Composite barium-based lubricating grease composition and preparation method thereof

A kind of grease, barium-based technology, applied in the field of compound barium-based grease composition and preparation thereof, can solve the problems of related research without graphene application, and achieve the effects of excellent thermal stability, high dropping point, and enhanced ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

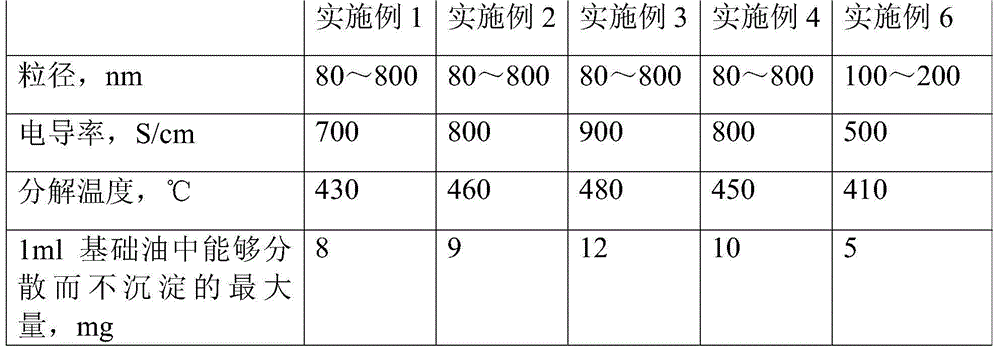

Examples

preparation example Construction

[0028] According to the second aspect of the present invention, the present invention provides a preparation method of composite barium-based grease, the method comprising: mixing graphene, composite barium-based thickener and part of the base oil uniformly, at a constant temperature of 170-220°C Refining, cooling, adding the remaining base oil and adding necessary additives to get the finished product.

[0029] Wherein, the amount of graphene, composite barium-based thickener and base oil makes the resulting composite barium-based grease, based on grease weight, include the following components: 65-95% lubricating base oil, 5-30% Composite barium-based thickener, 0.2-15% graphene.

[0030] Preferably, the amount of graphene, composite barium-based thickener and base oil makes the resulting composite barium-based grease, based on grease weight, include the following components: 70-93% lubricating base oil, 8-25% % composite barium-based thickener, 1-10% graphene.

[0031] Ac...

Embodiment 1

[0047] Preparation of graphene oxide:

[0048] Mix 1g of graphite flakes, 0.5g of sodium nitrate and 23ml of concentrated sulfuric acid in an ice bath, slowly add 3g of potassium permanganate while stirring, keep the temperature below 10°C and stir for 1h, then stir the mixture at 35°C for 0.5h, then add Dilute with 50ml of deionized water, a lot of heat is released during the process, keep the temperature below 100°C in an ice bath, after adding 50ml of water, stir the mixture for 0.5h, then add 200ml of deionized water for further dilution. Potassium permanganate was then reduced by adding 10 ml of a 30% by weight aqueous hydrogen peroxide solution. Finally, the mixture was washed and filtered with 5% hydrochloric acid (400ml) to remove metal ions. Then, the acid was removed with 0.5 L of deionized water, and dried at 60 °C for 24 h to obtain graphene oxide.

[0049] Preparation of graphene:

[0050] Add 0.1g of the graphene oxide prepared above to 100ml of water for ultr...

Embodiment 2

[0056] The preparation of graphene oxide is the same as in Example 1.

[0057] Preparation of graphene:

[0058] Add 0.1 g of the prepared graphene oxide into 100 ml of water for ultrasonic dispersion (ultrasonic frequency 35 kHz) for 30 min, then add 5 ml of hydrazine hydrate (mass concentration: 85%), and react in an oil bath at 100 ° C for 24 h. The powder obtained after water washing, suction filtration and drying is graphene, and the properties of graphene are shown in Table 2 below.

[0059] Preparation of complex barium grease:

[0060] Raw material components: graphene 30g; 150BS base oil 200g (viscosity at 100°C is 31mm 2 / s); 48.9g of barium hydroxide octahydrate; 21g of sebacic acid; 30.8g of 12-hydroxystearic acid; 1g of antioxidant diisooctyldiphenylamine.

[0061] Add 100 grams of base oil, 30 grams of graphene, 30.8 grams of 12-hydroxystearic acid and 21 grams of sebacic acid into the fat-making kettle, heat and stir, when the temperature rises to 105 ° C, sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com