Flame-retarded lubricating grease and preparation method thereof

A grease, flame-retardant technology, applied in the field of flame-retardant grease and its preparation, can solve the problems of easy blockage of pipelines, inability to solve the problems of self-ignition of grease by heat, lack of oil lubrication in machinery, etc., and achieves long service life and excellent mechanical properties. Stable, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

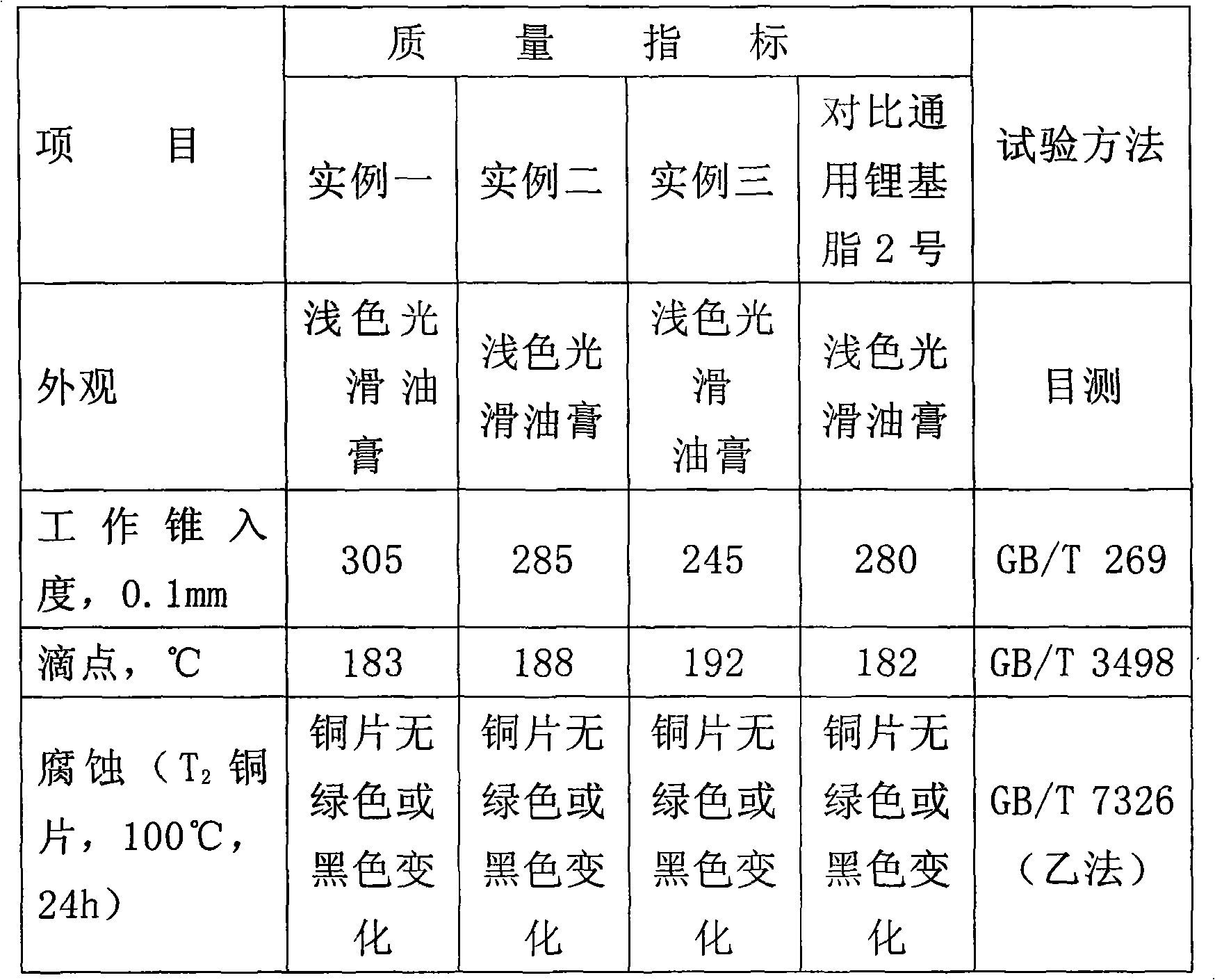

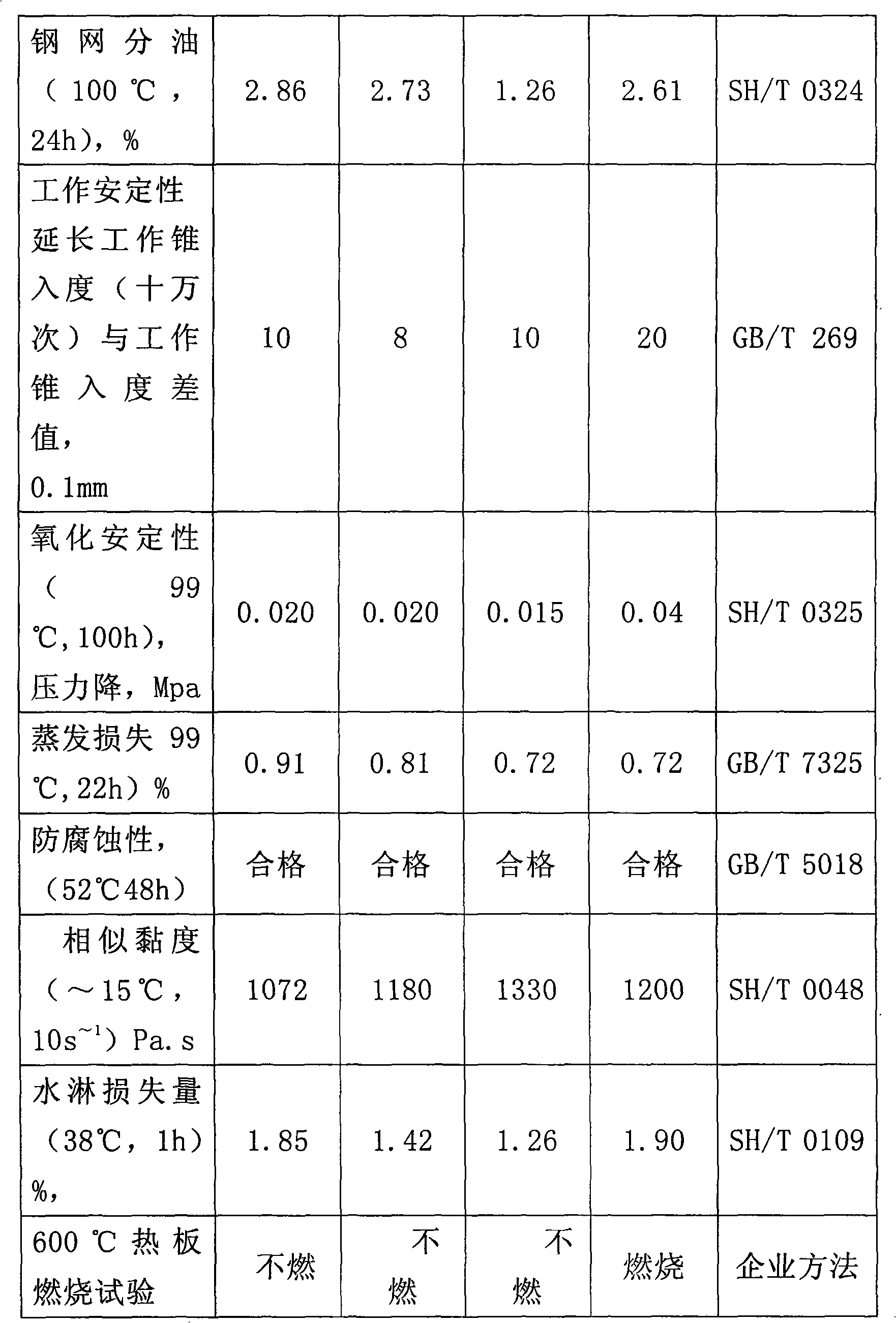

Examples

Embodiment 1

[0029] Embodiment 1: The preparation method of a kind of flame-retardant lubricating grease of the present invention adopts the following process steps:

[0030] 1. Fatty acid calcium soap is formed by the reaction of lauryl hydroxystearic acid, calcium hydroxide and water:

[0031] Heat 180g of water to 90°C, add 16.8g of dodecyl hydroxystearic acid, add 2.1g of calcium hydroxide after the lauryl hydroxystearic acid is melted, saponify for 1 hour, stir evenly, take a sample and measure it with a phenolphthalein indicator to show a reddish color It is alkaline, keep it warm for 0.8 hours at 95°C, put it in a container to dry, and set it aside.

[0032] 2. Lithium fatty acid soap is generated by the reaction of lauryl hydroxystearic acid, lithium hydroxide and water:

[0033] Heat 650g of water to 90°C, add 100.8g of lauryl hydroxystearic acid, add 8.4g of lithium hydroxide after the lauryl hydroxystearic acid is melted, saponify for 1 hour, stir evenly, take samples and measu...

Embodiment 2

[0037] Embodiment two: the preparation method of a kind of flame-retardant lubricating grease of the present invention adopts following process step:

[0038] 1. Fatty acid calcium soap is formed by the reaction of lauryl hydroxystearic acid, calcium hydroxide and water:

[0039] Heat 118g of water to 95°C, add 10.5g of dodecyl hydroxystearic acid, add 1.3g of calcium hydroxide after the lauryl hydroxystearic acid is melted, saponify for 1.25 hours, stir evenly, take a sample and measure it with a phenolphthalein indicator to show a reddish color It is alkaline, keep it warm for 1 hour at a temperature of 100°C, put it in a container to dry, and set it aside.

[0040] 2. Lithium fatty acid soap is generated by the reaction of lauryl hydroxystearic acid, lithium hydroxide and water:

[0041] Heat 450g of water to 95°C, add 62.4g of dodecyl hydroxystearic acid, add 5.2g of lithium hydroxide after the lauryl hydroxystearic acid is melted, saponify for 1.25 hours, stir evenly, take...

example 3

[0045] Example three: the preparation method of a kind of flame-retardant lubricating grease of the present invention, adopts following process steps:

[0046] 1. Fatty acid calcium soap is formed by the reaction of lauryl hydroxystearic acid, calcium hydroxide and water:

[0047] Heat 75g of water to 100°C, add 7.6g of dodecyl hydroxystearic acid, add 0.95g of calcium hydroxide after the dodecyl hydroxystearic acid is melted, saponify for 1.5 hours, stir evenly, take a sample and measure it with a phenolphthalein indicator to show a reddish color It is alkaline, keep it warm for 1.2 hours at 105°C, put it in a container to dry, and set it aside.

[0048] 2. Lithium fatty acid soap is generated by the reaction of lauryl hydroxystearic acid, lithium hydroxide and water:

[0049] Heat 110g of water to 100°C, add 11.4g of lauryl hydroxystearic acid, add 3.8g of lithium hydroxide after the lauryl hydroxystearic acid is melted, saponify for 1.5 hours, stir evenly, and take samples...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com