Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about How to "Improve shear stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

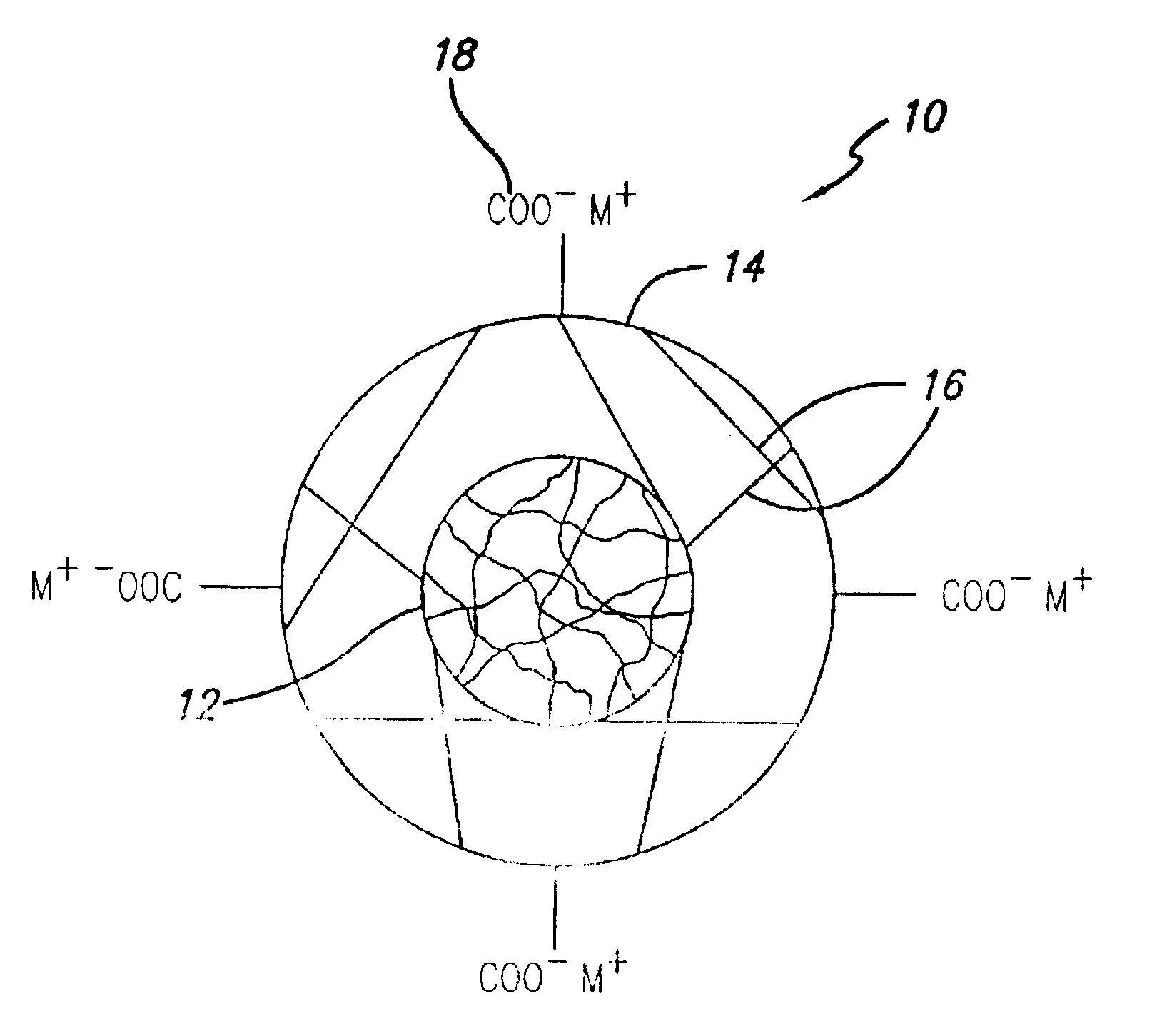

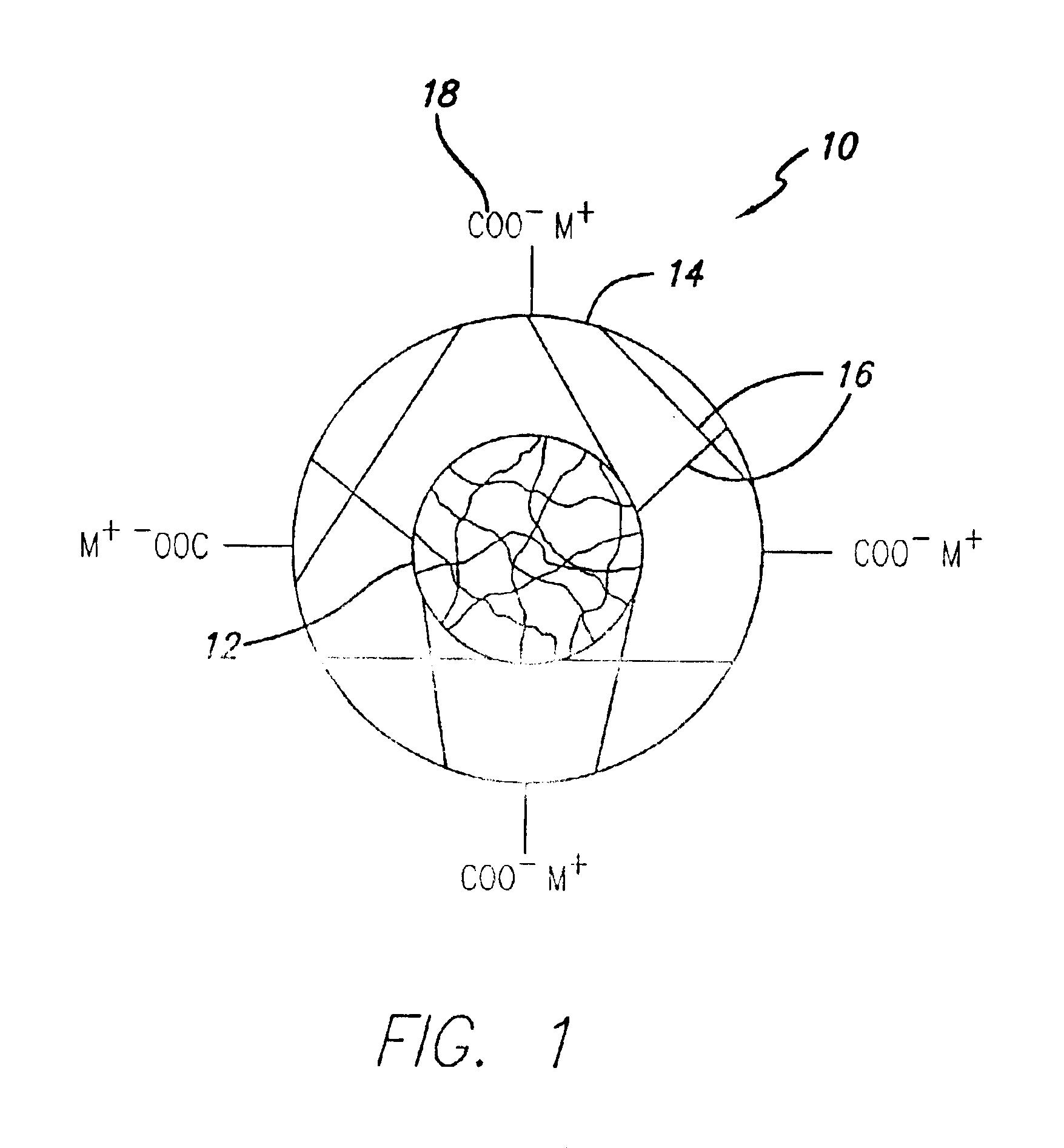

Specific core-shell polymer additive for ink-jet inks to improve durability

InactiveUS6858301B2Improve propertiesGood shear stabilityPhotosensitive materialsDuplicating/marking methodsHydrophilic monomerVitrification

Polymer particles are provided having (1) a core with a glass transition temperature within a range of −50° to +110° C. and (2) a shell surrounding the core. The core comprises at least one layer, with the layer(s) comprising at least one polymerized hydrophobic monomer and, optionally, a first cross-linker. The shell comprises a copolymerized mixture of least one hydrophobic monomer and at least one hydrophilic monomer and a second cross-linker for increasing thermal shear stability by forming cross-linkages. Use of these polymer particles in aqueous-based ink-jet inks provide laser print quality without any secondary treatment.

Owner:HEWLETT PACKARD DEV CO LP

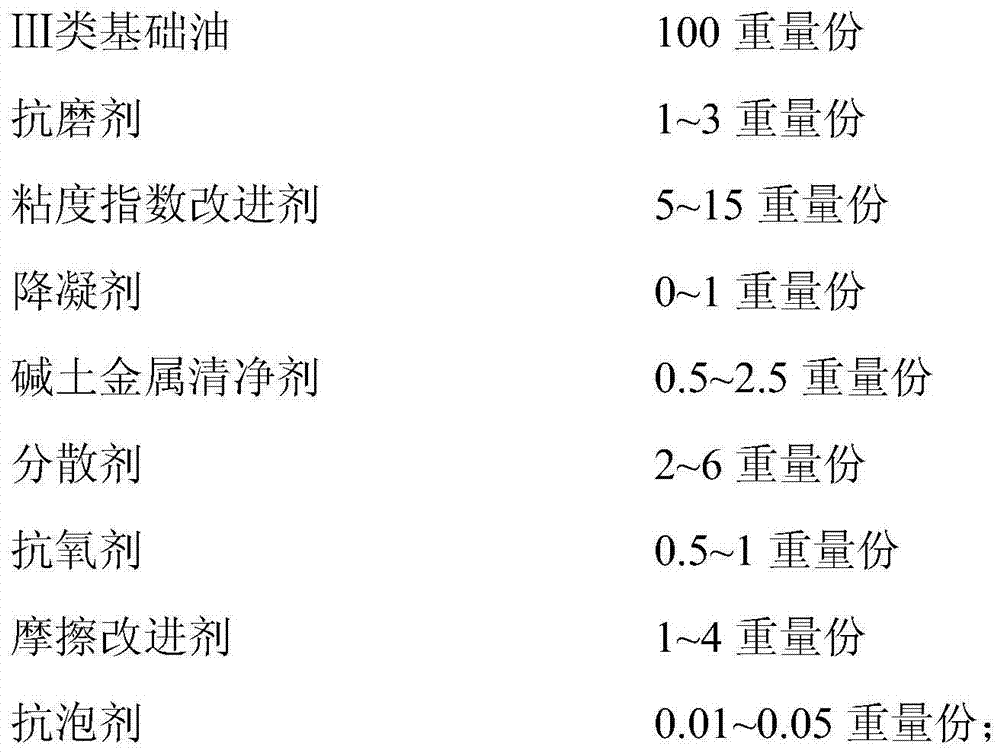

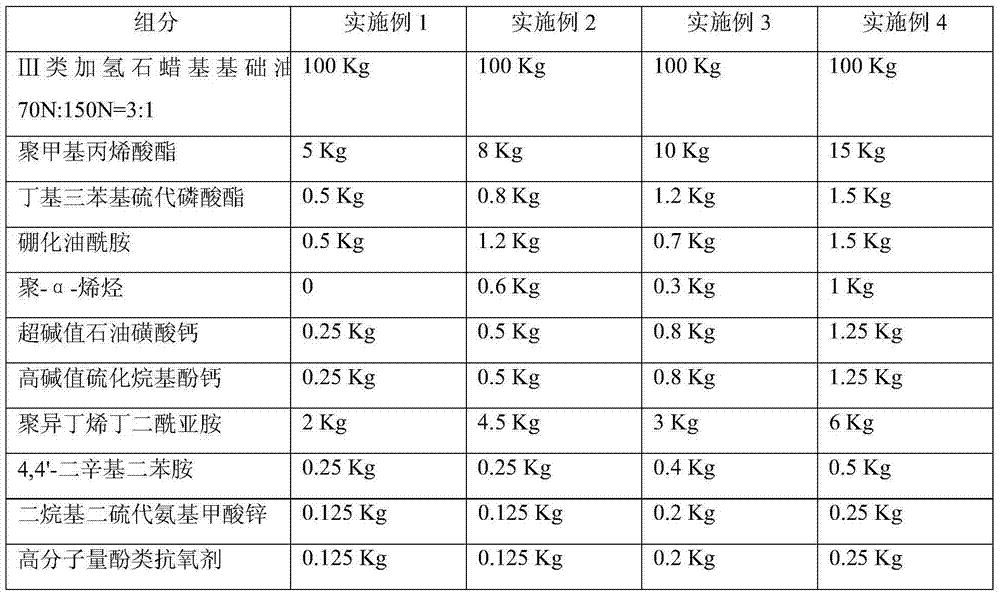

Automobile continuously variable transmission fluid and preparation method thereof

