Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

286results about How to "Good mechanical stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based epoxy zinc-rich primer

ActiveCN101104771AImprove construction efficiencyGood mechanical stabilityEmulsion paintsEpoxy resin coatingsChemistryCo solvent

This invention relates to a water-based epoxy zinc-rich priming paint. The water-based epoxy zinc-rich priming paint consists of two components, which is prepared by grinding, dispersing and other processes after the main base material of water-based epoxy resin and water-based epoxy curing agent are mixed with zinc powder, filler, additives, co-solvents, water and other ingredients. Safe and convenient in application, the water-based epoxy zinc-rich priming paint has no pollution to the environment and is harmless to the workers. Suitable for high-pressure airless spraying, the water-based epoxy zinc-rich priming panit is provided with high operation efficiency and a single 10-100um thick coating layer. The priming paint has advantages of fast drying, high mechanical strength of paint film, strong adhension and good anticorrosion performance. The priming paint can be used as an anticorrosion and protection layer of steel structure in ships, bridges and containers as well as priming paint of a workshop.

Owner:V ABC PAINTS MFG JIANGXI CO LTD

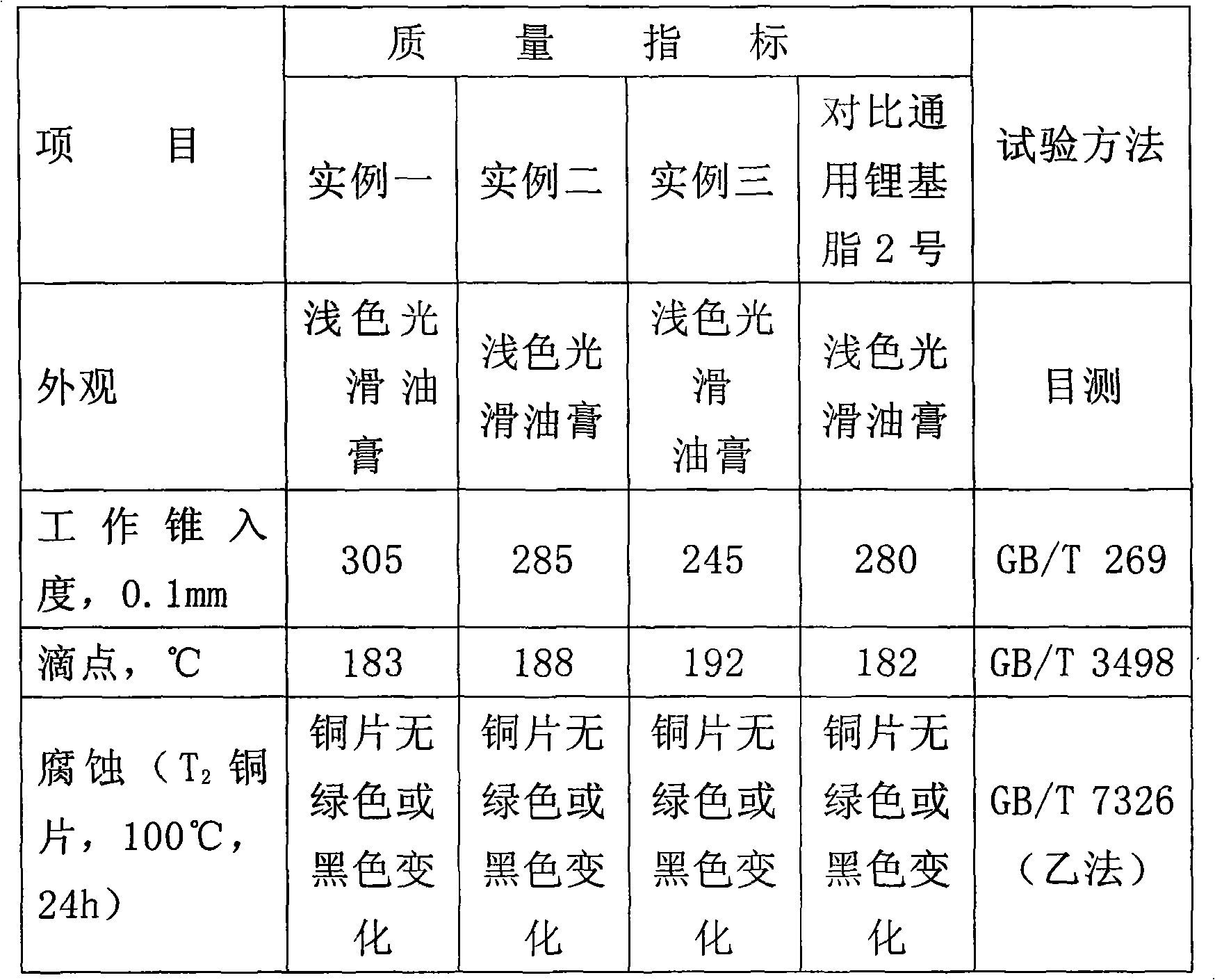

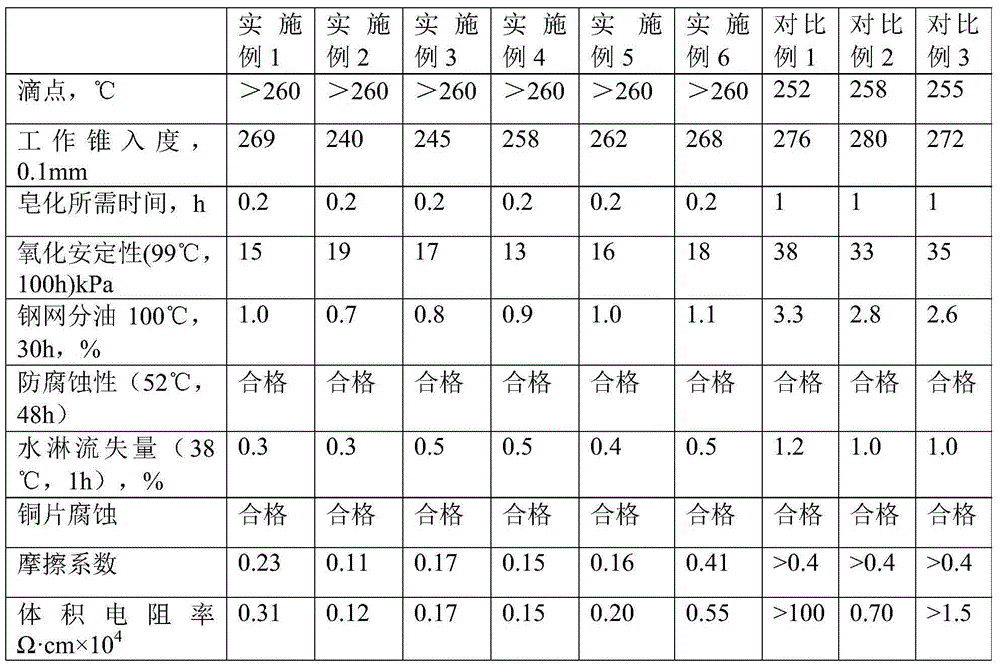

Composite lithium-base grease and method for making same

The present invention provides composite lithium-based lubricating grease and a preparation method thereof. The composite lithium-based lubricating grease consists of thickener, base oil and additive. The thickener consists of 12-hydroxy stearic acid lithium dibasic acid and / or lithium borate, and the mol ratio is 1 ®U 0.1 to 1 ®U 0.1to 1. The base oil is mineral oil or poly-alpha-olefin synthesis oil. The additive consists of organic amine compound antioxidant, benzotriazole and barium petroleum sulfonate or barium dinonylnaphthalene sulfonate anti-corrosion additive and rust protection agent, dialkyl dithiocarbamate or dibenzyl disulfide and sulfurized olefin cottonseed oil extreme pressure antiwear additive and nanometer copper powder repairing additive. The contents of the thickener and the base oil are respectively 6 percent to 18 percent and 82 percent to 94 percent according to the weight percentage. The lubricating grease has the multi-effect performances of high dripping point, good high-temperature performance and low-temperature performance, chemical invariability, colloid invariability, antiwear extreme pressure performance etc., and especially has the repairing function towards a damaged bearing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Projection optical system, exposure apparatus and exposure method

InactiveUS6909492B2Good mechanical stabilityHigh numberProjectorsSemiconductor/solid-state device manufacturingConditional expressionIntermediate image

Disclosed is a projection optical system having relatively large image-side numerical aperture and projection field and being excellent in mechanical stability in respect of vibrations, and the like. The projection optical system includes a first image-forming optical system for forming a first intermediate image of a first surface (R), a second image-forming optical system having a concave reflective mirror and for forming a second intermediate image based on a radiation beam from the first intermediate image, and a third image-forming optical system for forming a final image on a second surface based on a radiation beam from the second intermediate image. Then, predetermined conditional expressions are satisfied with regard to a clear aperture diameter of the concave reflective mirror, a distance (L) between the first surface and the second surface, and a distance (H) between the concave reflective mirror and a reference optical axis.

