LED filament point welding double-filament feeding device

A technology of LED filaments and filaments, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions claimed in the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

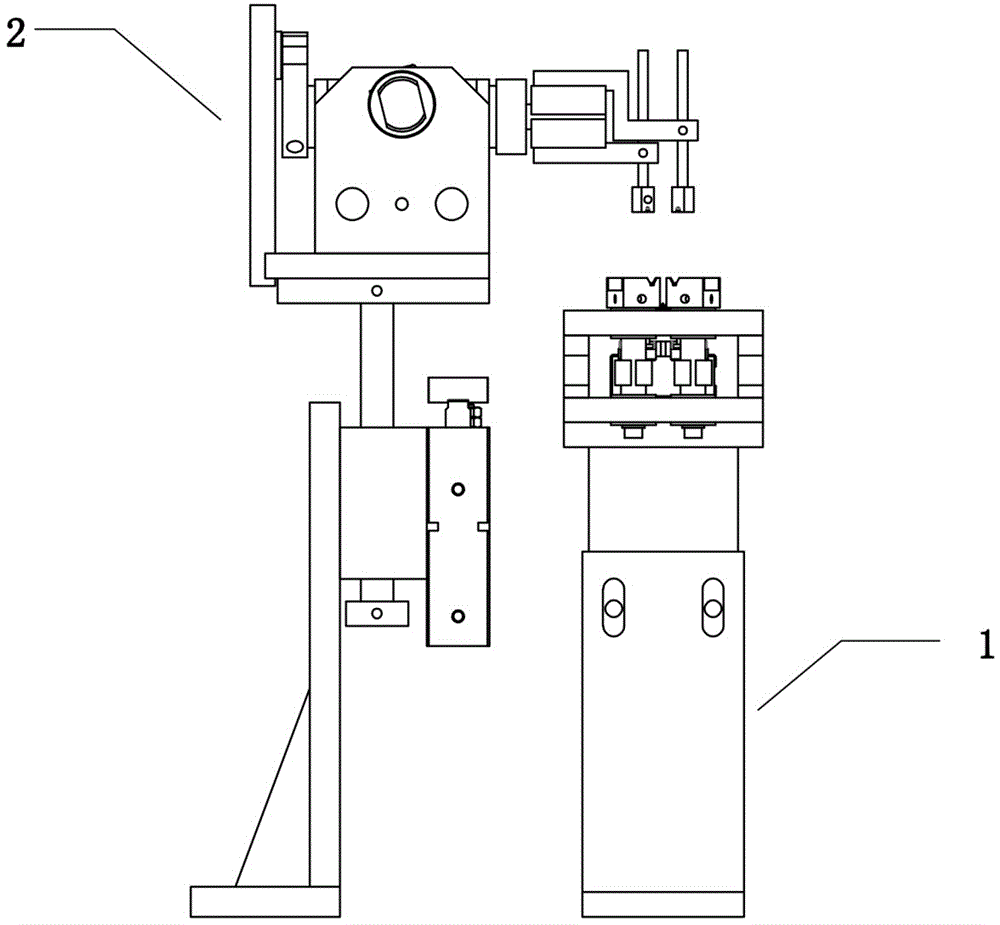

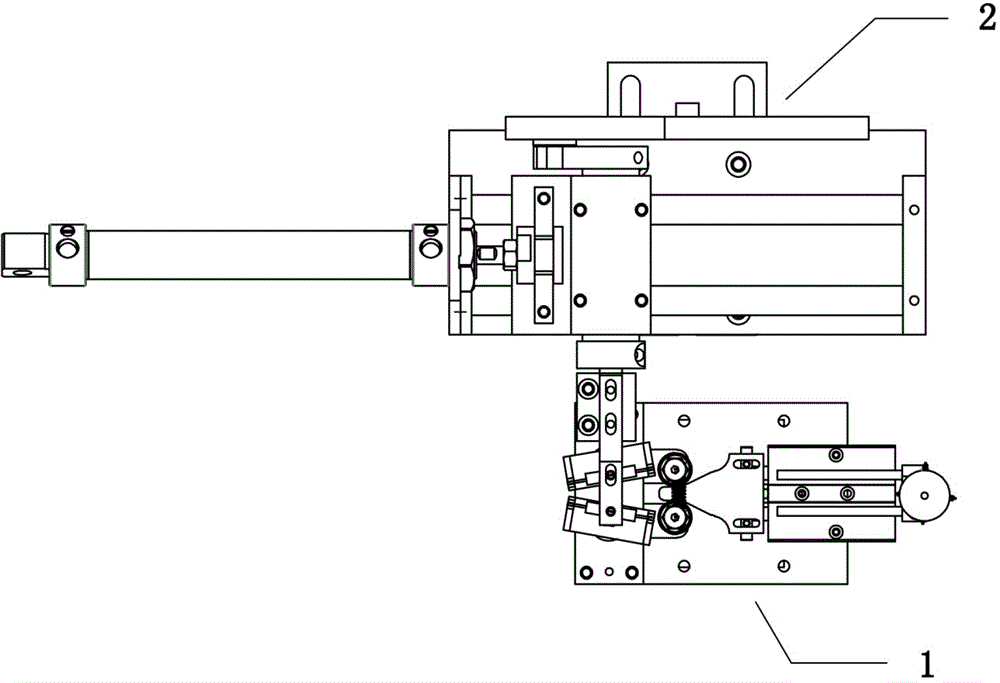

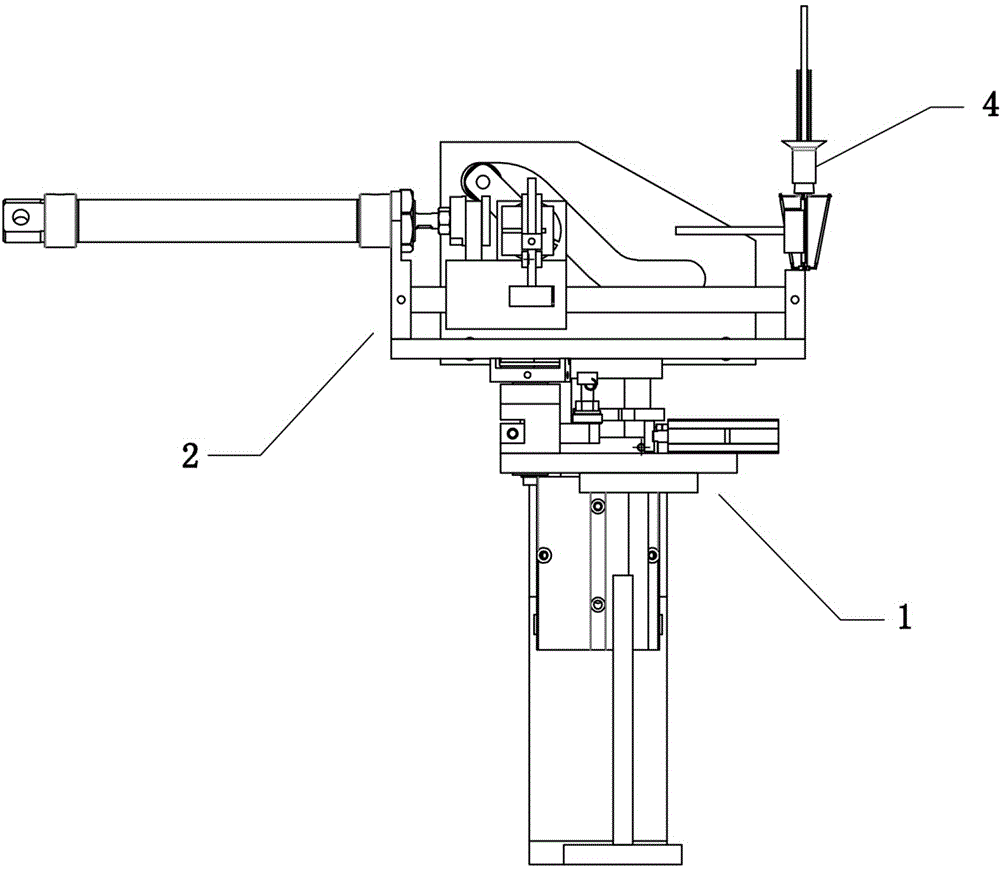

[0025] See attached Figure 1-4 As shown, the LED filament spot welding feeding mechanism of the present invention includes a filament positioning mechanism 1 and a filament feeding mechanism 2 . Among them, see attached Figure 5-7 As shown, the filament positioning mechanism 1 includes a base 11, a pair of positioning molds 12 rotatably connected to the upper surface of the base 11, and a positioning drive mechanism for driving the two positioning molds 12 to rotate at a set angle. Among them, the upper surfaces of the two positioning molds 12 are formed with filament placement grooves 121, which can respectively place two filaments horizontally and fixedly; the positioning drive mechanism includes two rotating arms 131 respectively connected to the two positioning molds 12 for tensioning. The extensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com