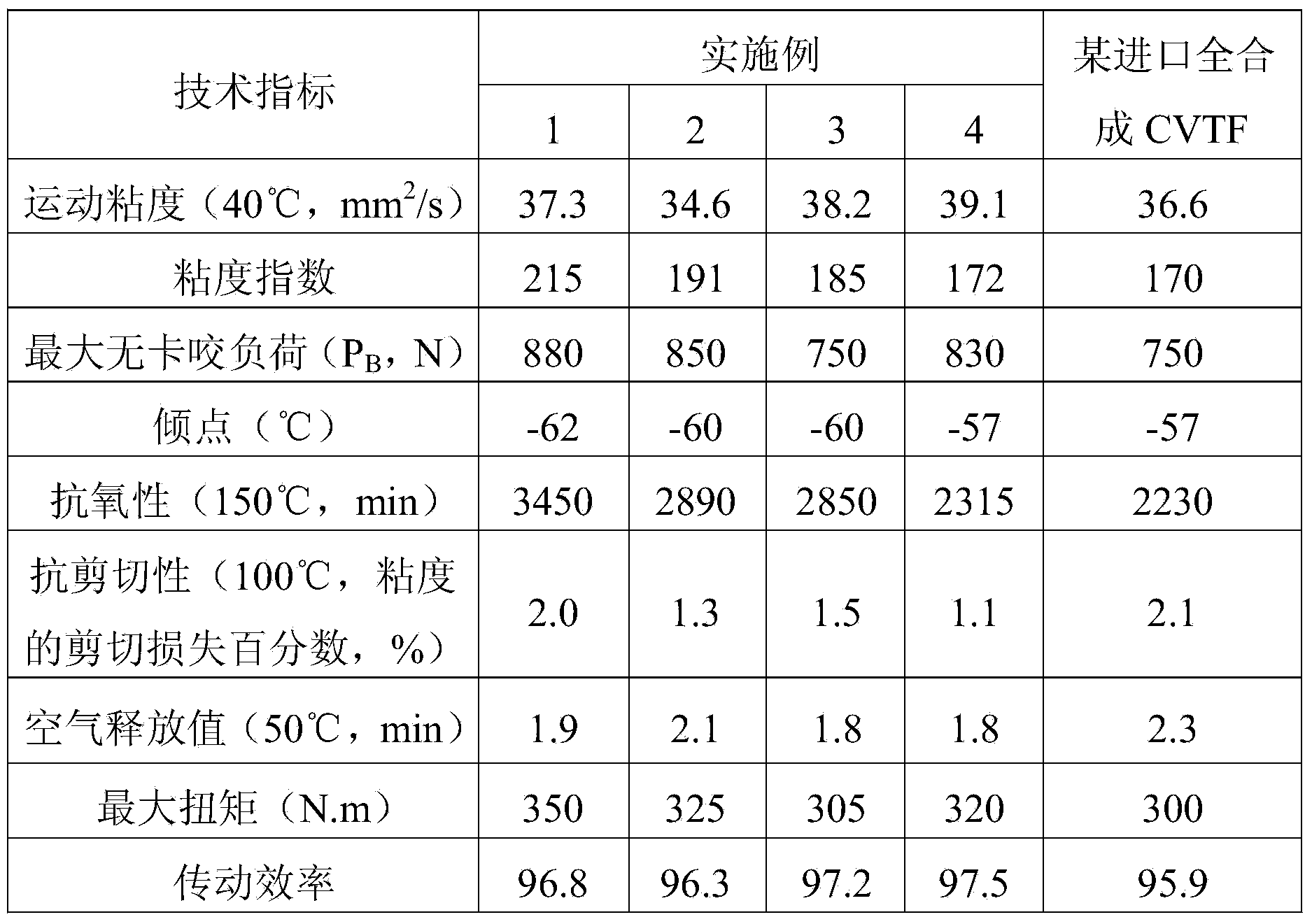

The invention discloses an automobile continuously variable transmission fluid and a preparation method thereof. The automobile continuously variable transmission fluid comprises the following components: 100 parts by weight of class III base oil, 1-3 parts by weight of antiwear agent, 5-15 parts by weight of viscosity index improver, 0-1 part by weight of pour point depressant, 0.5-2.5 parts by weight of alkaline earth clearing agent, 2-6 parts by weight of dispersant, 0.5-1 part by weight of antioxidant, 1-4 parts by weight of friction modifier and 0.01-0.05 part by weight of anti-foaming agent. According to the invention, the chosen additives are optimally combined together to obtain the CVTF, and the obtained CVTF has excellent comprehensive properties; the CVTF is excellent in viscosity index, oxidation stability, shear stability, wearing quality and cryogenic property, and more critically, large in torque, high in traction coefficient and high in transmission efficiency; and consequently, the use requirements of B-CVT and T-CVT can be met simultaneously.

