Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

175results about How to "Tight adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene material coating and preparing method thereof and air filtering device and system

InactiveCN106192376AImprove adsorption capacityUniform circulationGas treatmentDispersed particle filtrationHazardous substanceAir filter

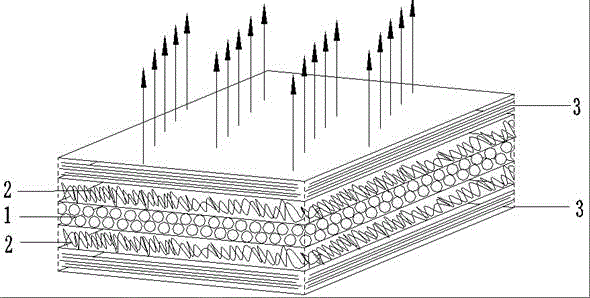

The invention relates to the technical field of air filtering, in particular to a graphene material coating and a preparing method thereof, and further relates to an a air filtering device and system based on the graphene material coating. The preparing method of the graphene material coating includes the following steps that S1, slurry-dispersion raw liquid is prepared, wherein a dispersing agent and a bonding agent are added into a solvent, and the mixture is stirred to generate the slurry-dispersion raw liquid; S2, a graphene surface coating is formed, wherein graphene powder is added into the slurry-dispersion raw liquid, the mixture is stirred to allow slurry to be even to be applied to the surface of a carrier, drying is carried out, and the graphene-material-coating finished product is obtained. By means of the graphene material coating and the preparing method thereof, the adsorption rate of hazardous substances in gas can be increased, and secondary pollution caused by unfirm adsorption is avoided.

Owner:张麟德

Permanent hydrophilic modification method for surface of porous membrane and porous membrane obtained by same

ActiveCN102423642AImprove solubilityReduce swellingSemi-permeable membranesCross-linkHydrophilic polymers

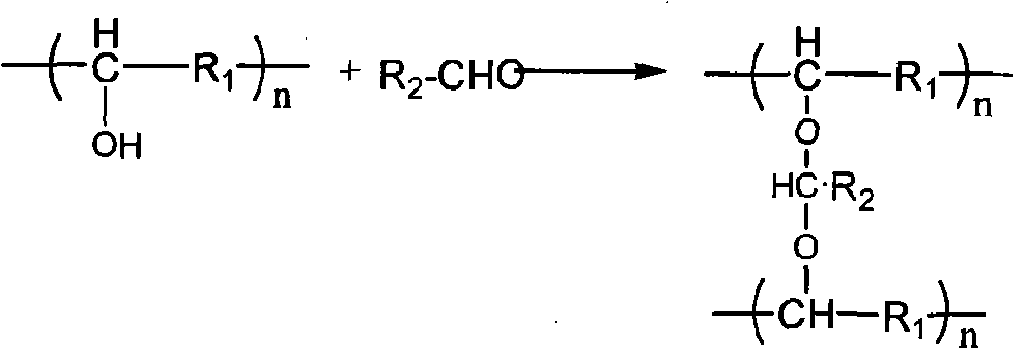

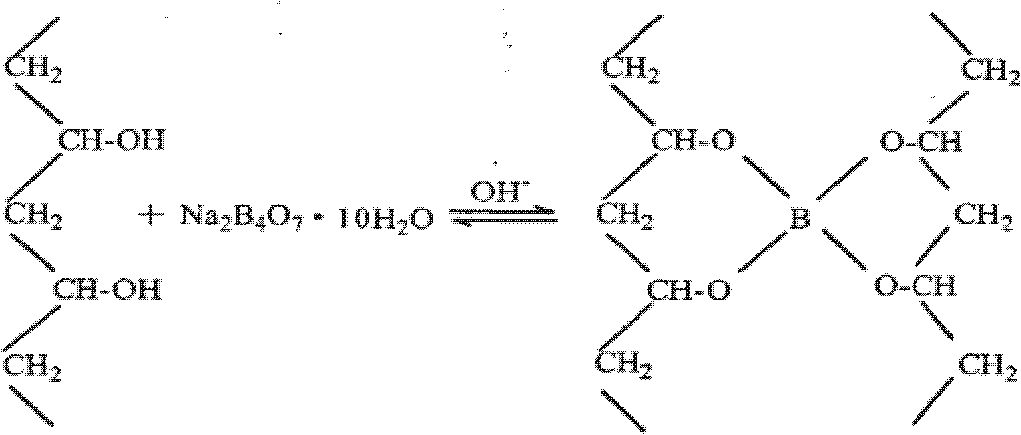

The invention relates to a permanent hydrophilic modification method for the surface of a porous membrane. The method comprises the following steps of: soaking a porous membrane with a polymer containing the solution of a vinyl alcohol chain segment, a first solvent and deionized water; evaporating to remove the solvent so that the hydrophilic polymer is adsorbed on the surface of the porous membrane and the surface of the membrane pores; and performing a cross-linking reaction with a cross-linking agent and the hydrophilic macromolecules adsorbed on the membrane surface to form a mesh-like hydrophilic polymer thin layer on the outer side of the porous membrane. Through the method provided by the invention, the flux reduction caused by pore blocking can be completely avoided, the generated hydrophilic coating is firmer, and the hydrophilic treatment effect is good.

Owner:BEIJING ORIGINWATER TECH CO LTD

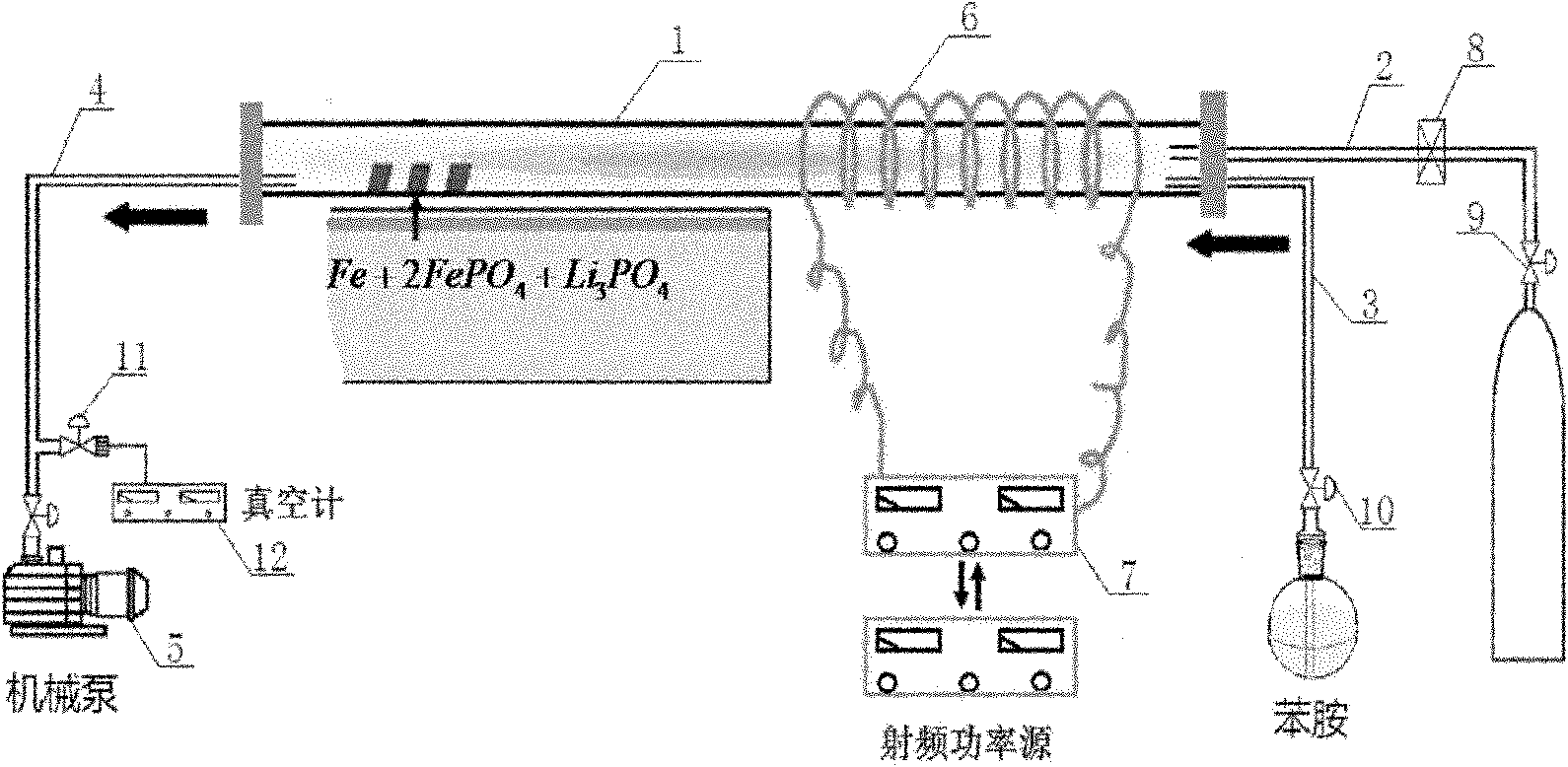

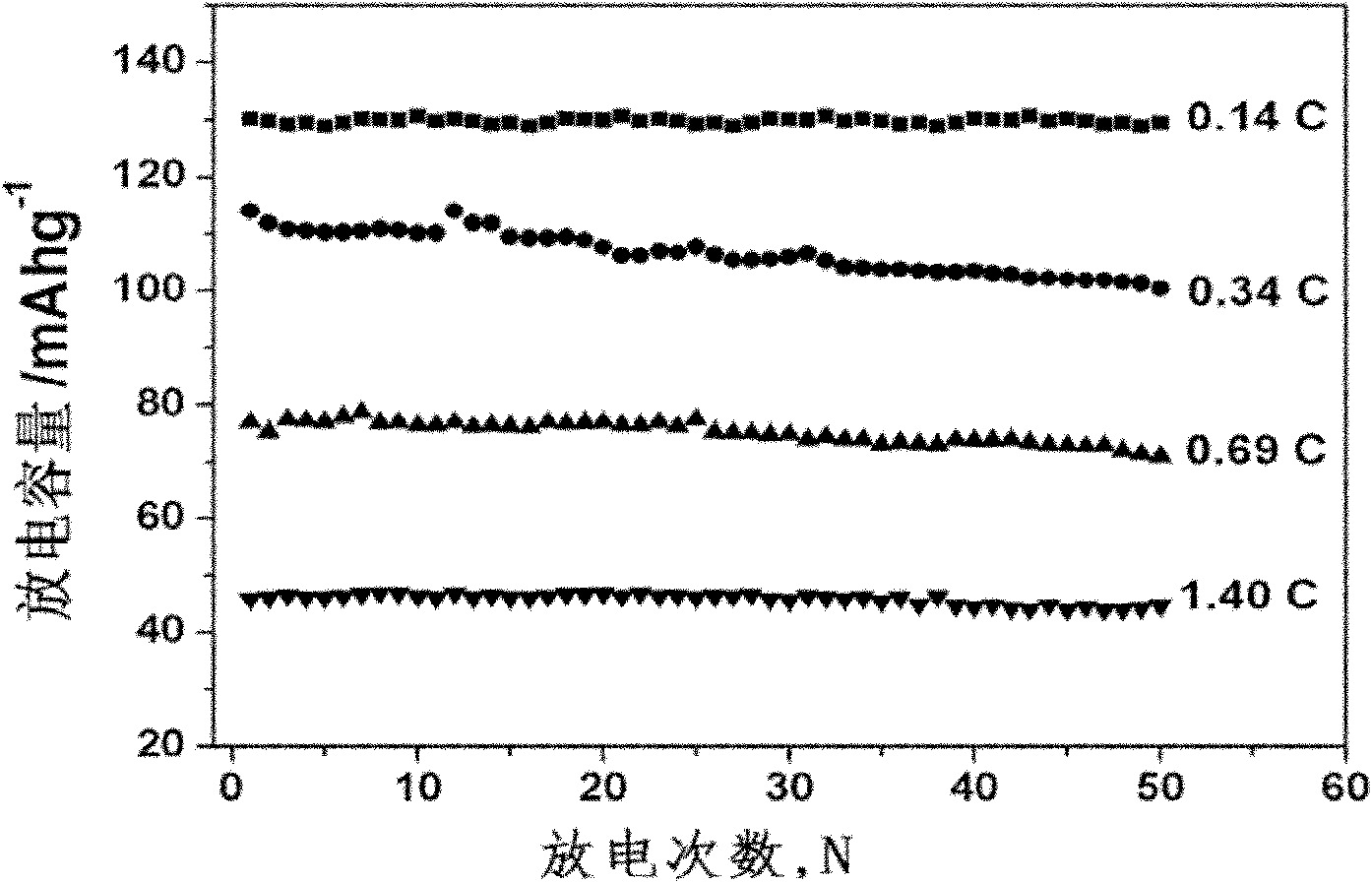

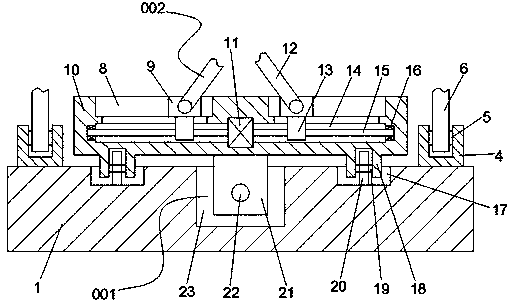

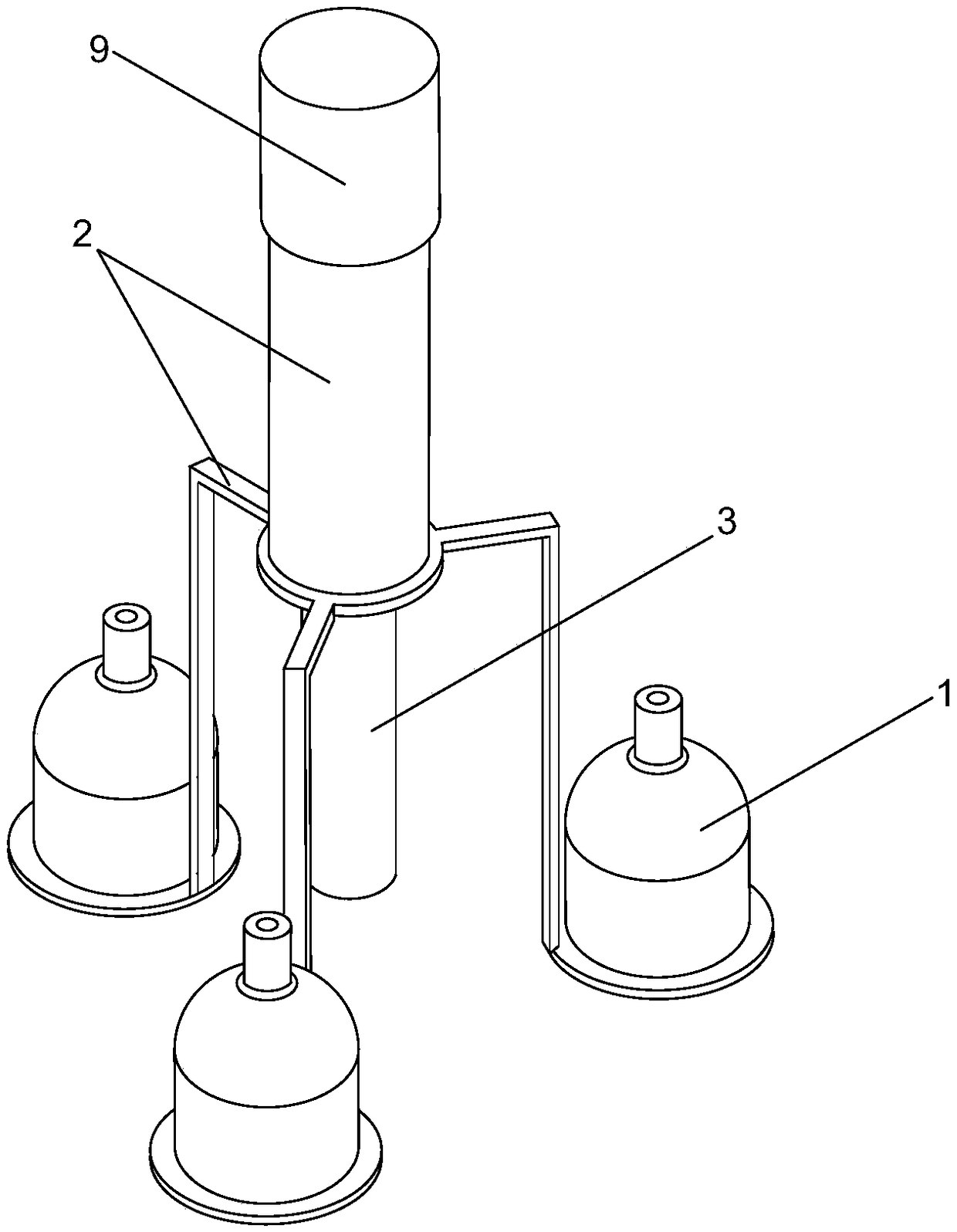

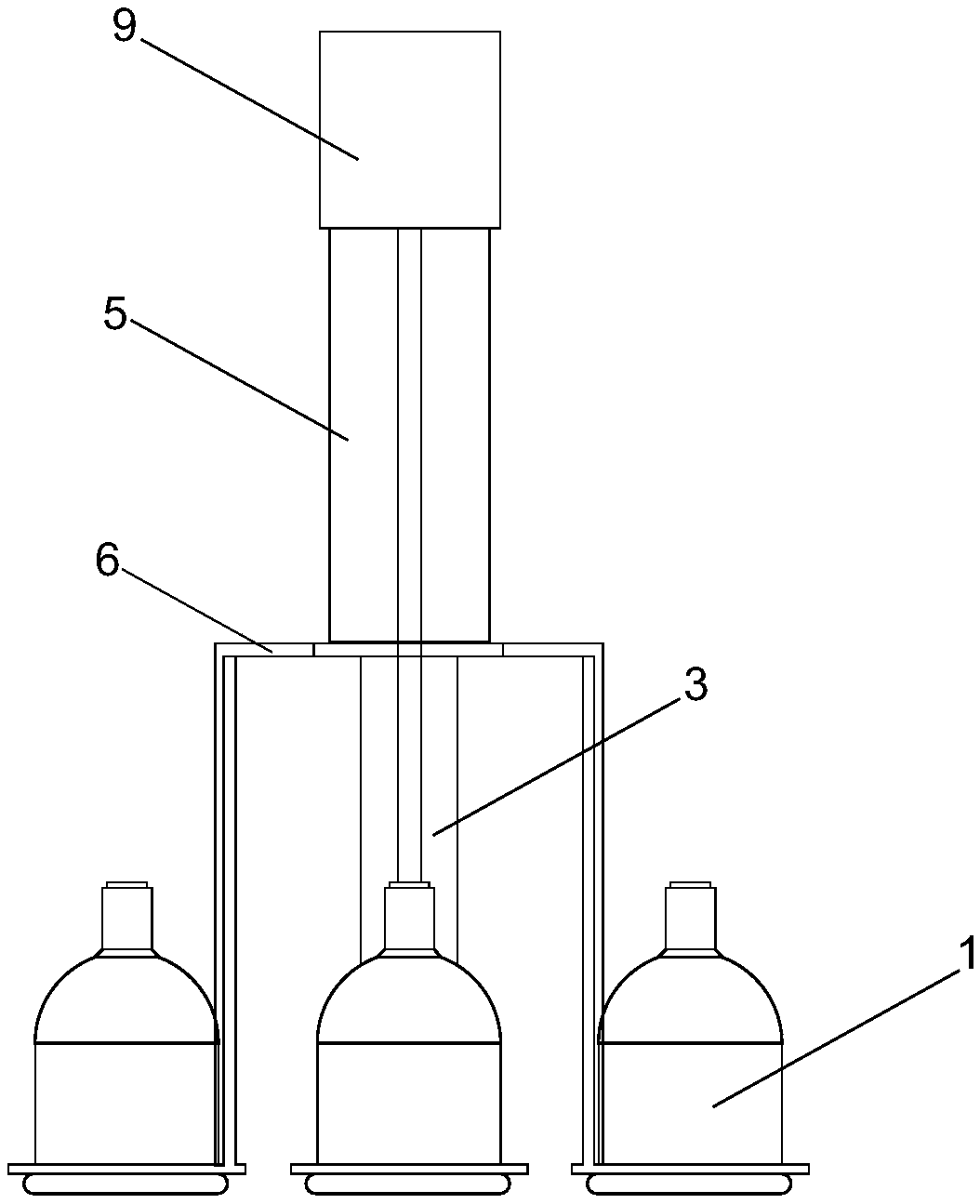

Preparation method of lithium ion battery anode composite material and special device thereof

InactiveCN102148368AEasy to prepareHigh bulk densityCell electrodesRadio frequencyIn situ polymerization

The invention discloses a preparation method of a lithium ion battery anode composite material and a special device thereof. The preparation method is characterized by comprising a first scheme, a second scheme and a third scheme, in the first scheme, a plasma-enhanced chemical vapor deposition method is used for synthesizing sp2-hybridized and carbon nano-material-coated lithium ion battery anode material LiFePO4 growing in-situ; in the second scheme, a direct plasma polymerization method is used for preparing LiFePO4 / conductive macromolecular composite material; and in the third scheme, a plasma in-situ polymerization method is used for preparing LiFePO4 / conductive macromolecular composite material. The special device for preparing the anode composite material comprises a plasma high-temperature quartz tube-type furnace, one end of the plasma high-temperature quartz tube-type furnace is provided with a reducing gas inlet pipe and a reaction gas inlet pipe and the other end of the same is provided with a gas suction pipe, and an inductance coupling plasma coil with two ends connected with radio frequency power sources is wound on the outer surface of the furnace. Tthe preparation method has the advantages of effectively improving the electric conductivity of the lithium ion battery and being simple in technological process, and the special device is simple in structure and convenient in operation.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