Owner:NIKON CORP

Optical fiber Fabry-Perot sensor and manufacture method therefore

InactiveCN101034007AGood mechanical stabilityMechanical stability High temperature resistanceFluid pressure measurement by electric/magnetic elementsForce measurementPhysicsSingle-mode optical fiber

This invention relates to a good mechanical stability, high temperature resistant and good optical property optical fiber sensor, includes optical fiber and by-met optical fiber. optical fiber or / and by- met fiber optic end face have micro-flutes, and via butt joint together; The described micro-flute forms a FP cavity which has plain optical reflection surface. The invention adoptive laser machining craft can apply to every kind of optical fiber; be able to cutting optical fiber precisely, and are prone to execute different kinds of range's pressure sensor; optical property of the sensor is very fine; both the two stage optical fiber can be common single mode optical fiber, they are completely compatible; The contrast ratio of sensor's reflecting stripe can reach 10 dB upwards.

Owner:冉曾令

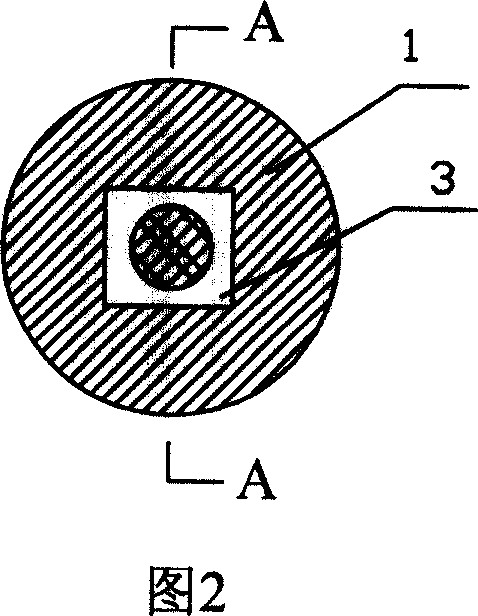

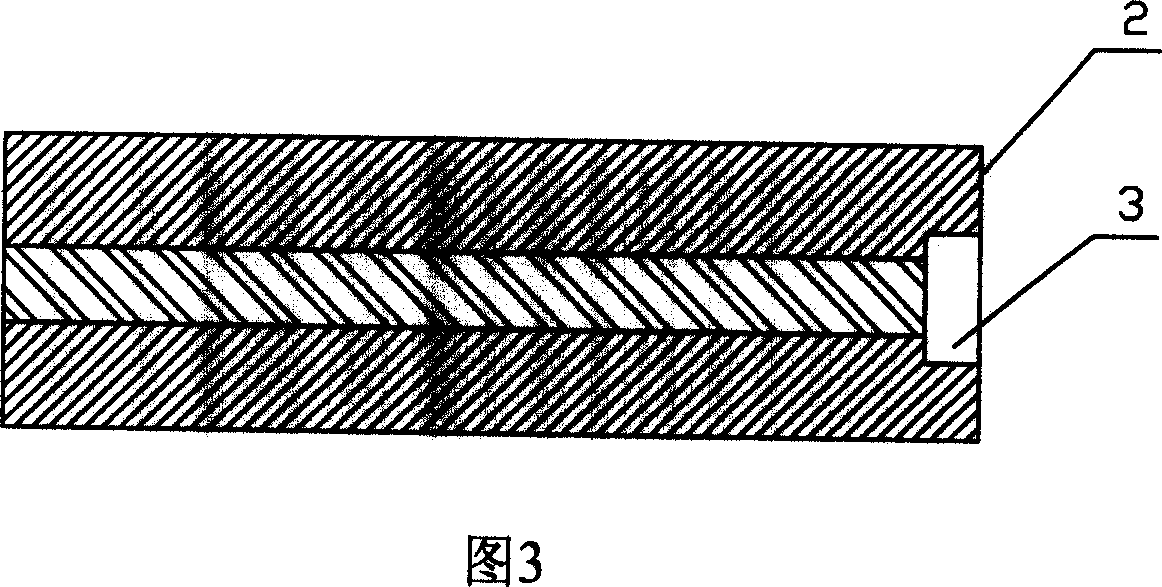

Composite calcium sulfonate lubricating grease composition and preparation method thereof

ActiveCN103740435ADrop point highGood extreme pressure and anti-wear propertiesThickenersChemistryBenzene

The invention relates to a composite calcium sulfonate lubricating grease composition and a preparation method thereof. The composite calcium sulfonate lubricating grease composition is prepared from the following raw materials in percentage by weight: 18 to 44 percent of high-base-number calcium sulfonate, 0.3 to 3 percent of glacial acetic acid, 3 to 8 percent of water for conversion, 1 to 4 percent of alkyl benzene sulfonic acid, 0.1 to 3 percent of calcium carbonate, 1 to 5 percent of fatty acid, 1 to 5 percent of a boric acid solution counted by using boric acid, 1 to 4 percent of a calcium hydroxide solution counted by using calcium hydroxide and the balance of base oil. The composite calcium sulfonate lubricating grease composition has the advantages of high dropping point, good extreme pressure antiwear property, excellent colloid stability and mechanical stability, and has a wide application range. The invention further relates to the preparation method for the composite calcium sulfonate lubricating grease composition.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

Flame-retarded lubricating grease and preparation method thereof

ActiveCN101619261AImprove performanceImprove flame retardant performanceThickenersAdditivesLithium soapAntioxidant

The invention relates to flame-retarded lubricating grease and a preparation method thereof. The preparation method comprises the following technical steps: firstly, putting base oil and an inorganic thickening agent in an open reaction kettle for stirring and mixing, adding a dispersant after heating and heating again to take the mixture out of the kettle for use; secondly, mixing fatty acid calcium soap with the base oil, adding fatty acid lithium soap after heating, keeping heat, dehydrating and refining; finally, removing the materials to a middle kettle, lowering the temperature by cooling, stirring the materials with lubricating grease prepared by the inorganic thickening agent, adding an antioxidant, a flame retardant and an anti-rusting agent for homogenization and filtering to obtain finished products. The lubricating grease not only keeps various excellent properties of original general lithium grease, but also specially enhances the incombustible flame retardance of a 600 DGE C hot plate. Assessment of the properties of the flame-retarded lubricating grease shows that the flame-retarded grease lubricant has excellent mechanical stability, water resistance, lubricating property, anti-rusting property and flame retardance, long service life and low cost, and can replace general lithium grease used in coal mine, subway, metallurgy and other industries at present.

Owner:无锡中石油润滑脂有限责任公司

Aqueous fluoric resin and its prepn and application

InactiveCN1362422AGood chemical stabilityGood mechanical stabilityCoatingsVinyl esterPolymer chemistry

The present invention relates to a water fluororesin, its preparation and applicaltion. It is a multicomponent copolymer containing trifluorochloroethylene (A) and aliphatic carboxylic vinyl ester (B), and its composition contans (by weight portion ratio) A:B: water: emulsifying agent: initiator=15-40:10-70:90-160:0.5-8.0:0.1-1.0. Said invented product possesses good chemical stability and mechanical stability, and can be extensively used in the fields of building industry, wooden ware and paper-making industry, etc.