Owner:GUANGZHOU MECHANICAL ENG RES INST

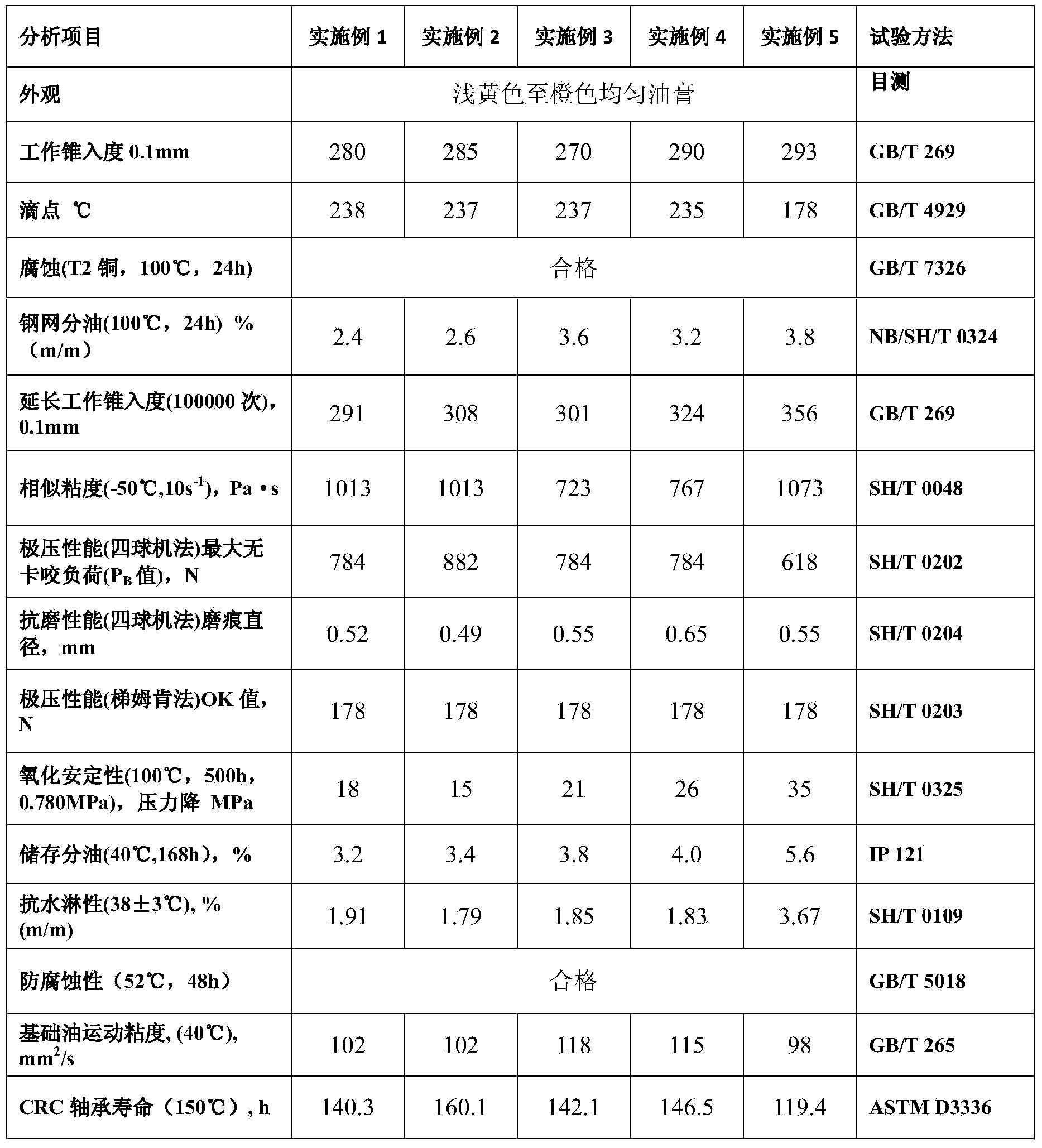

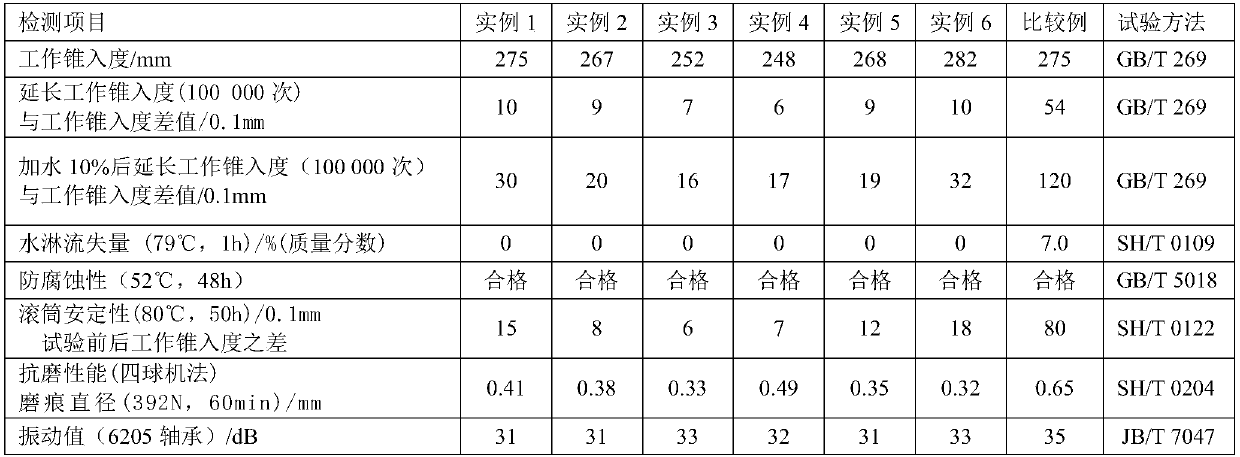

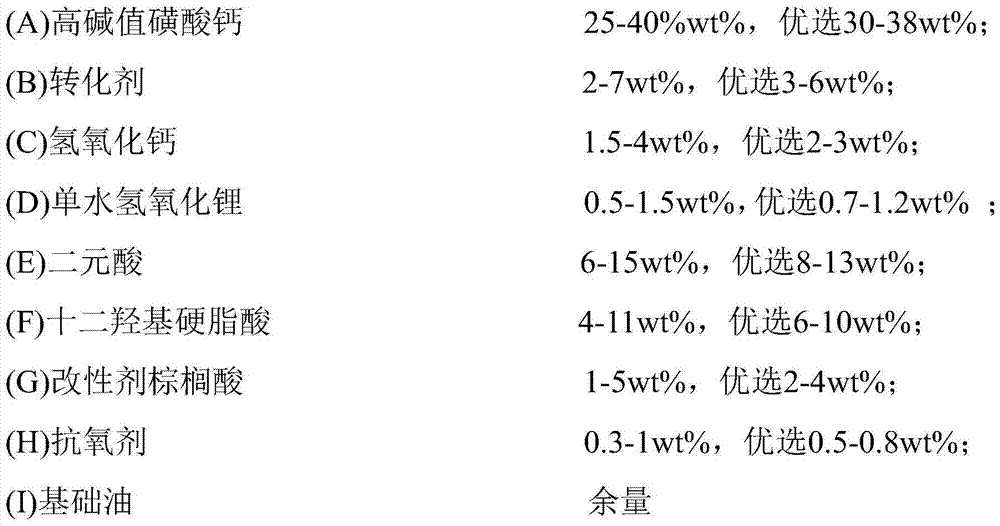

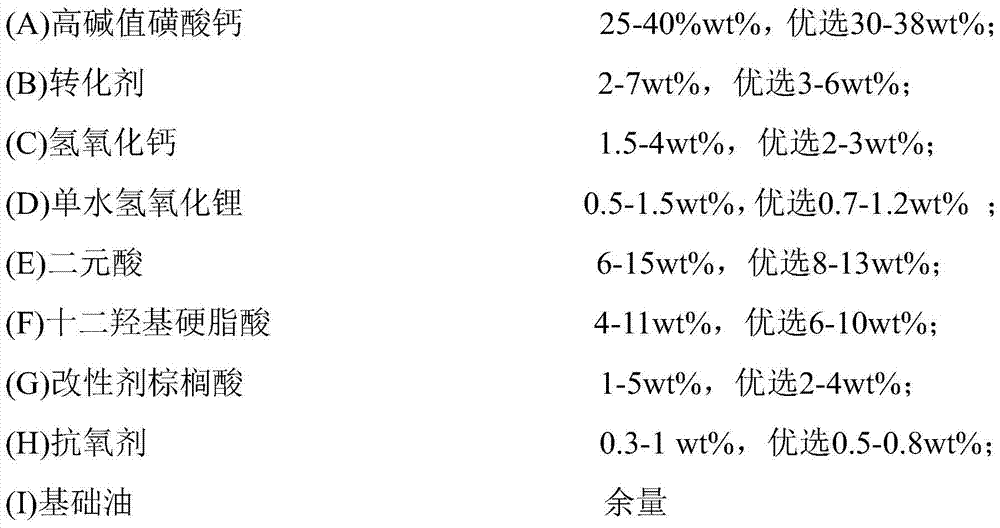

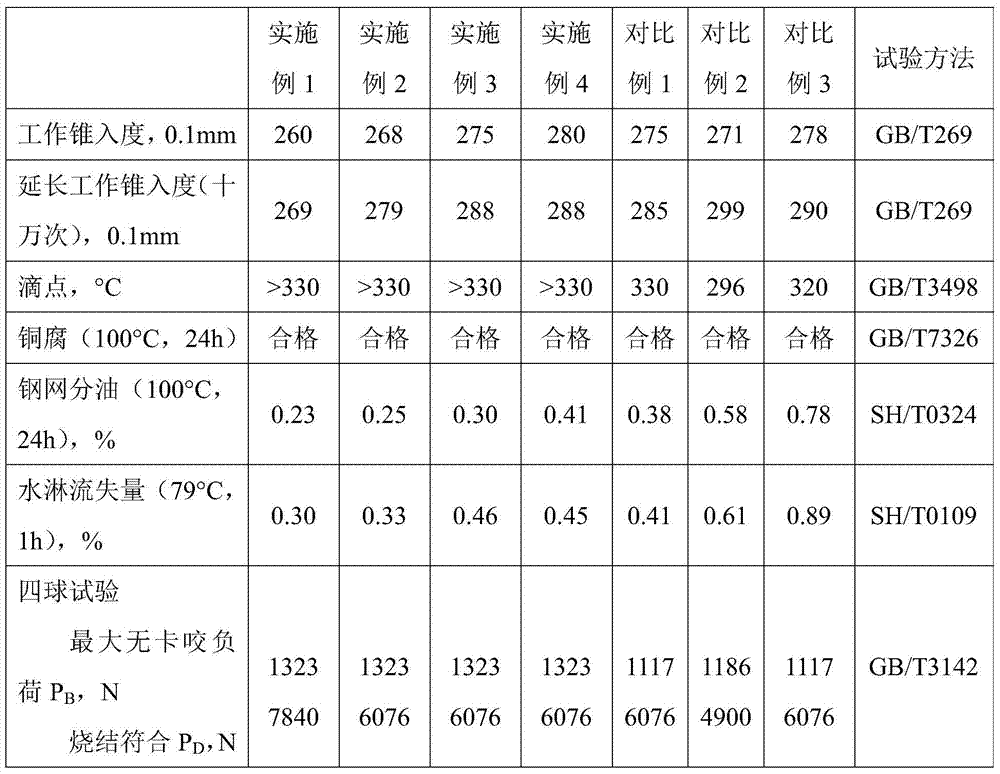

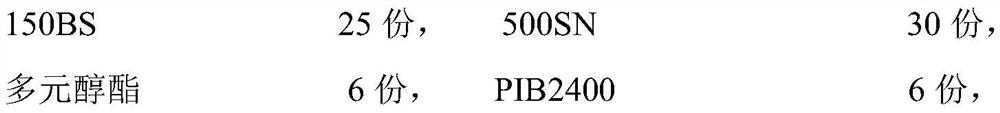

Composite lithium-calcium base lubricating grease and preparation method thereof

ActiveCN102977979AGood mechanical stabilityGood extreme pressure and anti-wear propertiesThickenersWater resistanceLithium

The invention relates to lubricating grease and a preparation method thereof, particularly relates to composite lubricating grease and a preparation method thereof, and belongs to the technical field of chemistry. According to the invention, base oil, thickener and additive are prepared into lithium-calcium base lubricating grease according to a proper ratio; the lithium-calcium base lubricating grease has the characteristics of favorable high temperature property, shear stability, extreme pressure wear resistance, water resistance and the like; and the invention is simple in preparation method, stable in product performance, low in product comprehensive cost and is suitable for large-scale industrial production.

Owner:JIANGSU LOPALTECH

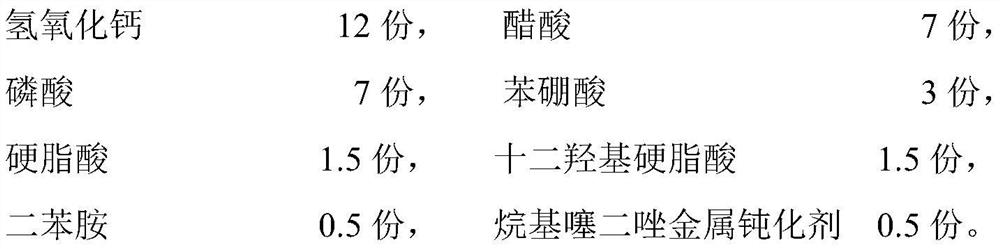

Multifunctional superstrong extreme pressure antiwear lubricating grease and preparation method thereof

InactiveCN102690716AStrong extreme pressureWear scar diameter is smallLubricant compositionAcetic acidCalcium hydroxide

The invention relates to superstrong extreme pressure antiwear lubricating grease and a preparation method thereof; particularly, a densifier is generated by calcium sulfonate with a high base number through a phase inversion reaction, and the lubricating grease is prepared by combining base oil with other functional additives, wherein the base oil is combined by base oil with high viscosity and medium viscosity. The method comprises the following steps: stirring and mixing the composite base oil and the calcium sulfonate in a reaction vessel, heating, adding a phase inversion promoter, glacial acetic acid, and water, heating and reacting at a constant temperature, adding calcium hydrate, aliphatic acid and boric acid after the phase inversion is completed, reacting at a constant temperature, heating and dehydrating, adding an anti-oxidant, refining, transferring the materials into a blending vessel, adding an eutectic rolling additive and an adhesion improver, dispersing and homogenizing the mixture, filtering, and degassing to obtain the finished product. The lubricating grease of the invention has excellent water sprinkling resistance, excellent high and low temperature performance, superstrong extreme pressure antiwear performance, excellent pumping performance, outstanding shearing stability, and antirust performance.

Owner:超美科技(深圳)有限公司

Preparation of nano silicon dioxide lubricating grease

The invention discloses a preparation method of high-performance silicon dioxide grease, which comprises the following components, base oil of 70 to 90 weight percent, silica of 5 to 30 weight percent, modifying agent is in a dose of 5-30 weight percent of the silicon dioxide. The silicon dioxide grease of the invention has a very good storage stability and shear stability, good colloidal stability, water resistant properties of high temperature and low temperature performance. The silicon dioxide grease can be used for electrical insulation, damping system lubrication, vacuum sealed, instruments and cock sealing and lubricating, can also be used for resistant chemical media site lubricating and sealing, and so on. In addition, the silicon dioxide grease can also be used for preparing valves grease, methanol resistance grease, and is applicable in lubrication and interrupter of the metal contact of switch silvering, silver plating, and tinning and other.

Owner:益田润石(北京)化工有限公司

Lube base oil, lubricating oil composition for internal combustion engine, and lubricating oil composition for drive transmission device

InactiveCN101379171AExcellent viscosity-temperature characteristicsReduce energy lossBase-materialsMeth-Chemical composition

A lube base oil satisfying at least one of the following requirements (a) and (b). A lubricating oil composition for internal combustion engines is provided which comprises the lube base oil, an ash-free antioxidant containing no sulfur as a constituent element, and at least one member selected among ash-free antioxidants containing sulfur as a constituent element and organ omolybdenum compounds. Also provided is a lubricating oil composition for drive transmission devices which comprises the lube base oil, a poly(meth)acrylate-type viscosity index modifier, and a phosphorus compound. (a) The content of saturated matters is 90 mass% or higher and the proportion of cyclic saturated matters in those saturated matters is 10-40 mass%. (b) The lube base oil satisfies the relationship represented by the following expression (1). 1.440=n20-0.002OEv100=1.453 (1) [In the expression, n20 indicates the refractive index at 20 DEG C of the lube base oil and kv100 indicates the dynamic viscosity (mm2 / s) at 100 DEG C of the lube base oil].

Owner:NIPPON OIL CO LTD +1

Anti-rust extreme pressure lithium lubricating grease composition and preparation method

InactiveCN105331426AImprove extreme pressure performanceImprove shear stabilityLubricant compositionAntioxidantLithium hydroxide

The invention relates to an anti-rust extreme pressure lithium lubricating grease composition and a preparation method thereof. The composition is prepared from 5.5%-12.5% of thickening agents, 72.8%-91.3% of base oil, 0.5%-3.8% of extreme pressure anti-wear agents, 0.28%-1.25% of antioxidants and 0.02%-1.05% of anti-rust anti-corrosion agents, wherein the base oil is high-viscosity mineral oil. The preparation method of the composition comprises the steps that one third of the base oil and 12-hydroxy stearin or a mixture of 12-hydroxy stearin and stearic acid are heated to the temperature ranging from 60 DEG C to 80 DEG C, a lithium hydroxide solution is added, the temperature is raised to range from 180 DEG C to 220 DEG C after a reaction is completed, one third of quenching oil is added, the extreme pressure anti-wear agents, the anti-rust anti-corrosion agents and the rest of the base oil are added after cooling is conducted, and the composition is prepared after grounding is conducted. The novel lubricating grease containing the extreme pressure components and the anti-rust anti-corrosion components has the excellent extreme pressure property and anti-corrosion property and can be widely applied to severer environment conditions with a medium or heavy load and water.

