Phase-change energy-storing fiber and preparation method thereof

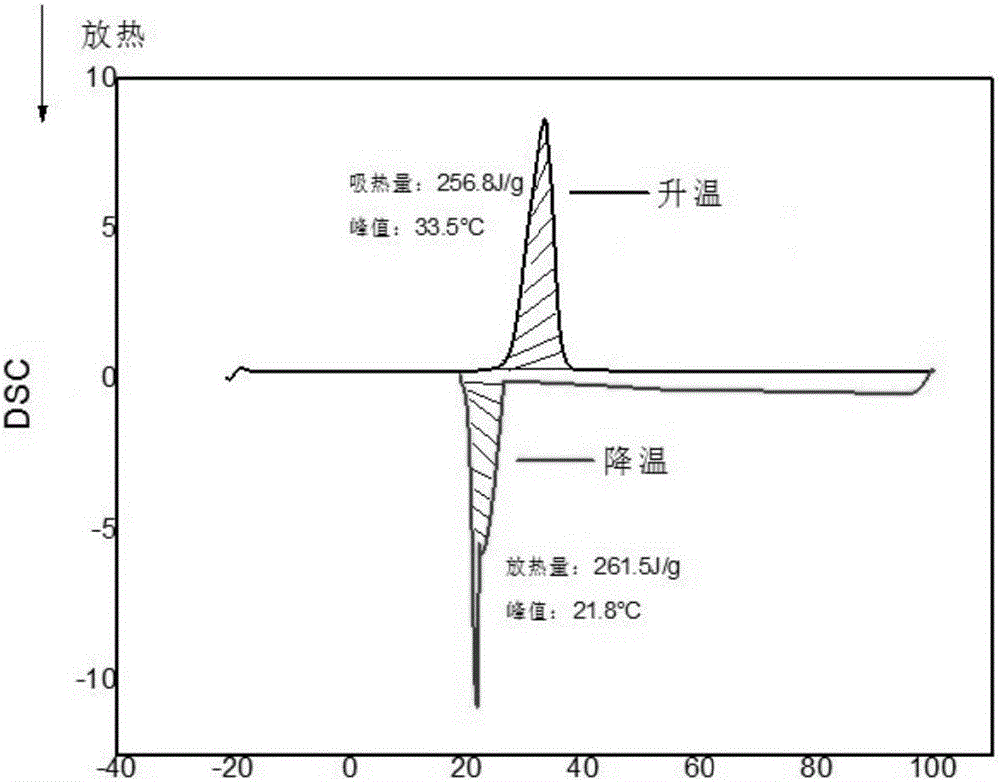

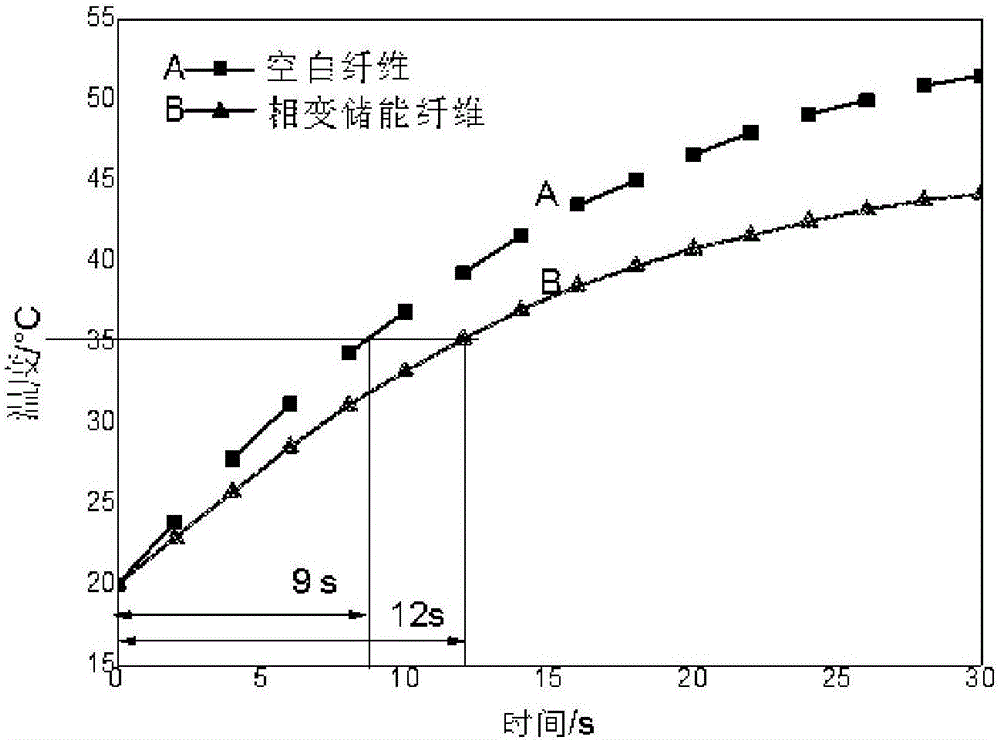

A phase change energy storage and fiber technology, which is applied in fiber processing, fiber chemical characteristics, chemical instruments and methods, etc. problem, to achieve the effect of large melting/crystallization phase change enthalpy, preventing leakage, good fatigue strength and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a phase change energy storage fiber, the specific steps are as follows:

[0038] 1) Preparation of core layer raw materials:

[0039]In parts by weight, get 10 parts of paraffin after melting and 10 parts of octadecane and mix uniformly to obtain a phase change material, 20 parts of attapulgite powder, and mix the phase change material and attapulgite powder under vacuum condition Mix evenly under ultrasonic oscillation, the ultrasonic oscillation temperature is 80°C, the oscillation time is 40min, and then placed in a vacuum oven, the temperature of the vacuum oven is 80°C, and the time of placing in the vacuum oven is 12h, to obtain a composite phase change material;

[0040] Take 60 parts of polyester and mix evenly with the prepared composite phase change energy storage material to obtain the core layer raw material;

[0041] 2) Preparation of phase change energy storage fibers:

[0042] Take thermoplastic polymer as the raw material of the ...

Embodiment 2

[0044] A method for preparing a phase change energy storage fiber, the specific steps are as follows:

[0045] 1) Preparation of core layer raw materials:

[0046] In parts by weight, take 5 parts of melted paraffin and 10 parts of octadecane and mix evenly to obtain a phase change material, 5 parts of kaolin powder, and mix the weighed phase change material and kaolin powder under vacuum conditions Uniform, the ultrasonic oscillation temperature is 60°C, the oscillation time is 60min, and then placed in a vacuum oven, the temperature of the vacuum oven is 60°C, and the time of placing in the vacuum oven is 24h, to obtain a composite phase change material;

[0047] Take 80 parts of polyamide and mix evenly with the prepared composite phase change energy storage material to obtain the core layer raw material;

[0048] 2) Preparation of phase change energy storage fibers:

[0049] Polyamide is used as the raw material of the skin layer, and the skin layer raw material and the ...

Embodiment 3

[0051] A method for preparing a phase change energy storage fiber, the specific steps are as follows:

[0052] 1) Preparation of core layer raw materials:

[0053] In terms of parts by weight, take 20 parts of hexadecane and 20 parts of montmorillonite powder, and mix the weighed phase change material and montmorillonite powder evenly under vacuum conditions by ultrasonic oscillation, and the ultrasonic oscillation temperature is 70°C. The shaking time is 50min, and then placed in a vacuum oven, the temperature of the vacuum oven is 70°C, and the time of placing in the vacuum oven is 18h, to obtain a composite phase change material;

[0054] Take 60 parts of polypropylene and mix evenly with the prepared composite phase change energy storage material to obtain the core layer raw material;

[0055] 2) Preparation of phase change energy storage fibers:

[0056] Polypropylene is used as the raw material of the skin layer, and the raw material of the skin layer and the core laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

| heat release | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com