Owner:大连振邦氟涂料股份有限公司

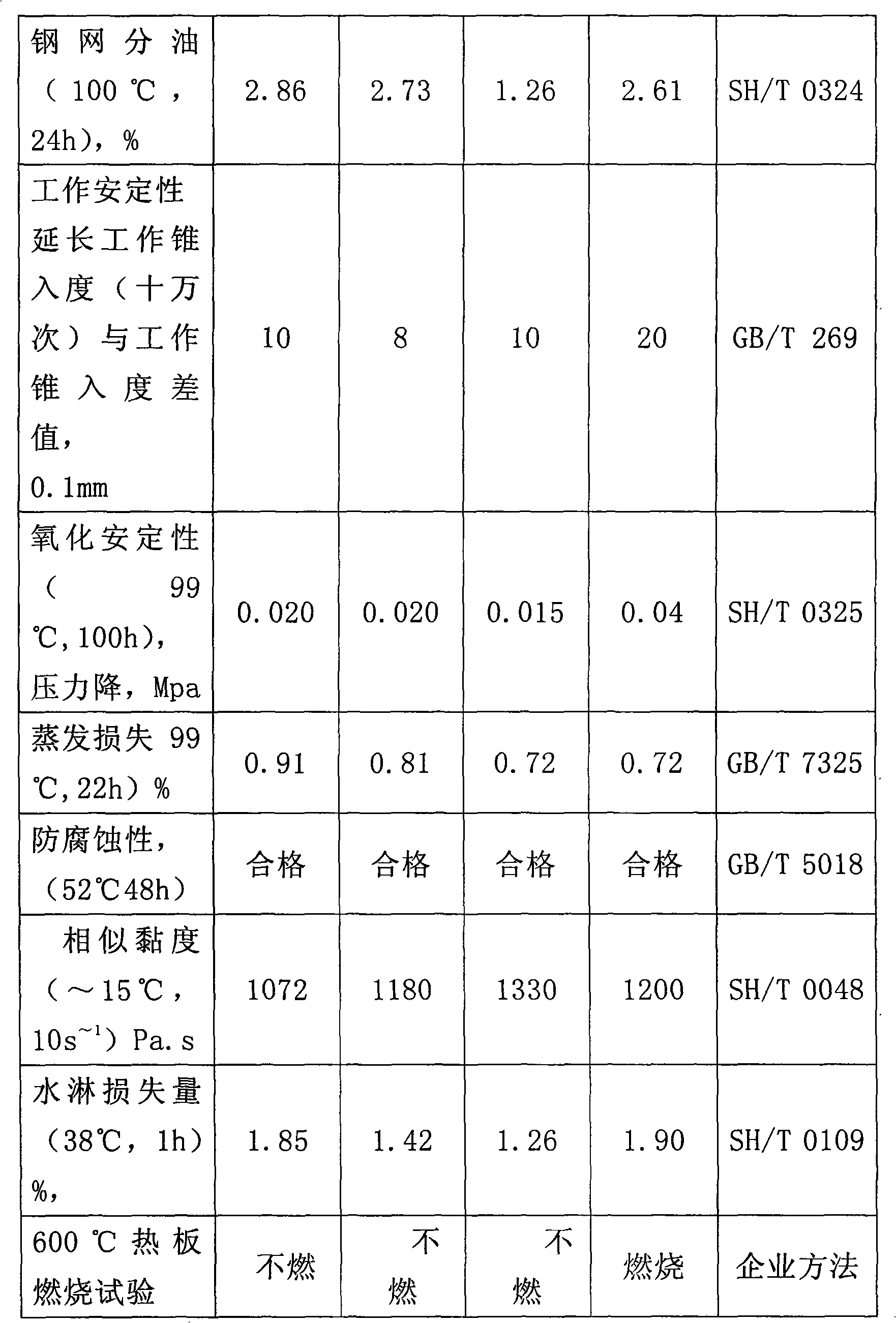

Composite lithium-calcium base lubricating grease and preparation method thereof

ActiveCN102977979AGood mechanical stabilityGood extreme pressure and anti-wear propertiesThickenersWater resistanceLithium

The invention relates to lubricating grease and a preparation method thereof, particularly relates to composite lubricating grease and a preparation method thereof, and belongs to the technical field of chemistry. According to the invention, base oil, thickener and additive are prepared into lithium-calcium base lubricating grease according to a proper ratio; the lithium-calcium base lubricating grease has the characteristics of favorable high temperature property, shear stability, extreme pressure wear resistance, water resistance and the like; and the invention is simple in preparation method, stable in product performance, low in product comprehensive cost and is suitable for large-scale industrial production.

Owner:JIANGSU LOPALTECH

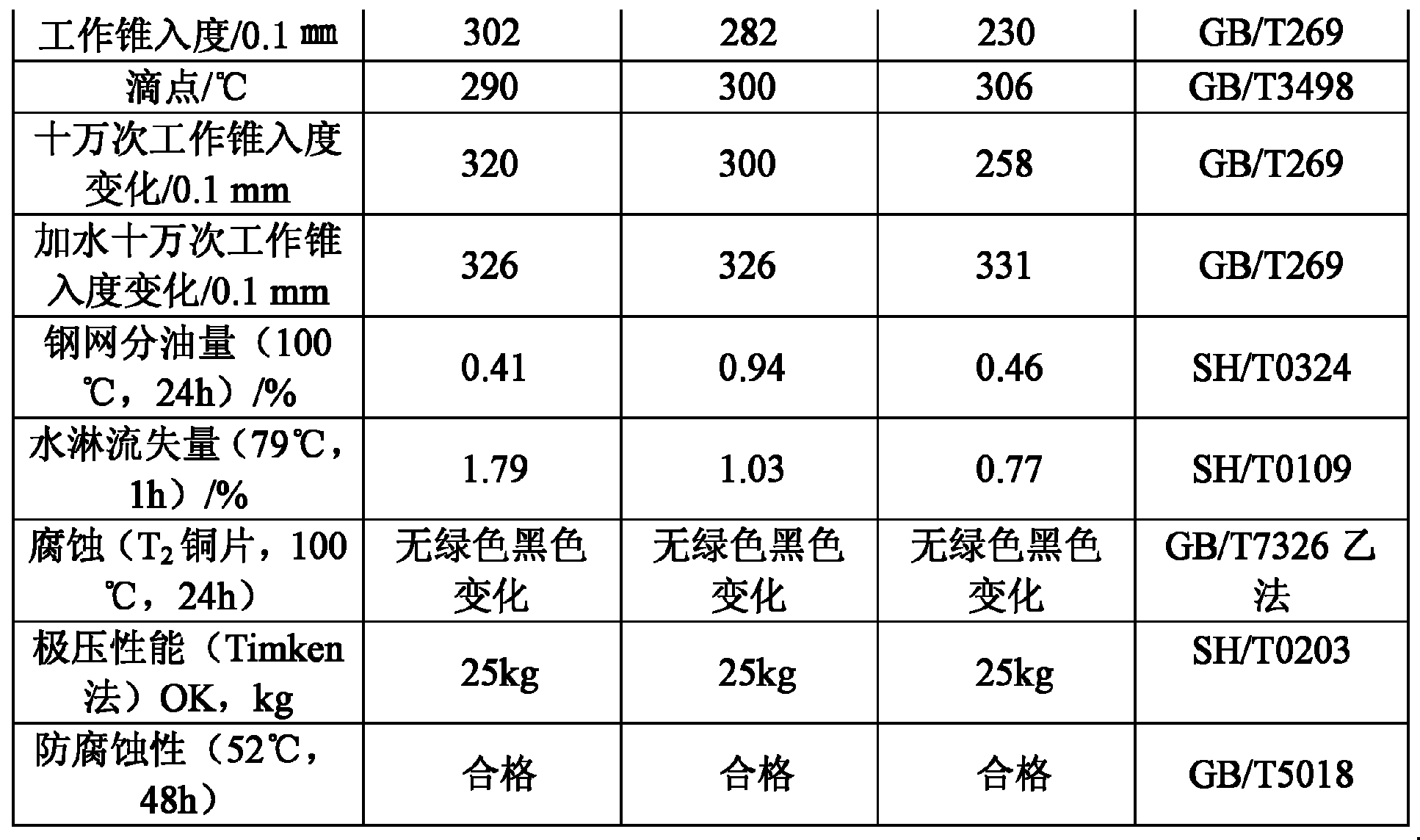

Complex lithium base grease and preparation method thereof

The invention relates to complex lithium base grease and a preparation method thereof. The preparation method comprises the following processes of: adding 1 / 4 of base oil and dibasic organic acid into a reaction kettle, heating and melting, and adding monobasic organic acid for reaction; adding 1 / 4 of base oil, cooling the base oil, and adding lithium hydroxide oil solution for saponification andwarming; adding 1 / 4 of base oil, moving materials in the reaction kettle to an intermediate kettle, adding the rest 1 / 4 of base oil into the intermediate kettle, and circulating and cooling; adding an antioxidant, a corrosion inhibitor and an extreme pressure antiwear additive; and uniformly stirring, homogenizing and degassing to obtain the complex lithium base grease. The complex lithium base grease has a simple process, the time for producing the complex lithium base grease with a normal-pressure kettle is short, energy resources are saved, production cost is reduced, the utilization rate of equipment is improved, and the saponification reaction is quick and full.