Owner:CHINA PETROLEUM & CHEM CORP

Lubricating grease containing modified silica component and preparation method of lubricating grease

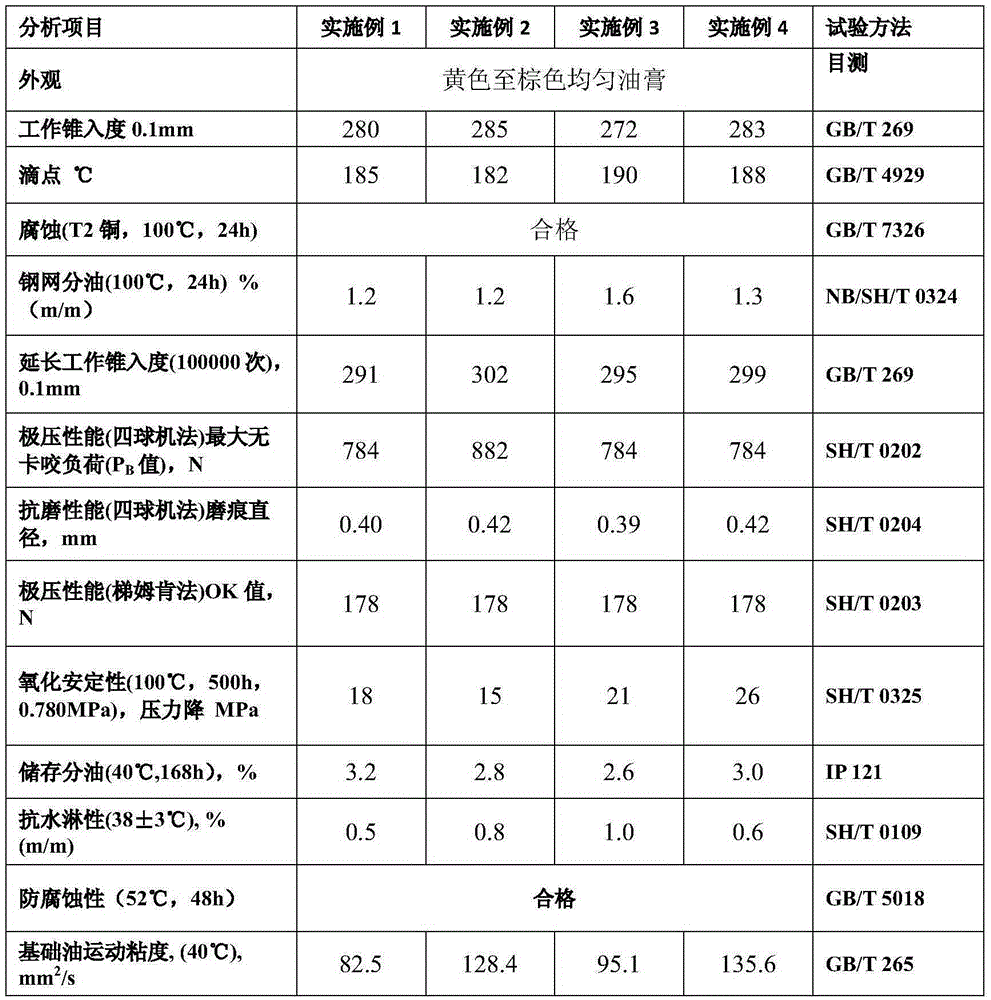

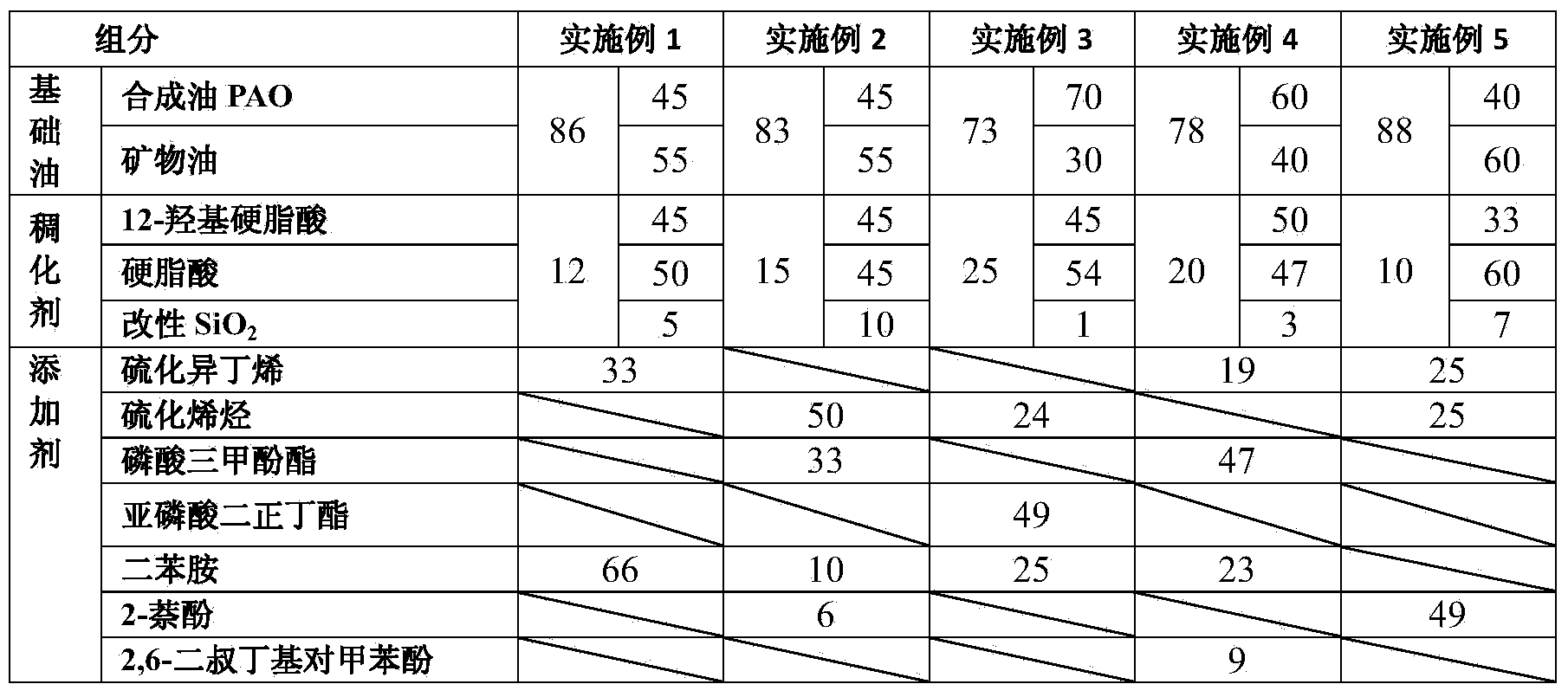

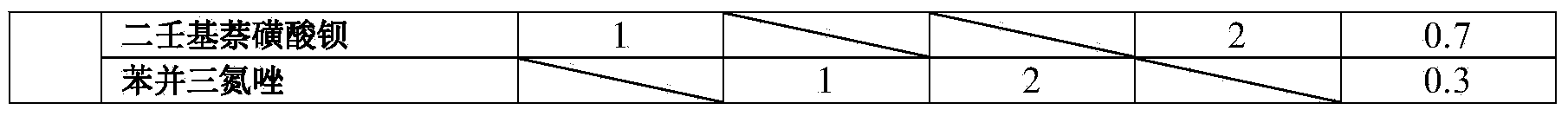

ActiveCN103484204AImprove shear stabilityLittle change in cone penetrationPigment treatment with organosilicon compoundsLubricant compositionAntioxidantHydroxystearic Acid

The invention relates to lubricating grease containing a modified silica component and a preparation method of the lubricating grease. The excellent properties of silicone grease and lithium lubricating grease are well combined through modified SiO2. With total weight of a composition as benchmark, the lubricating grease provided by the invention comprises the following components: a thickening agent accounting for 10-25% of the total weight and including 12-hydroxystearic acid, stearic acid and the modified SiO2; base oil accounting for 73-88% of the total weight and consisting of synthetic oil and mineral oil; and additives mainly including the following three types: (a) 0.6-1.8% of anti-wear reagent at extreme pressure, (b) 0.32-1.32% of antioxidant, and (c) 0.02-0.04% of antirust preservative. The novel lubricating grease containing modified SiO2 has excellent shear stability and storage stability and is a kind of SiO2-containing lithium lubricating grease in which high and low temperature, colloid stability and water resistance are greatly improved. The lubricating grease is especially suitable for application under harsh environmental conditions of high temperature and heavy load.