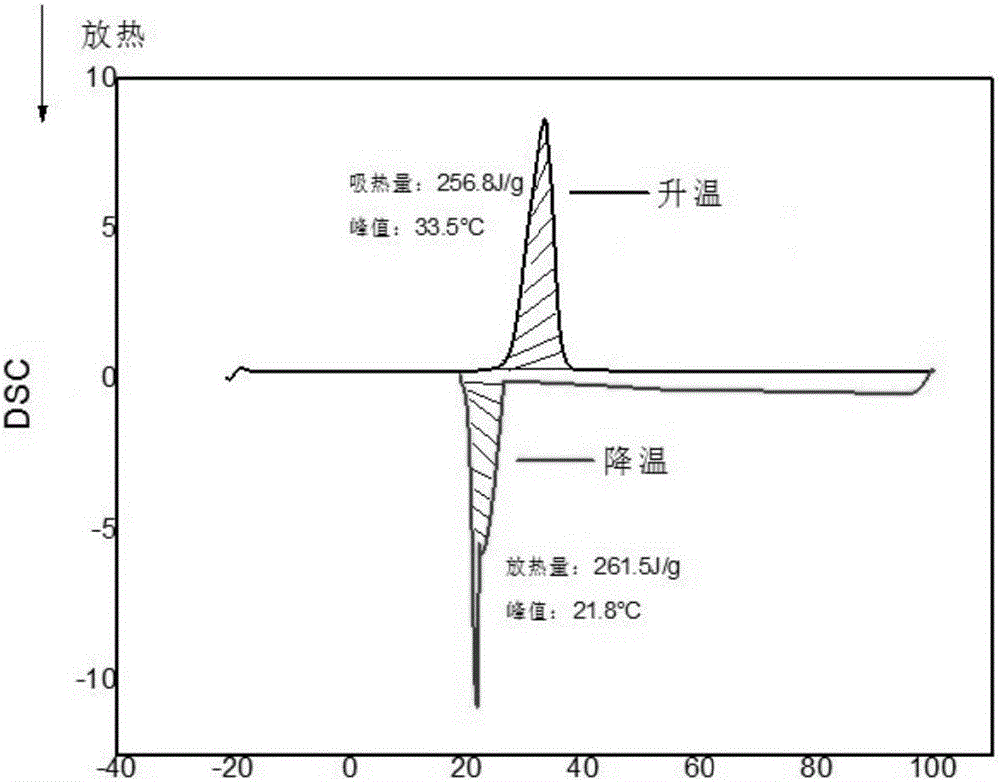

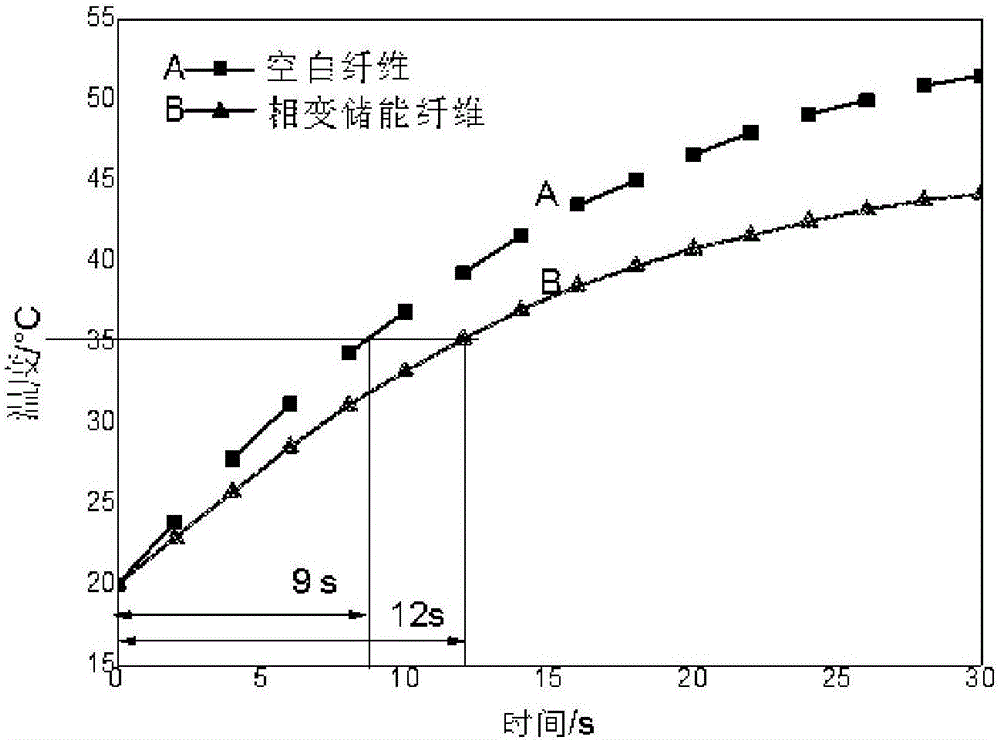

Phase-change energy-storing fiber and preparation method thereof

InactiveCN106801266AIncrease contentAvoid liquidityFilament/thread formingHeat-exchange elementsPhase change enthalpyClay minerals

The invention discloses a phase-change energy-storing fiber. The phase-change energy-storing fiber is of a skin-core structure which comprises a skin layer and a core layer, wherein a skin layer raw material is a thermoplastic polymer; and a core layer raw material is a mixture of the thermoplastic polymer, clay mineral powder and a phase-change material. A preparation method of the phase-change energy-storing fiber comprises the following steps: (1) weighing 2-20 parts of the phase-change material and 5-20 parts of the clay mineral powder in parts by weight, uniformly mixing the weighed phase-change material and clay mineral powder by virtue of ultrasonic oscillation under a vacuum condition, putting the mixture into a vacuum oven so as to obtain a composite phase-change material, and uniformly mixing 60-90 parts of thermoplastic polymer with the prepared composite phase-change material, so as to obtain the core layer raw material; and (2) carrying out melt spinning on the thermoplastic polymer, as skin layer raw material, and the core layer raw material by virtue of a compound spinning machine, so as to obtain the phase-change energy-storing fiber being of the skin-core structure. The preparation method is simple and low in cost, and the prepared phase-change energy-storing fiber has large phase-change enthalpy and a uniform temperature regulation effect.

Owner:WUHAN TEXTILE UNIV

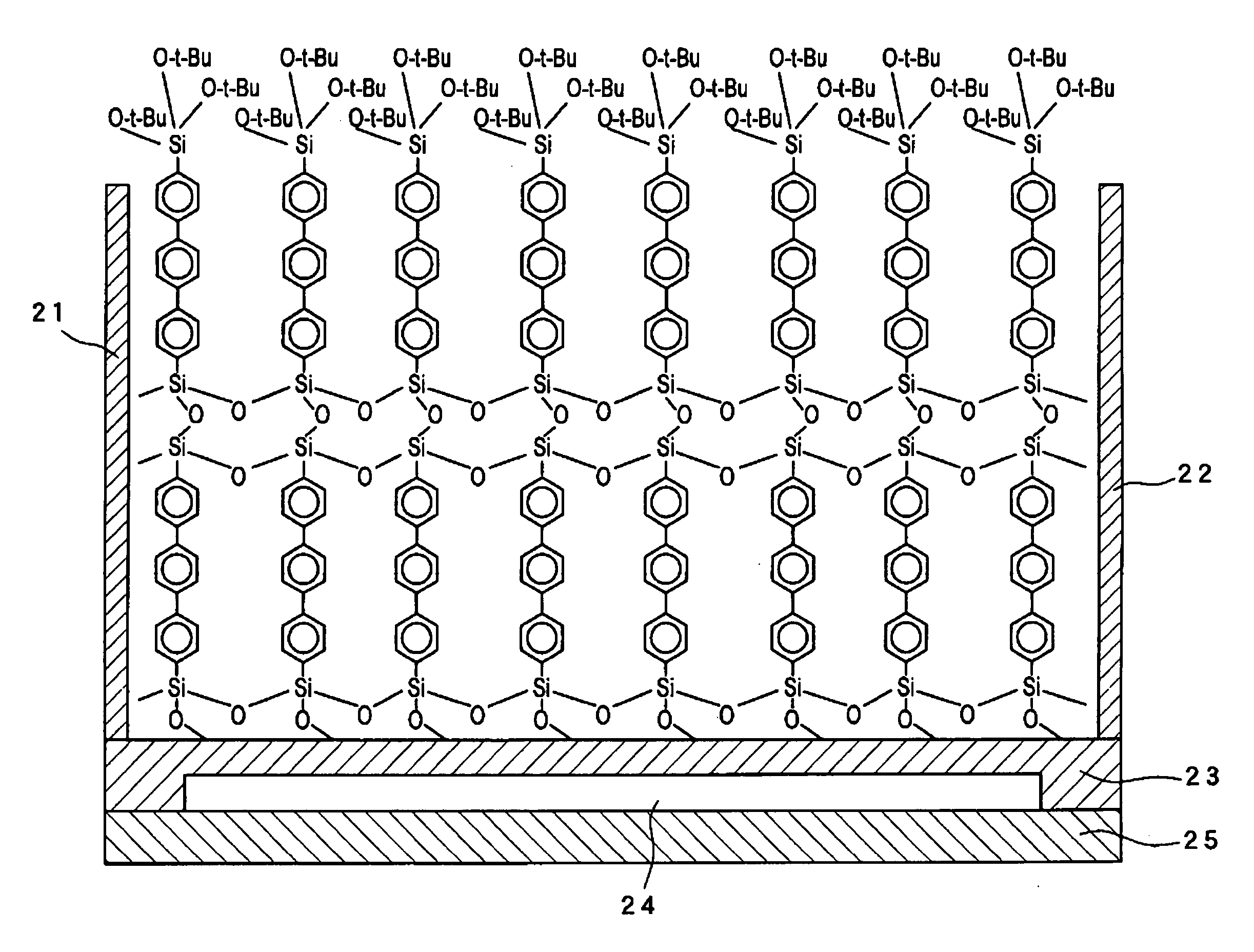

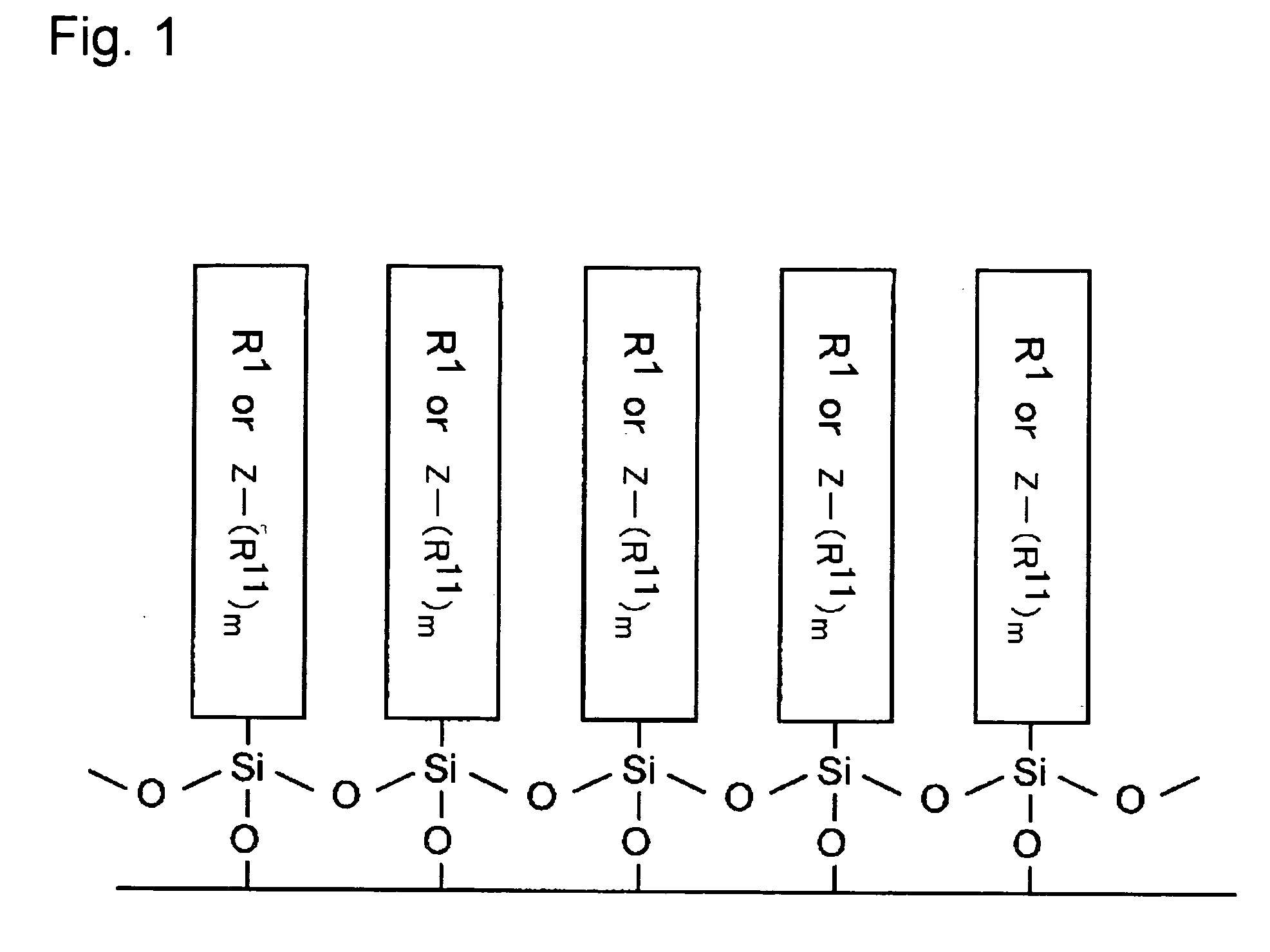

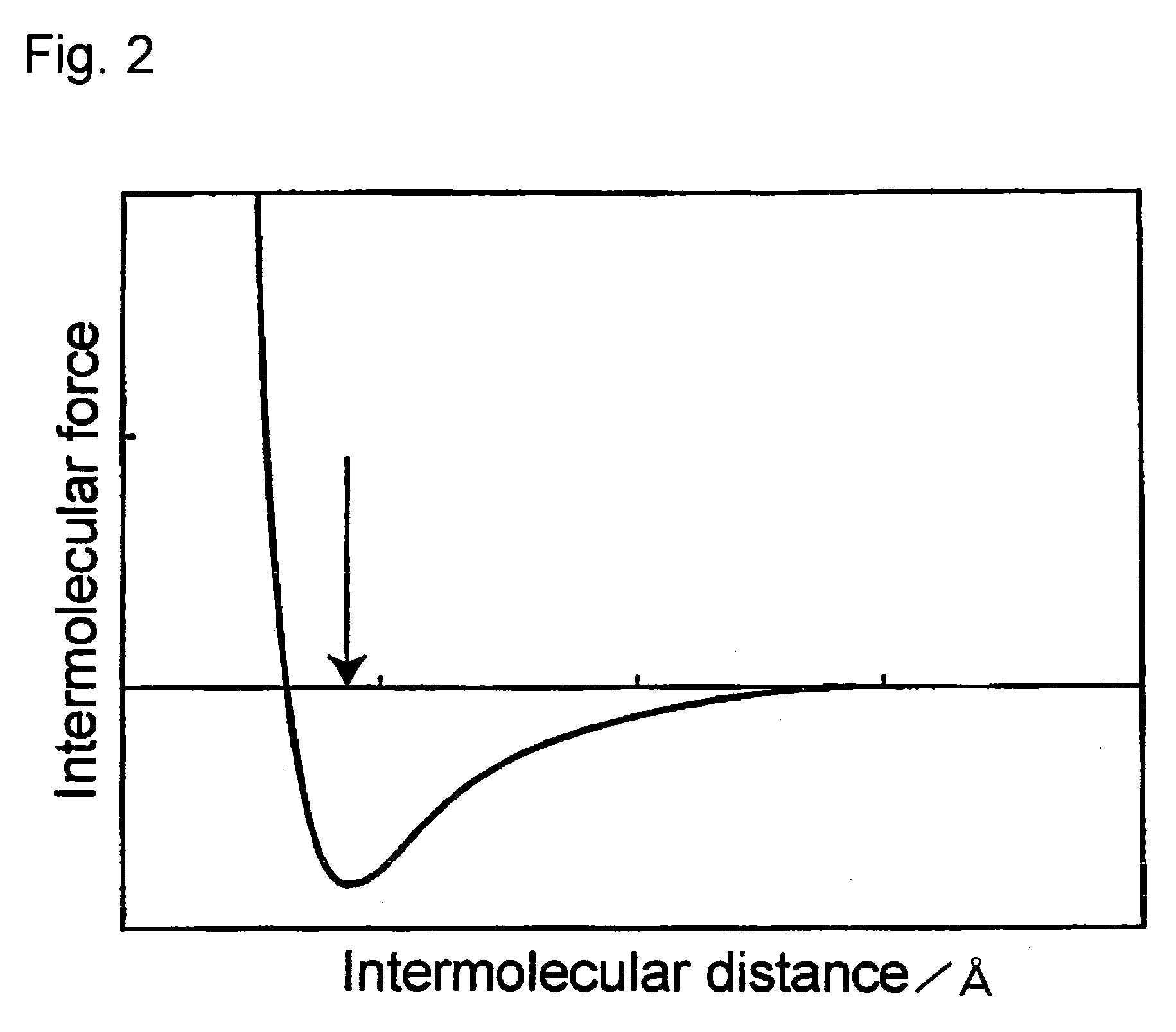

Organic compound having functional groups different in elimination reactivity at both terminals, organic thin film, organic device and method of producing the same

InactiveUS20070195576A1Prevents physical exfoliationImprove stabilityTransistorSilicon organic compoundsSilyleneHalogen

Provided are a single monomolecular film uniform in film thickness and highly ordered in molecule alignment and its multilayer film, an organic compound allowing production of such films at high reproducibility, an organic device superior in electroconductive properties and a method of producing the same. An organic compound represented by Formula:Si(A1)(A2)(A3)-B—Si(A4)(A5)(A6)(A1 to A6 each represent a hydrogen atom, a halogen atom, an alkoxy group or an alkyl group and satisfy the relationship in elimination reactivity of: A1 to A3>A4 to A6; and B represents a bivalent organic group), an organic thin film using the compound, and an organic device having the thin film; A method of producing an organic thin film and organic device, comprising a step of forming a single monomolecular film by allowing the silyl group having A1 to A3 in the organic compound to react with the substrate surface; a step of removing unreacted organic compounds by using a non-aqueous solvent; and a step of forming an additional monomolecular film of the organic compound by using the unreacted silyl groups present on the film surface side of the monomolecular film obtained as the sites for adsorption reaction.

Owner:SHARP KK

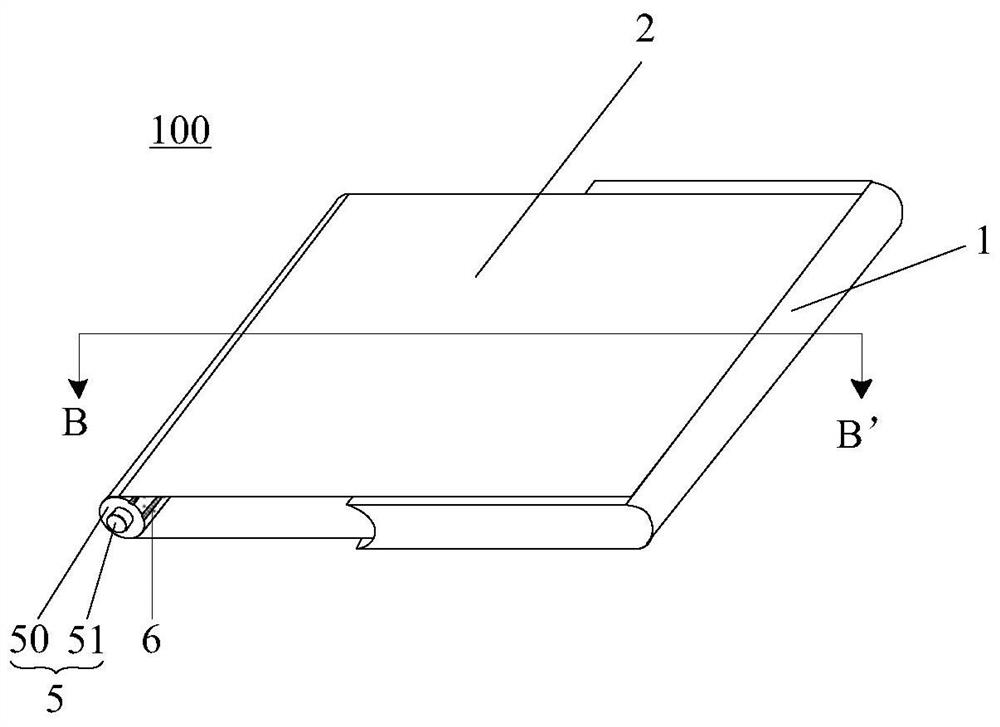

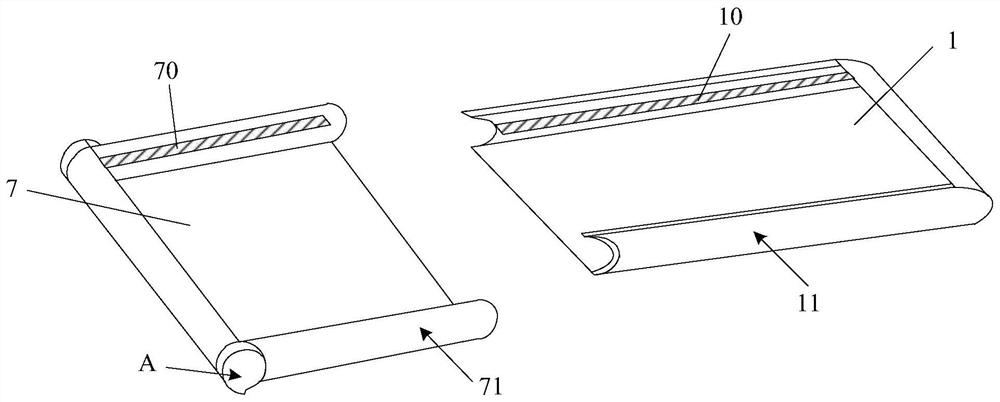

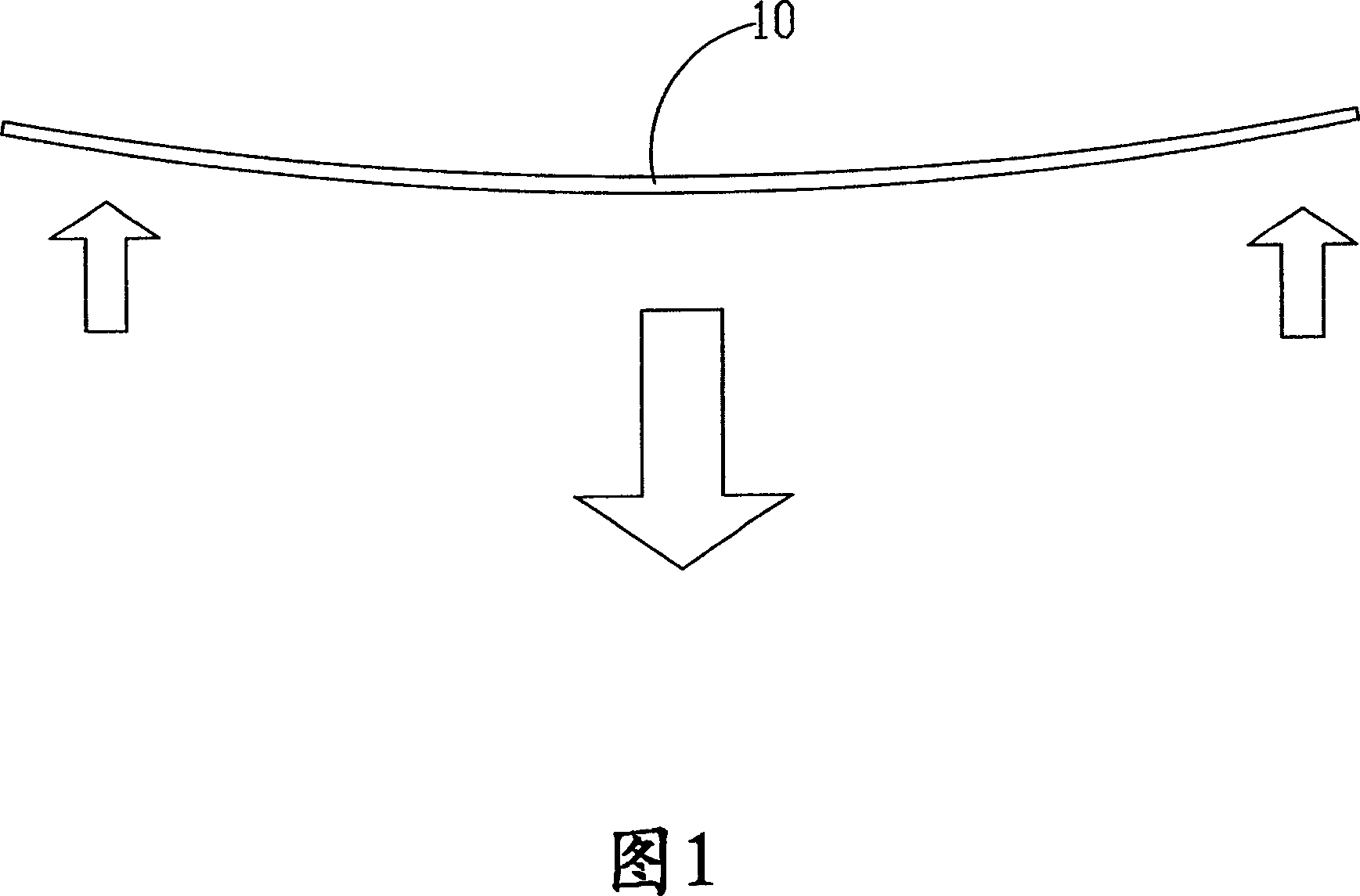

Display device

The embodiment of the invention provides a display device, relates to the technical field of the display, and can solve the problems that a flexible display screen is bulged to be damaged and slippingand idling occur between a reel and a flexible metal supporting layer, and the display device comprises a first shell which is provided with a first supporting surface, at least one part of the flexible display screen covers the first supporting surface; the flexible metal supporting layer is arranged on the side, close to the first supporting face, of the flexible display screen and connected with the flexible display screen. The first end of the flexible metal supporting layer covers the first supporting surface and is connected with the first supporting surface; the elastic element is located in the first shell and connected with the first shell and the second end of the flexible metal supporting layer. The reel is arranged on the side, away from the flexible display screen, of the flexible metal supporting layer. The flexible display screen and the flexible metal layer are wound on the scroll; the magnetic element is located between the reel and the flexible metal supporting layer, connected with the reel and magnetically attracted to the flexible metal supporting layer.

