thereof

A phase change material, a new type of technology, applied in the direction of microsphere preparation, heat exchange materials, chemical instruments and methods, etc., can solve the problems of reducing the phase change enthalpy of phase change materials, affecting the heat storage performance of phase change materials, etc., to achieve compensation Flammability, broaden applications, and improve the effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

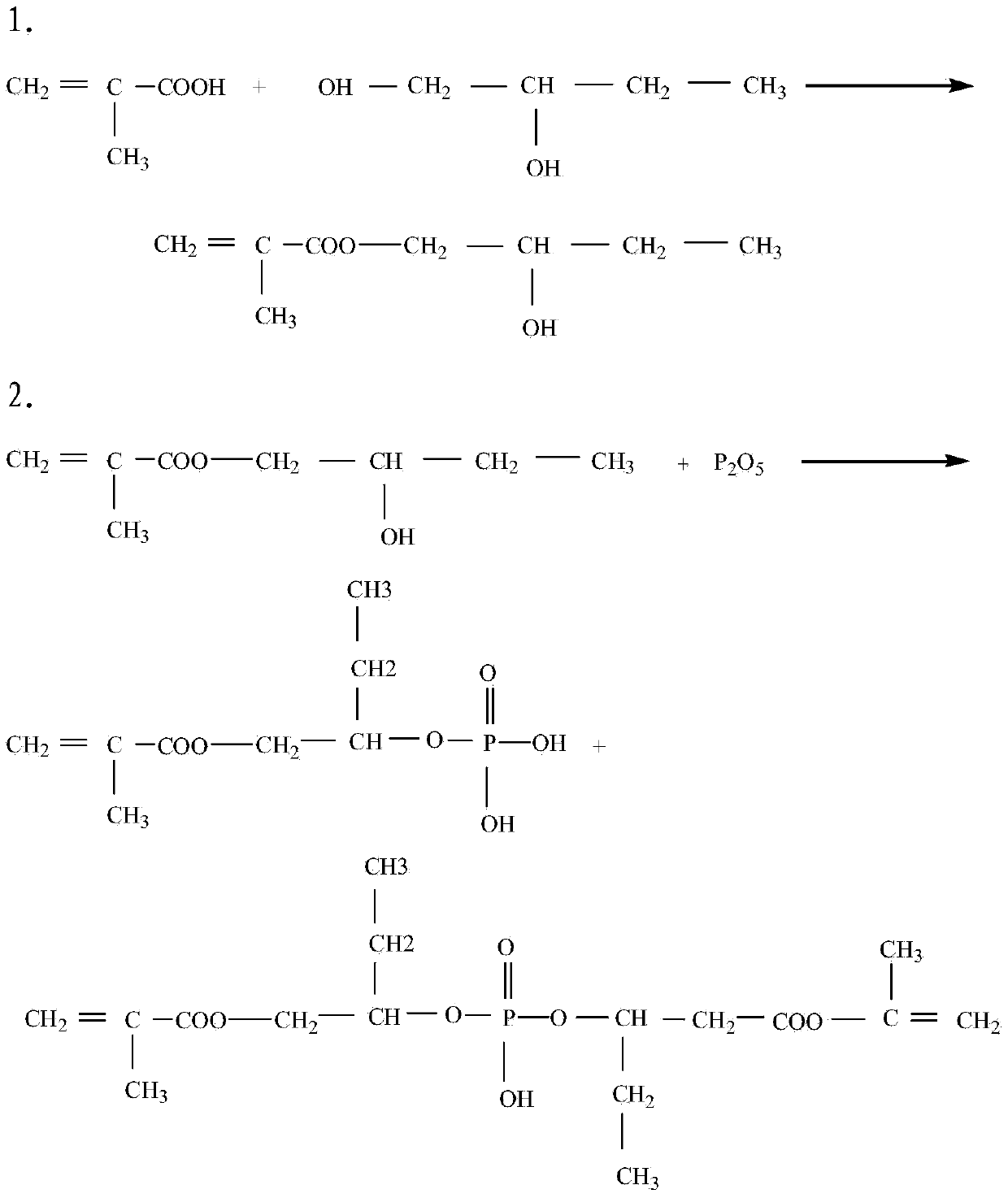

[0025] Weigh 9g of butanediol, 4g of cyclohexane, 0.20g of butyl titanate and 0.12g of hydroquinone, put them into the reaction kettle, stir evenly, at 65°C at a rate of 0.2 drops / second After slowly adding 8.6g of methacrylic acid dropwise, the temperature was raised to 85°C for 6 hours, and then the temperature was lowered to below 40°C, and the mixture was obtained by distillation under reduced pressure. The mixture was stirred at a speed of 1500r / min and 7g of phosphorus pentoxide was divided into Add 3 to 5 times, react at 75°C for 6 hours, add 2 g of deionized water dropwise at a rate of 0.3 drops / second, raise the temperature to 110°C, and react for 2 hours to obtain a phosphate functional monomer.

[0026] Add 6g of methacrylic acid, 4g of phosphate ester functional monomer, 0.025g of dibenzoyl peroxide and 20g of paraffin into the vessel, stir and mix and ultrasonically disperse for 60 seconds to obtain an oil phase. At the same time, 150 g of deionized water and 0.5 ...

Embodiment 2

[0029] Weigh 4.5g of butanediol, 6g of benzene, 0.125g of concentrated sulfuric acid and 0.23g of tert-butylcatechol into the reaction kettle, stir well and slowly add 4.3g of methyl For acrylic acid, heat up to 60°C and react for 8 hours, then cool down to below 40°C, distill under reduced pressure to obtain the mixture, stir the mixture at a speed of 1700r / min and add 5g of phosphorus pentoxide in 3 to 5 times. After reacting at 50°C for 8 hours, 1 g of deionized water was added dropwise at a rate of 0.5 drops / second, the temperature was raised to 90°C, and the phosphate ester functional monomer was obtained after reacting for 3 hours.

[0030] Add 16g of acrylic acid and methyl methacrylate mixture (the ratio of the two is 1:1), 14g of phosphate functional monomer, 0.01g of azobisisobutyronitrile and 30g of capric acid into the vessel, stir to mix and ultrasonically disperse for 120s An oily phase is obtained. At the same time, 100 g of deionized water and 0.2 g of sodium ...

Embodiment 3

[0033]Weigh 10g of butanediol, 8g of petroleum ether, 0.165g of thionyl chloride and 0.4g of m-dinitrobenzene into the reaction kettle, stir evenly, and slowly drop 10g of formazan at a rate of 1 drop / second at 75°C. Base acrylic acid, heat up to 75°C and react for 6.5 hours, then cool down to below 40°C, and distill under reduced pressure to obtain the mixture. Stir the mixture at a speed of 1500r / min and add 10g of phosphorus pentoxide in 3 to 5 times, react at 65°C for 5 hours, add 3g of deionized water, raise the temperature to 100°C, and react for 1.5 hours Finally, the phosphate functional monomer is obtained.

[0034] Add 12g of a mixture of methacrylic acid, ethyl methacrylate and hydroxyethyl methacrylate (the ratio of the three is 2:1:1), 8g of phosphate functional monomer, 0.04g of ammonium persulfate and 50g of lauric acid into the vessel , the oil phase was obtained after stirring and ultrasonic dispersion for 180 seconds. Stir and mix 130 g of deionized water a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com