Owner:CHINA PETROLEUM & CHEM CORP

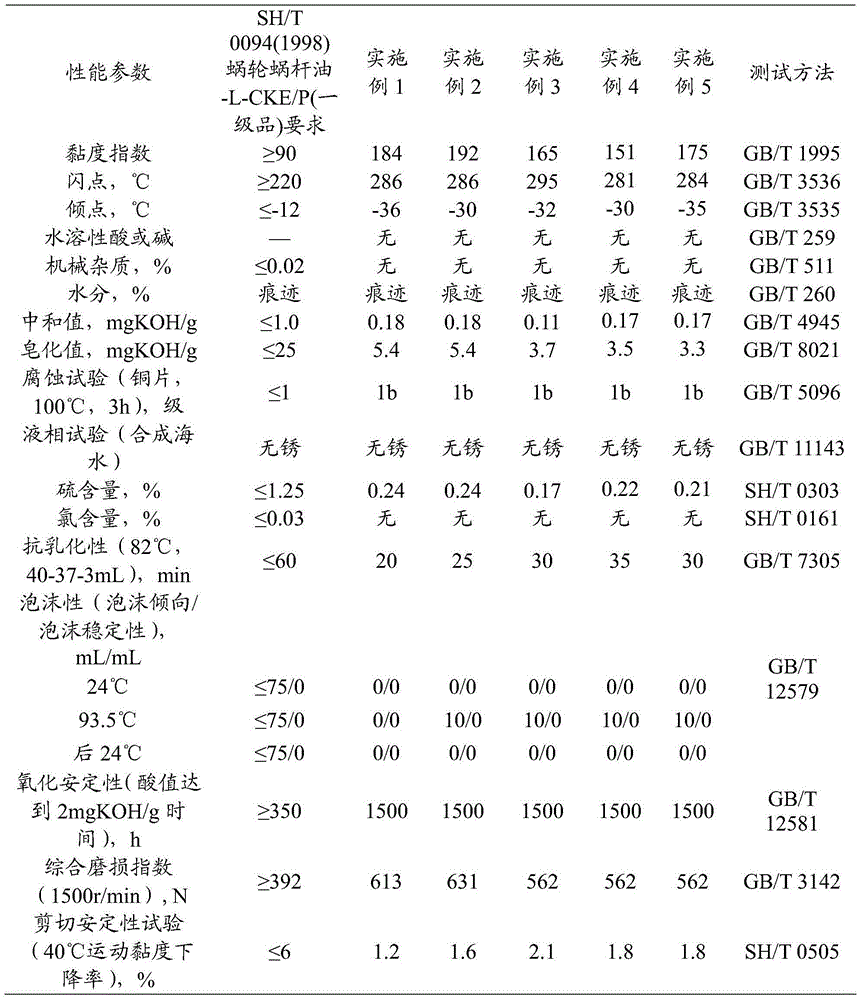

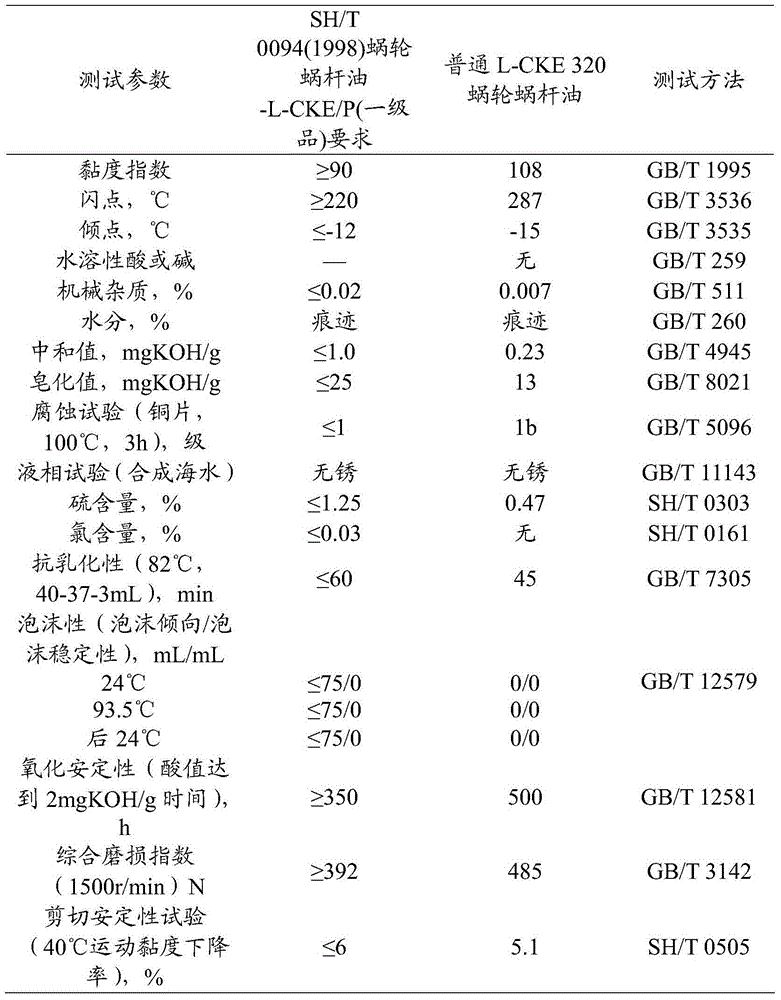

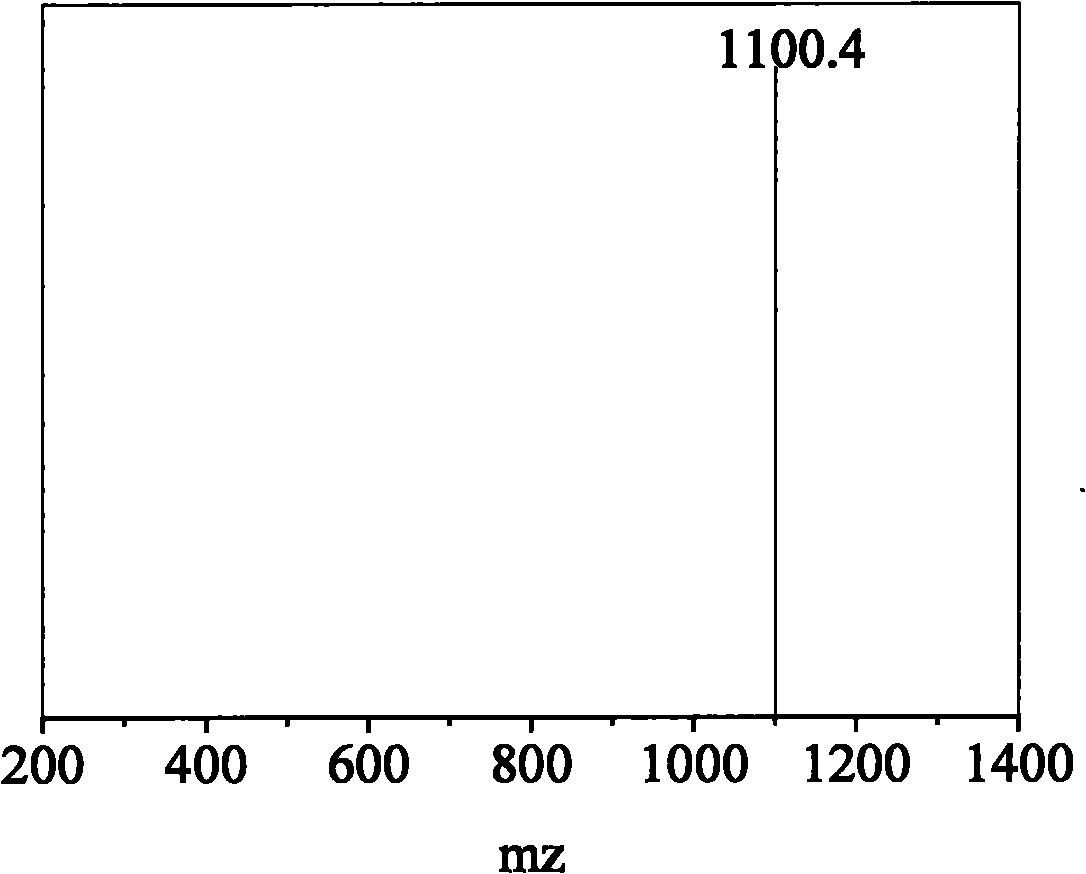

Worm wheel worm rod lubricating oil composition and preparation method thereof

ActiveCN104403741AImprove extreme pressure and anti-wear performanceImprove Oxidation StabilityLubricant compositionPolyolefinFoaming agent

The present invention provides a worm wheel worm rod lubricating oil composition and a preparation method thereof. The worm wheel worm rod lubricating oil composition comprises 45-75 wt% of poly[alpha]-olefin, 10-45 wt% of oil-soluble polyether, 0.1-5 wt% of an antioxidant, 0.01-0.5 wt% of a metal deactivator, 0.1-5 wt% of a corrosion inhibitor, 0.5-5 wt% of an extreme pressure anti-wear agent, and 0.0005-0.05 wt% of an anti-foaming agent. According to the present invention, the poly[alpha]-olefin and the oil-soluble polyether are adopted as the base oils, the antioxidant, the metal deactivator, the corrosion inhibitor, the extreme pressure anti-wear agent and the anti-foaming agent are adopted as the additives, and the contents of each component are controlled within the content range, such that the worm wheel worm rod lubricating oil composition has the good extreme pressure anti-wear property and the excellent oxidation stability; and the worm wheel worm rod lubricating oil composition further has characteristics of excellent corrosion resistance, excellent rust resistance, excellent shear stability, good oil-water separation property and good anti-foam property.

Owner:CHINA PETROLEUM & CHEM CORP

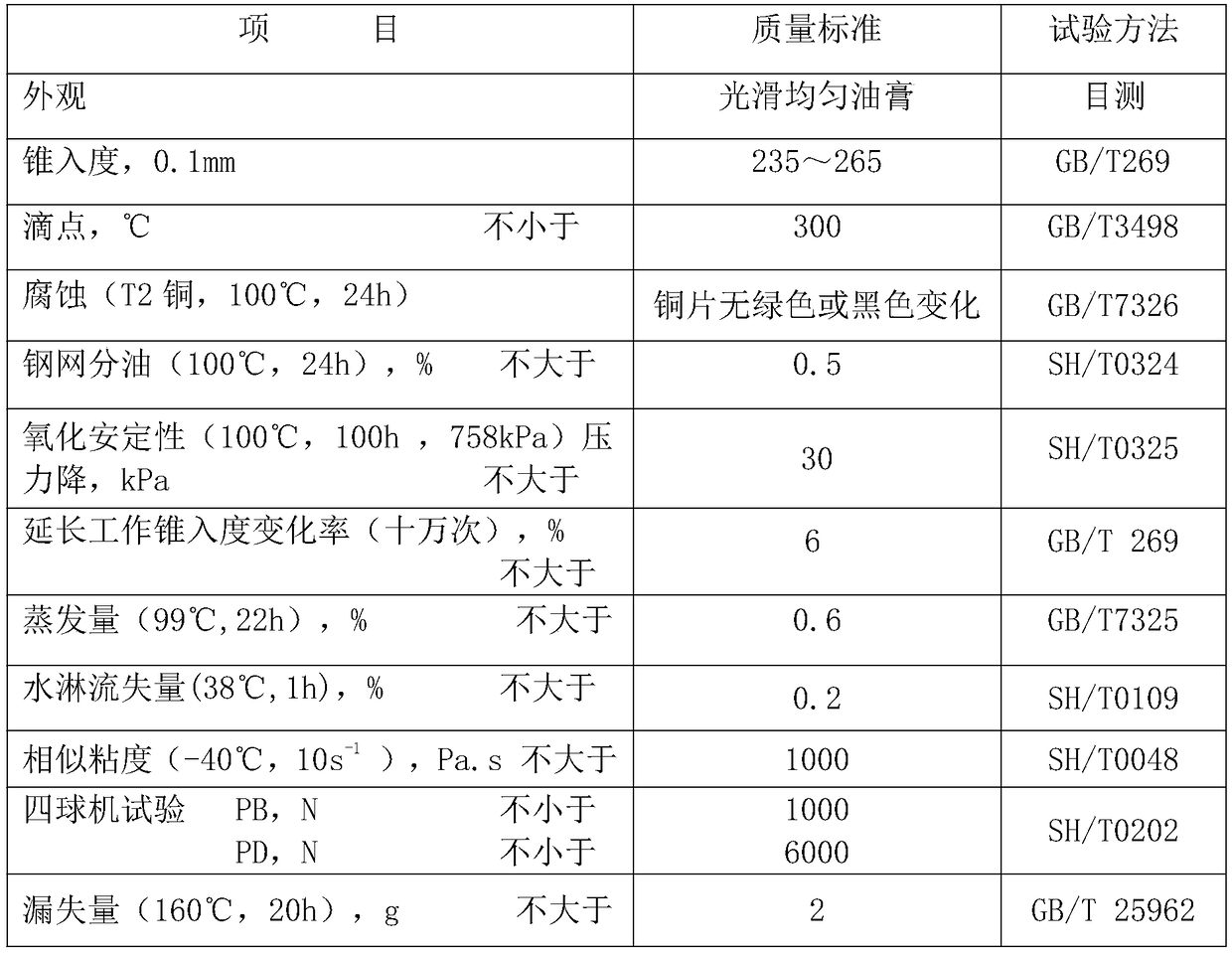

Composite of food-grade compound calcium sulfonate-base lubricating grease and preparation method thereof

InactiveCN102899134AImprove high temperature resistanceImprove shear stabilityThickenersCalciteStearic acid

The invention relates to a composite of food-grade compound calcium sulfonate-base lubricating grease and a preparation method of the composite. The preparation method comprises the following steps of: feeding mixture of 40-60% synthesized calcium sulfonate with high base number, water and ethanol into a reaction kettle, stirring and heating to 60-80DEG C, adding 0.5-2% of acetic acid to convert calcium carbonate with a calcite structure, adding 1-5% of calcium hydroxide and 2-5% of stearic acid under 90-100 DEG C after 1h of constant temperature, carrying out saponification reaction for 120min, rising temperature after saponification, adding 1-5% of calcium borate after 1h of 130-140 DEG C constant temperature, rising the temperature to 180-200DEG C keeping constant temperature for 5-10min, cooling the temperature to 100-110DEG C, adding 0.2-1.5% of antioxygen, homogenizing, adjusting thickness by adding base oil, degassing in a filtering way, and filling to form finished products. The dropping point of the composite provided by the invention is more than 300DEG C, the 0.1-milliom times shear difference value is within 20, and the PD (potential difference) value is not less than 400kg.

Owner:CHINA PETROLEUM & CHEM CORP

Excellent carbamido lubricating grease composition with shear stability and preparation method thereof

The invention discloses an excellent carbamido lubricating grease composition with shear stability and a preparation method of the carbamido lubricating grease composition. The carbamido lubricating grease provided by the invention comprises: (a) base oil, (b) a carbamido thickening agent, and (c) a surfactant, wherein the carbamido thickening agent is generated by a reaction of two or more kinds of diisocyanates, mono-aromatic amine and fatty amine; and borate oil, an extreme pressure antiwear agent containing sulfur, an antioxidant, an antirusting agent and the like are added to improve various performances of the carbamido lubricating grease. The carbamido lubricating grease prepared by the preparation method provided by the invention has good mechanical stability, water-resistance, heat resistance, extreme pressure abrasion resistance, pumping performance and the like, can be applied to the lubrication and the protection of a turret, a crystallizer, a segment roller bed, a withdrawal and straightening unit, a pendulum shear and a conveying roller of metallurgy continuous casting equipment, and is also applied to the lubrication of a tandem mill, bearings of friction parts of high-temperature heavy-duty equipment and the like.

Owner:杭州得润宝油脂股份有限公司

Tetra-urea lubricating grease and preparation method thereof

The invention provides a tetra-urea lubricating grease and a preparation method thereof. The tetra-urea lubricating grease comprises lubricating oil basic oil and a tetra-urea thickening agent, and does not contain di-urea thickening agent and fatty acid metal salt. In the preparation method, the tetra-urea lubricating grease is obtained by the reaction of diisocyanate, diamine and monoamine. Compared with the di-urea lubricating grease, the tetra-urea lubricating grease has higher dropping point, better extreme pressure property, colloid stability and shearing stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified SiO2 lubricating grease and preparation method thereof

The invention discloses a modified SiO2 lubricating grease and a preparation method thereof. The modified SiO2 lubricating grease comprises the following components by mass: 8-12% of a thickening agent, 45-65% of base oil, and 3-5% of a modifier. The thickening agent is industrial SiO2, the base oil is NBR silicone oil, dimethicone and PAO-40 oil, and the modifier is silanol. The preparation method includes: putting 45-65% of base oil into a reaction kettle, raising the temperature to 155-160DEG C, adding 3-5% of the modifier, further raising the temperature and fully mixing the materials to make the modifier fully dissolved in the base oil; and when the temperature is raised to 160-165DEG C, adding 8-12% of the thickening agent, stirring the mixture uniformly, and carrying out oil rolling by a three-roller grinding mill, thus obtaining the modified SiO2 lubricating grease. According to the invention, the industrial product SiO2 with small particle size, large specific surface area and controllable surface is adopted as the thickening agent, thus facilitating quick formation of a grid structure and reaching a new equilibrium state. Thus, the obtained SiO2 lubricating grease has good storage stability and shear stability. By using silanol as the modifier, the compatibility of SiO2 particles and the base oil is enhanced.