Owner:BOE TECH GRP CO LTD

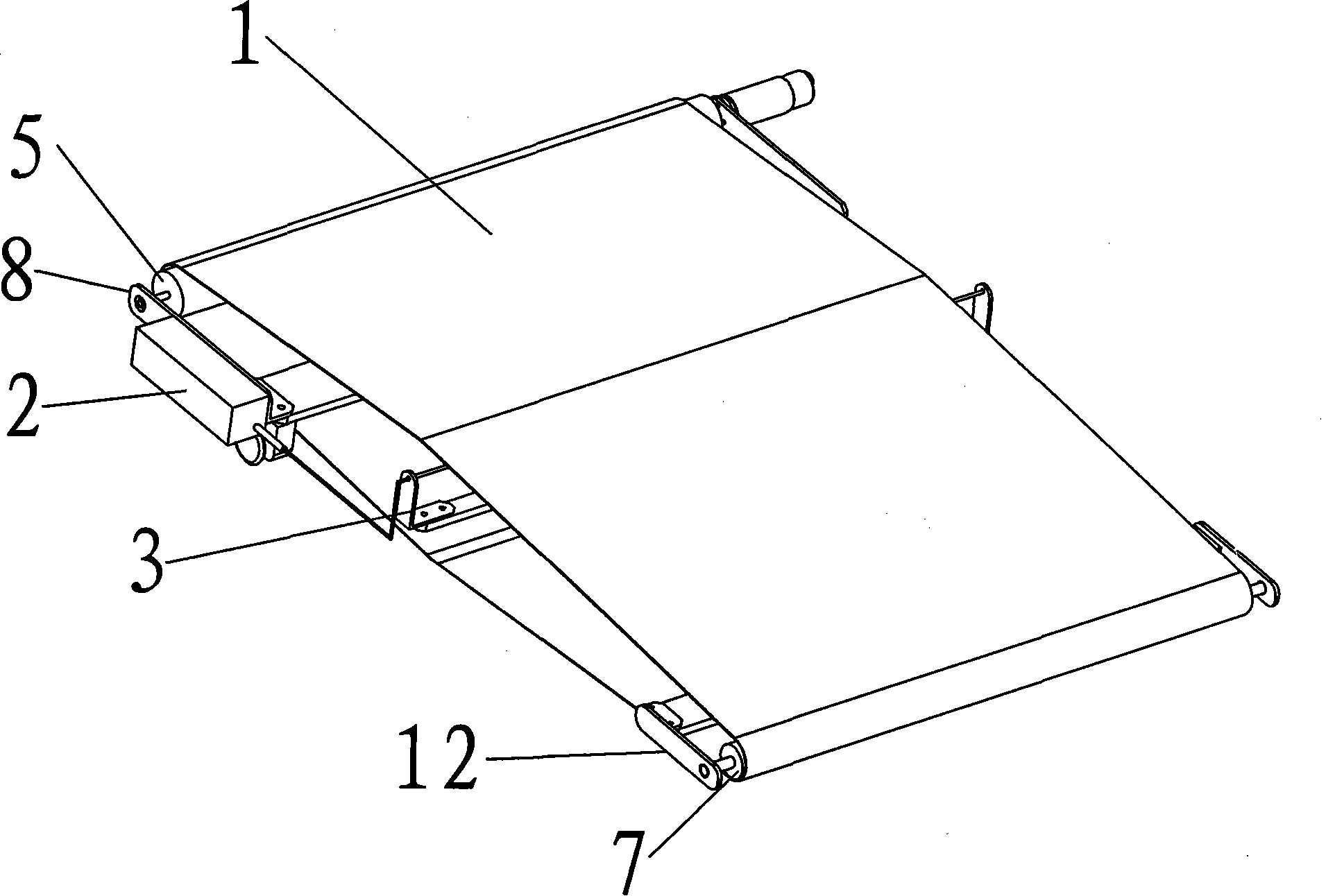

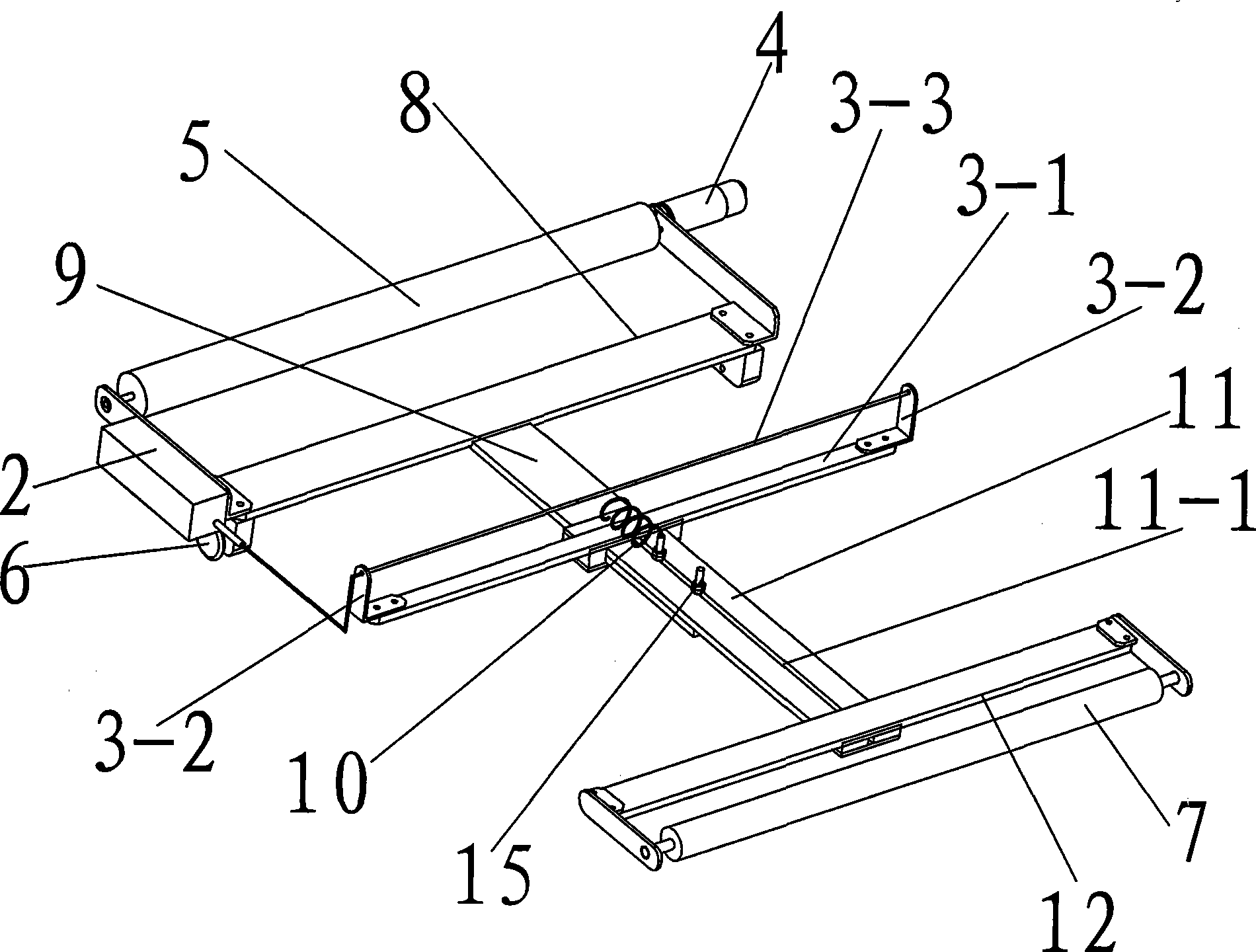

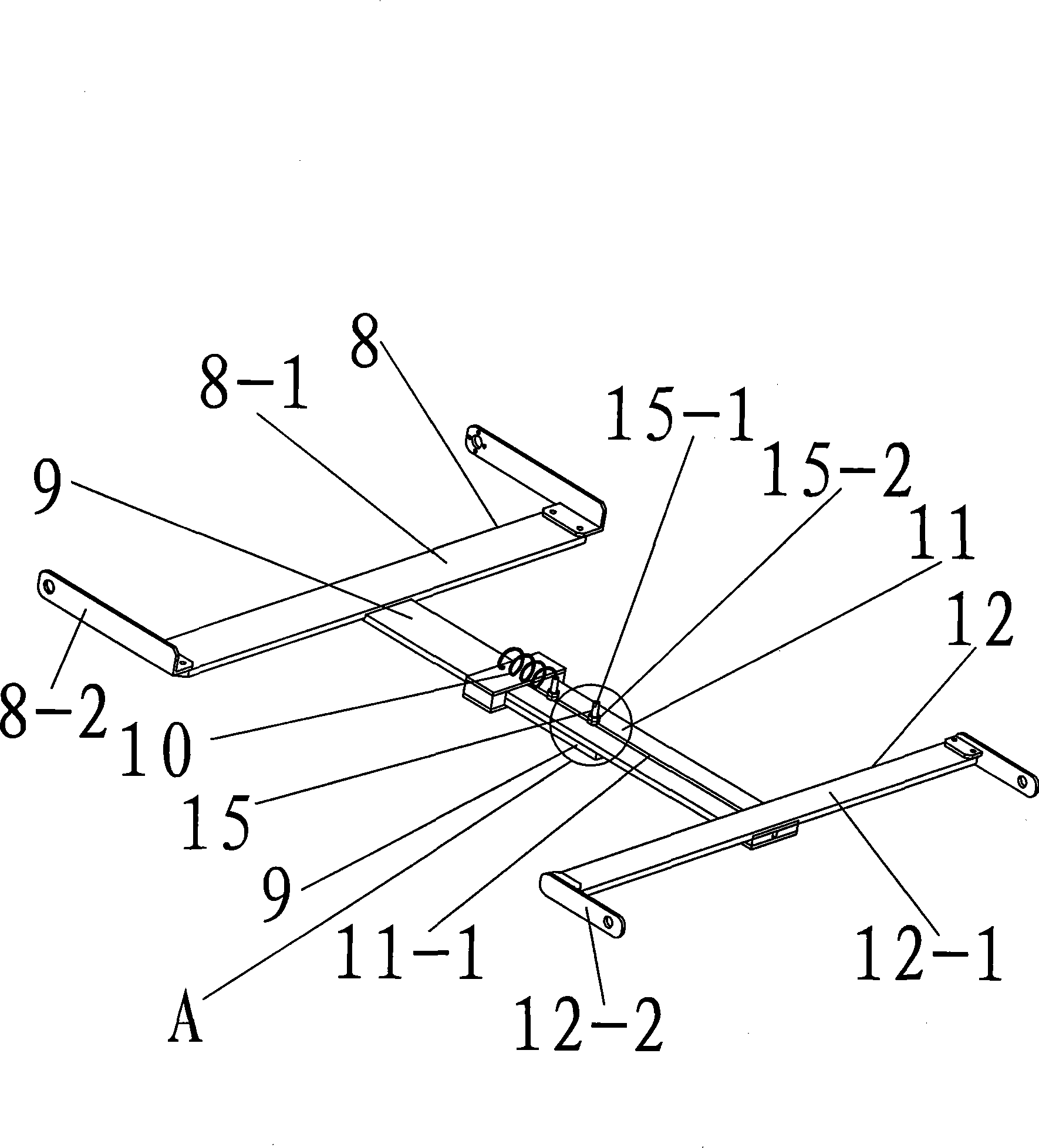

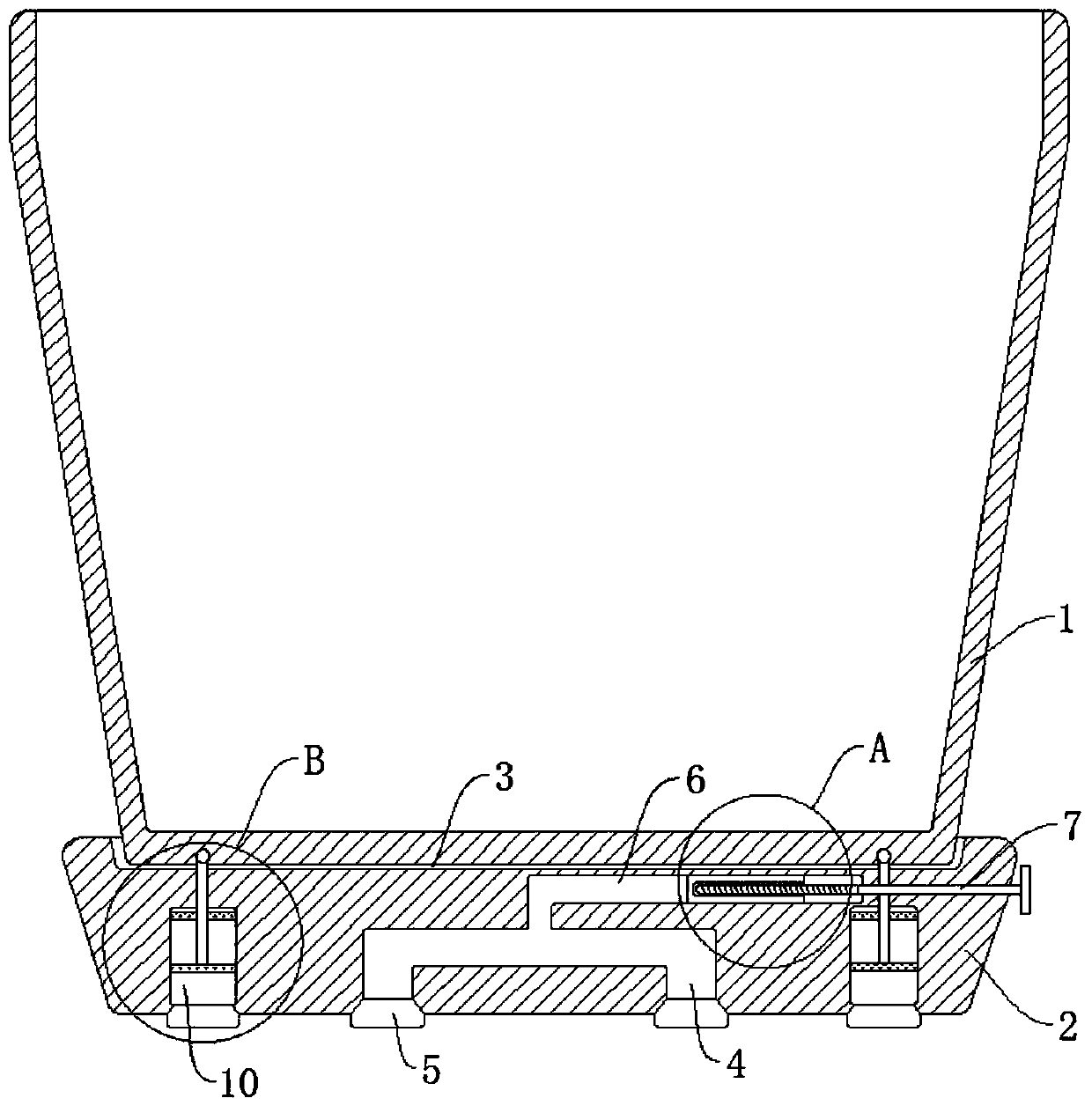

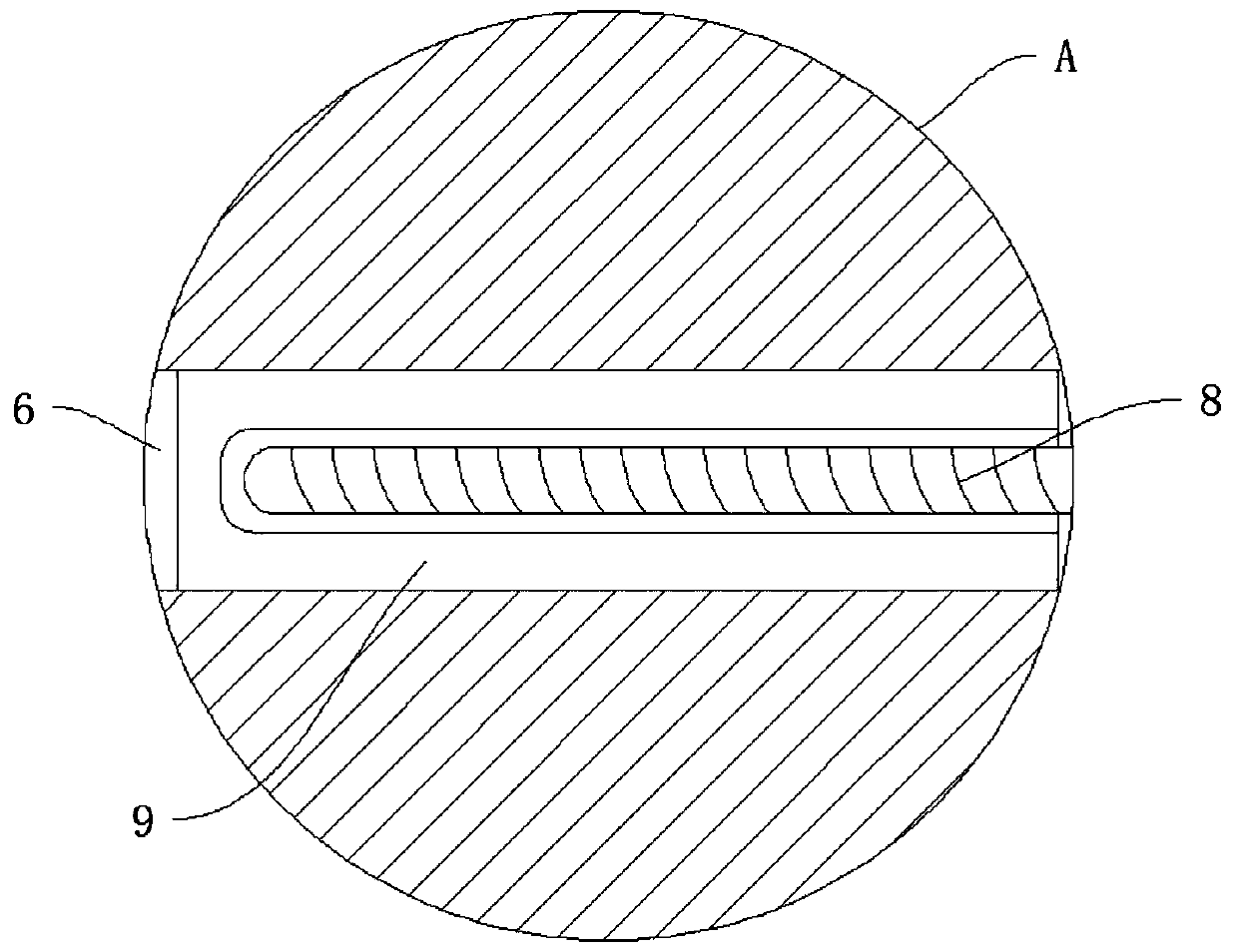

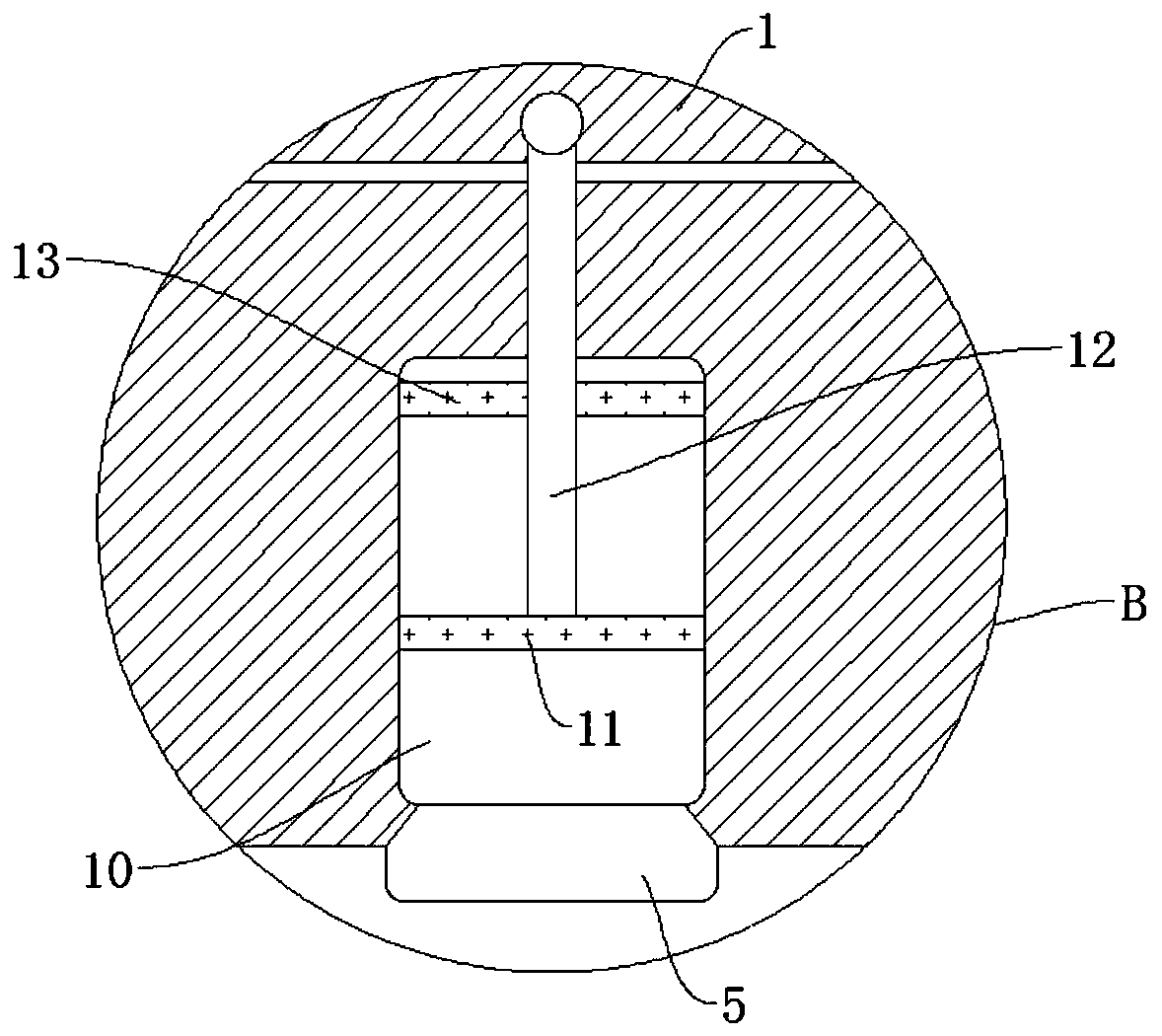

Single crawler type wall climbing robot based on electrostatic absorption principle

The invention discloses a single-crawler type wall climbing robot based on the electrostatic adherence theory, and relates to a wall climbing robot. The invention aims to provide a wall climbing robot which has the advantages of large range adapting to wall surface materials, low noise, smaller volume, small electrostatic adherence device self weight and high moving speed. Flexible aluminum plated film crawlers are adopted as a walking device and an adherence device of the robot. One end of a slide base plate is overlapped with one end of a slide guide plate, and the base plate is connected with an end part of the slide guide plate. One end of a spring is connected with a guiding and positioning rod piece, while the other end is connected with an end part of the slide guide plate. The other end of the slide base plate is perpendicularly connected with the middle part of a driving wheel supporting frame main body of a driving wheel supporting frame, and the other end of the slide guide plate is perpendicularly connected with the middle part of an inducement wheel supporting frame main body of an inducement wheel supporting frame. The wall climbing robot has the advantages of large range adapting to the wall surface materials, low noise, smaller volume, small electrostatic adherence device self weight and high moving speed, and has board application prospect in the aspects of anti-terrorism detection, high building detection and so on.