Owner:无锡中石油润滑脂有限责任公司

Lubricating grease for hubs of heavy trucks and preparation method for lubricating grease

ActiveCN102618368AStable structureImprove water resistanceLubricant compositionLithium soapHeat resistance

The invention discloses lubricating grease for hubs of heavy trucks. The lubricating grease consists of base oil, thickening agent and additive, the thickening agent is composite lithium soap thickener, and the additive consists of borate oiling agent, compound viscosity index improver, purification dispersant, amine-type antioxidant, sulfur-phosphorous-type antioxidant and sulfonate antirusting agent. The special lubricating grease for hubs of trucks which is obtained by means of circular shearing treatment is excellent in heat resistance, adhesion, mechanical stability, water resistance, extreme pressure abrasion resistance and the like, and can meet requirements on lubrication and protection for bearings of the hubs of the trucks under harsh conditions.

Owner:杭州得润宝油脂股份有限公司

Lithium-calcium complex lubricating grease composition and preparation method

InactiveCN104449983AGood mechanical stabilityGood colloidal stabilityLubricant compositionLithium soapLong chain fatty acid

The invention relates to a lithium-calcium complex lubricating grease composition and a preparation method. The lubricating grease comprises the following components: (1) 60%-87% of base oil; (2) 10%-38% of a thickening agent; and (3) 1.5%-11% of an additive, wherein the thickening agent disclosed by the invention is a lithium-calcium complex thickening agent, comprises one or more long-chain fatty acid lithium soap and one or more micromolecular acid calcium soap, and is obtained from the reactants of acid and lithium hydroxide and calcium hydroxide. The lithium-calcium complex lubricating grease prepared by the method has good mechanical stability, colloid stability, water resistance and good extreme pressure antiwear property; and above all, the hardening phenomenon is not generated under room-temperature long-term storage and high-temperature (120 DEG C) conditions on the basis that excellent performances of the original lithium-calcium complex lubricating grease are reserved.

Owner:CHINA PETROLEUM & CHEM CORP

Composite aluminum base grease and its preparing method

The composite aluminum base grease is prepared with high alkalinity calcium sulfonate 20-50 weight portions, thickener of composite aluminum soap 5-15 weight portions and base oil 35-75 weight portions. The preparation process includes the steps of converting the high alkalinity calcium sulfonate from Netwtonian substance into non-Netwtonian substance; adding stearic acid, benzoic acid and aluminum trimer to prepare composite aluminum soap; heating to refining and cooling to obtain the grease. The composite aluminum base grease has high water resistance, high antirust performance, high extreme pressure resistance, high mechanical stability and high temperature colloid stability.

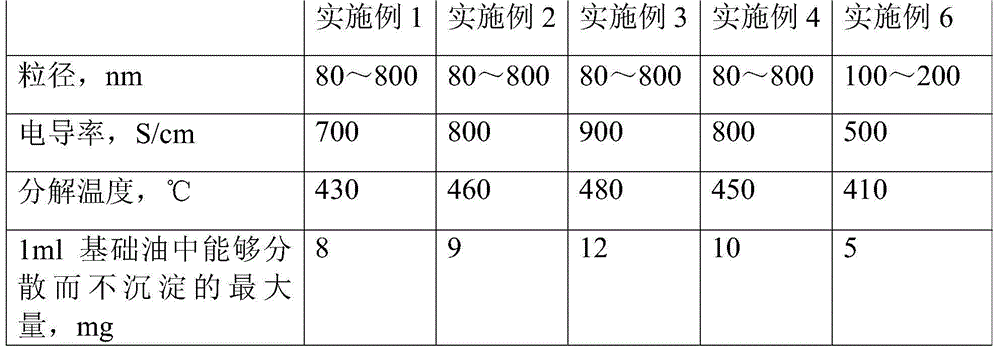

Lithium-based lubricating grease and preparation method thereof

The invention discloses lithium-based lubricating grease and a preparation method thereof. The lithium-based lubricating grease is characterized by being prepared from the following components on the basis of the weight of the lubricating grease: 65-95% of lubricating base oil, 6-20% of lithium-based thickening agent and 0.5-15% of graphene. The lithium-based lubricating grease has excellent properties such as excellent high temperature resistance, water and adhesion resistance, colloidal stability, extreme pressure antiwear property, long lubricating service life, corrosion resistance and salt mist resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyurea-based lubricating grease with high mechanical stability and preparation method thereof

The invention belongs to the field of polyurea-based lubricating grease, and in particular provides polyurea-based lubricating grease with high mechanical stability and a preparation method thereof. The polyurea-based lubricating grease consists of the following components in percentage by weight: 70 to 90 percent of base oil and 10 to 30 percent of polyurea-based lubricating grease thickening agent, wherein the polyurea-based lubricating grease thickening agent is prepared by mixing diisocyanate and organic amine and directly thickening the base oil; isocyanate ions and amine ions have the same molar content; and the organic amine consists of fatty amine, naphthene amine and aromatic amine in the molar ratio of (2-4):(1-2):5. The polyurea-based lubricating grease has high mechanical stability and long service life.

Owner:长沙众城石油化工股份有限公司

Water-based adhesive and preparation method thereof

InactiveCN105885739AGood chemical stabilityGood mechanical stabilityMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesChemistryEmulsion

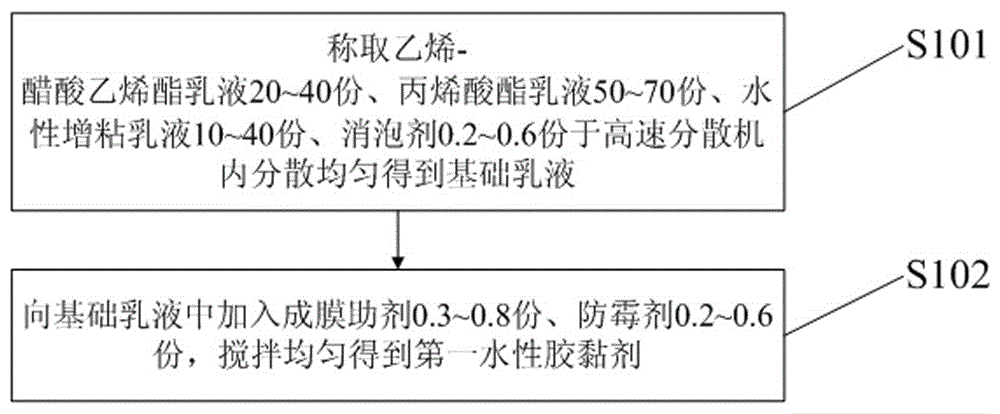

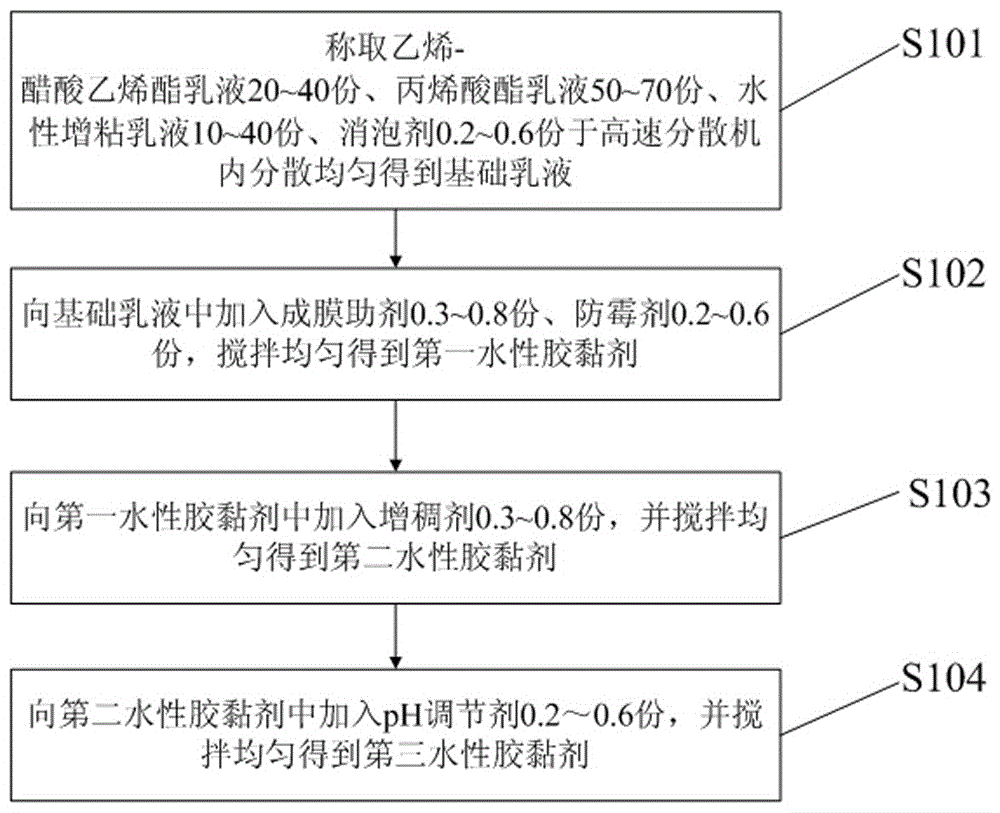

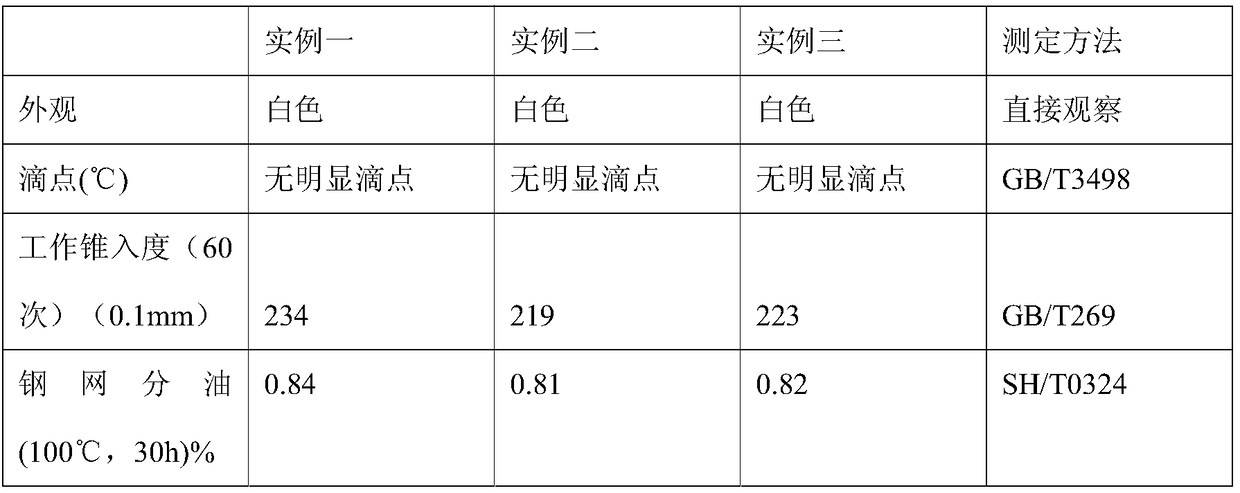

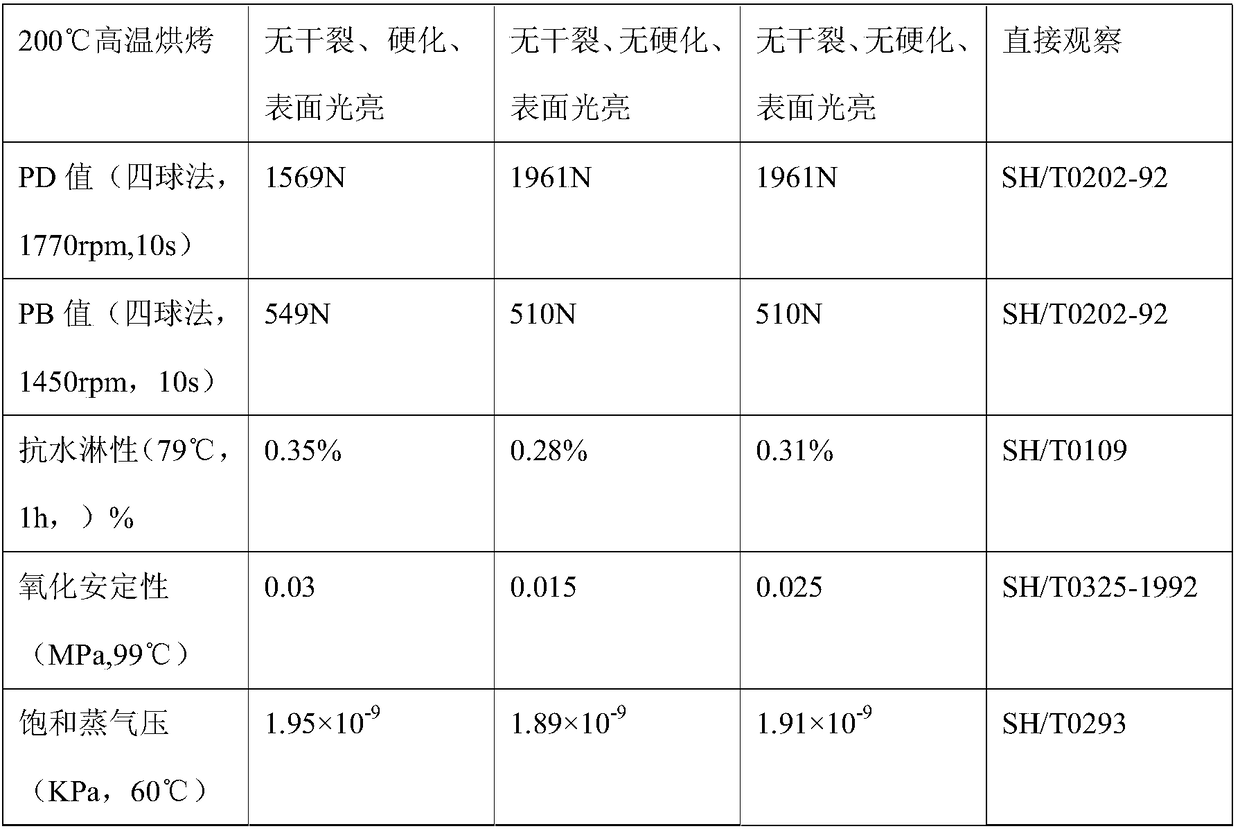

The invention discloses a water-based adhesive and a preparation method thereof. The preparation method of the water-based adhesive comprises the following steps: (1) weighing 20-40 parts of ethylene-vinyl acetate emulsion, 50-70 parts of acrylate emulsions, 10-40 parts of a water-based viscous emulsion and 0.2-0.6 part of an antifoaming agent, dispersing the weighed raw materials evenly in a high-speed disperser to obtain a base emulsion; (2) adding 0.3-0.8 part of a coalescing agent and 0.2-0.6 part of a mildew preventive to the base emulsion, stirring evenly to obtain the first water-based adhesive. In such manner, the water-based adhesive which is fast cured, high in initial adhesion and excellent in permanent adhesion can be provided.

Owner:东莞铭丰生物质科技有限公司 +1

Preparation method of composite titanium radical lubricating grease and product produced thereby

ActiveCN101117605AGood mechanical stabilityThickenersBase-materialsTetraisopropyl titanateDistilled water

The present invention provides a preparation method for compound titanium base grease lubricant, according to the sequence, the following steps are included: firstly, fatty acid and base oil are mixed together and heated, when the temperature is raised to 70 to 90 DEG C, the tetraiopropyl titanate is added in for reaction; secondly, when the temperature is raised to 130 to 150 DEG C, aromatic acid is added in for reaction; thirdly, cool oil is added in for reducing the temperature, and distilled water is added in; fourthly, the temperature is increased to 170 to 200 DEG C for high temperature refining, the rest cool oil is added in, the temperature is reduced, and the reactant is ground to get the end product. The product got from the present invention has obviously better mechanical stability, as well as better abrasion resistance under the extreme pressure than that got from the prior technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

Resistive random access memory structure and preparation method thereof

InactiveCN103824938AReduce power consumptionGood mechanical stabilityElectrical apparatusDigital storageMetal deviceUltra low power

The invention provides a resistive random access memory structure and a preparation method thereof. A bottom electrode and / or a top electrode of the resistive random access memory structure are / is graphene. The invention also provides a preparation method of the resistive random access memory structure. The preparation method comprises the step of preparing the bottom electrode and / or the top electrode of the resistive random access memory structure from graphene. The bottom electrode and / or the top electrode of the resistive random access memory structure provided by the invention are / is made of large-area graphene instead of traditional metal, and therefore, compared with a traditional metal / oxide / metal device, a graphene-contained resistive random access memory device with the resistive random access memory structure has the advantages that the starting and stopping power consumptions can be respectively greatly reduced, and the performances on the aspects of switch ratio, cycle frequency and the like are kept equivalent. A transparent and bendable flexible resistive random access memory structure with ultra-low power consumption can be obtained through preparing the device structure on a transparent flexible polyethylene naphthalate substrate.