Owner:WUXI FEITIAN GREASE

Full-synthetic continuously variable transmission (CVT) transmission fluid as well as preparation method and application thereof

InactiveCN103725385AImprove performanceImprove viscosity indexAdditivesAlkaline earth metalClearing Agent

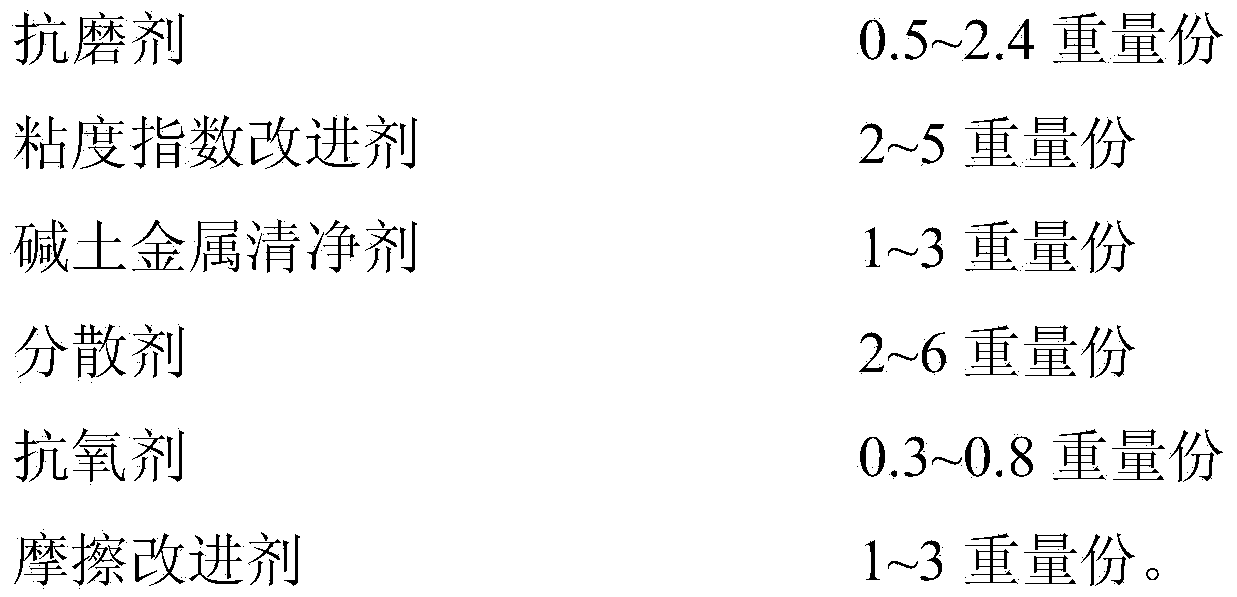

The invention belongs to the technical field of automobile transmission and discloses full-synthetic continuously variable transmission (CVT) transmission fluid as well as a preparation method and application thereof. The transmission fluid comprises the following components in parts by weight: 100 parts of type IV base oil, 0-20 parts of type V base oil, 0.5-2.4 parts of an anti-wear agent, 2-5 parts of viscosity index improvers, 1-3 parts of an alkaline-earth metal clearing agent, 2-6 parts of a dispersing agent, 0.3-0.8 part of an antioxidant and 1-3 parts of a friction modifier. The full-synthetic continuously variable transmission transmission fluid has excellent comprehensive performance, has excellent viscosity index, oxidation stability, shear stability, wear resistance, low-temperature resistance and high transmission efficiency, and can simultaneously meet strict service requirements of various CVTs.

Owner:SOUTH CHINA UNIV OF TECH

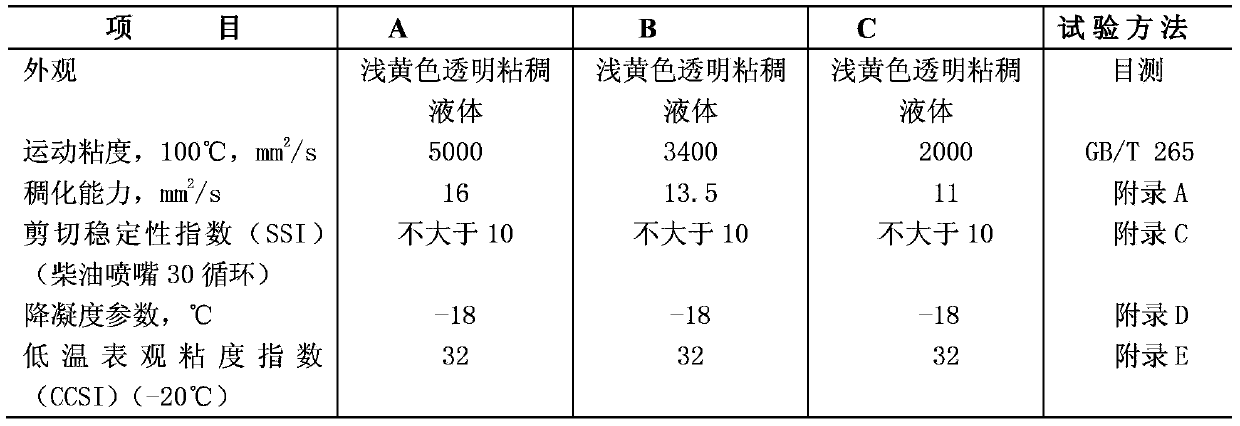

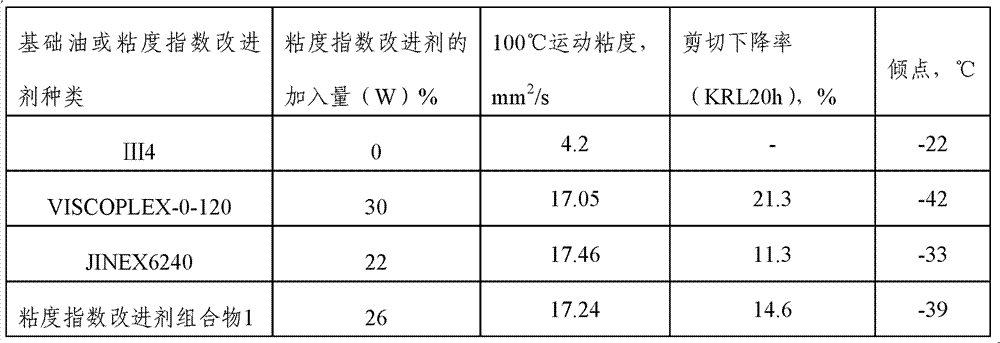

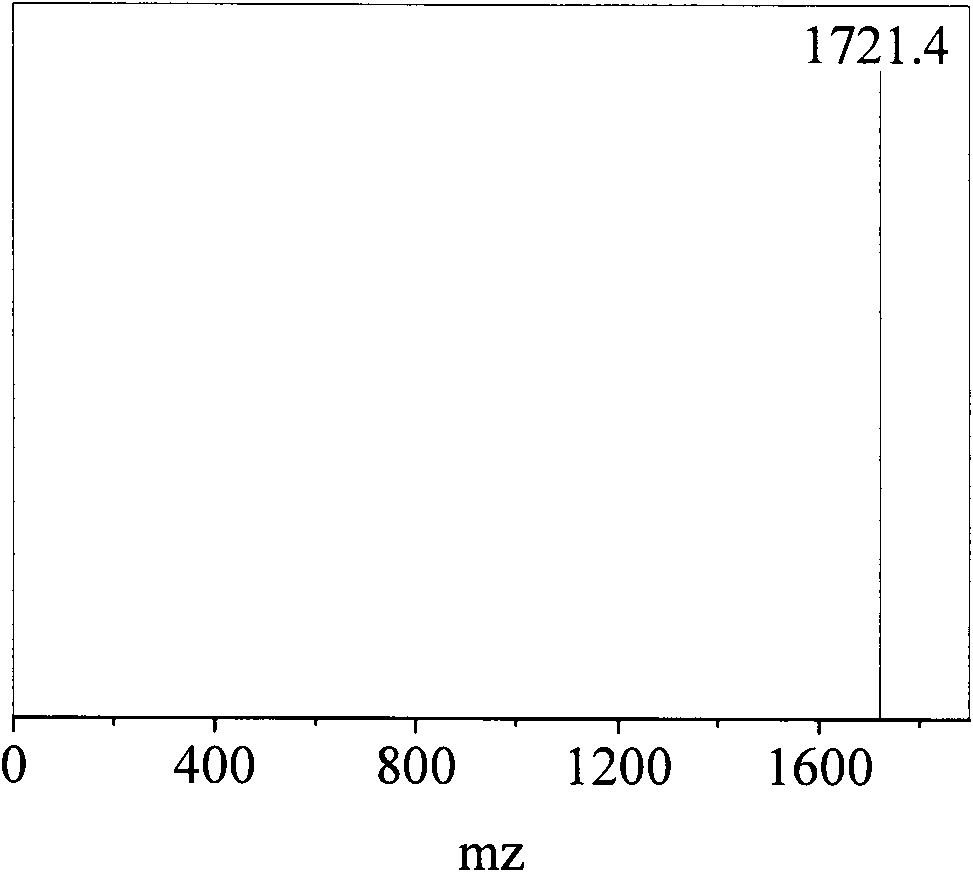

Viscosity index improver for recombined type lubrication oil

The invention discloses a viscosity index improver for recombined type lubrication oil. The improved viscosity index improver for the lubrication oil is at least composed of the following components by weight: 0.1-30% of an ethylene-propylene copolymer (Olefin Copolymer, OCP), 0.1-30% of a styrene or styrene / conjugated diene (butadiene, isoprene) polymer (HSD) and 40-99.8% of base oil, wherein the olefin copolymer is grafted or mixed with a styrene or hydrogenated styrene / conjugated diene polymer. The olefin copolymer is grafted or mixed with the styrene or hydrogenated styrene / conjugated diene polymer; thickening capacity, shearing stability and low temperature viscosity of the viscosity index improver can be effectively improved through hydrocarbon recombination of the above two materials; at the same time, a viscosity index improver-adding amount can be greatly reduced; and production cost is reduced.

Owner:SHENZHEN KUNVII PETROCHEMICAL TECH CO LTD

Preparation method of high shear stability lithium grease

InactiveCN101619260AOvercoming the defects of uneven growthImprove shear stabilityAdditivesBase-materialsLithiumMechanical equipment

The invention discloses a preparation method of high shear stability lithium grease, comprising the following steps: saponifying, heating to dehydrate, refining at high temperature, quenching sharply to mix, standing, mixing into grease, shearing, homogenizing, re-shearing and deaerating. The preparation method of high shear stability lithium grease adds the steps of standing and recutting and overcomes the defect of uneven growth of soap fibers in the traditional lithium grease production technology, and the length of the soap fibers has a proper proportion, therefore, a three-dimensional cavity formed by the soap fibers can absorb a large amount of base oil, and an orienting arrayed crystal fiber structure is formed. When the good colloid stability of the lithium grease is ensured, the lithium grease has prominent high shear stability, the penetration change rate of 100 thousand time extended work is less than 8 percent, a bearing grease exchanging period can be extended above 2000 hours / time from 500 hours / time generally, and the service life of mechanical equipment can be prolonged by 4-5 times.

Owner:安徽中天石化股份有限公司

Ball grinding mill bearing bush lubricating oil and manufacturing method thereof

ActiveCN102559347AImprove the lubrication effectReduce the temperatureBase-materialsPolyesterEngineering

Ball grinding mill bearing bush lubricating oil and a manufacturing method thereof solve the problem that a ball grinding mill bearing bush is poor in lubrication in the severe environment. The ball grinding mill bearing bush lubricating oil is formed by using synthetic oil as base oil and refining multiple added efficient composite additives, has the advantages of being abrasion-resisting, high-temperature-resisting, oxidation-resisting, firm in formed film and the like, and can repair wire drawing and reduce abrasion and bearing bush temperature at fastest speed. The work efficiency and the product quality are improved obviously, the repair and maintenance costs are reduced, the service life of a device is prolonged, and energy consumption is reduced greatly. The ball grinding mill bearing bush lubricating oil is composed of, by mass, mineral lubricating oil 49%-69%, polyester synthetic oil 20%-40%, thickening agent 0.05%-0.15%, organic molybdenum composite additive 2.5%-4.5%, T306 additive 1%-3%, T202 antioxygen 0.4%-0.6%, T551 metal deactivator 0.7%-0.9% and T704 antirust additive 0.6%-0.8%, wherein the summation of the components is a hundred percent.