Owner:SHENZHEN LONGHAITE ROBOT TECH CO LTD

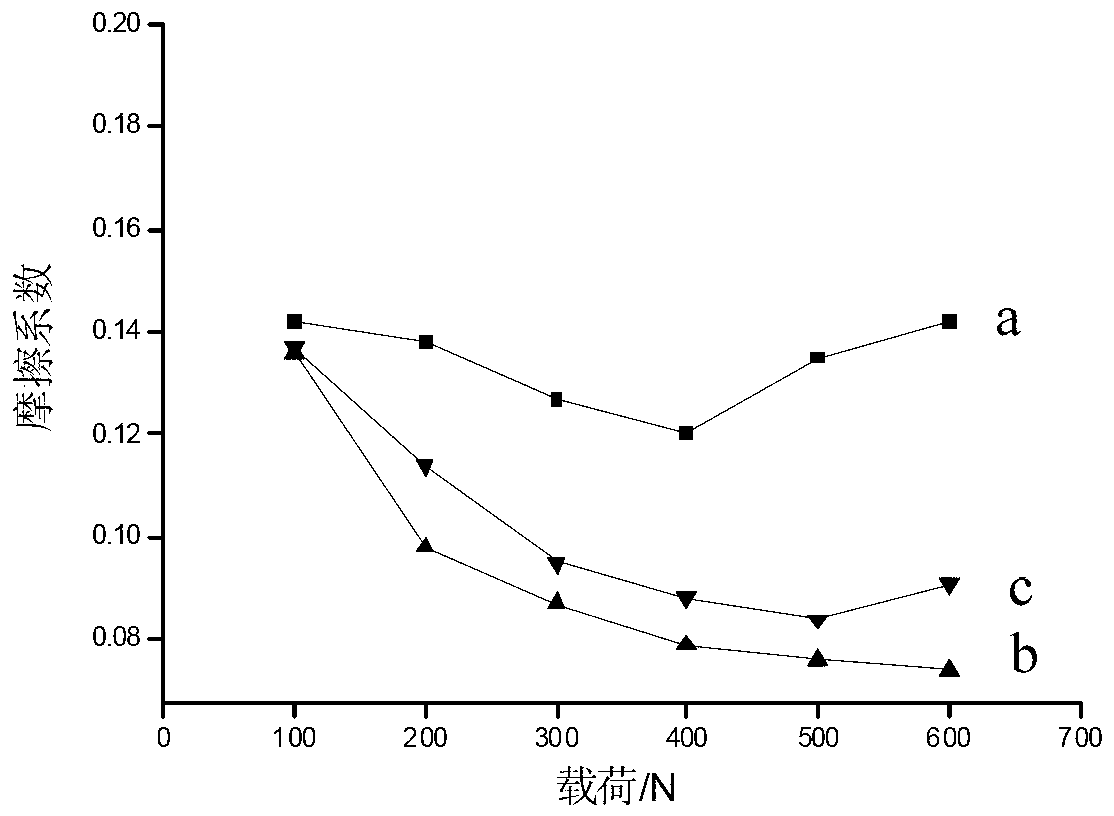

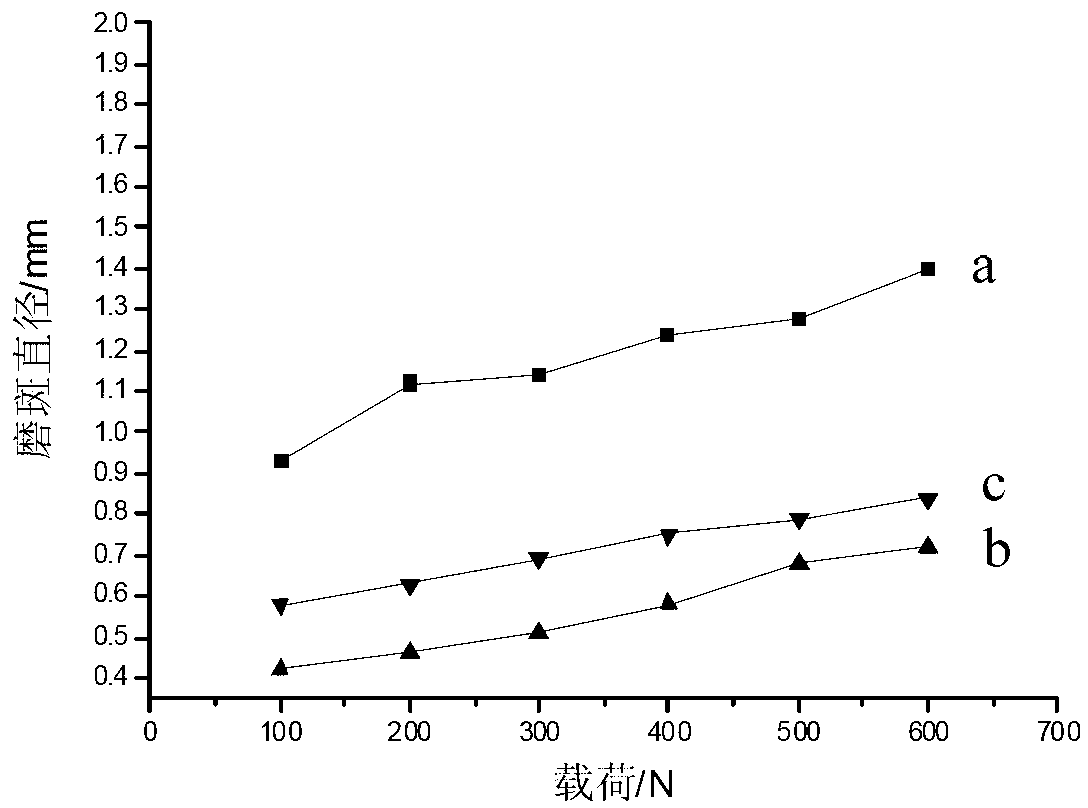

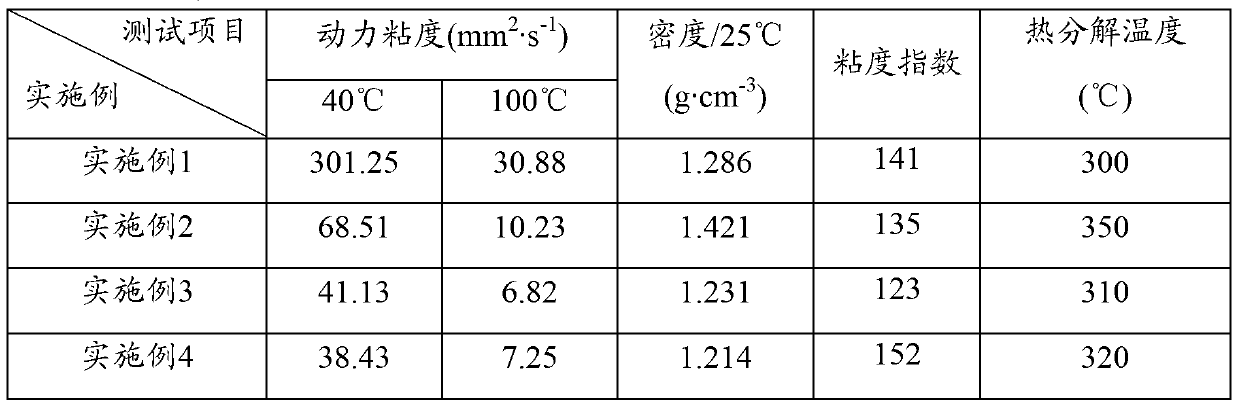

Functionalized ionic liquid lubricating agent

InactiveCN103343030AImprove anti-wear performanceImprove adsorption capacityAdditivesViscosity indexWear resistance

The invention provides a functionalized ionic liquid lubricating agent. The functionalized ionic liquid lubricating agent comprises an ionic liquid shown in a formula (I) and an ionic liquid shown in a formula (II). Ester groups, hydroxyl groups, carboxylic groups or sulfonic acid groups are introduced into an imidazole ionic liquid to serve as functionalized radicals, so that the functionalized ionic liquid lubricating agent is easily adsorbed on the surface of a metal through an electrostatic effect, thus the wear resistance of the lubricating agent at a high temperature is improved; and the ionic liquids containing different functionalized radicals are mixed, so that the functionalized ionic liquid lubricating agent is tightly adsorbed on the metal, and the wear resistance of the lubricating agent is further improved. The results of performance test on the prepared lubricating agent show that the viscosity index of the functionalized ionic liquid lubricating agent is greater than 90, the thermal decomposition temperature of the functionalized ionic liquid lubricating agent is higher than 300 DEG C, and the functionalized ionic liquid lubricating agent has good wear resistance on the metal. The formula (I) and the formula (II) are shown in descriptions.

Owner:陈立功

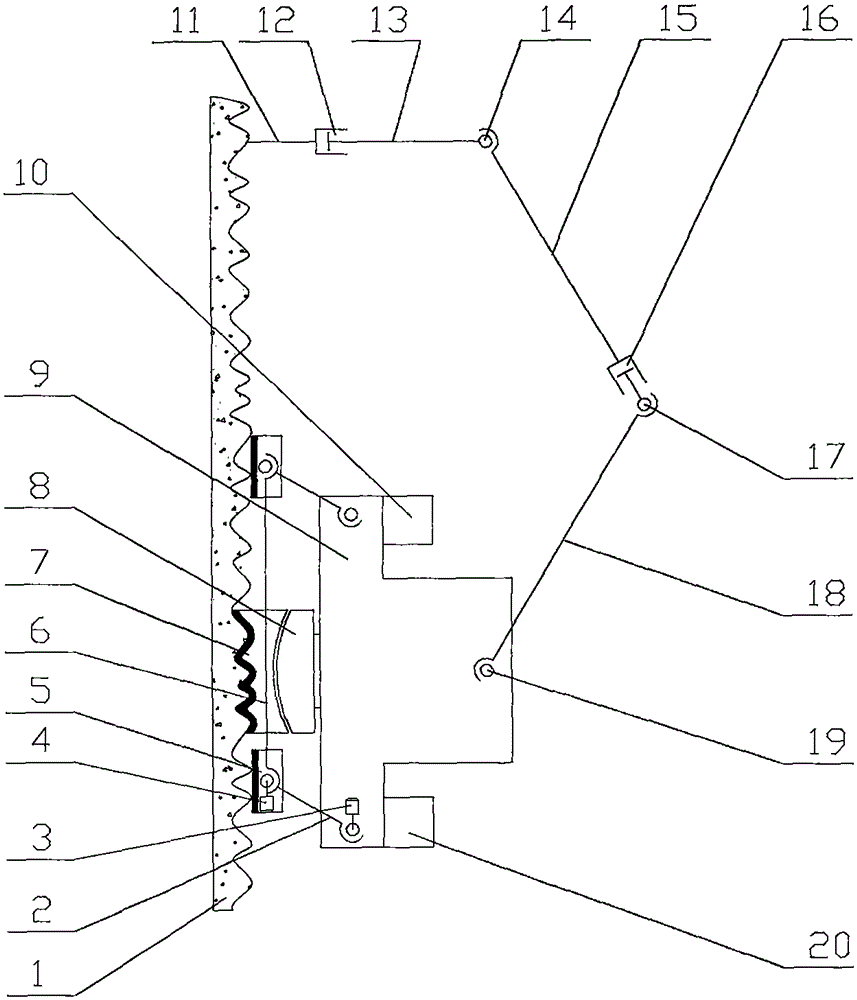

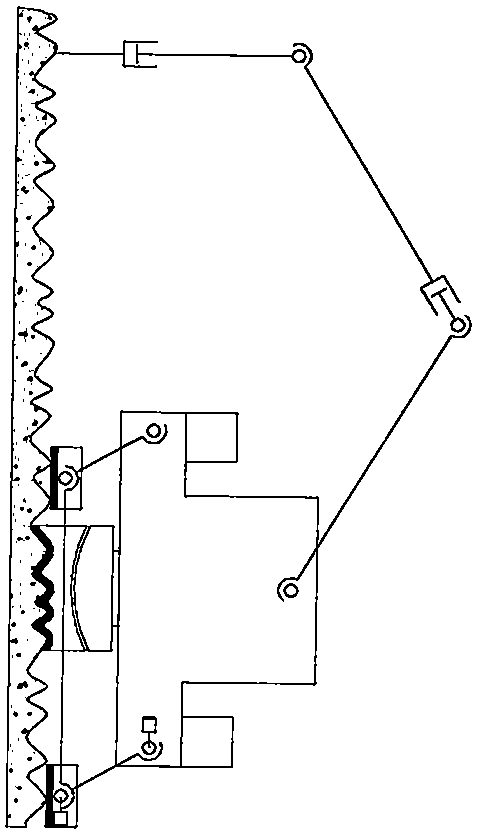

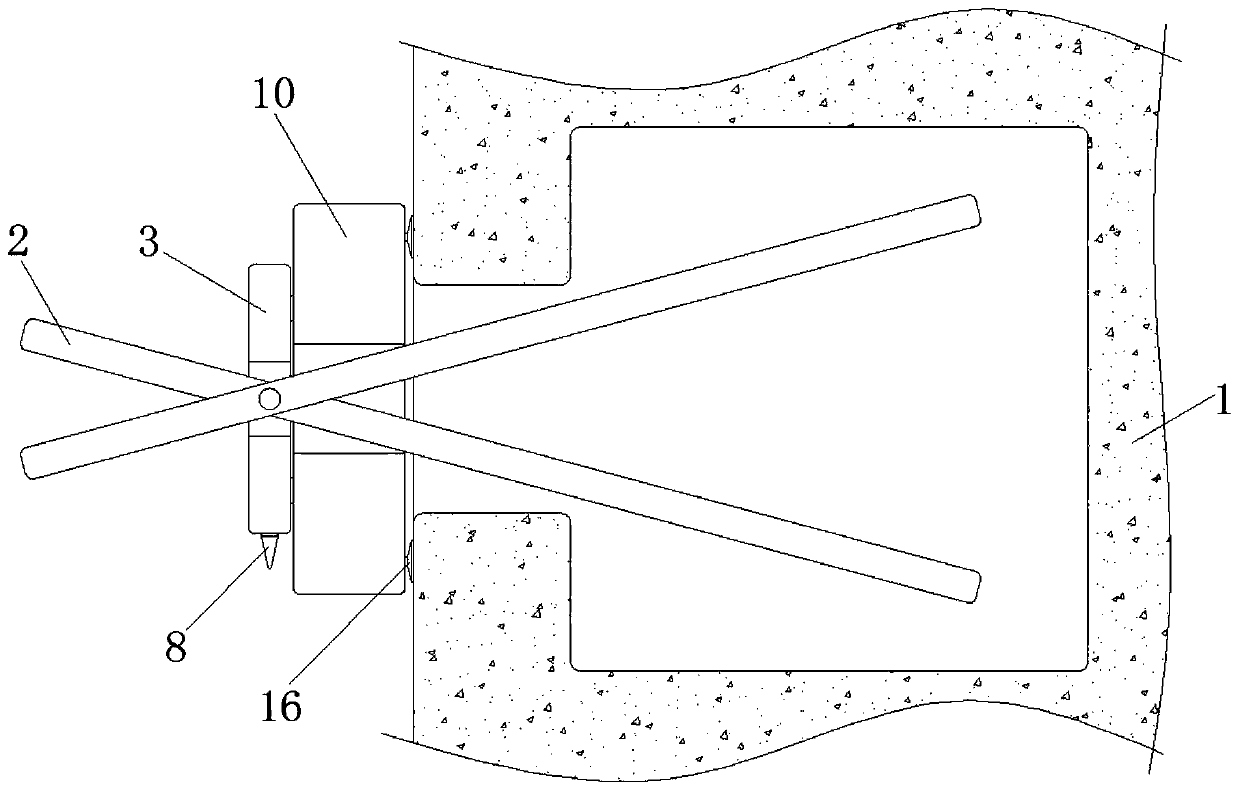

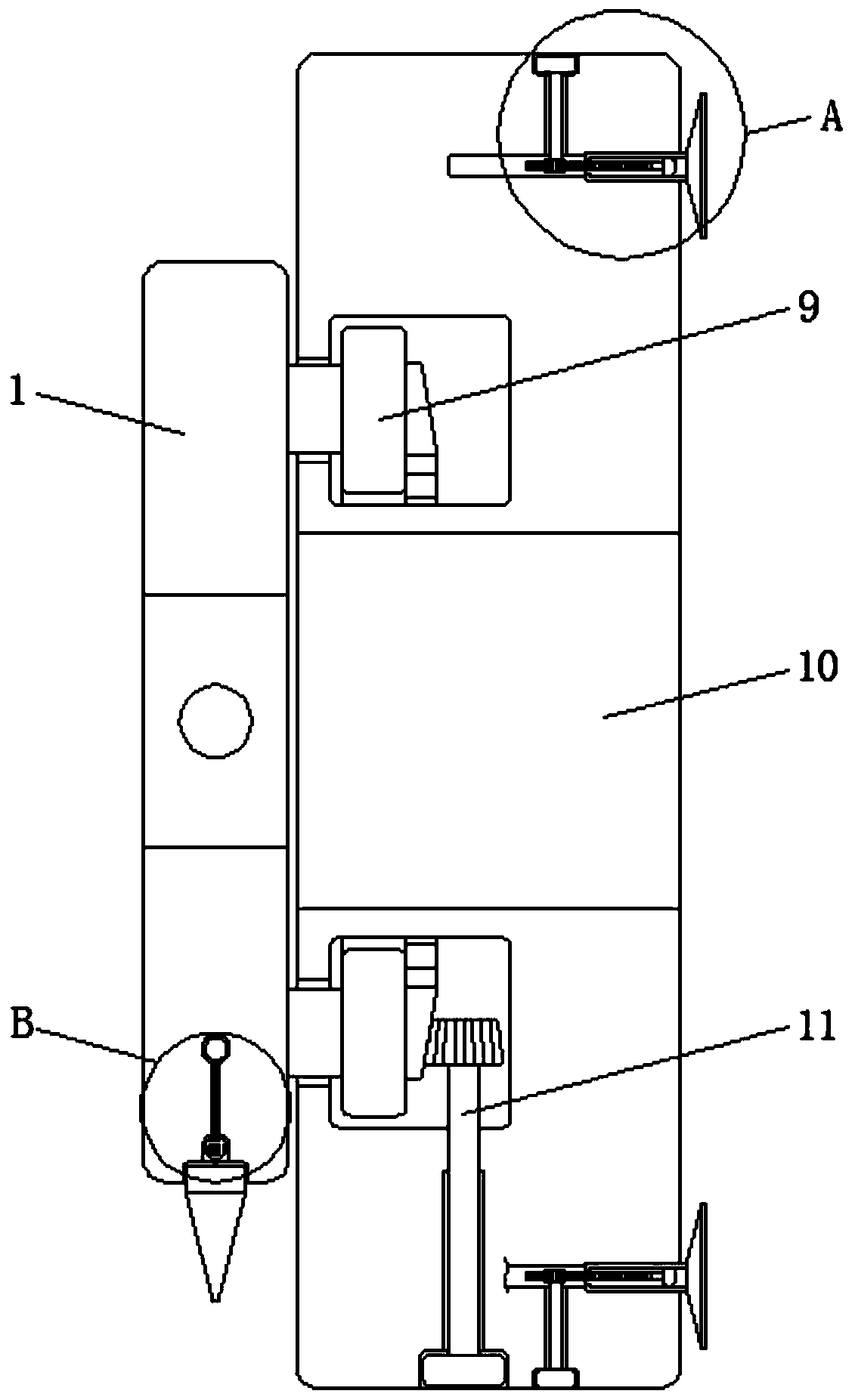

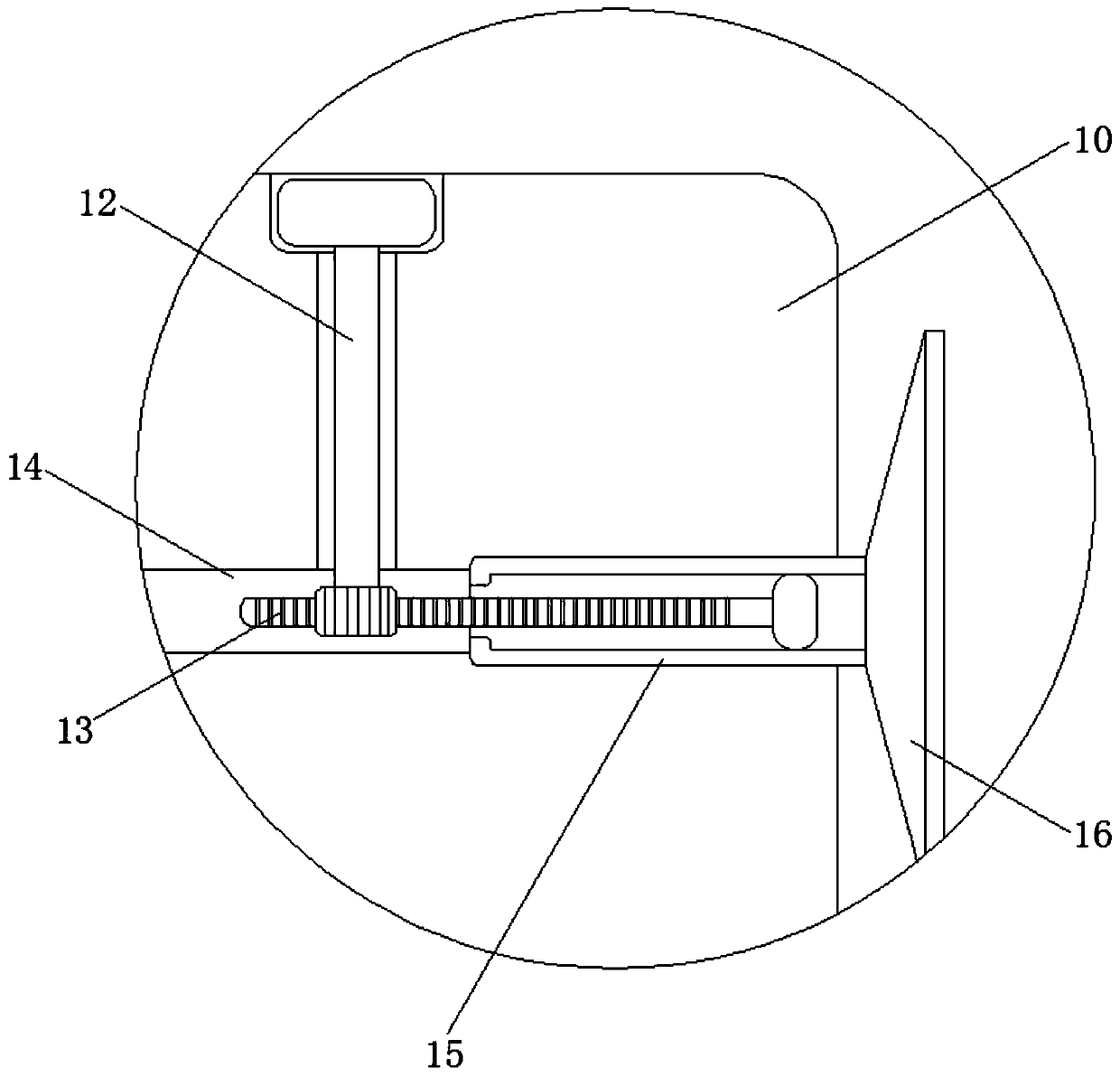

Sucking cup type wall face operation robot

ActiveCN105108753ARealize all-round operationTight adsorptionManipulatorVehiclesElectric controlControl theory

The invention discloses a sucking cup type wall face operation robot used for operation on the outside wall of a building. The sucking cup type wall face operation robot comprises a working platform, a traveling mechanism, a robot body, a pneumatic system and an electric control system. The traveling mechanism comprises four traveling sucking cups, a working sucking cup, a traveling motor, four rocking bars, two connecting rods and a swing motor. The traveling sucking cups and the pneumatic system are in power connection. The traveling sucking cups and the traveling motor are in driving connection. The four traveling sucking cups are connected through the connecting rods. The two ends of each connecting rod are in driving connection with the swing motor through two rocking bars respectively. The working sucking cup is mounted on the working platform and is in power connection with the pneumatic system. The robot body comprises a robot chassis and a mechanical arm. The mechanical arm is mounted on the robot chassis, and the robot chassis is mounted on the working platform. The pneumatic system, the mechanical arm, the traveling motor and the swing motor are all in communicating connection with the electric control system. The sucking cup type wall face operation robot can be used for operation on the outside wall of the building.

