Functionalized ionic liquid lubricating agent

An ionic liquid, functionalized technology, used in lubricating compositions, additives, petroleum industry, etc., can solve the problems of limited wide application and poor anti-wear performance, and achieve the effect of improving anti-wear performance and tight adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Mix 0.1mol N-methylimidazole and 0.1mol ethyl chloroacetate in 100mL of acetone, then place the mixture in a microwave oven with a radiant power of 240W, heat intermittently for 30S, 20S, 20S, 15S, 15S, 15S, and At each interval, remove the reaction bottle from the microwave oven and shake and mix for 10 seconds. After the reaction, the reaction system changes from turbid to viscous liquid. Wash it with 25mL ether for 3 times, and let it stand for layers. The lower layer is a viscous liquid, and the upper layer is a transparent solution. , separate the lower layer liquid, and carry out rotary evaporation under reduced pressure at room temperature to obtain a functionalized ionic liquid intermediate whose anion is a halogen anion; then it is mixed with 0.1mol NaBF 4 Mix the acetonitrile solution and stir at room temperature (25°C) for 48 hours. After the reaction, remove the solid by filtration, and wash the solid with ether, then combine the filtrates, rotary distillatio...

Embodiment 2

[0063] Mix 0.1mol N-methylimidazole and 0.1mol ethyl chloroacetate in 100mL of acetone, then place the mixture in a microwave oven with a radiant power of 240W, heat intermittently for 30S, 20S, 20S, 15S, 15S, 15S, and At each interval, remove the reaction bottle from the microwave oven and shake and mix for 10 seconds. After the reaction, the reaction system changes from turbid to viscous liquid. Wash it with 25mL ether for 3 times, and let it stand for layers. The lower layer is a viscous liquid, and the upper layer is a transparent solution. , separate the lower layer liquid and carry out rotary evaporation under reduced pressure at room temperature to obtain a functionalized ionic liquid intermediate whose anion is a halide anion; then it is mixed with 0.1mol bistrifluoromethanesulfonimide lithium aqueous solution, room temperature ( 25°C) Stir the reaction for 48h. After the reaction, remove the solid by filtration and wash the solid with ether, then combine the filtrates,...

Embodiment 3

[0070] The lubricant prepared in Example 1 was mixed with the ester oil diisooctyl sebacate at a mass ratio of 1:100 to obtain a lubricant containing base oil.

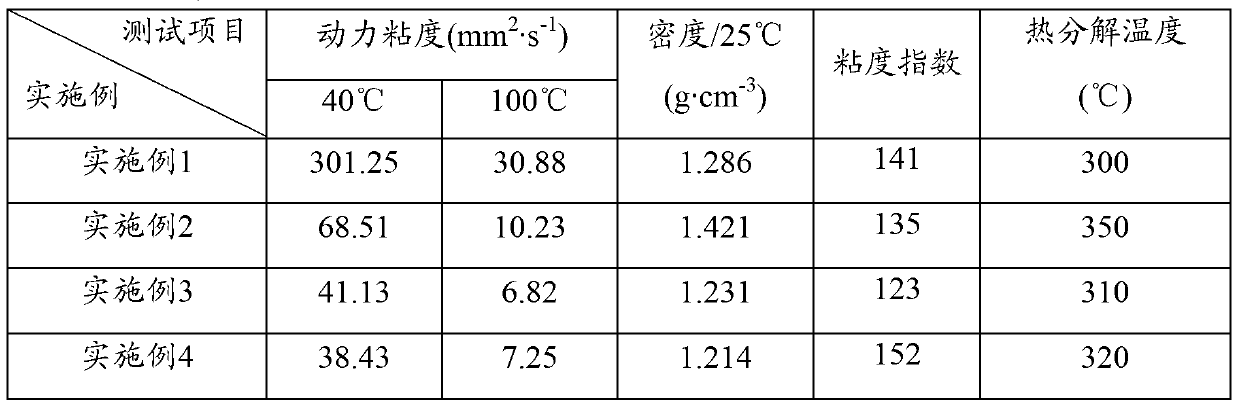

[0071] According to the method of Example 1, the performance test of the lubricant prepared in this example was carried out, and the test results are shown in Table 1. Table 1 is a summary of the performance test data of the lubricant prepared in the example of the present invention.

