High-temperature lubricating grease for food processing and preparation method thereof

A food processing and lubricating grease technology, applied in the chemical field, can solve problems such as poor mechanical stability, food safety accidents, and decreased adhesion, and achieve the effects of avoiding damage, reducing dosage, and small changes in consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

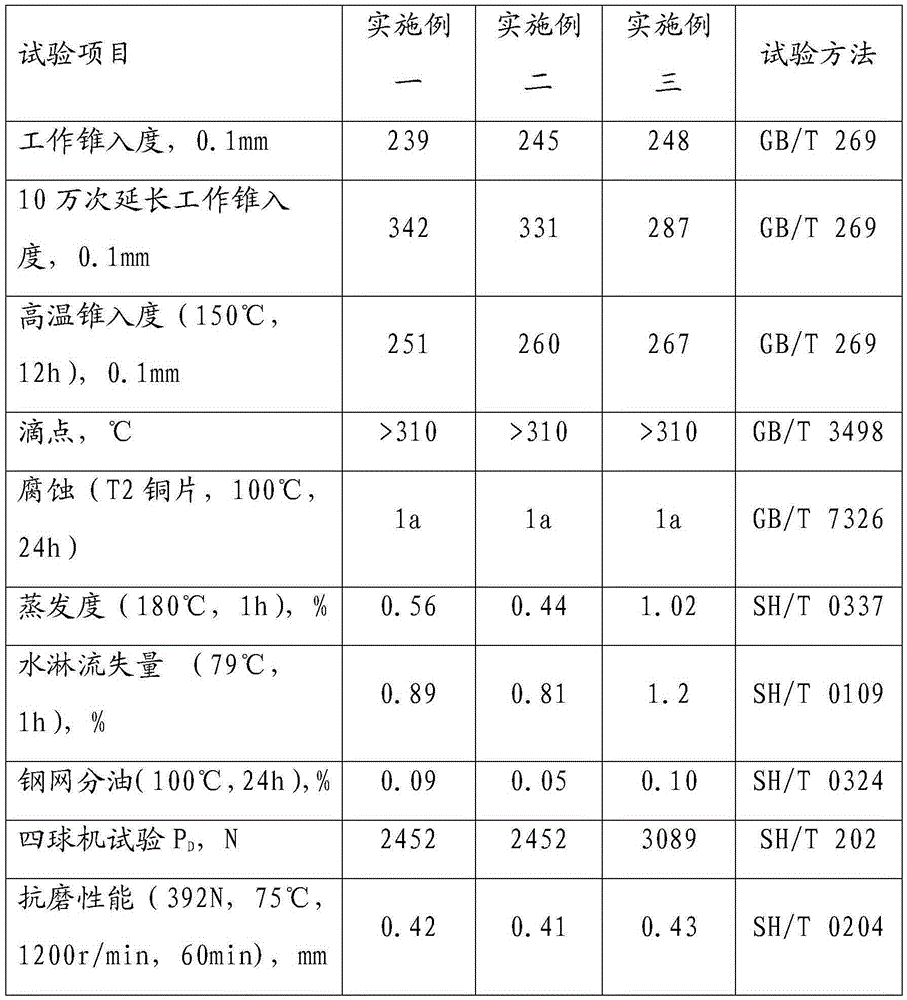

Examples

Embodiment 1

[0024] In this embodiment, the raw materials are prepared as follows for high-temperature lubricating grease for food processing:

[0025] Step 1. Add 48kgPAO40, 32.5kg100# food grade white oil, 5kg polyisobutylene, 1kg p-dioctyl diphenylamine, 9kg organic bentonite Baragel20 in the mixing kettle in turn, turn on the high-speed shear disperser, and set the stirring speed to 500rpm , raise the temperature of the material to 60-70°C, increase the speed of the disperser to 1500rpm, and disperse for 30min;

[0026] Step 2. Slowly add 1kg of 95% pharmaceutical grade ethanol to the kettle, and the adding time is controlled at 10 minutes. After adding, continue high-speed shearing for about 40 minutes to thicken the material. Add 0.5kg AdditinRC3760, 1.0kgAddtinRC4820 and 2kg food-grade PTFE micropowder Continue to stir and mix for 15 minutes;

[0027] Step 3, then use a colloid mill to grind the material 2 times. Import the ground fat into a degassing kettle, keep the temperature ...

Embodiment 2

[0029] In this embodiment, the raw materials are prepared as follows for high-temperature lubricating grease for food processing:

[0030] Step 1. Add 82.5kg PAO40, 2.4kg ethylene propylene copolymer, 0.5kg2,6-di-tert-butyl-4 cresol, 0.5kg phenyl-α-naphthylamine, 10kgBaragel3000 organobentonite to the mixing kettle, and turn on the high-speed For the shear disperser, set the stirring speed to 500rpm, raise the temperature of the material to 60-70°C, increase the speed of the disperser to 1500rpm, and disperse for 20 minutes;

[0031] Step 2. Slowly add 0.5kg of propylene carbonate with a purity of 99.9% pharmaceutical grade to the kettle. The addition time is controlled at 15 minutes. After adding, continue high-speed shearing for about 60 minutes to thicken the material. Add 0.5kg AdditinRC6340, 0.5kgAddtinRC4820 and 3kg carbonic acid Calcium micropowder was stirred and mixed for 15 minutes;

[0032] Step 3: After thickening, use a colloid mill to grind the material twice. ...

Embodiment 3

[0034] In this embodiment, the raw materials are prepared as follows for high-temperature lubricating grease for food processing:

[0035] Step 1. Add 55kgPAO40, 28.1kgPAO10, 5kg polyisobutylene, 0.5kg p-dioctyl diphenylamine, 6kg Bentone34 organic bentonite in the mixing kettle in turn, turn on the high-speed shear disperser, set the stirring speed to 500rpm, and heat the material to 60~70℃, increase the speed of the disperser to 1500rpm, and disperse for 30min;

[0036] Step 2. Slowly add 0.2kg of 95% pharmaceutical grade ethanol and 0.3kg of propylene carbonate to the kettle, and continue high-speed shearing for about 45 minutes to thicken the material; then add 3kg of Degussa R972 silica and stir to thicken After melting for 15 minutes, add 0.3kg AdditinRC6340, 0.5kgAddtinRC4820 and 3kg polytetrafluoroethylene powder and stir and mix for 20 minutes;

[0037] Step 3, then use a colloid mill to grind the material twice. Import the ground fat into a degassing kettle, keep t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear scar diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com