Owner:HXXN ELECTRICITY

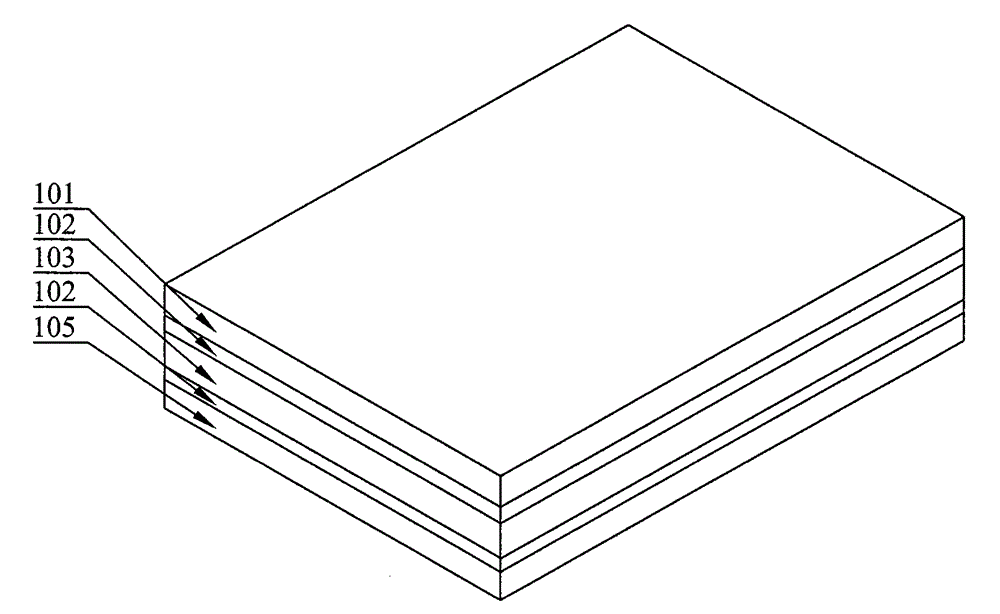

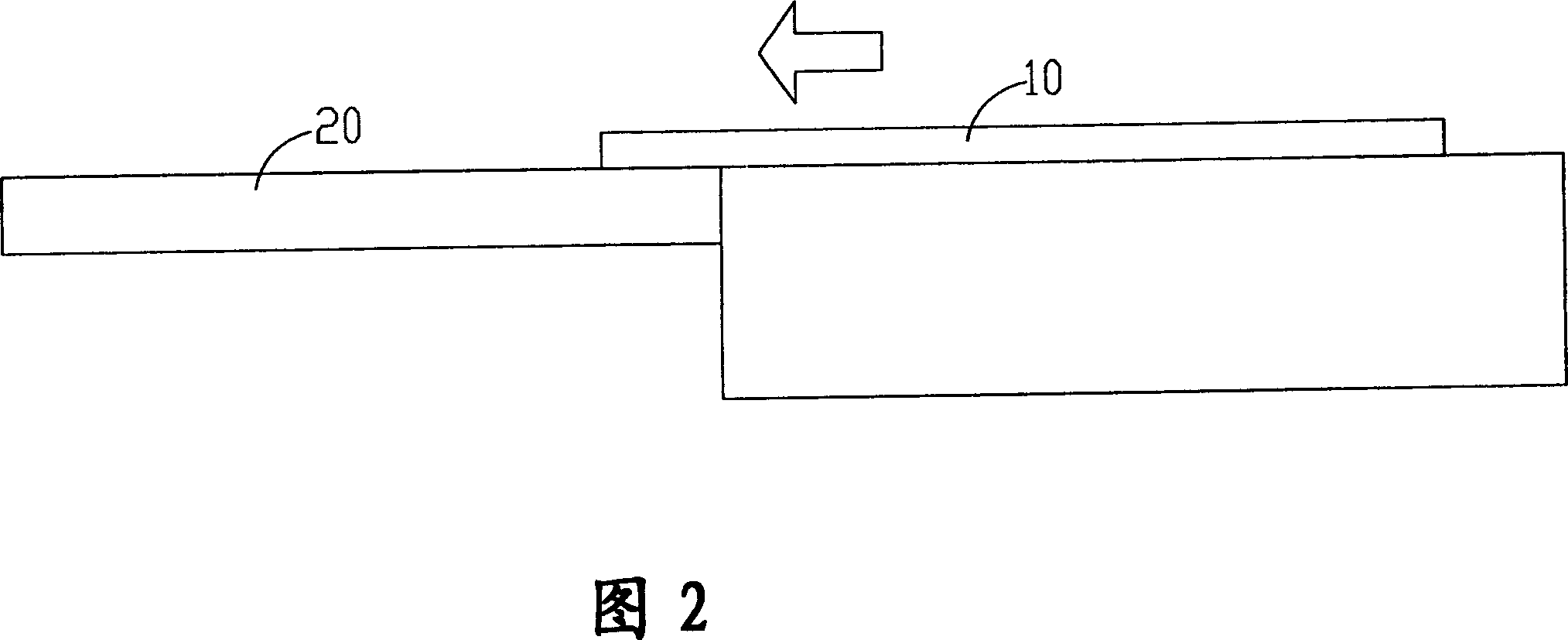

Touch screen separating device and touch screen separating method

ActiveCN104320505APrecise cutting effectImprove efficiencyTelephone set constructionsHuman–computer interactionSeparation method

The invention provides a touch screen separating device, offering a touch screen, and the touch screen comprises a plurality of layered assembles, the layered assembles are pasted together through the sticking layer, the touch screen separating device comprises a cutting line, the cutting line works in periodicity for cutting the sticking layer for separating the layered assembles in the touch screen. The touch screen separating method is also provided and the method comprises the steps as follows: S1, offering the touch screen, and fixing the touch screen on a screen fixing device; S2, offering the cutting line, adjusting the height of the cutting line; S3, receiving and releasing the cutting line in periodicity for cutting the sticking layer on the touch screen. The screen separating efficiency is high by adopting the touch screen separating device or the touch screen separating method and the separating effect is good.

Owner:SHENZHEN BENKS TECH

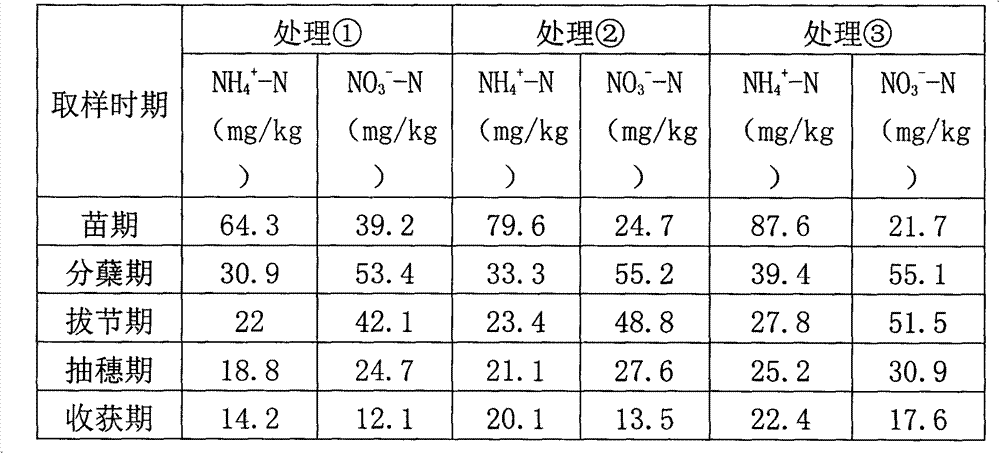

Non-metallic mineral long-acting nitrogenous fertilizer nitrification inhibitor and preparation method thereof

InactiveCN103193555ATight adsorptionEnhanced inhibitory effectAgriculture gas emission reductionFertilizer mixturesNitrification inhibitorsAqueous solution

The invention discloses a non-metallic mineral long-acting nitrogenous fertilizer nitrification inhibitor and a preparation method thereof. The preparation method is characterized by comprising the following steps: introducing 1-50 parts of the nitrification inhibitor into 100 parts of 25-100 DEG C water so as to make a solution; adding 25-75 parts of nitrification inhibitor solution into every 100 parts of non-metallic mineral powder; and sufficiently stirring and drying so as to obtain the nitrification inhibitor; or a binder accounting for 1-5% of the total weight of the non-metallic mineral and the nitrification inhibitor solution is added, sufficiently stirred, palletized and dried; or a mixture of the non-metallic mineral and the nitrification inhibitor solution or a screened powder product covers the outer surface of the fertilizer. The product is prepared by utilizing the excellent abruption property of the non-metallic mineral, the process is simple, the cost is low, the slow-release effect is better, and the inhibition effect on the activity of soil enzyme is longer; and meanwhile the non-metallic mineral can further provide various beneficial elements to the soil, so that the physicochemical properties of the soil are improved.

Owner:QIONGZHOU UNIVERSITY

Anti-corrosion and anti-rust concrete and preparation method thereof

The invention discloses anti-corrosion and anti-rust concrete and a preparation method thereof. The anti-corrosion and anti-rust concrete is prepared from the following components in parts by weight:270-290 parts of cement, 60-70 parts of mineral powder, 70-90 parts of fly ash, 673-727 parts of sand, 950-970 parts of stone, 111-165 parts of water and 30-40 parts of additives. The additives comprise a pumping agent and an anti-corrosion and anti-rust agent, and the anti-corrosion and anti-rust agent comprises the following components in parts by weight: 5-9 parts of modified epoxy resin, 1-5 parts of a GWZB820 type reinforcing agent, 1.5-3.5 parts of eleostearic acid, 2.3-3.1 parts of 2BaO. SiO2, 3.2-4.8 parts of polymeric aluminum phosphate, 2.6-3.4 parts of water glass, 1.5-3.5 parts ofsodium molybdate and 1.8-2.6 parts of didecyl dimethyl ammonium chloride. The anti-corrosion and anti-rust concrete has the advantages of being good in anti-corrosion and anti-rust effect, excellent in durability and high in heat preservation and heat insulation performance.

Owner:青岛兴业商砼有限公司

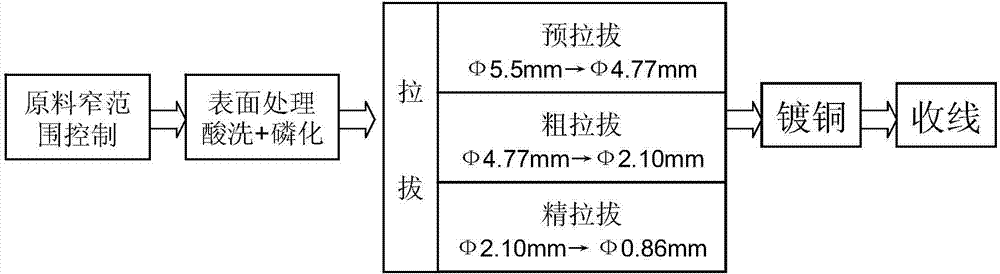

Novel process for producing low carbon gas shielded welding wire

ActiveCN103753056AHelp with attachmentUniform adsorptionLiquid/solution decomposition chemical coatingWelding/cutting media/materialsWire rodCopper plating

Disclosed is a novel process for producing a low carbon gas shielded welding wire. The novel process for producing the low carbon gas shielded welding wire includes following steps of (1) raw material selection, (2) surface treatment processes, (3) drawing process and (4) copper plating process, wherein the step (1) includes that as for steel wire rod composition, C is equal to 0.06-0.010%, Si is equal to 0.80-1.00%, Mn is equal to 1.40-1.60%, P or S is smaller than or equal to 0.020%, and Ca is smaller than or equal to 0.0015%; the step (2) includes an acid pickling process and a phosphating process, as for the acid pickling process, pickling solution proportion includes that prewash hydrochloric acid concentration is 5-10%, hydrochloric acid concentration for substrate washing is 15-20% and FeC12 is smaller than or equal to 300g / l, acid pickling time is 10-25minutes, washing is performed by high pressure water instantly after acid pickling, and as for the phosphating process, phosphating solution proportion includes that Ta total acidity is 50-110pt and Fa free acidity is 5-20pt, phosphating temperature is 70-80DEG C and phosphating time is 1-3 minutes. By means of the novel process for producing the low carbon gas shielded welding wire, a chemical adsorption film is formed on the surface of a steel wire rod, a thin phosphating film is formed on the surface of the steel wire rod by mid-temperature phosphating process and short phosphating time, adsorption of surface lubricating agents is more uniform and compact, the steel wire rod is directly drawn to form a finished product wire in an unannealed state after surface treatment, costs are reduced by 50-80 yuan / ton compared with those of common processes, the wire breaking rate is decreased by 70%, and the producing efficiency is increased by 40%.

Owner:TIANJIN IRON & STEEL GRP

Anti-rust liquor and processing method therefor

The invention relates to antirust fluid. The invention also relates to a processing method of the antirust fluid. The antirust fluid made by the method is provided with obvious antirust function and has light even no pollution to the environment. The antirust fluid is generated mainly from the action of alkcnyl succinic acid and monoethanolamine. The mole ratio of alkcnyl succinic acid to monoethanolamine is 0.5-1 to 1. The main components of the antirust fluid are alkcnyl succinic acid dodecenylbutadioic, water and monoethanolamine.

Owner:马国伟 +1

Preparation method of hydrotalcite-like compound with uniform particle size and high stability

PendingCN110395753AAvoid uneven particle size distributionImprove structural strengthNanotechnologyHydrotalciteFiberCellulose

The invention discloses a preparation method of a hydrotalcite-like compound with a uniform particle size and high stability, and belongs to the technical field of metal oxide preparation. According to the method provided by the invention, bean dregs and starch are mixed, proteins and plant fibers in the bean dregs are hydrolyzed to produce amino acid, cellulose and the like respectively through ahigh-temperature high-pressure reaction, hydroxyl groups in the cellulose and the plant fibers are oxidized to form carboxyl groups by using sulfuric acid and potassium permanganate, the carboxyl groups and ethylene glycol are subjected to an esterification reaction, so that a part of ester compounds are coagulated at the surfaces of the fibers, the plant fibers are used to bind components of thehydrotalcite-like compound to avoid non-uniform distribution of particle sizes of the hydrotalcite-like compound product, and the compatibility of the hydrotalcite-like compound with other materialsis improved; and organic components such as the cellulose and saccharide compounds are extracted from the bean dregs and the starch, the organic matter and other components in the hydrotalcite-like compound form a binder adsorption effect, mixing and crystallizing nucleation are performed at a high temperature, so that the structural strength of the hydrotalcite-like compound is improved, and thedurability and stability of the hydrotalcite-like compound are enhanced.

Owner:王志胜

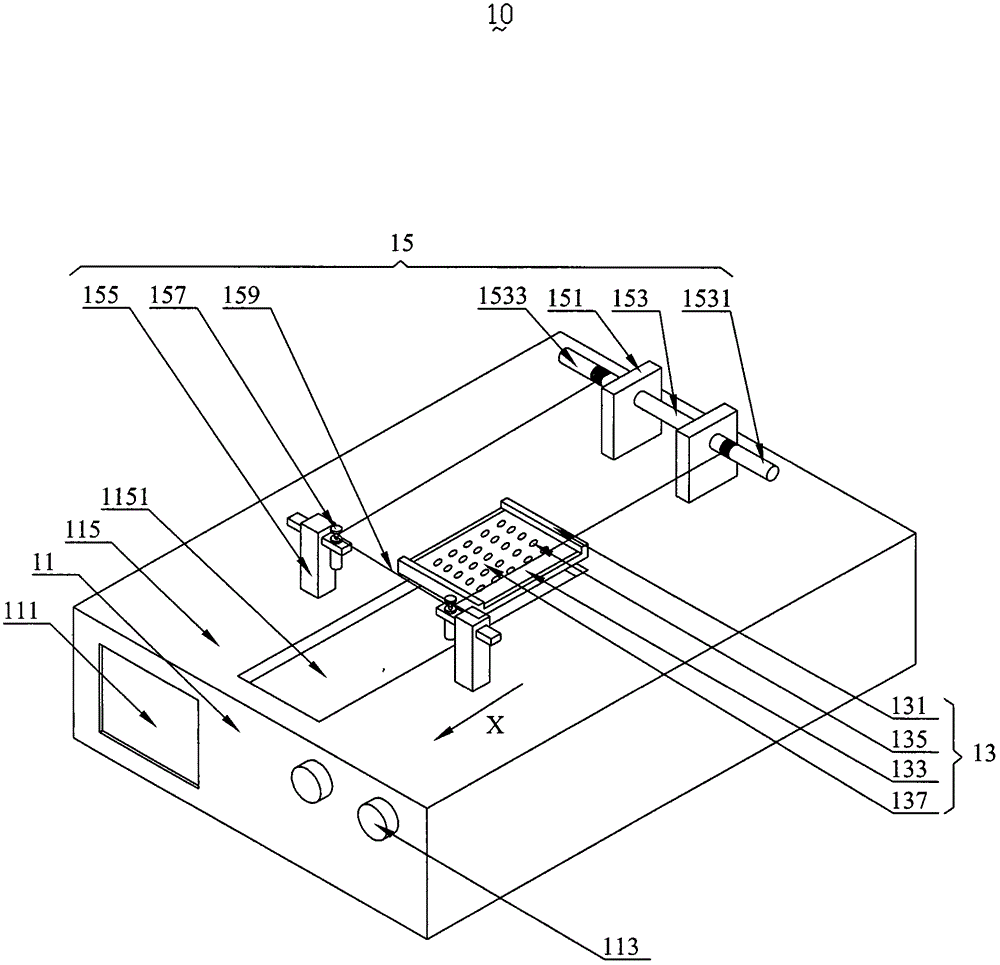

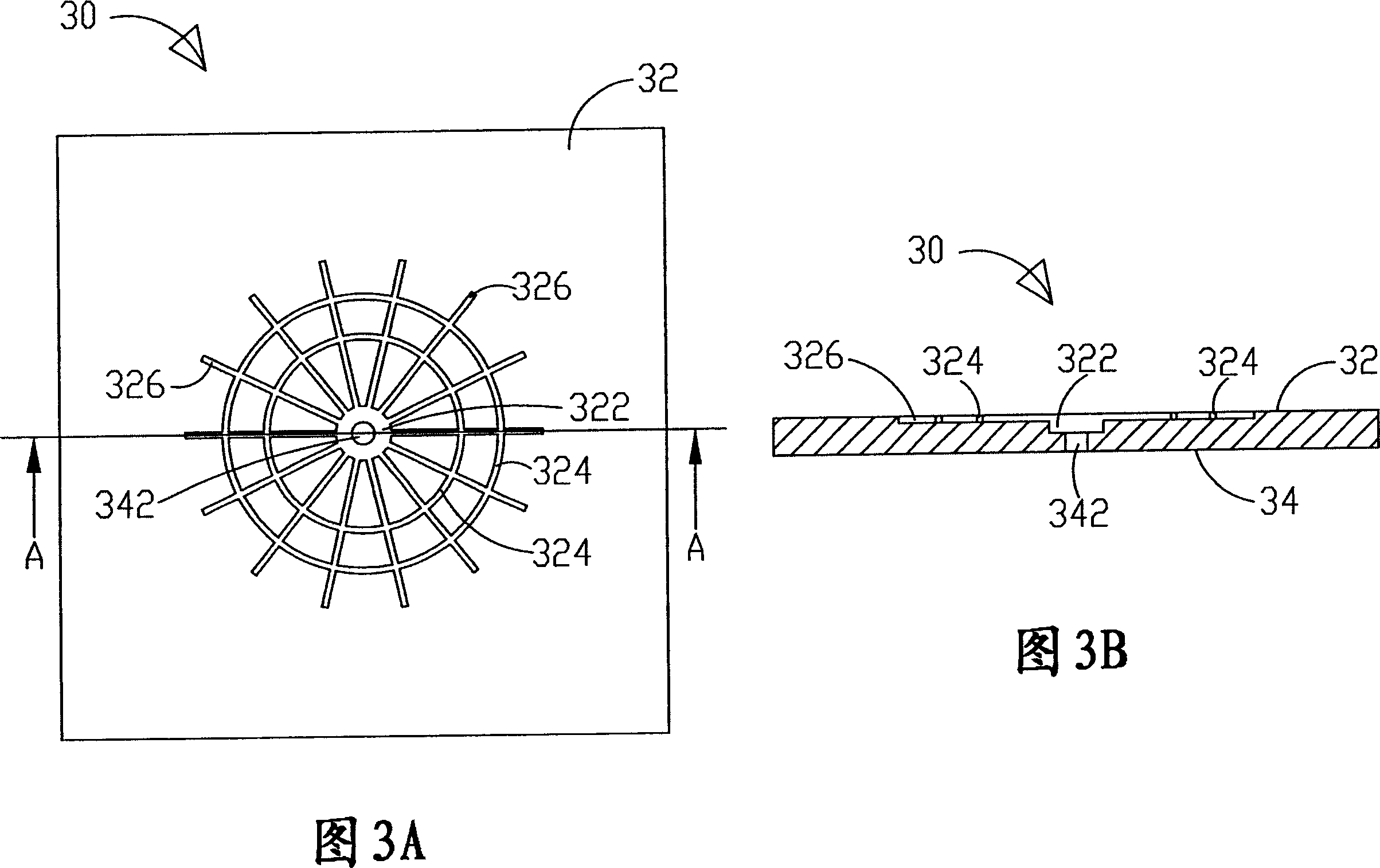

Adsorption apparatus

InactiveCN1963620AAvoid damageSmall pressure lossNon-linear opticsArchitectural engineeringEngineering

Owner:AU OPTRONICS CORP

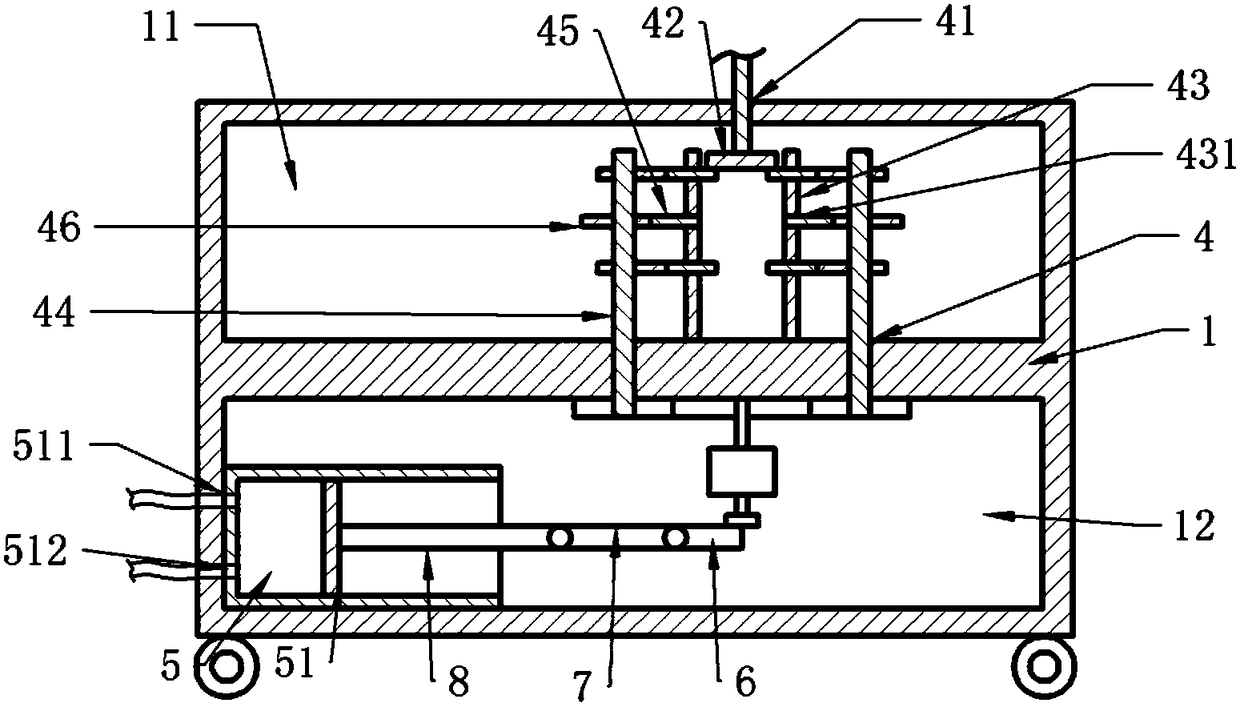

Large glass auxiliary installation and transportation device

InactiveCN111232649AEasy to installTight adsorptionCharge manipulationConveyor partsEngineeringStructural engineering

The invention discloses a large glass auxiliary installation and transportation device which comprises a device body with a movable base slidably installed on the upper side end face. A first slidingcavity is formed in the upper side end face of the device body, and a driving device capable of driving the movable base to move front and back is arranged in the first sliding cavity. According to amechanical arm device disclosed by the invention, a rubber sucking disc capable of steering and adjusting the grabbing range is arranged, so that large glass can be effectively and tightly adsorbed; through the mechanical arm device, a lifting device, a stretchable device and a rotating device, the large glass can be grabbed, different positions and angles of the large glass around the device bodycan be adjusted, and installation of the large glass is facilitated; and the device body can be driven to move by pushing handle drive and universal wheels, and the large glass is transported and transferred.