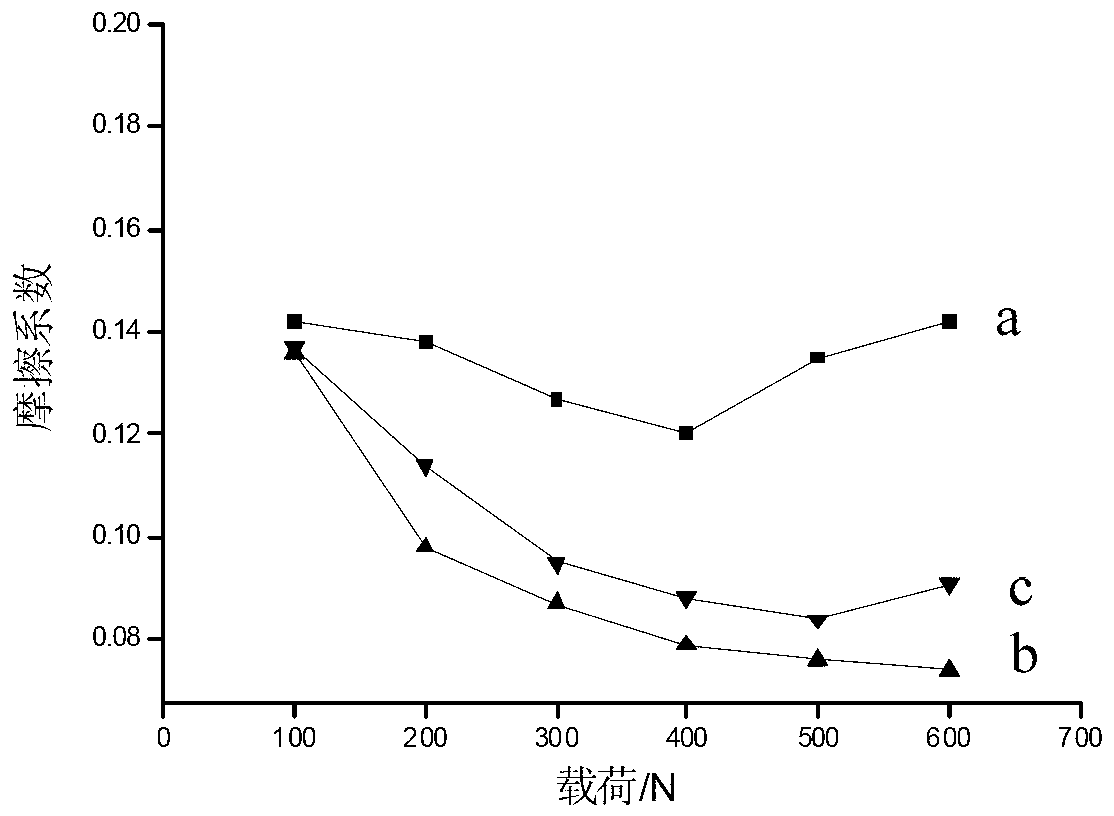

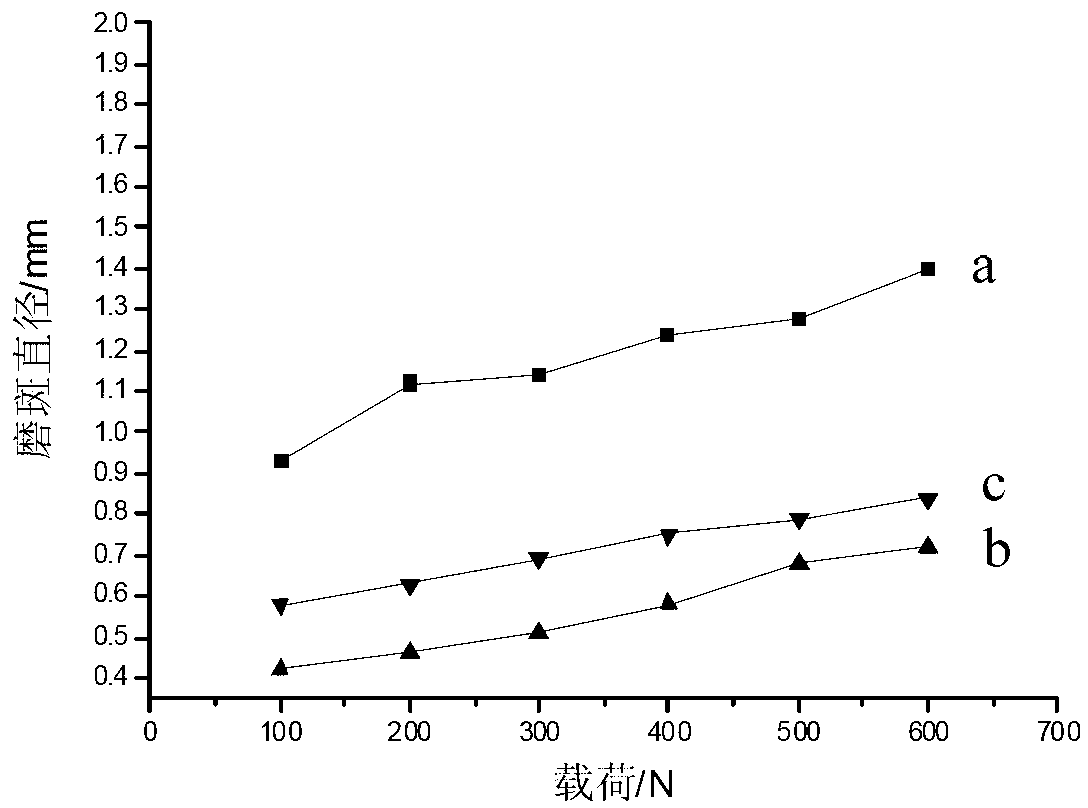

[0072] The friction performance test of the prepared lubricant was carried out using a vertical universal friction and wear testing machine (Jinan Shunmao Testing Instrument Co., Ltd.), the test conditions: speed 1450±50r / min, load 392N, temperature at room temperature, time 30min; used Steel ball: GCR15 bearing steel, diameter 12.7mm, hardness 59-61HRC; test results see figure 1 and figure 2 , figure 1 is the friction coefficient test graph of the lubricant prepared in the embodiment of the present invention and the comparative exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com