Owner:洛阳正本润滑材料有限公司

Lubricating grease for shear-resistant bearings, and preparation method thereof

InactiveCN107603716AImprove shear stabilityImprove wear resistanceLubricant compositionDiphenylmethaneAntioxidant

The invention relates to a lubricating grease for shear-resistant bearings, and a preparation method thereof. The preparation method comprises the following steps: adding diphenylmethane diisocyanateand a part of base oil into a reaction kettle A according to a ratio of a polyureido group to a lithium base being 1:8 to 1:10, heating the reaction kettle to 50 DEG C, adding two amines molten by a part of the base oil after the diphenylmethane diisocyanate is completely molten, carrying out a reaction, heating the reaction kettle A to a refining temperature of 90 DEG C, keeping the temperature unchanged for 1 h, adding the remaining base oil and all 12-hydroxystearic acid into a reaction kettle B, heating the reaction kettle to 80 DEG C, pouring the obtained mixture into the reaction kettleA after the 12-hydroxystearic acid is completely molten, and dropwise adding an aqueous solution of LiOH into the reaction kettle A to carry out saponification for 0.5 h; adding 0.1% of water after the saponification is finished, and heating the reaction kettle A to 185 DEG C; and keeping the temperature unchanged for 1-2 h, adding an antioxidant, naturally cooling the reaction kettle to 85 DEG C,adding other additives, uniformly stirring above substances, carrying out rolling oil fine filtration, and filling the finished degassed finished product.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method of ethylene propylene copolymer used for modifying lubricating oil

InactiveCN1427016AChange the viscosity-temperature performanceGood viscosity and temperatureBase-materialsHydrogenSolvent

A process for preparing the ethylene-propylene copolymer used to modify lubricating oil includes such steps as heating hexane to 10-50 deg.C, introducing the gas mixture of ethylene, propylene and hydrogen gas in a polyreactor while adding acetylacetone vanadium as catalyst and halogenated alkylaluminium as cocatalyst, stirring while reaction for 1-3 hr until reaction finished, adding methanol for termination, washing with alkali solution, and vacuum drying.

Owner:PETROCHINA CO LTD

Automobile seat motor regulator lubricating grease

InactiveCN104403736AReduce coefficient of frictionImprove carrying capacityLubricant compositionLithium soapCar seat

The invention relates to the lubricating grease technical field, and particularly relates to an automobile seat motor regulator lubricating grease formula and a preparation process thereof. The lubricating grease is prepared from the following components by the weight percentage: 55-80% of poly-alpha-olefin synthetic oil, 8-20% of a lithium soap powder, 5-15% of liquid silica gel, 3-8% of a solid additive, 0.5-3% of an antioxidant, 0.1-5% of an anti-wear and extreme-pressure agent, and 1-3% of an anti-rust agent. Compared with the prior art, the lubricating grease has the beneficial effects of extremely small friction coefficient, excellent bearing capacity, excellent wear resistance, wide range of operation temperature, extremely low evaporation loss and diffusivity, excellent oxidation resistance stability, excellent shear stability, excellent mechanical stability, extremely long service life, excellent anti-water and anti-corrosion abilities, excellent vibration attenuation, excellent noise reduction, and good compatibility with the vast variety of plastics and elastic colloids.

Owner:WUXI FEITIAN GREASE

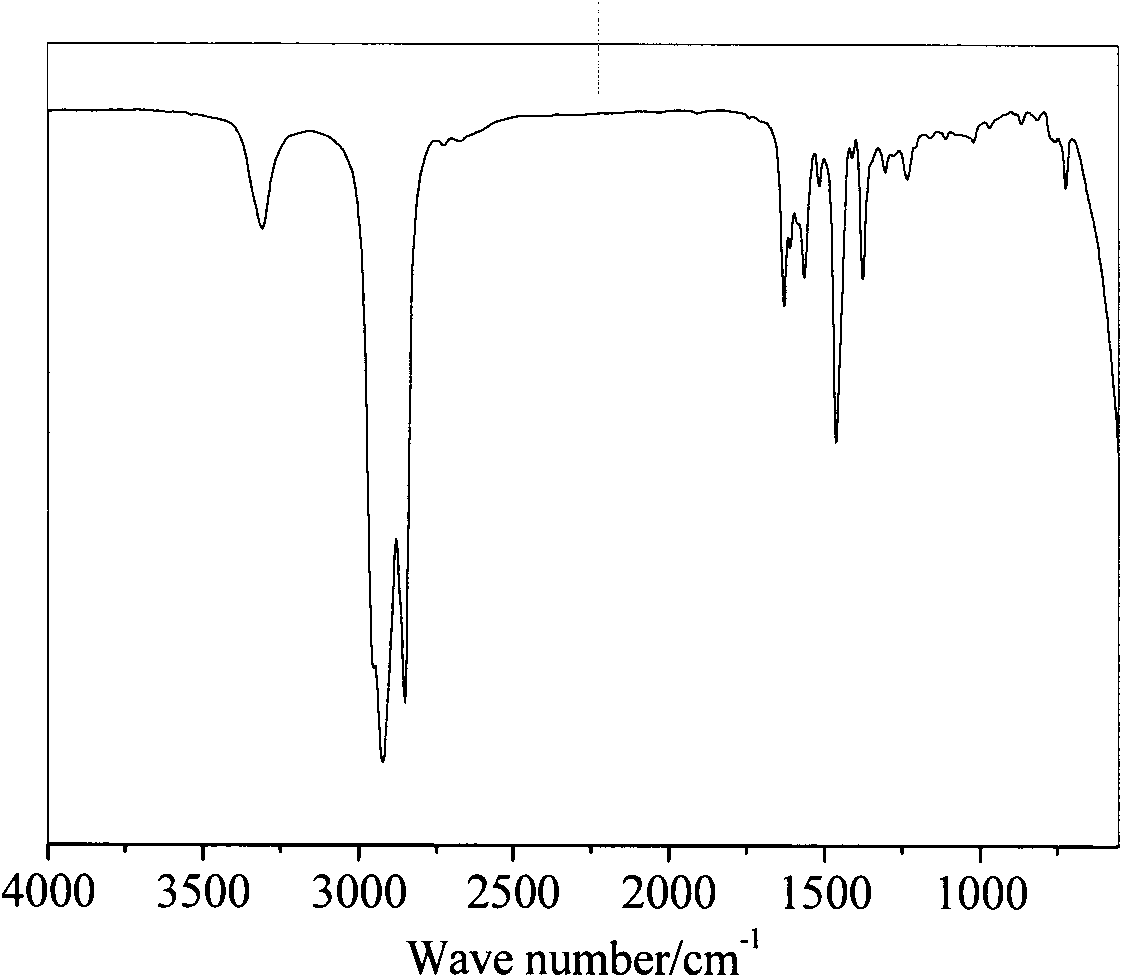

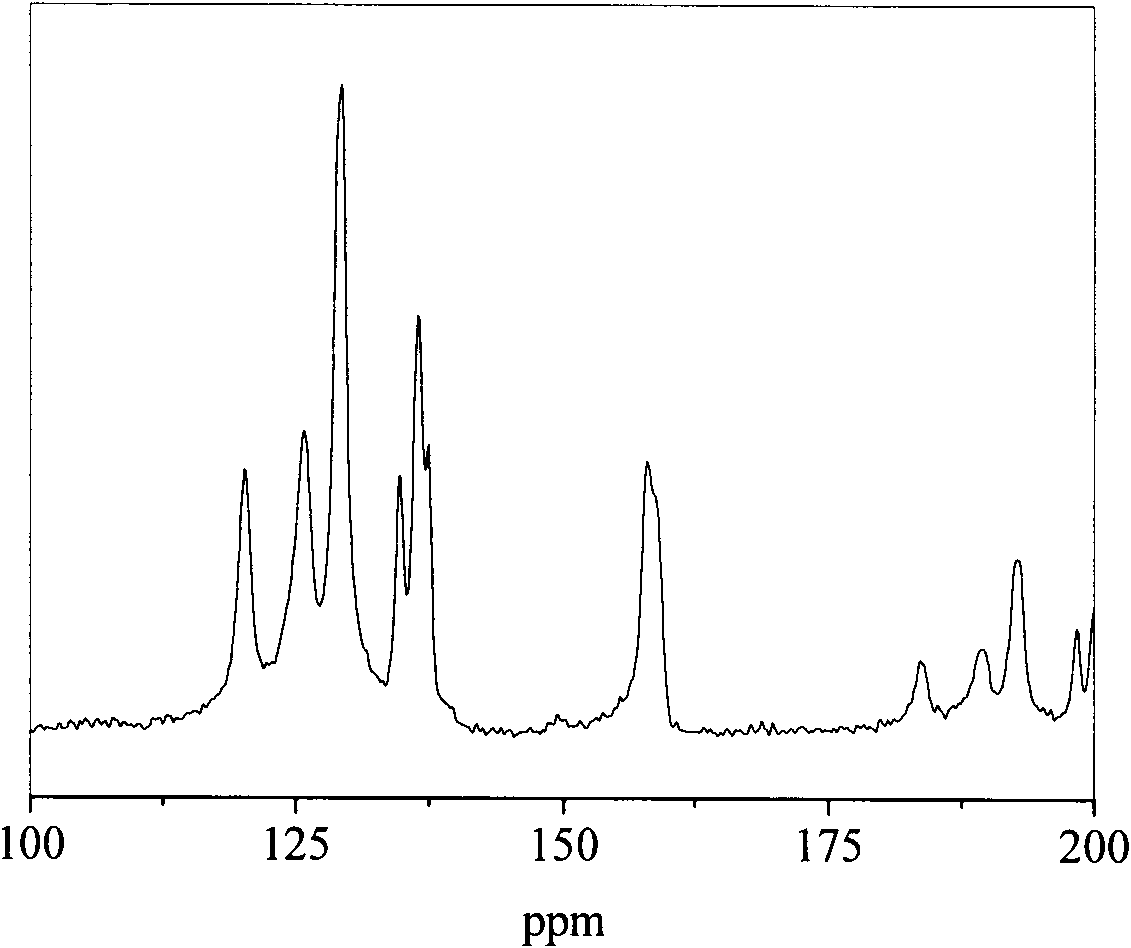

Viscosity index improver composition and application thereof

ActiveCN103087803AImprove low temperature performanceHigh viscosity indexLubricant compositionViscosity indexBase oil

The invention provides a viscosity index improver composition, comprising the following components by weight: 10-90% of polymethacrylate, 10-90% of polyisobutylene and 0-20% of base oil. The viscosity index improver composition provided by the invention can be used in gearbox or vehicle gear oil, and has a good shearing stability and low temperature performance.

Owner:CHINA PETROLEUM & CHEM CORP

8-uril grease lubricant and its preparation method

An 8-uril grease lubricant contains, by weight, 70-90% of lubricating base oil and 10-30% of an 8-uril densifier calculated according to the total weight of the grease lubricant being 100%. The preparation method of the 8-uril grease lubricant provided by the invention comprises a step of respectively performing reactions between diisocyanate and diamines and between diisocyanate and monoamines to obtain the 8-uril grease lubricant. In comparison with a 2-uril grease lubricant, the 8-uril grease lubricant has higher dropping point, better extreme pressure performance, colloid stability and shearing stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