Owner:福州高新区磊莎玻璃有限公司

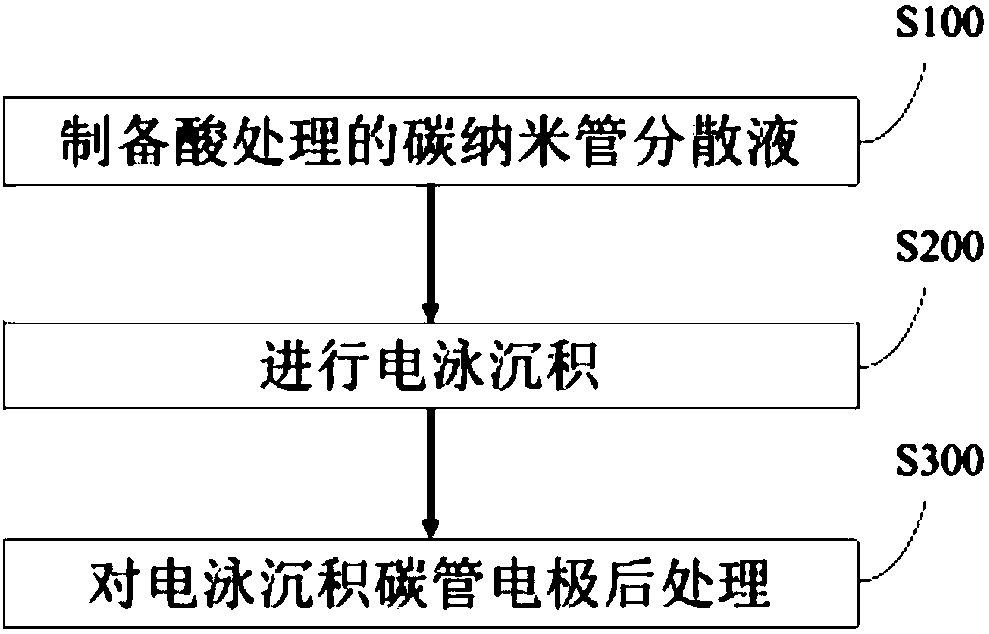

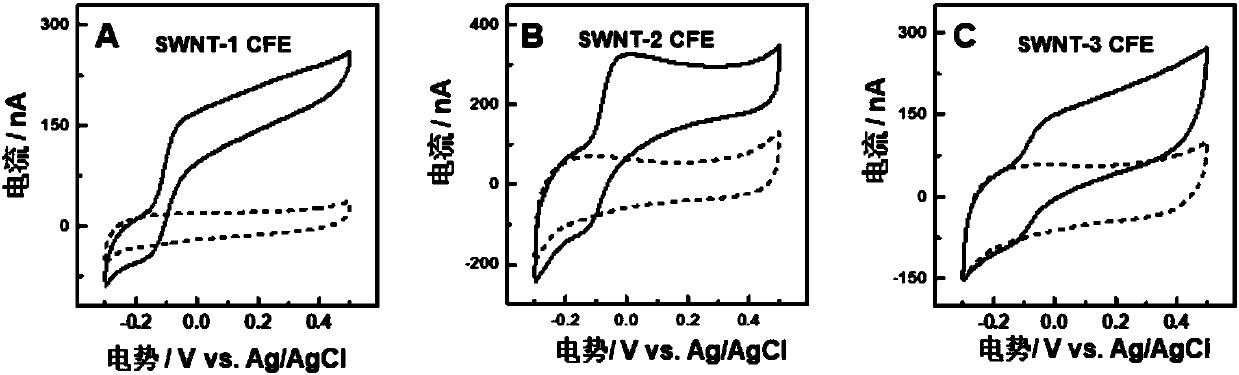

Electrophoretically-deposited carbon nano tube modified carbon fiber electrode and application thereof in in-vivo detection of ascorbic acid

ActiveCN110057897AHigh selectivityHigh sensitivityMaterial analysis by electric/magnetic meansFiberCarbon fibers

The invention discloses a new method used for modifying a carbon fiber electrode with carbon nano tubes. The method comprises the step of depositing single-walled carbon nano tubes on a carbon fiber electrode by adopting an electrophoretic deposition method, wherein electrophoretic deposition is realized by virtue of a two-electrode system, and the method comprises the following specific steps: inserting the carbon fiber electrode and a Pt wire into single-walled carbon nano tube dispersion, applying a voltage of 1.9-2.5V by virtue of amperometry and performing electrophoretic deposition for 10-100s, thus the carbon fiber electrode modified by the uniformly deposited carbon nano tubes can be obtained. Before in vivo analysis is performed, high temperature and electrochemical simple treatment is performed on the carbon nano tube modified carbon fiber electrode, so that the electrode can have high selectivity and sensitivity on ascorbic acid and can be used for in vivo intracerebral in situ determination on change of concentration of ascorbic acid.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

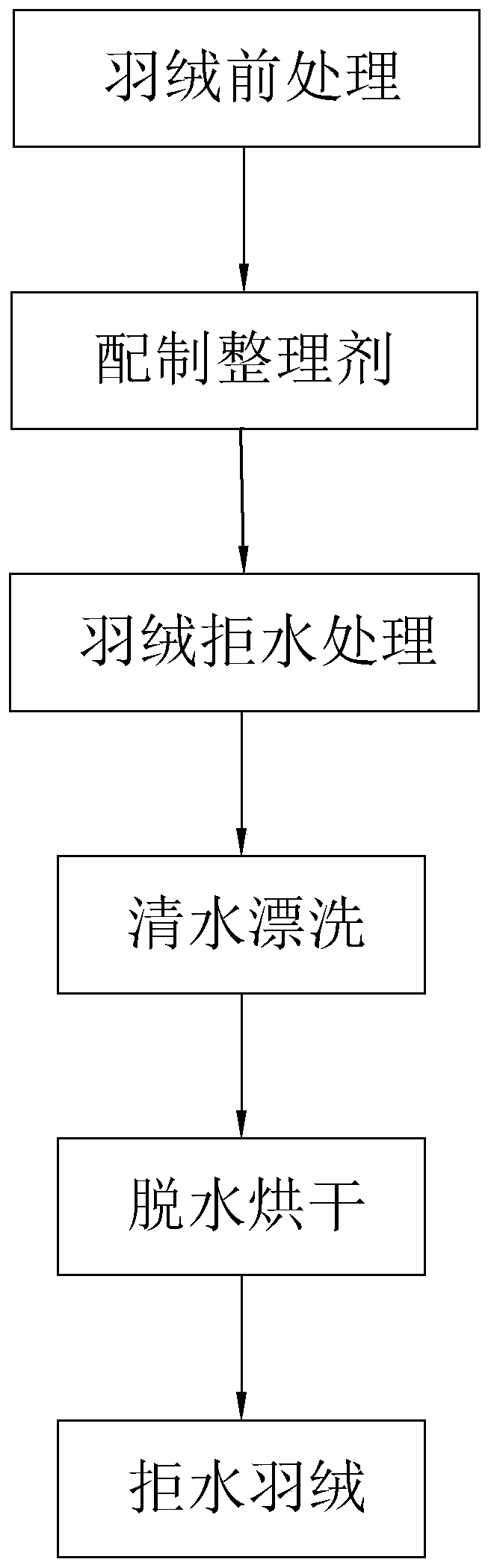

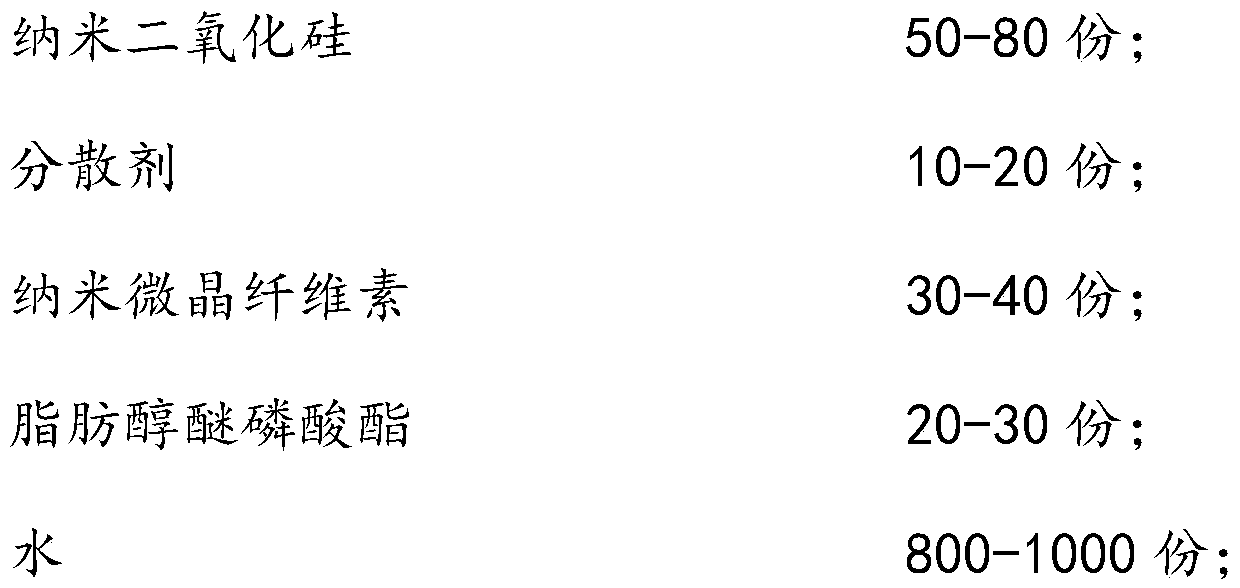

Nano water-repellent down production process

The invention discloses a nano water-repellent down production process, and relates to the technical field of down production. The process comprises the following steps that S1, a down material is immersed in a pre-treatment liquid for pre-treatment at first; S2, a finishing agent is prepared, wherein the finishing agent is prepared from, by weight, 50-80 parts of nano silica, 10-20 parts of a dispersant, 30-40 parts of nano microcrystalline cellulose, 20-30 parts of fatty alcohol ether phosphate and 800-1,000 parts of water; S3, the down is added into a washing stirrer at first, and then water and the finishing agent are added for stirring and mixing; S4, the stirred down is rinsed with clear water 10 times; S5, the rinsed down is spin-dried and dewatered; S6, the dewatered down is put into a drying box for stirring and drying. The process has the advantage that the adhesion tightness of the nano silica and the nano microcrystalline cellulose to the surface of the down is improved.

Owner:浙江茂龙家纺有限公司

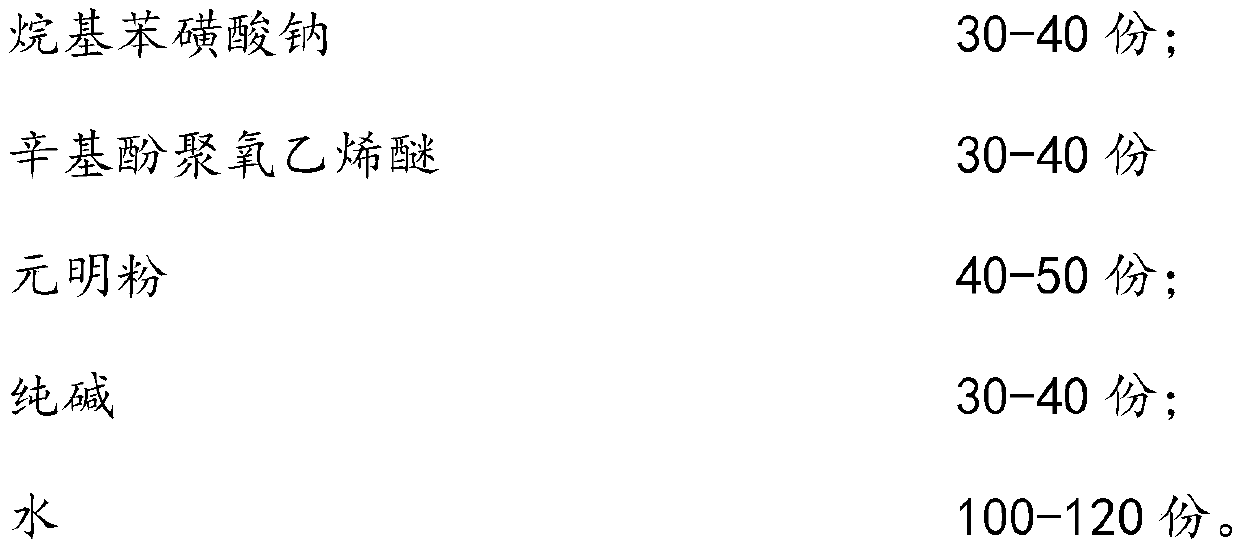

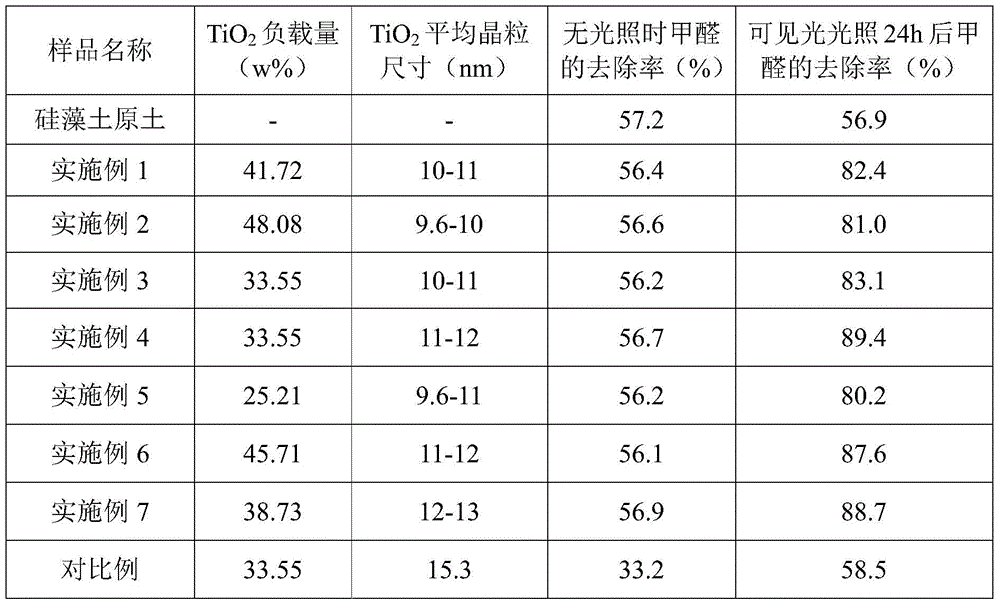

Nano TiO2-diatomite composite photocatalyst and preparation method thereof

ActiveCN105727921APicklingSave the craftPhysical/chemical process catalystsTitanium tetrachlorideAmmonium sulfate

The invention discloses a nano TiO2-diatomite composite photocatalyst and a preparation method thereof. The nano TiO2-diatomite composite photocatalyst is prepared from the following raw materials: raw diatomite, titanium tetrachloride, ammonium sulfate and iron salt, wherein the mass ratio of the raw materials is that the ratio of the raw diatomite to the titanium tetrachloride is 100 to (80-200), and the ratio of the titanium tetrachloride to the ammonium sulfate to the iron salt is 100 to (17-66) to (0-0.7). With the adoption of the composite photocatalyst, the problems in the prior art that the visible light utilization rate of the composite photocatalyst is low and the degradation capability on organic pollutants is low are solved, the visible light utilization rate of the composite photocatalyst is improved, and the degradation capability on the organic pollutants is improved.

Owner:CHINA BUILDING MATERIALS ACAD

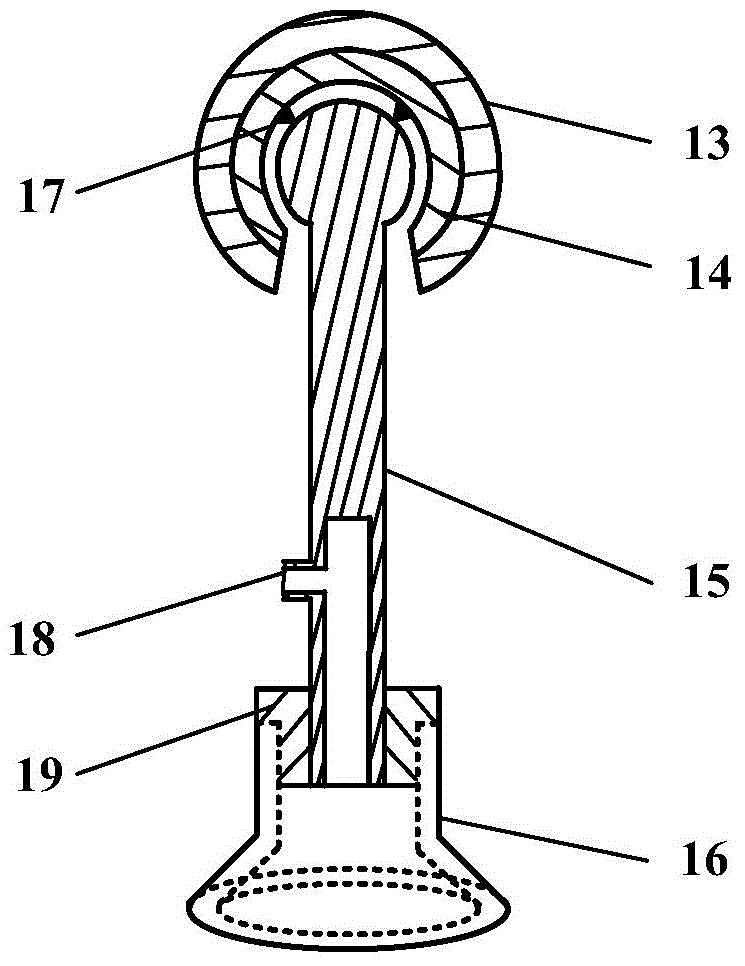

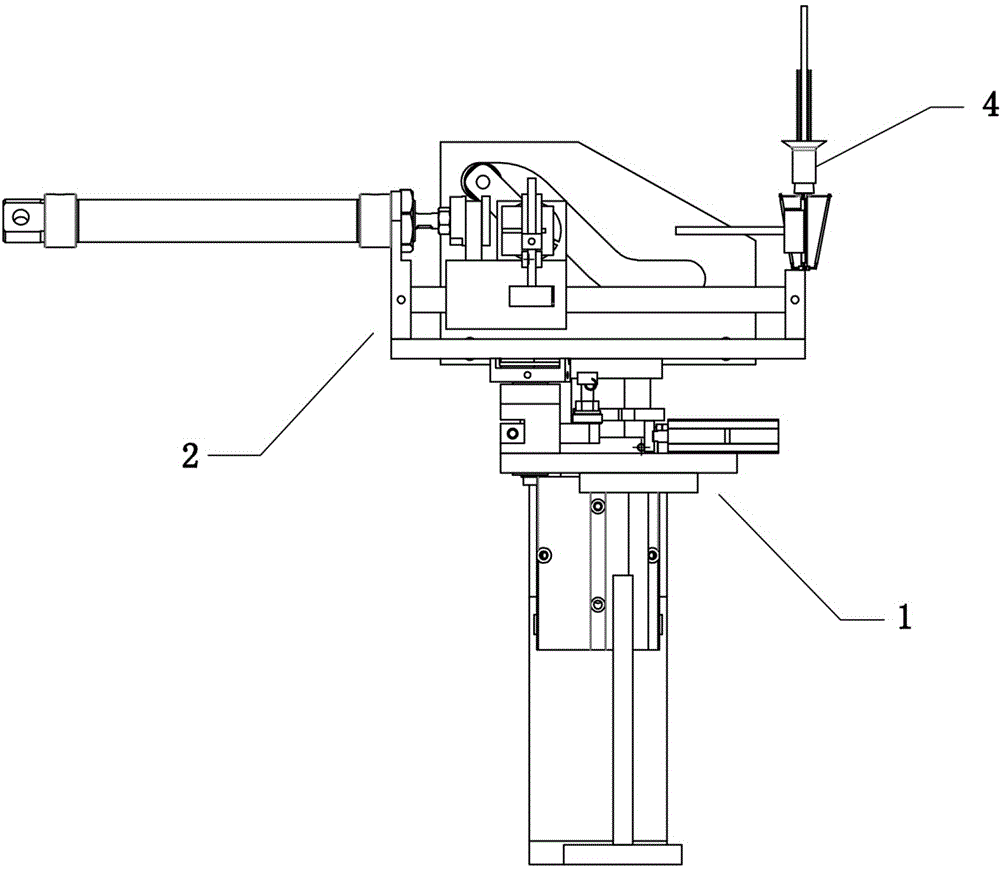

Automatic moxa-moxibustion device

ActiveCN108938403AReduce work intensityGuaranteed curative effectDevices for heating/cooling reflex pointsPneumatic massageElectricityTreatment effect

The invention discloses an automatic moxa-moxibustion device which comprises a cupping device, a machine frame and an automatic moxa feeder with moxa sticks. The cupping device is fixedly connected tothe bottom of the machine frame. The automatic moxa feeder is movably connected to the machine frame. A motor and an electronic thermometer are arranged on the machine frame. The motor is in transmission connection with the automatic moxa feeder. The motor and the electronic thermometer are electrically connected with a controller. The automatic moxa-moxibustion device is light in structure and convenient to use and can be reliably fixed on a human body to replace the repeated manual movements, the work intensity of an operator is relieved, the time duration and frequency of moxa-moxibustioncan not be influenced by the physical decline of the operator, and the treatment effect is better ensured. In addition, by means of the automatic moxa-moxibustion device, cupping and moxa-moxibustionare combined, tonifying and discharging are integrated, and the treatment effect is better.