Owner:NANJING UNIV

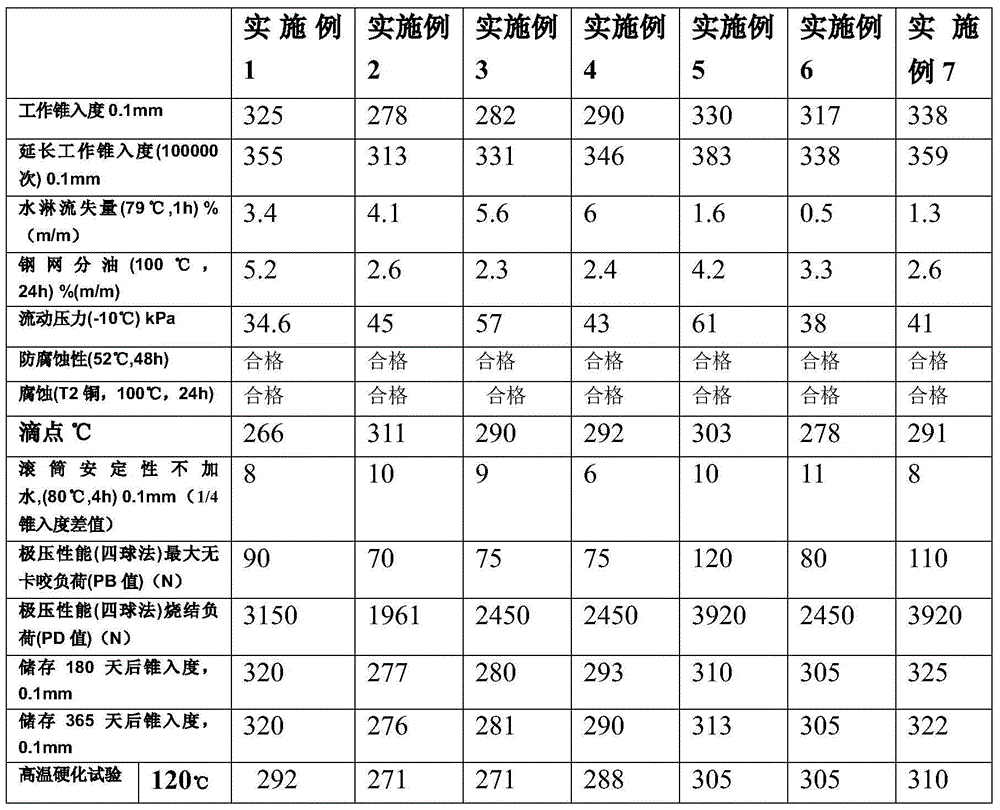

Compound lithium base grease composite and preparation method thereof

ActiveCN101838580AGood colloidal stabilityGood mechanical stabilityAdditivesLithiumMechanical stability

The invention discloses a compound lithium base grease composite, which comprises the following materials in percentage by weight: 70-89% of grease base oil, 10-25% of densifier, 0.02-2% of additive, and 0.01-5% of bismuth oxide. In the compound lithium base grease composite, micron-level bismuth oxide powder is added as an extreme-pressure additive, and the prepared compound lithium base grease composite has good colloidal stability and mechanical stability, and better high temperature performance and extreme pressure resisting performance.

Owner:SUN YAT SEN UNIV

High-temperature-resistant polytetrafluoroethylene lubricating grease for sealing and preparation method thereof

The invention provides high-temperature-resistant polytetrafluoroethylene lubricating grease for sealing. The lubricating grease is prepared from, by mass, 30-70% of base oil, 25-55% of thickener, 2-5% of structural stabilizer, 1-5% of tackifier and 1-5% of lubricant. The invention further provides a preparation method of the lubricating grease, polytetrafluoroethylene micro powder serves as the thickener to thicken silicone oil as the base oil, meanwhile a certain amount of the structural stabilizer, the tackifier and the lubricant are added at the same time, and then the lubricating grease is prepared through corresponding preparation processes. The prepared polytetrafluoroethylene lubricating grease has excellent high temperature resistance, good sealing performance, excellent lubricity, adhesion and oxidation resistance, high load, water spraying resistance and other properties, the lubricating grease has no suncrack, oil splitting and hardening phenomena at the high temperature more than 200 DEG C, and has good sealing property, adhesion property and high temperature resistance.

Owner:SHANGHAI INST OF TECH +1

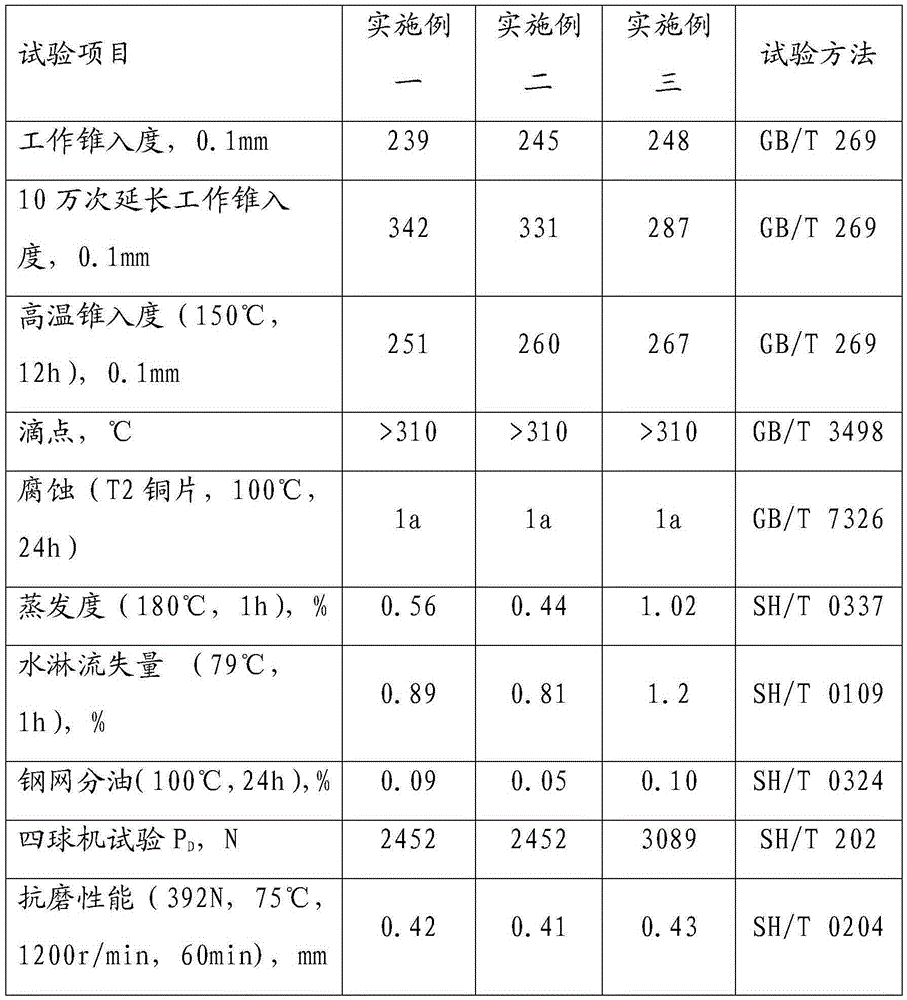

Turbine worm lubricating grease composition and preparation method thereof

InactiveCN106497659AImprove water resistanceImprove antioxidant capacityAdditivesLithium hydroxideEvaporation