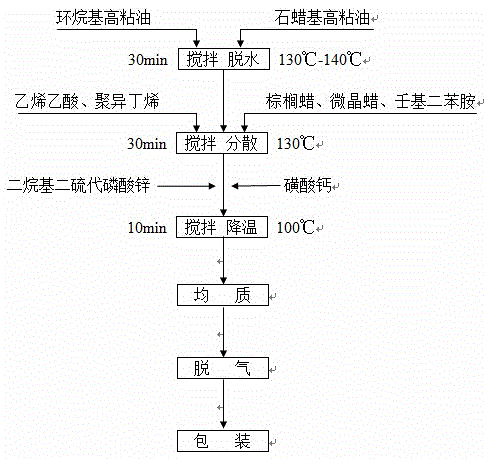

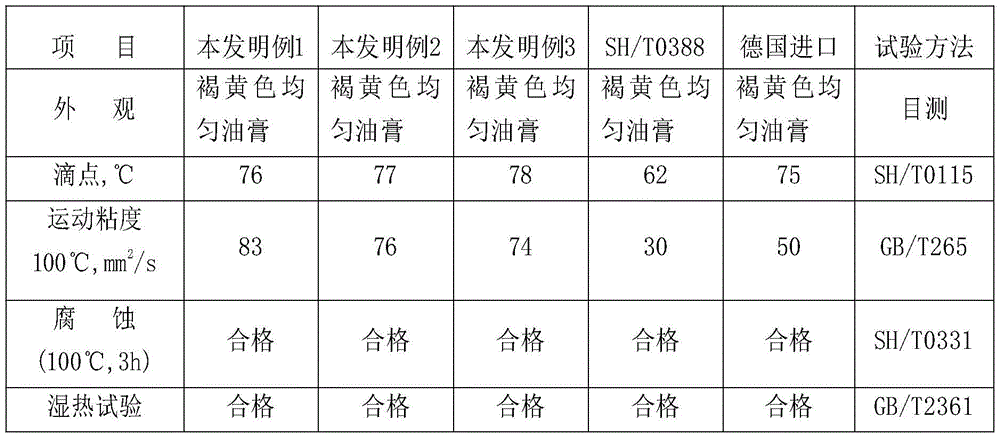

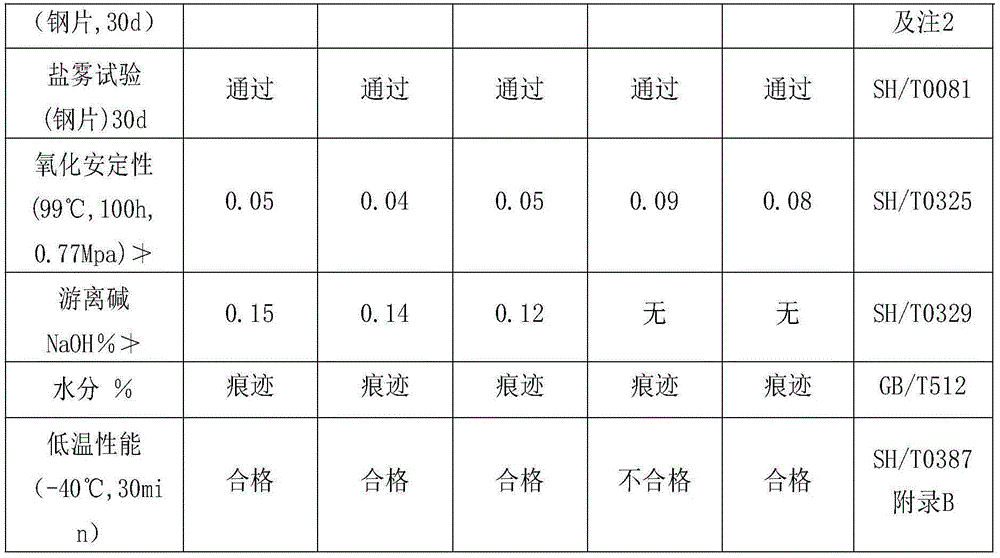

Long-acting wire rope hemp core grease

InactiveCN105542924AGood compatibilityHigh melting point (dropping point)Textile cablesLubricant compositionParaffin waxMicrocrystalline wax

The invention relates to a long-acting wire rope hemp core grease. The long-acting wire rope hemp core grease comprises 13-17wt% of palm wax, 16-19wt% of microcrystalline wax, 15-19wt% of naphthenic high-viscosity oil, 24-28wt% of paraffinic high-viscosity oil, 1.6-4.6wt% of zinc dialkyl dithiophosphate, 1.4-4.4wt% of nonyldiphenylamine, 4.5-8.5wt% of vinylacetic acid, 8.5-12.5wt% of polyisobutylene and 0.1-1wt% of calcium sulfonate. Compared with hemp core greases in the prior art, the long-acting wire rope hemp core grease has the advantages of high dropping point, no flowing in hot weather, fast online solidification after rope immersion, no loss, energy saving, no pollution to environment, large kinematic viscosity data, good adhesiveness, and realization of good fluidity and no flowing of a grease film in the motion and compressed processes. Prominently, the property of traditional hemp core greases (including imported hemp core greases) is changed to become weakly alkaline (the free base value is not greater than 0.15, NaOH%), so oxidation is effectively inhibited, generated free acids are neutralized, SH / T0325 oxidation stability test and SH / T0331 corrosion test are extremely well passed, the safe service life of a wire rope is effectively prolonged, and use environment is purified.

Owner:GUANGZHOU ROSTON PETROCHEM CO LTD

Modified complex calcium sulfonate grease and preparation method thereof

ActiveCN104711080BImprove shear stabilityImprove water resistanceLubricant compositionAlkalinityCalcium hydroxide

Owner:埃优诺特种新材料科技(山东)有限公司

Composite calcium-based lubricating grease and preparation method thereof

ActiveCN111718778AImprove anti-friction and anti-wear effectGood extreme pressure and anti-wear propertiesLubricant compositionCalcium biphosphateCalcium pidolate

The invention relates to novel composite calcium-based lubricating grease and a preparation method thereof. The novel composite calcium-based lubricating grease is prepared from, by weight, 50-80% ofa base liquid, 20-40% of a novel composite calcium-based composite calcium soap thickening agent and 0.1-5% of a function improvement additive. The novel composite calcium-based lubricating grease ischaracterized in that the novel composite calcium-based thickening agent is adopted, a calcium phenylborate-calcium phosphate component is introduced to improve the friction and wear resistance and the antioxidant stability of the composite calcium-based thickening agent and improve the storage hardening problem of the composite calcium-based lubricating grease, and meanwhile, the characteristicsof excellent extreme pressure wear resistance, mechanical stability, water resistance and the like of the composite calcium-based thickening agent are fully utilized, so that the prepared novel composite calcium-based lubricating grease can meet the use requirements of high temperature, high speed, high reliability and long service life of the hub bearing of the heavy-duty vehicle.

Owner:长沙众城石油化工股份有限公司

High-viscosity high-pressure antiwear hydraulic oil

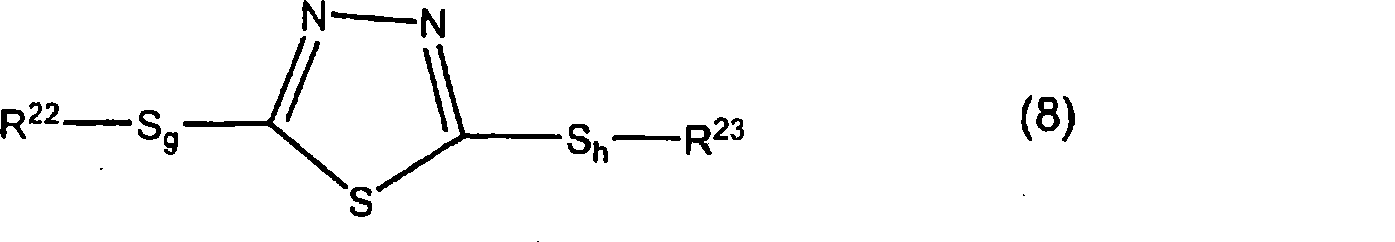

InactiveCN104673443AImprove shear stabilityStrong demulsification abilityLubricant compositionAntioxidantHigh pressure

The invention discloses a high-viscosity high-pressure antiwear hydraulic oil which is prepared from the following raw materials in parts by weight: 30-50 parts of base oil, 8-16 parts of diisodecyl sebacate, 4-8 parts of polymethacrylate (PMA), 3-9 parts of dustless dithiophosphate, 2-14 parts of thiadiazole derivative, 3-6 parts of arylamine antioxidant, 1-6 parts of sulfonate, 2-4 parts of high-base-number sulfurized calcium alkyl phenate, 6-12 parts of vulcanized isobutylene, 2-8 parts of pentaerythritol ester, 7-10 parts of vulcanized isobutylene, 2-4 parts of di-n-butyl phosphite and 1-6 parts of di-tert-butyl-para-cresol. The high-viscosity high-pressure antiwear hydraulic oil has the advantages of favorable demulsibility, favorable hydrolytic stability, favorable heat stability, favorable filterability, outstanding wear resistance and obvious energy-saving effect.

Owner:QINGDAO KERUN PLASTIC MACHINERY

Gear oil composition, gear oil and preparation method of gear oil

InactiveCN108913313AGood viscosity and temperatureGood thermo-oxidative stabilityBase-materialsAgricultural engineeringPerformance index

The invention provides a gear oil composition, gear oil and a preparation method of the gear oil, wherein the gear oil composition comprises a high-branched polyethylene synthetic base oil and additives, wherein the weight average molecular weight of high-branched polyethylene is 280-20000, and the branched degree of the high-branched polyethylene is 0.15-0.5. The gear oil prepared by the gear oilcomposition provided by the embodiment of the invention has the advantages of excellent viscosity-temperature properties, wear resistance, thermal oxidation stability, good shear stability, good extrusion resistance, good foam resistance, good corrosion resistance, good rust resistance, and good comprehensive performance; and the preparation method is simple, the production cost is low, the performance indexes can meet application requirements, and the gear oil has wide application scope.

Owner:HUZHOU MAILONG MACHINERY CO LTD

Composite briquette binder

ActiveCN110747029APromote productionGuaranteed stabilitySolid fuelsWaste based fuelSodium aluminosilicateChemistry

The invention discloses a composite briquette binder, and belongs to the field of briquettes. Lithium-based lubricating grease, sodium-based bentonite, sodium aluminosilicate and the like are taken asraw materials to prepare a briquette binding material A, wherein the lithium-based grease has good fretting-wear-resisting performance, and while providing hydrophobicity and permeability effects andthe stable thermal effect, added hydrogen-containing silicone oil also possibly assists in providing the bonding stability of a blend, improves the bunching effect on pulverized coal particles and steadily improves the thermal effect and formation effect of the briquettes; and fish skin, rice straw, Lactobacillus bulgaricus and the like are blended and fermented, fish skin tissue and straw tissueare destroyed by microbial metabolism to obtain gum and saccharides, and thus the carbon content is increased while cohesiveness is ensured. The problems of high ash content, low carbon content and poor structural stability of the briquettes prepared through a briquette binder commonly used at present are solved.

Owner:曲阳县建硕型煤有限公司

Heavy load bearing lubricating grease and preparation method thereof

The invention discloses heavy load bearing lubricating grease which comprises the following raw materials in parts by weight: 8-10 parts of octadecylamine, 4-6 parts of MDI (diphenylmethane-4,4'-diisocyanate), 8-10 parts of macromolecule fatty acid, 6-8 parts of low molecular acid, 7-8 parts of lithium hydroxide, 20-25 parts of water, 60-80 parts of base oil A, 40-60 parts of base oil B, 0.2-0.5 parts of an antioxidant A, 0.6-0.8 parts of an antioxidant B, 0.2-0.4 parts of an antirust agent, 0.2-0.5 parts of an extreme pressure anti-wear agent A, 1-2 parts of an extreme pressure anti-wear agent B, 5-15 parts of a tackifier, 2-3 parts of a stabilizer and 6-8 parts of a structure improver. Except the heavy load bearing lubricating grease disclosed by the invention is excellent in high temperature resistance, lubricating property, adhesivity, pumpability, oxidation stability and heat stability, the heavy load bearing lubricating grease is more excellent in shear stability, colloid stability, water resistance and extreme pressure anti-wear property.

Owner:安徽中天石化股份有限公司

High extreme pressure lithium-based lubricating grease

InactiveCN103937591AImprove water resistanceReduce churnLubricant compositionAntioxidantLithium hydroxide

The invention relates to high extreme pressure lithium-based lubricating grease. The production process comprises the following steps: adding 1 / 2 of base oil high-viscosity mineral oil, fatty acid, lithium hydroxide and calcium hydroxide according to the stipulated mixture ratio in parts by weight, performing saponification reaction at the temperature of 100 DEG C, then adding the heated oil, namely the remaining 1 / 2 of the base oil high-viscosity mineral oil, heating to 200 DEG C to the greatest extent to perform high-temperature refining, then cooling to 180 DEG C, further cooling to 110 DEG C, adding an antioxidant, an extreme pressure agent, an oily agent and a tackifier, then performing post-treatment by using a homogenizer or a cyclic shearing machine, filtering and packaging. Tests prove that the grease becomes thin when meeting water, the thinness is far less than that of traditional extreme pressure lithium, the grease is less prone to loss and can provide good anti-rust protection for bearings, when the water content in the grease is 15%, the extreme pressure performance is reduced to a smaller extent and higher than the extreme pressure performance of the traditional extreme pressure lithium grease, the bearings are not worn at all, the production is not affected, and the grease is very suitable for high load, high temperature, high speed and much water working conditions of the bearings.

Owner:青州市东能润滑油脂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com