Owner:JIYANG COLLEGE OF ZHEJIANG A & F UNIV

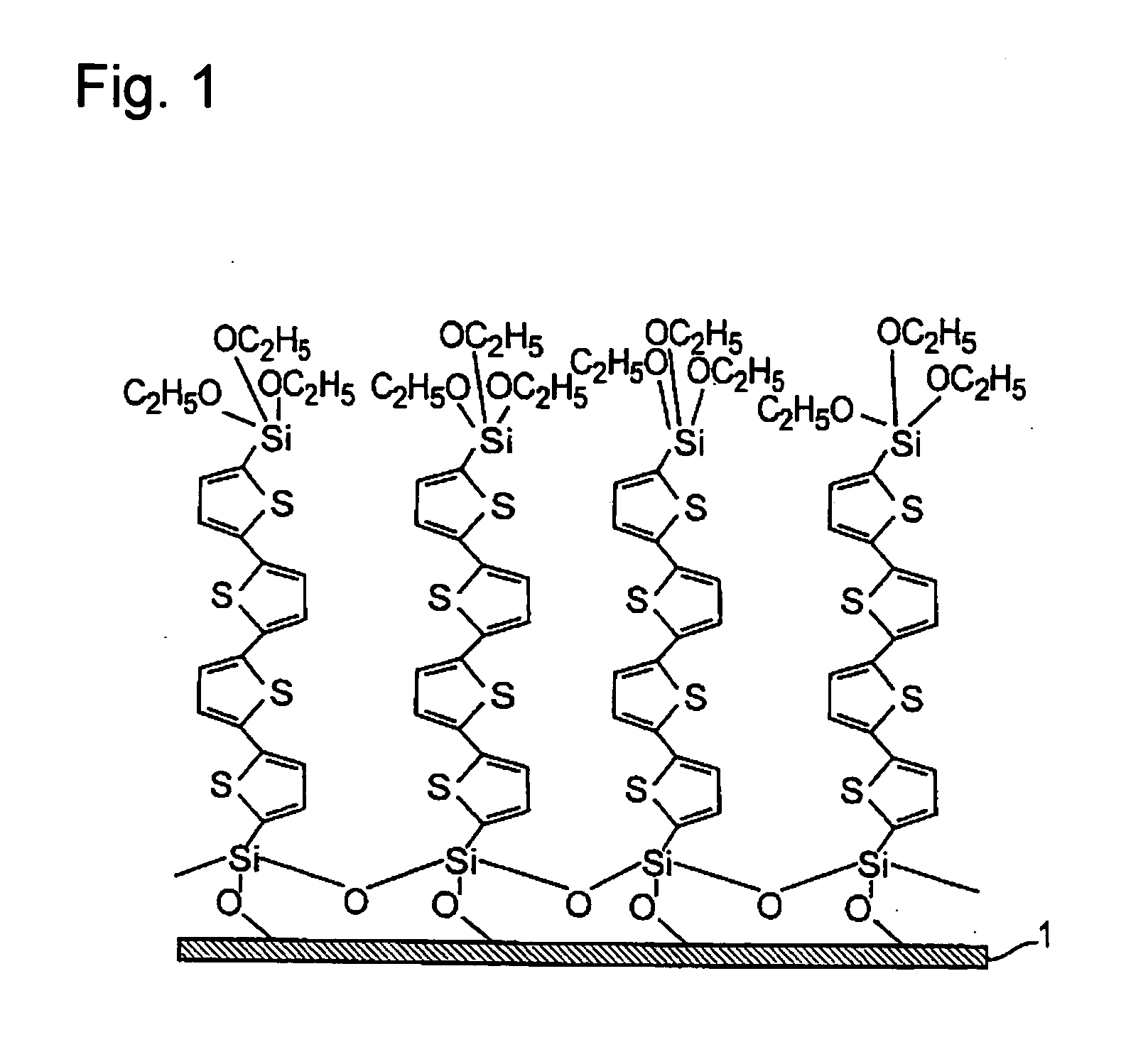

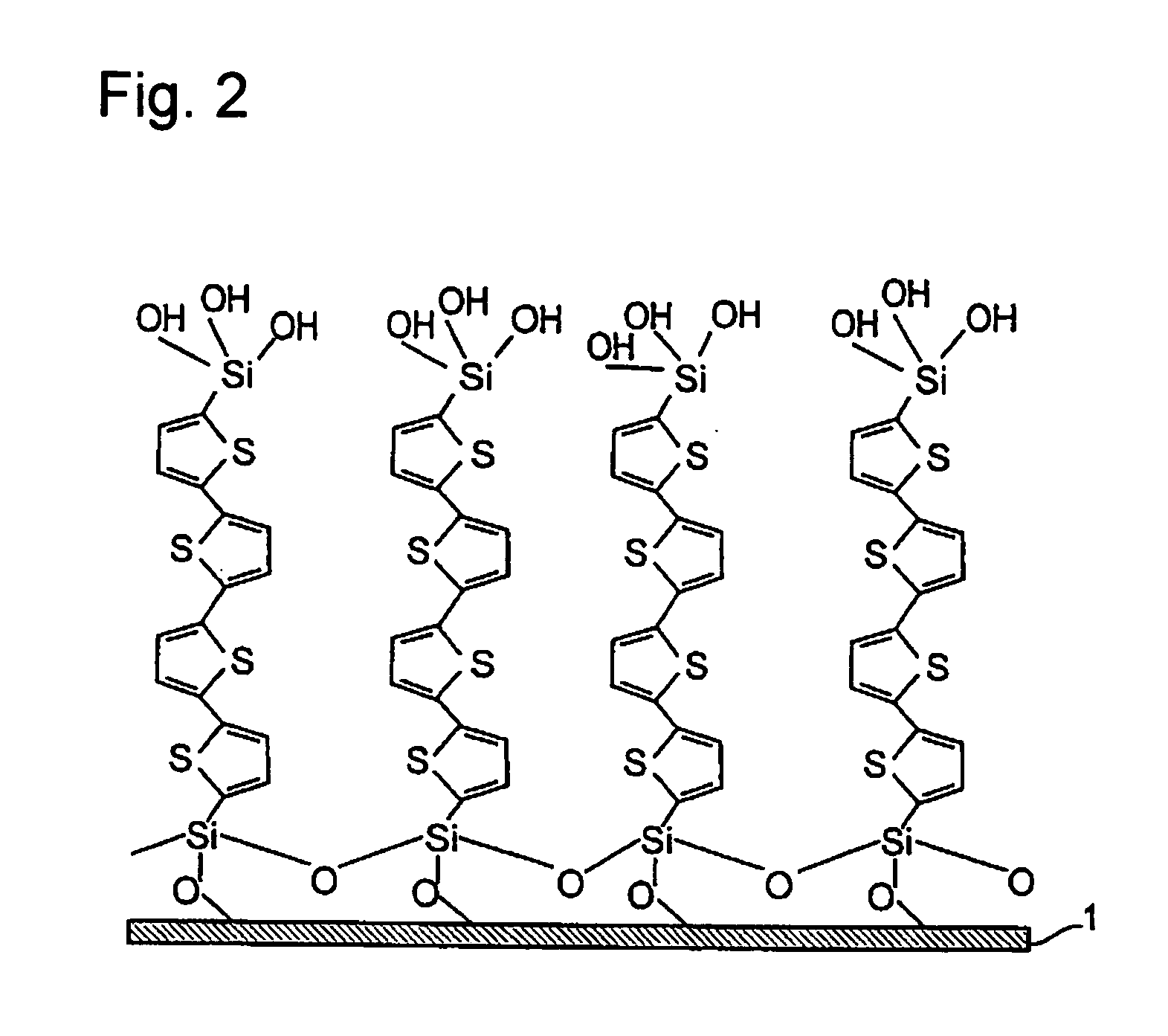

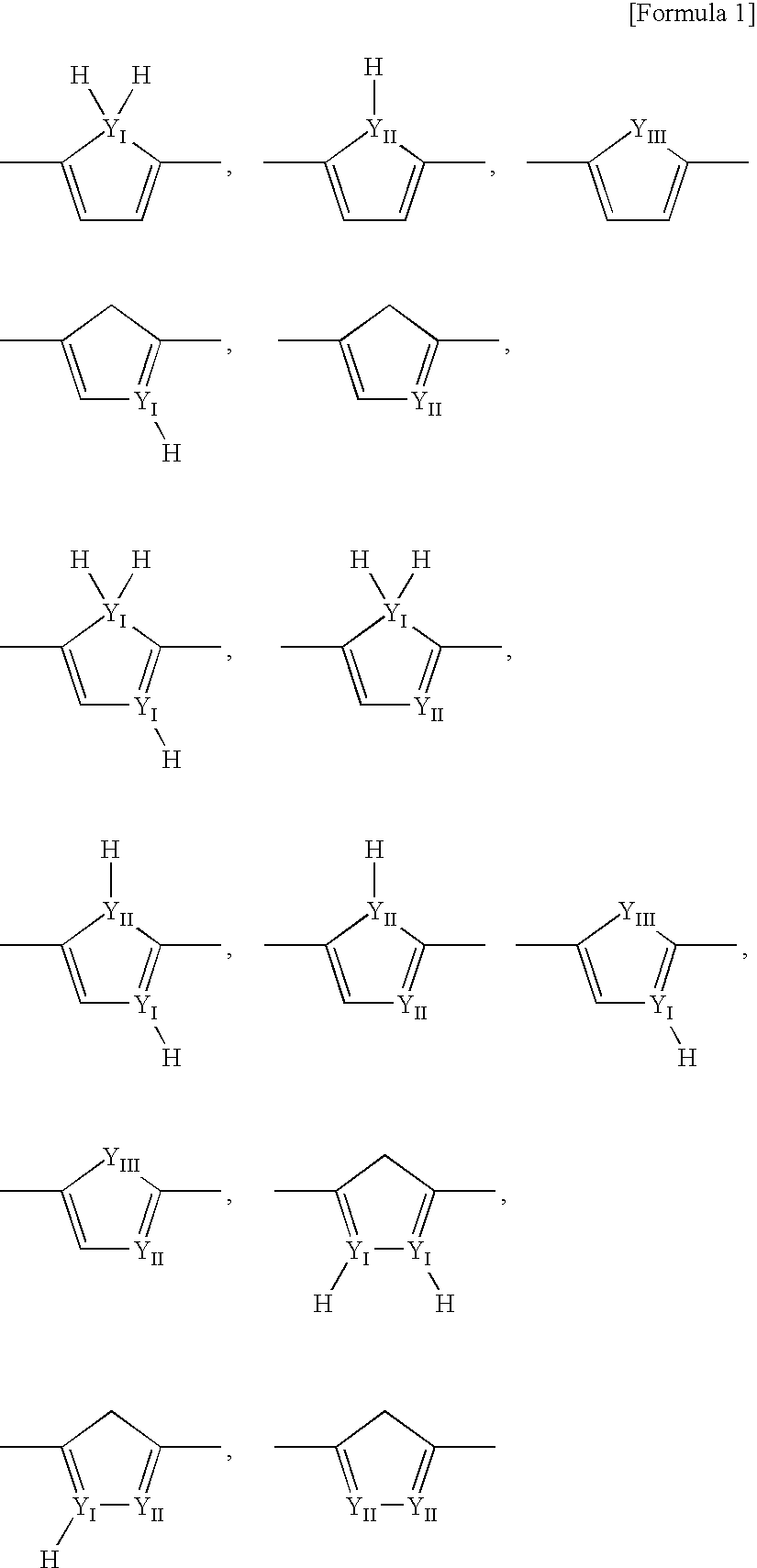

Electron-Conjugated Organic Silane Compound and Production Method Thereof

InactiveUS20090005557A1Resistant to physical exfoliationEasy to produceSilicon organic compoundsConductive materialSilane compoundsHydrogen

The present invention provides a π-electron-conjugated organice silane compound that give an organic thin film superior in peeling restance, orientation, crystallinity and eletroconductive properties, and a production method thereof.A π-electron-conjugated organice silane compound represented by General Formula: R1-SiX1X2X3 (R1 represents an organic group having a particular monocyclic heterocyclic unit; and X1 to X3 are a group giving a hydroxyl group by hydrolysis). A method of producing the organic silane compound, comprising allowing a compound represented by General Formula: R1-Li (R1 is the same as above) or a compound represented by General Formula: R1-MgX5 (R1 is the same as above; and X5 represents a halogen atom) with a compound represented by General Formula: X4-SiX1X2X3 (X1 to X3 are the same as above; and X4 represents a hydrogen or halogen atom or a lower alkoxy group).A π-electron-conjugated organic silane compound represented by General Formula; Z-(R11)m-SiR12R13R14 (Z represents a organice group derived froma particular fused polycyclic heterocyclic compound; R11 represents a bivalent organic group; m is 0 to 10; and R12 to R14 represents a halogen atom or an alkoxy group). A method of producing the organic silane compound, comprising allowing a compound represented by General Formula: Z-(R11)m-MgX30 (Z, R11 and m are the same as above; and X30 represents a halogen atom) to react with a compound represented by General Formula: X31-SiR12R13R14 (X31 represents a hydrogen or halogen atom or an alkoxy group; and R12 to R14 are the same as above).

Owner:SHARP KK

Measuring caliper used for buildings capable of measuring multiple angle step hole diameters

ActiveCN110470199AGuaranteed accuracyHigh precisionMechanical diameter measurementsEngineeringSurveyor

The present invention discloses a measuring caliper used for buildings capable of measuring multiple angle step hole diameters, pertaining to the technical field of building surveying. The caliper comprises a step wall. The left side of the step wall is inserted with a measuring caliper. The middle part of the measuring caliper is fixedly connected with a turning block via a connecting rod, the middle part of the turning block is fixedly connected a uniformly-distributed rewinding device. The measuring caliper used for the buildings capable of measuring multiple angle step hole diameters is used combining with a fixing seat and a sucker. When used, the whole measuring caliper is firstly sucked on the surface of the step wall via the sucker, then a second toothed bar is turned by using a tool, and the second toothed bar can drive a piston rod to move towards the middle part of the fixing seat, pumping the air in a piston sleeve, allowing the sucker to suck more tightly and ensuring thatthe measuring caliper can not move during measurement, so that the accuracy of measurement data is ensured, the effect of improving the precision is realized, the measurement error is reduced, and the reliability of the measurement data is ensured.

