Graphene material coating and preparing method thereof and air filtering device and system

An air filtration device, graphene technology, applied in the direction of coating, filtration separation, membrane filter, etc., can solve the problems of secondary pollution, loss of effectiveness, etc., to improve the removal rate, avoid secondary pollution, and achieve significant adsorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

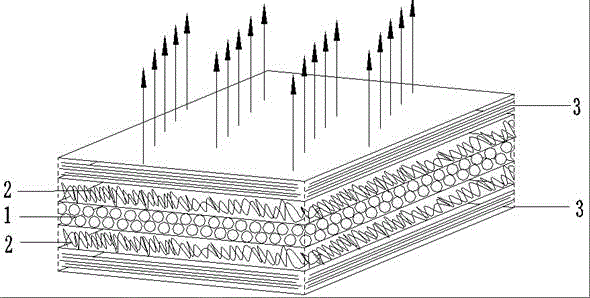

Image

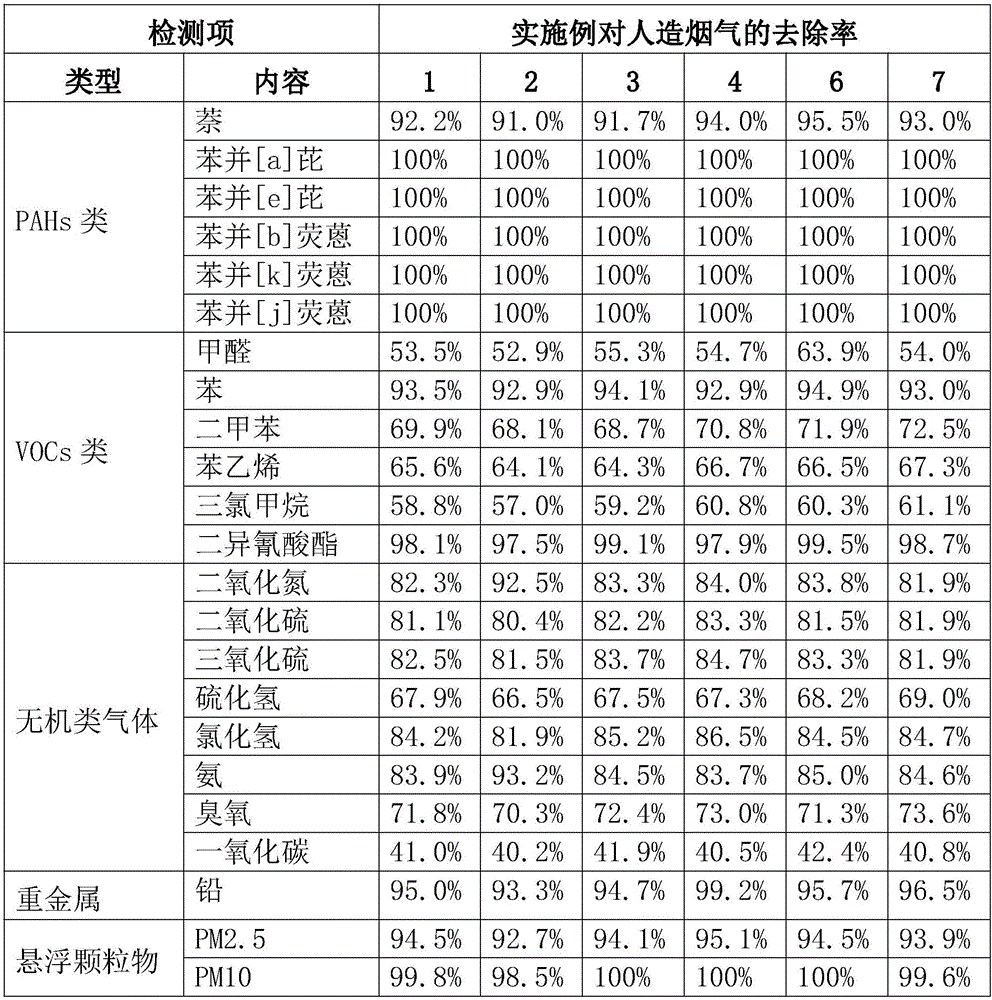

Examples

preparation example Construction

[0040] The present invention also provides a kind of graphene material coating preparation method, it comprises the following steps:

[0041] S1) Prepare slurry dispersion stock solution: add dispersant and binder into the solvent, and stir to form slurry dispersion stock solution.

[0042] The above-mentioned solvent is a purified organic solvent and / or aqueous solvent, wherein the purification method of the organic solvent includes one or more of redistillation, dehydration and drying; the purification method of the above-mentioned aqueous solvent includes redistillation, deionization And one or more of reverse osmosis. The above-mentioned solvent preferably includes water, deionized water, ultrapure water, N-methylpyrrolidone, N,N-dimethylformamide, tetrahydrofuran, ethanol, n-pentane, ethyl acetate, butanone, heptane, benzene, Toluene, 4-methyl-2-pentanone, isobutyl acetate, n-butyl acetate, m-xylene, n-butanol, 2-heptanone, n-hexane, ethylene glycol dimethyl ether, petro...

Embodiment 1

[0068] Add the dispersant polyvinylpyrrolidone and the binder polyacrylamide-polyacrylic acid emulsion to the deionized water respectively, and prepare a dispersion with the mass volume ratio of the dispersant being 2%, and the mass volume ratio of the binder being 25%, and stirring at 100rpm After 2 hours, a uniform emulsion is formed, and vacuum defoaming is carried out. After completion, the single-layer graphene powder is added to the dispersion in batches for several times. Homogenize and disperse with high-speed shear force at 6000rpm for 30min. After completion, coat the surface of polypropylene spunlace non-woven fabric by scraping, and send it to a vacuum drying oven for drying at 80°C. After drying for 6h, constant Heavy, forming a graphene material coating finished coating thickness is 50um. Using this layer as the filter layer and support layer / filter-aid layer, pure cotton gauze as the outer covering layer, packaging, cutting, sewing, calendering and molding to ob...

Embodiment 2

[0070] A mixture of dispersant sodium polystyrene sulfonate and sodium dodecyl sulfonate, a mixture of polyethylene glycol and sodium polyacrylate as a binder were respectively added to butanone, and the mass volume ratio of the dispersant was 0.1%, and the binder The dispersion with a mass volume ratio of 5% was stirred at 30 rpm for 1 h to form a uniform emulsion, and then vacuum degassed. After completion, carboxylated graphene was added to the dispersion in batches for several times. Homogenize, disperse with high-speed shear force at 3000rpm for 20min, and apply it on the surface of polyester terephthalate needle-punched / spunlace non-woven fabric by scraping after completion, and send it into hot air to dry at 60°C Carry out drying, form the graphene material coating finished coating thickness after drying 2h is 3um. The layer is used as the filter layer and the support layer, and the composition of pure cotton gauze and pure cotton crepe is used as the outer covering lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com