The invention relates to a turbine worm lubricating grease composition and a preparation method. The turbine worm lubricating grease composition is prepared from 85-90% of base oil, 10-15% of thickener, 0.5-1% of antioxidant, 0.05-0.1% of antirust agent, 0.5-2% of extreme-pressure abrasion-resisting agent and 0.5-1% of tackifier. The thickener is generated through reaction of fatty acid and an alkaline water solution, wherein the fatty acid is a mixture of 12-hydroxy stearic acid and sebacic acid, and alkali is the mixture of lithium hydroxide and calcium hydroxide. The lubricating grease is of a unique mixed thickener type, so that the water-resistant and shearing properties of the lubricating grease are remarkable, and the usage requirement for the 30-70 DEG C wide temperature range of a turbine worm accessory itself can be well met. The colloid stability, water resistance and oxidation resistance of the lubricating grease are effectively improved, meanwhile the lubricating grease composition has the advantages of being low in oil separation rate, small in evaporation loss, high in shear stability, good in high and low temperature performance and corrosion protection effect and the like, and the usage temperature range of the lubricating grease is 30-150 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP

High-temperature lubricating grease for food processing and preparation method thereof

The invention relates to lubricating grease and a preparation method thereof, in particular to high-temperature lubricating grease for food processing and a preparation method thereof, and belongs to the technical field of chemistry. The high-temperature lubricating grease is prepared from base oil accounting for 70%-92% of the total weight of the lubricating grease, an inorganic thickening agent accounting for 3%-20% of the total weight of the lubricating grease, a tackifier accounting for 2%-6% of the total weight of the lubricating grease, an auxiliary dispersant accounting for 0.1%-1.5% of the total weight of the lubricating grease, an antioxidant accounting for 0.3%-1.0% of the total weight of the lubricating grease, a corrosion inhibitor accounting for 0.05%-1% of the total weight of the lubricating grease, a friction modifier accounting for 0.1%-0.5% of the total weight of the lubricating grease and a solid additive accounting for 2%-10% of the total weight of the lubricating grease. The high-temperature lubricating grease has the advantages of being capable of not being fused at high temperature, high in dropping point, few in high-temperature consistence change, good in colloid stability and the like and especially suitable for lubricating and sealing high-temperature food processing equipment.

Owner:JIANGSU LOPALTECH

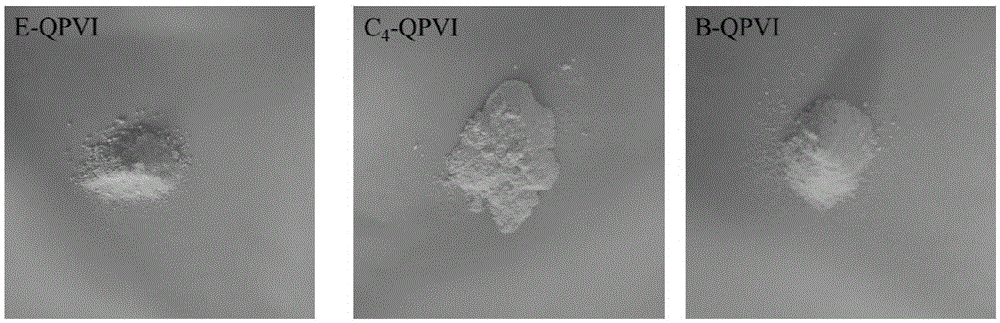

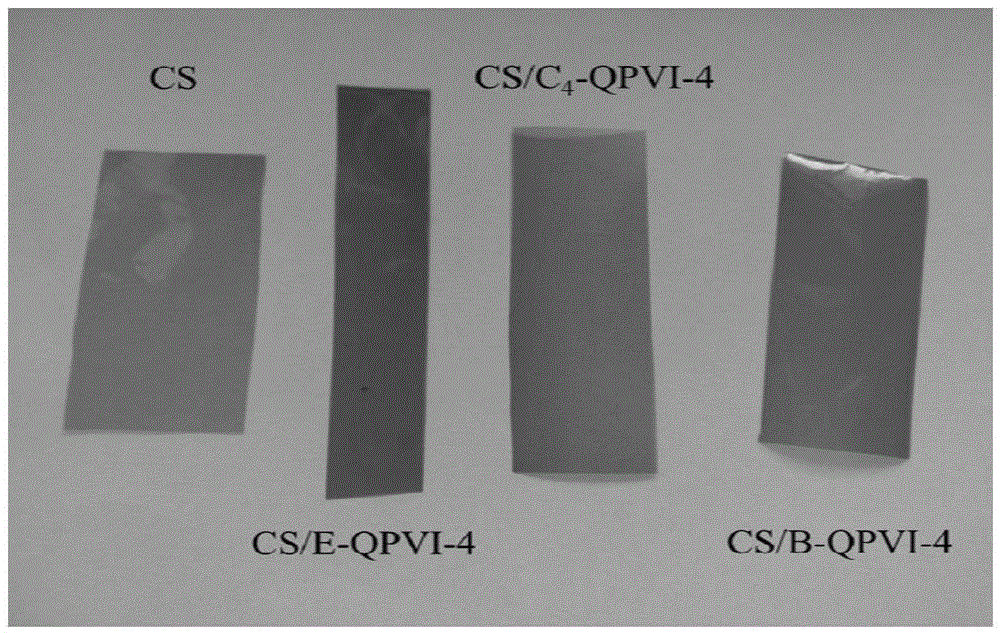

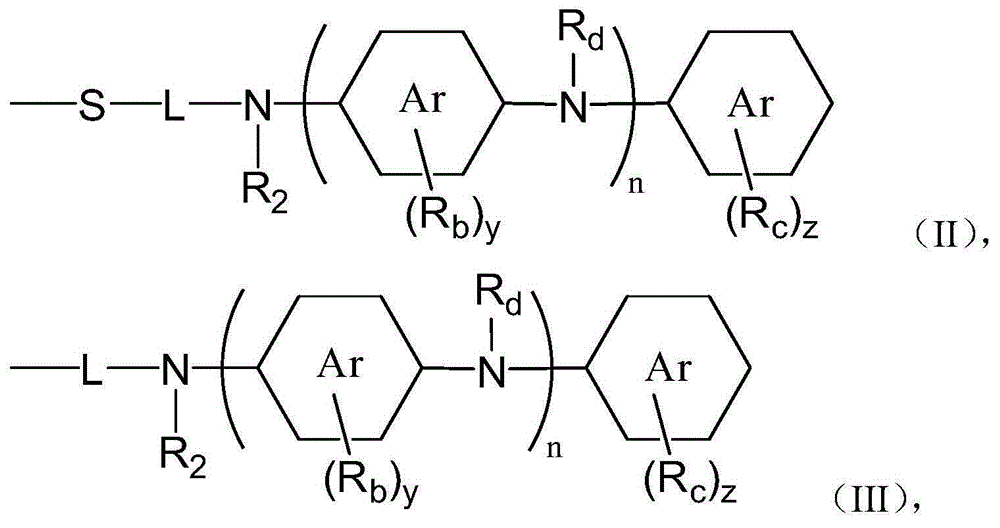

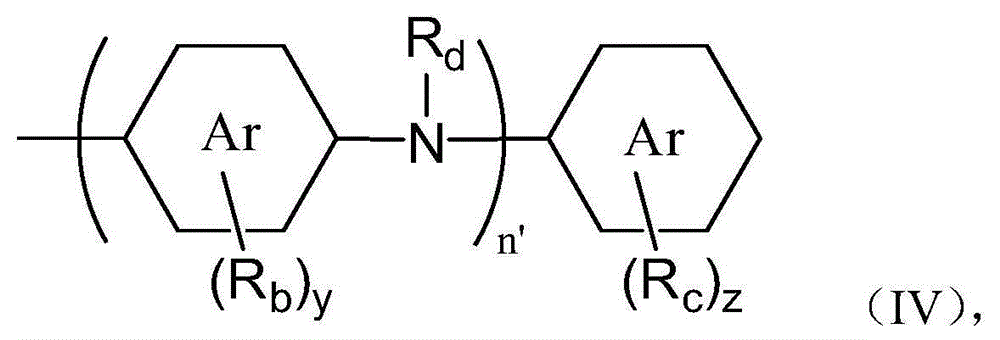

Organic nano-composite anion exchange membrane and preparation method therefor and application thereof

ActiveCN105237818AImprove conductivityGood mechanical stabilityCell component detailsIon-exchange membranesAlkaline anion exchange membrane fuel cells

The present invention belongs to the technical field of alkaline anion exchange membrane fuel cells, and particularly relates to an organic nano-composite anion exchange membrane and a preparation method therefor and an application thereof. The exchange membrane is a composite anion exchange membrane of chitosan and quaternized imidazole microspheres, wherein the mass ratio of the chitosan and the quaternized imidazole microspheres in the membrane is 100:(2-10). The nano-composite anion exchange membrane provided by the present invention exhibits performance which is higher than that of a membrane free of chitosan.