Owner:南京市六合区金牛湖新市镇建设投资有限公司

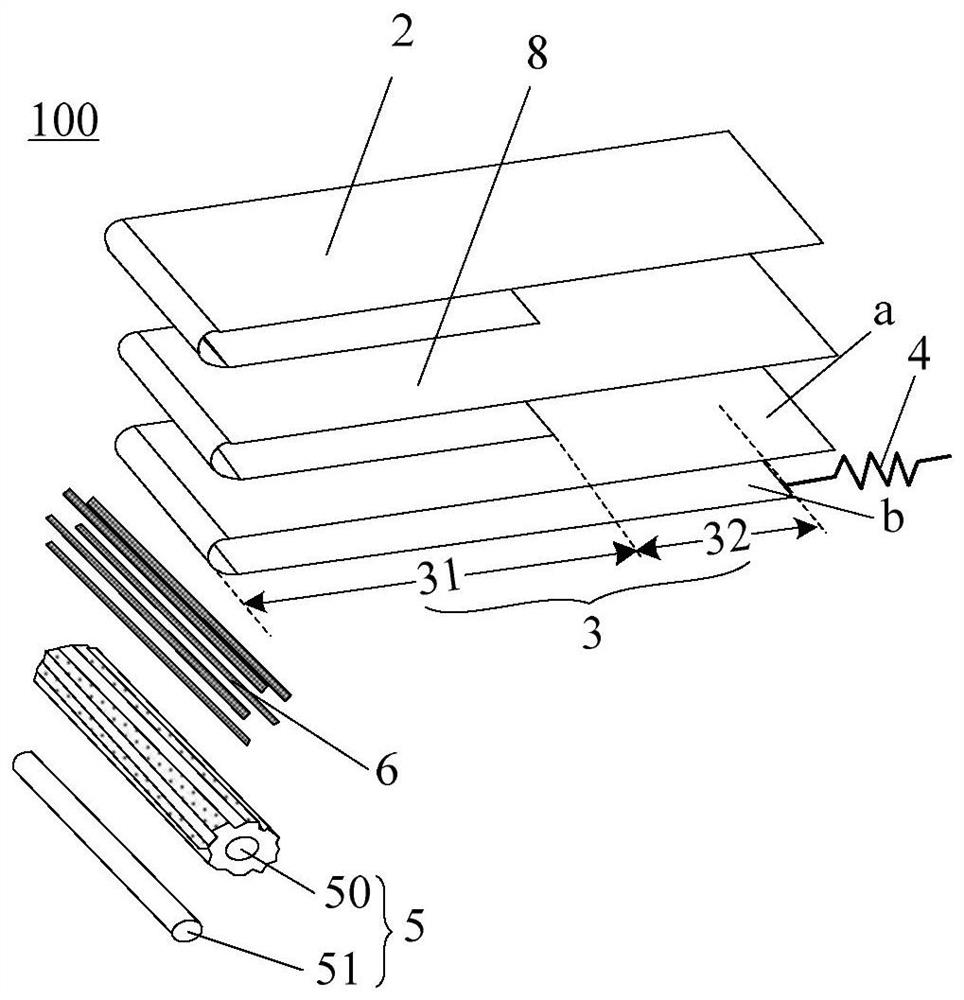

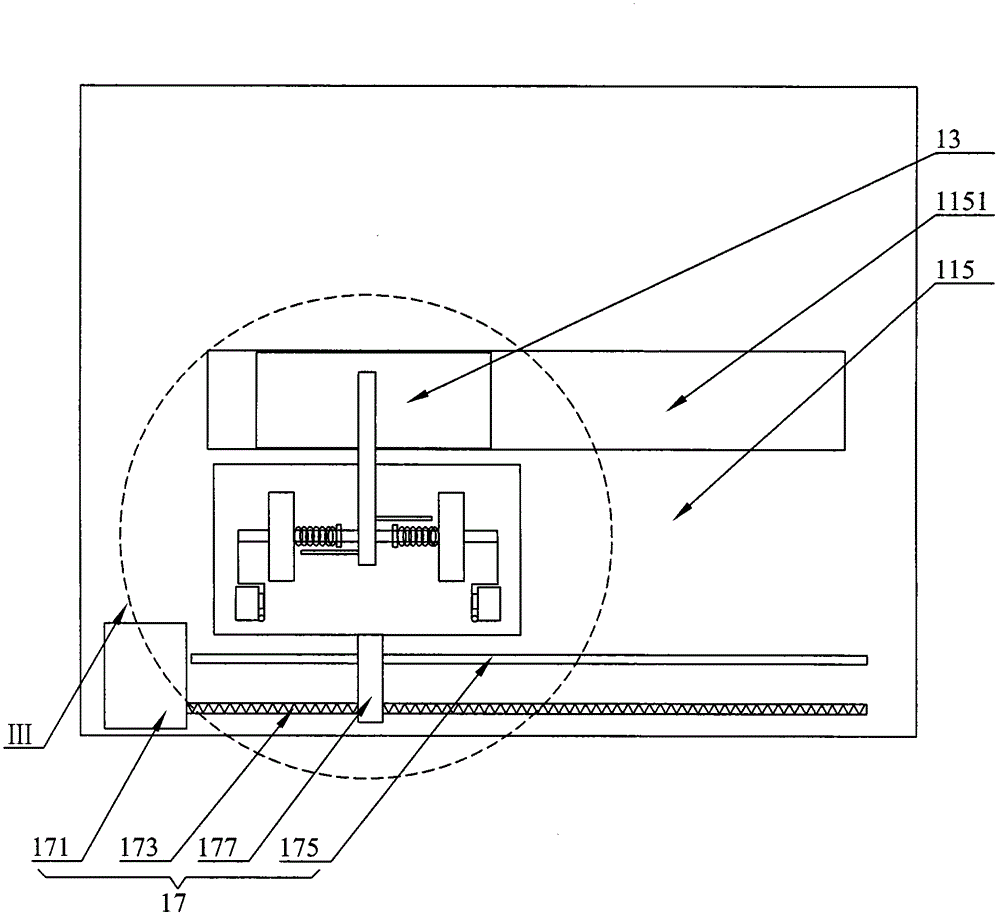

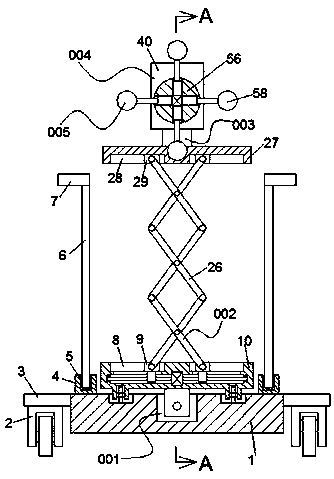

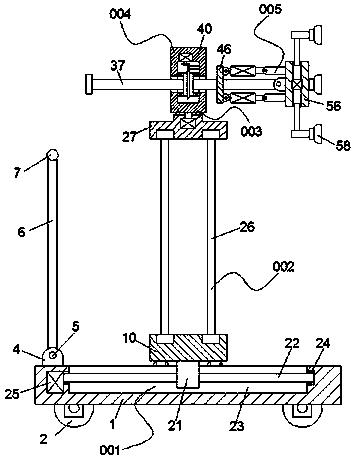

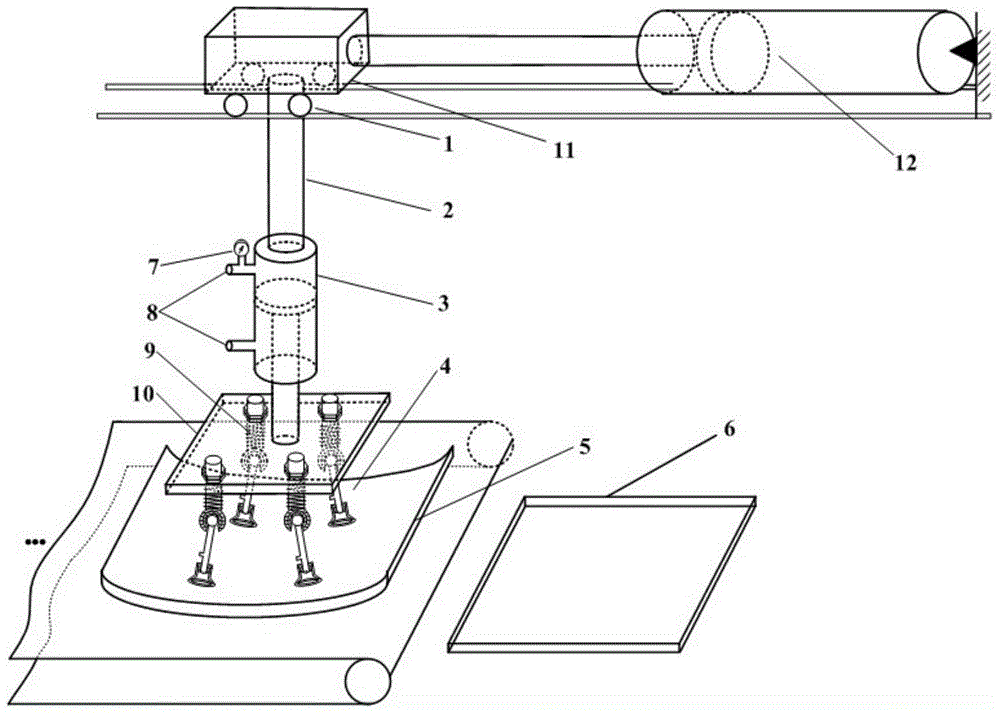

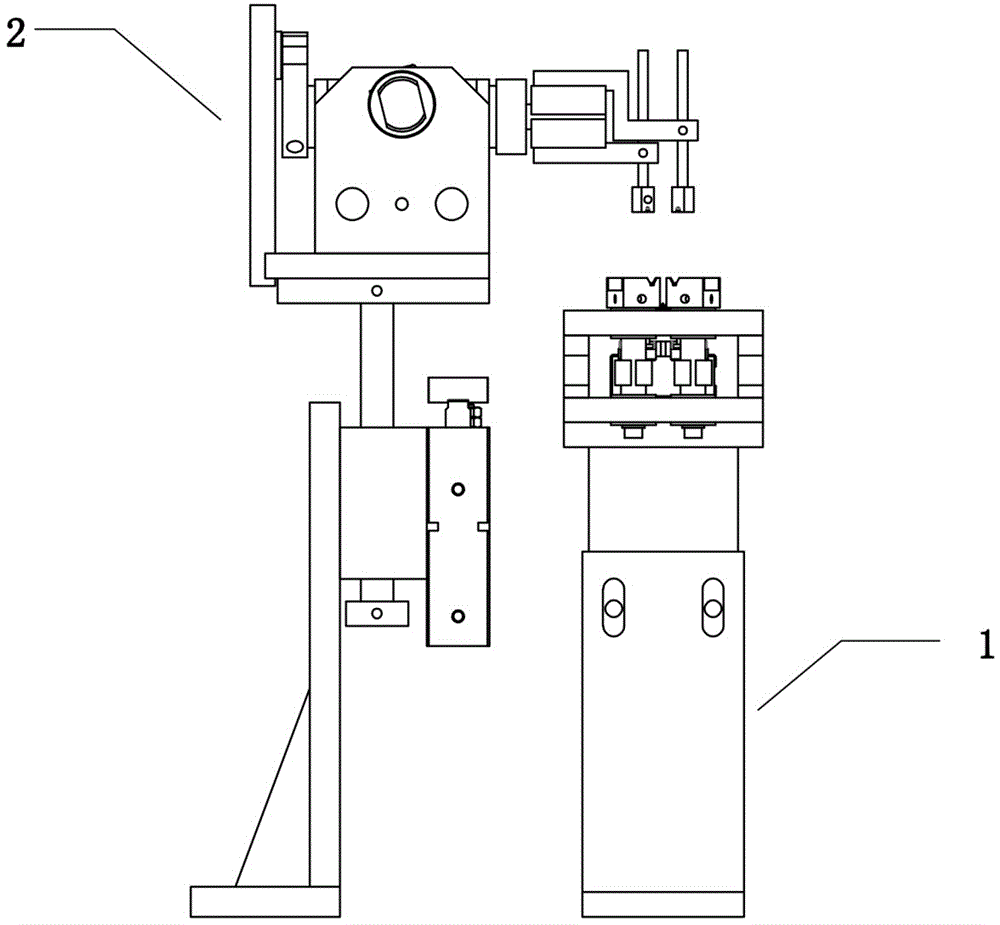

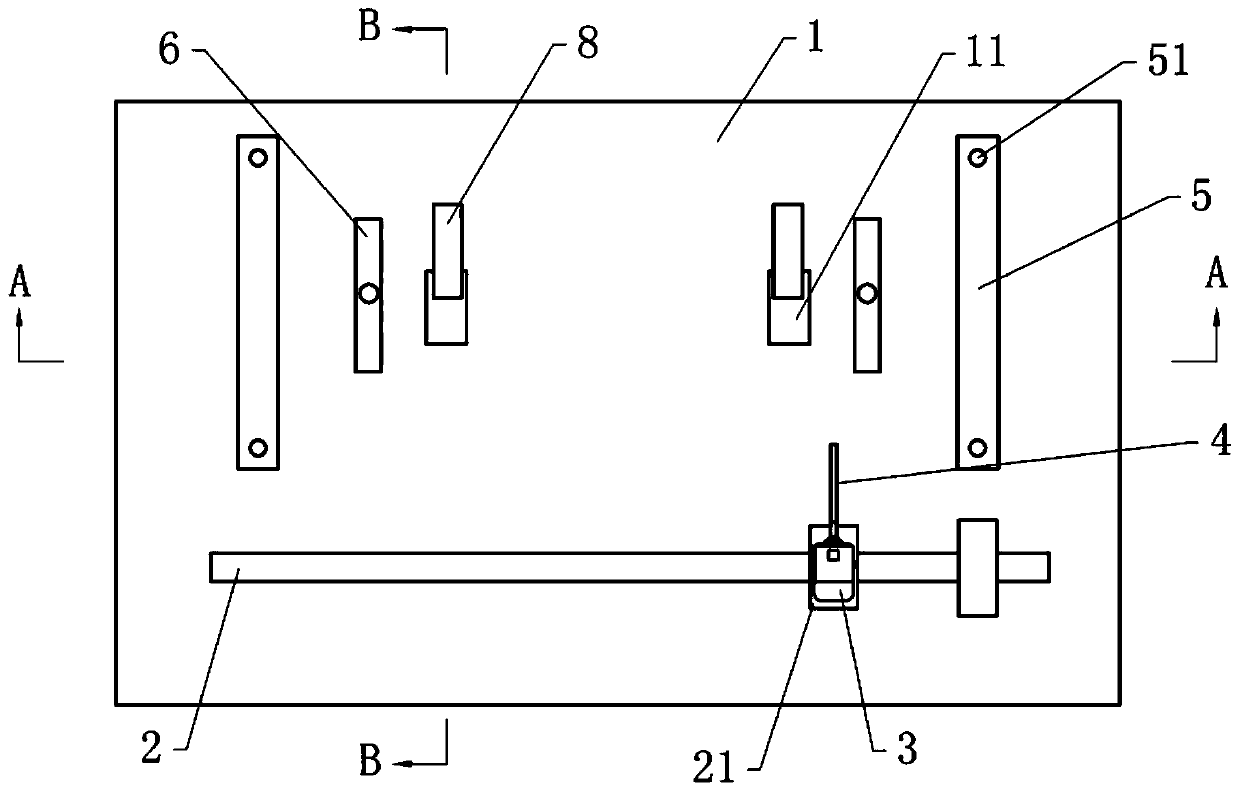

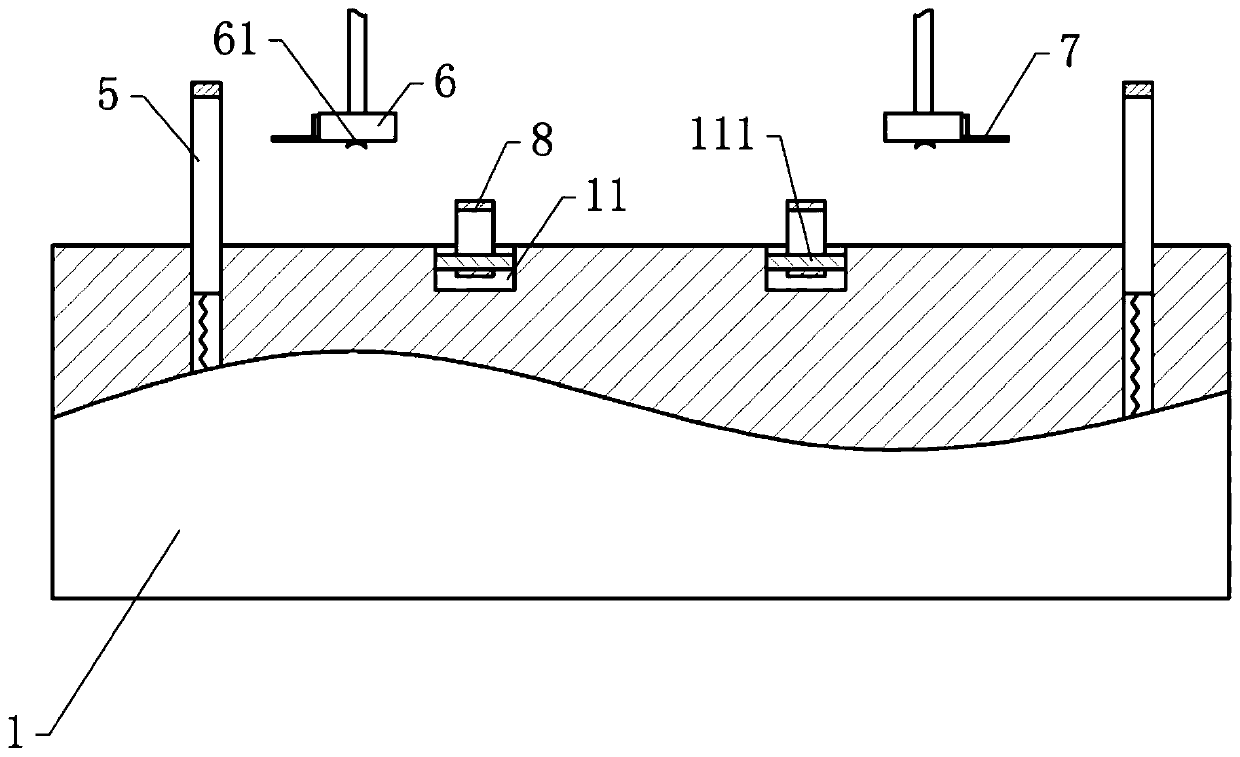

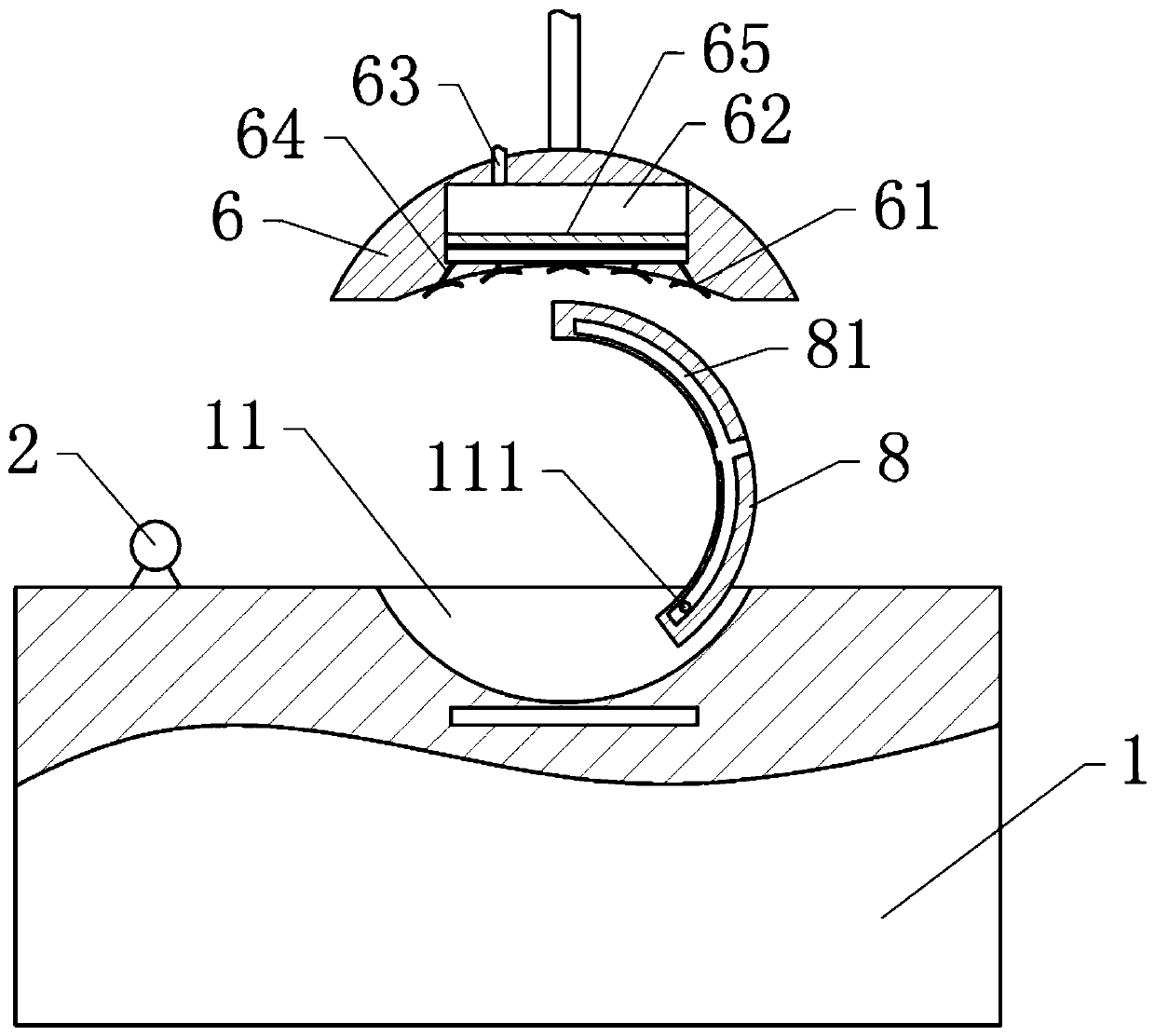

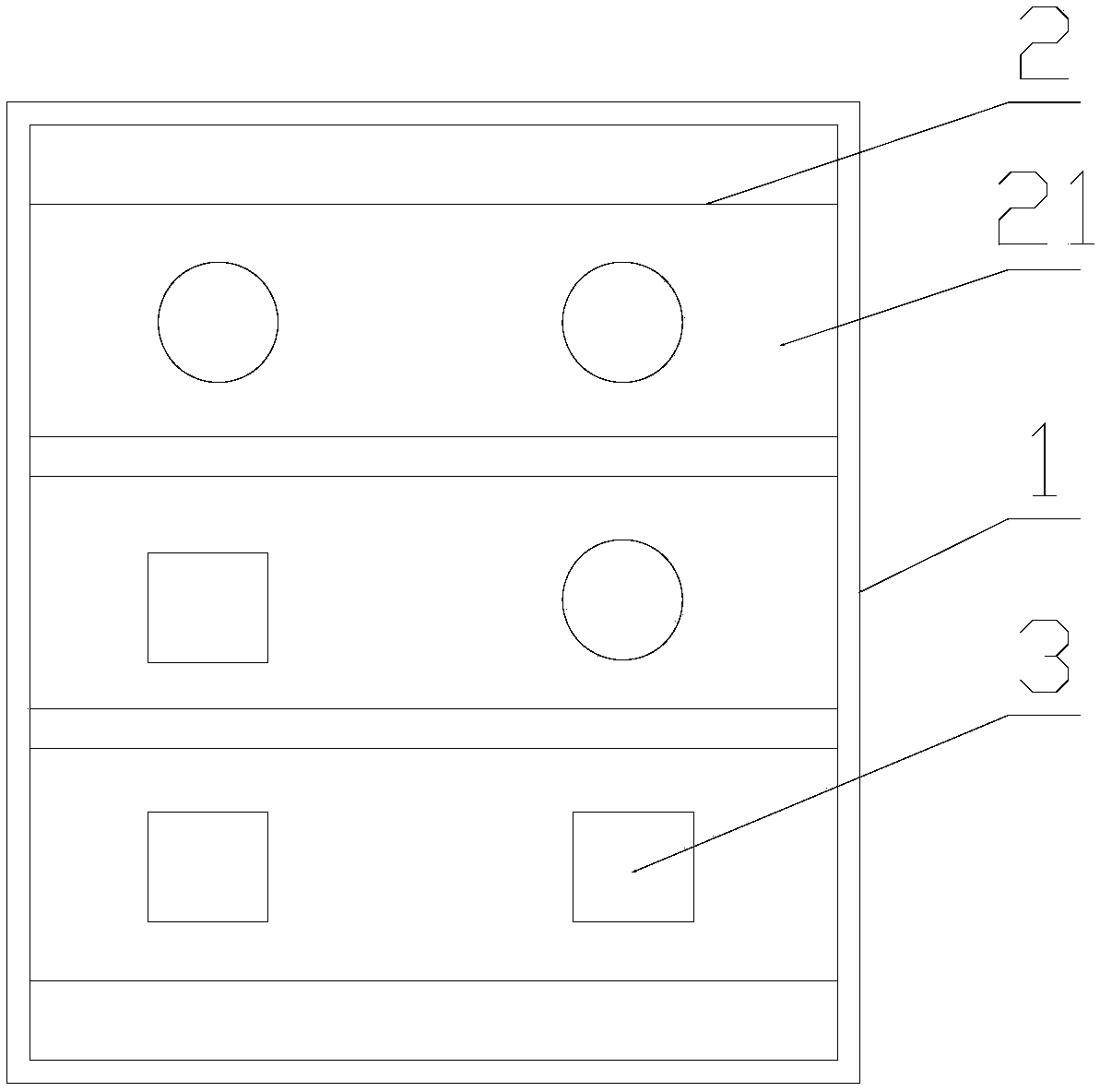

Feeding and discharging device of large-area warping elastic thin plate

ActiveCN104399837ATight adsorptionRealize loading and unloadingMetal-working feeding devicesStripping-off devicesHydraulic cylinderProduction line

The invention discloses a feeding and discharging device of a large-area warping elastic thin plate. The device comprises a horizontal moving device, a vertical moving device and an adsorption device, wherein the horizontal moving device consists of a crane and a horizontal driving hydraulic cylinder thereof, is arranged on a plate shaping production line and is parallel to the production line; the vertical moving device is arranged below the horizontal moving crane and comprises a vertical hydraulic cylinder; the vertical hydraulic cylinder is connected with the adsorption device through a spherical universal joint. The device has a simple structure and is convenient to operate; the deflecting direction of suction nozzles can be automatically adjusted to adapt to the deformation of the plate according the conditions such as warping and chattering deformation of the plate, so that the suction nozzles can closely adsorb the warping elastic thin plate all the time and feeding and discharging of the warping elastic thin plate is realized.

Owner:平邑经济开发区投资发展有限公司

Anti-toppling household garbage can

InactiveCN110803417AImprove stabilityTight adsorptionRefuse receptaclesControl theoryIndustrial engineering

The invention discloses an anti-toppling household garbage can. The anti-toppling household garbage can comprises a garbage can body, and a round base is arranged at the lower end of the garbage can body. A groove matched with the lower end of the garbage can body is formed in the upper end of the base. Multiple U-shaped cavities are symmetrically formed in the base along the axis. The lower end of the base is fixedly connected with multiple suction cups communicating with the U-shaped cavities. An adsorption device for preventing the garbage can body from toppling when bearing external garbage impacts is mounted on the base. According to the anti-toppling household garbage can, a closed space formed by a sliding block and the suction cups is formed in an L-shaped cavity, air pressure between the sliding block and the suction cups can be reduced by pushing the sliding block to move, and therefore the suction cups are tightly adsorbed on the ground, and the stability of the garbage canbody is improved; and by arranging magnetic sliding blocks slidably connected in the cavities, the magnetic sliding blocks move upwards, so that the air pressure between the magnetic sliding blocks and the suction cups is reduced, and the stability of the garbage can body is improved when the garbage can body bears the external garbage impacts.

Owner:张军

A steel bar rust inhibitor containing gemini amino ester

ActiveCN108069634BImprove control abilityReduce electrochemical corrosion reactionAdsorptive membraneRebar corrosion

Owner:JIANGSU SOBUTE NEW MATERIALS

Stone clamping device for excavating robot

The invention belongs to the technical field of excavating aids, and discloses a stone clamping device for an excavating robot. The stone clamping device comprises a base and a support plate as well as a clamping mechanism and an adjusting mechanism; the clamping mechanism comprises a mounting shaft and a rotating roller which are hollow; the mounting shaft is slidably connected to the support plate, and provided with a first through hole and a second through hole; the mounting shaft is provided with two baffles, and divided into a negative pressure chamber and a pressure relief chamber by thetwo baffles; the rotating roller is connected to four connecting rods which are provided with industrial vacuum chucks; the base is internally provided with a cavity which is internally provided witha motor, a piston barrel and a piston, and the stone clamping device further comprises a first support rod, a second support rod and a third support rod which are hinged in sequence; the motor is connected to a rotating disk, and the first support rod is fixed to the rotating disk; the third support rod is hinged to the piston; and the piston barrel is provided with an air inlet and an air outlet. According to the stone clamping device disclosed by the invention, the problem that the stone clamping efficiency is low since stones can be clamped one by one only in the prior art is solved.

Owner:CHONGQING UNIV OF ARTS & SCI

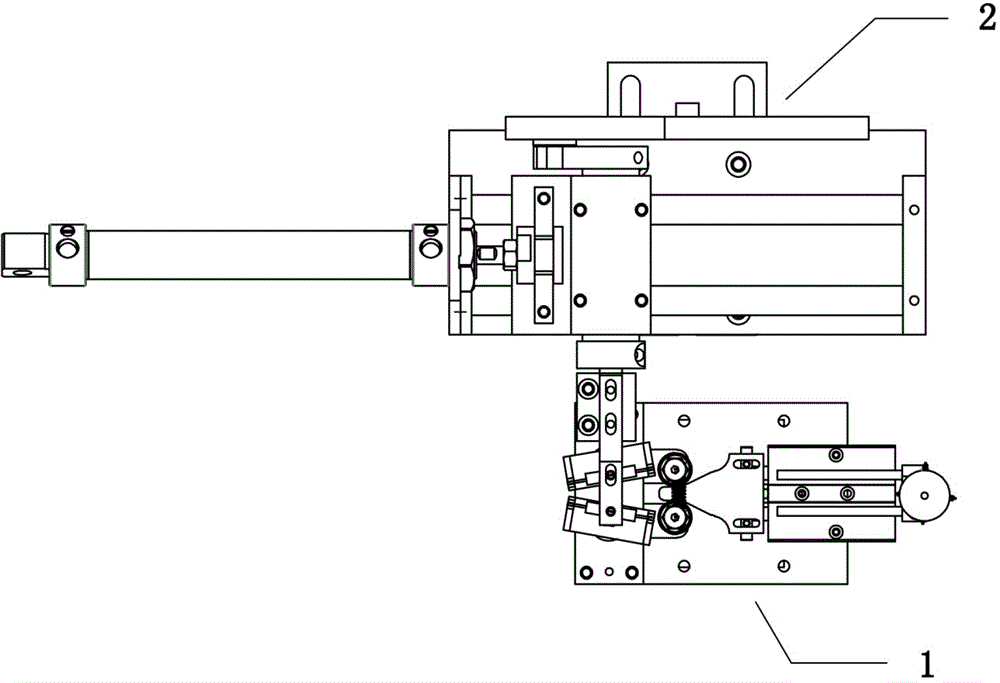

LED filament point welding double-filament feeding device

ActiveCN104858591ATight adsorptionIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesLED filamentEngineering

The invention discloses an LED filament point welding double-filament feeding device which comprises a filament positioning mechanism and a filament feeding mechanism for sucking filaments from the filament positioning mechanism and sending the filaments to a welding position. The filament positioning mechanism comprises two rotatable positioning dies. The upper surfaces of the two positioning dies can be each horizontally and fixedly provided with one filament. After the two positioning dies are rotated to be at the set angle, the angle between the two filaments on the two positioning dies is equal to the angle of the filaments at the corresponding positions in a produced lampwick. The filament feeding mechanism comprises two suckers for sucking the filaments. The bottom faces of the two suckers are provided with filament grooves matched with the filaments respectively. The angle between the two filament grooves is equal to the angle of the filaments at the corresponding positions in the produced lampwick.

Owner:佛山市飞驰自动化设备有限公司

Gypsum cutting device for orthopedic treatment

ActiveCN110916906AAchieve fixationPrevent movementStone-like material working toolsBandagesHuman bodyOrthopedic department

The invention belongs to the technical field of medical instruments for cutting various bandages, and discloses a gypsum cutting device for orthopedic treatment. The device comprises a workbench, a sliding groove is formed in the workbench, a cutting knife driven by a motor is connected to the sliding groove in a sliding mode, the device further comprises a sliding block connected into the slidinggroove in a sliding mode, the cutting knife is connected to the sliding block in a sliding mode in a direction perpendicular to the sliding groove, and an infrared detector and a controller controlling the cutting knife to slide are arranged on the sliding block; and a gypsum containing groove is further formed on the workbench, two sets of sliding holes are further formed in the positions, located on the two sides of the gypsum containing groove, of the upper surface of the workbench, two human body fixing rings sliding along the sliding holes are further included, threaded mounting holes are formed on the human body fixing rings, and threaded locking holes are formed in the positions, located below the mounting holes, of the workbench. The invention solves the problems that: in the prior art, when gypsum is cut, a patient moves due to mental stress and stress reaction and then makes contact with a cutting knife, and consequently the skin is injured.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

Metal mask plate and manufacturing method thereof

InactiveCN107675126AReduce gapReduce shadowsSolid-state devicesVacuum evaporation coatingEngineeringMetal

The invention relates to a metal mask plate and a manufacturing method thereof. The metal mask plate comprises a mask frame; the mask frame is provided with a diaphragm set with meshes; and a magneticmaterial coating layer which is magnetized is arranged on the surface of the diaphragm set. The attracting force between a substrate and diaphragms is increased through the magnetic material coatinglayer on the diaphragm set; and under the same magnetic force condition, a magnetic plate of an evaporation machine enables a fine metal mask plate or an opening mask plate mold to tighter absorb withthe substrate, so that a gap between the diaphragm set and the substrate is reduced, the evaporation shadow is reduced, and the product yield is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com