Owner:ZHENGZHOU UNIV

Composite sodium-based lubricating grease and preparation method thereof

ActiveCN104560315AImprove antioxidant capacityImprove high drop pointThickenersSalt resistanceGraphene

The invention discloses composite sodium-based lubricating grease and a preparation method thereof. By the weight of the lubricating grease, the compound sodium-based lubricating grease comprises the following components: 65-95% of lubricating base oil, 5-30% of a composite sodium-based thickener and 0.2-15% of graphene. The composite sodium-based lubricating grease disclosed by the invention has excellent properties such as high temperature resistance, water resistance, adhesivity, colloid stability, extreme pressure antiwear property, long lubricating life, corrosion resistance and salt fog resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lithium lubricating grease and preparation method thereof

ActiveCN109810748AGood mechanical stabilityLong mechanical stabilityAdditivesBase-materialsLithiumAntioxidant

The invention discloses lithium lubricating grease. The lithium lubricating grease is prepared from raw materials in parts by weight: 75-88 parts of base oil, 0.5-2.5 parts of an anti-wear agent, 0.1-1.5 parts of an anti-rust agent, 0.1-1.5 parts of an antioxidant, 5-25 parts of a lubricating agent, 5-15 parts of a thickening agent and 0.6-2.0 parts of a saponifying agent. The lithium lubricatinggrease has the advantages of good colloid resistivity, superior mechanical resistivity and the like of traditional lithium lubricating grease, and meanwhile, the anti-wear property of the lithium lubricating grease is greatly improved. Furthermore, the lithium lubricating grease has a superior anti-oxygen property, can significantly shorten the saponifying reaction time, reduce the saponifying reaction temperature, and greatly improve the resistivity, stability and the wear-resistant property of basic lithium lubricating grease, and the lithium lubricating grease can be qualified for the severworking conditions of high temperature, high speed, high load, excessive water and the like.

Owner:GUANGXI LIUGONG MASCH CO LTD

Flexible electrical generators

InactiveUS20130284267A1Good mechanical stabilityGood durabilityPhotovoltaicsSemiconductor/solid-state device manufacturingEngineeringHigh intensity

The invention relates to a flexible electrical generator comprising at least one photovoltaic device and a flexible support, wherein said photovoltaic device is attached to the flexible support and wherein the flexible support comprises a fabric comprising high-strength polymeric fibers, said flexible support comprising also a plastomer wherein said plastomer is a semi-crystalline copolymer of ethylene or propylene and one or more C2 to C12 α-olefin co-monomers and wherein said plastomer having a density as measured according to ISO1183 of between 860 and 930 kg / m3.

Owner:DSM IP ASSETS BV

Polyurea grease composition and preparation method thereof

ActiveCN103275785AImprove water resistanceGood mechanical stabilityThickenersAliphatic amineMechanical stability

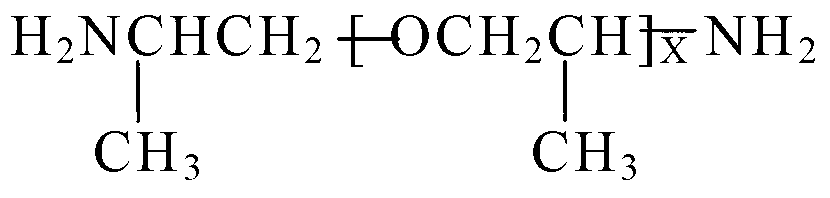

The invention provides a polyurea grease composition and a preparation method thereof. The composition has excellent mechanical stability, water resistance, oxidation resistance, colloid stability, and the like, comprises base oil and a polyurea densifier, and is characterized in that the polyurea densifier is obtained through the reaction between diisocyanate and organic amine, and the organic amine is composed of aliphatic amine, aromatic amine, and polyether amine.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

Complex aluminum-base lubricating grease and preparation method thereof

ActiveCN104560314AImprove antioxidant capacityImprove high drop pointLubricant compositionSalt resistanceGraphene

The invention discloses complex aluminum-base lubricating grease and a preparation method thereof. On a lubricating grease weight basis, the complex aluminum-base lubricating grease comprises the following components: 65-95 percent of lubricating base oil, 5-30 percent of complex aluminum-base thickening agent and 0.2-15 percent of graphene. The complex aluminum-base lubricating grease provided by the invention has excellent properties such as high-temperature resistance, water resistance, adhesivity, colloid stability, extreme pressure wearability, lubricating life, corrosion resistance and salt fog resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite barium-based lubricating grease composition and preparation method thereof

The invention discloses a composite barium-based lubricating grease composition and a preparation method thereof. By taking the weight of the lubricating grease as a benchmark, the composite barium-based lubricating grease composition comprises the following components: 65-95% of lubricating base oil, 5-30% of a composite barium-based thickening agent and 0.2-15% of graphene. The composite barium-based lubricating grease has excellent high temperature resistance, water resistance, adhesion, colloidal stability, extreme pressure antiwear property, anti-corrosion property, salt and spray resistance and the like and long lubricating life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lubricating grease for wheels of airplanes and its preparing method

A lubricating grease for the wheels of airplane contains composite Li or Ca soap as thickening agent (3-20 wt.%), graphite powder (2-20%), phosphate (0.1-5.0%), arylamine as antioxidizing agent (0.01-3%), phenyltriazole salt of fatty acid as antirust agent (0.01-3.0%), and poly-alpha-olefine oil (rest). Its advantages are better high and low temp nature, high stability, extreme pressure performance and antirust nature, and good compatibility to rubber.

Owner:CHINA PETROLEUM & CHEM CORP +1

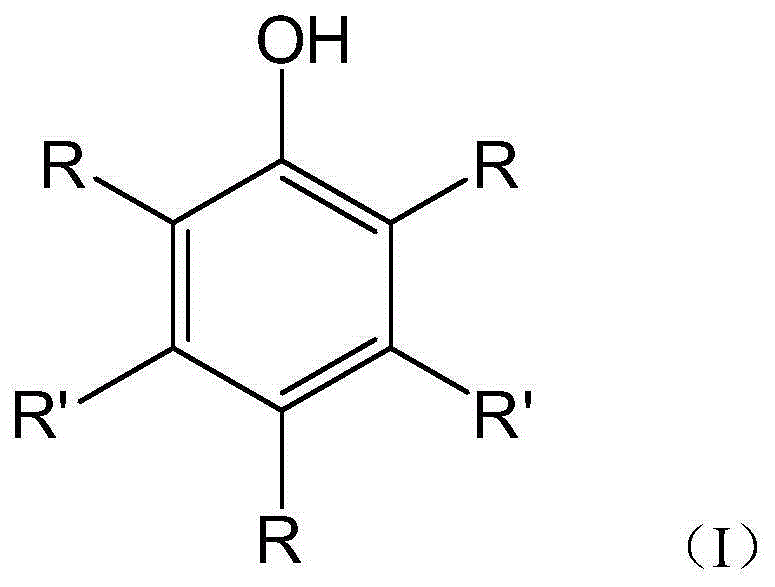

Complex calcium-based lubricating grease and preparing method thereof

ActiveCN106590886ADrop point highGood mechanical stabilityAdditivesHeat stabilityMechanical equipment

The invention provides a complex calcium-based lubricating grease and a preparing method thereof. The lubricating grease comprises 0.01%-1.0% of hindered phenol compound, 5%-35% of complex calcium-based thickening agent and a main amount of lubricating base oil, wherein the structure of the hindered phenol compound is shown in the specifications. According to the complex calcium-based lubricating grease and the preparing method thereof, the complex calcium-based lubricating grease has a high dropping point, good mechanical stability, excellent heat stability, colloid stability, high-temperature oxygen resistance, anti-corrosion performance, anti-water spraying performance, and anti-extreme pressure performance, hardening conditions of the complex calcium-based lubricating grease are improved to some extent, thus the complex calcium-based lubricating grease is capable of being qualified in lubrication of various kinds of motors, electric generators, air blowers, transportation industries, iron and steel enterprises and other various kinds of commercial units, and is especially applicable to lubrication of friction parts of various kinds of mechanical equipment under high-temperature and moist conditions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com