Pre-stressed duct grouting agent, and preparation and application methods thereof

A channel grouting and prestressing technology, which is applied in the preparation of the above-mentioned channel grouting agent, the prestressed channel grouting agent added with a setting time regulator, and the field of prestressed channel grouting agent, which can solve the problem that the air temperature is greatly affected, Sensitivity to temperature effects, strength shrinkage, etc., to achieve the effects of wide sources, steady increase in strength, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

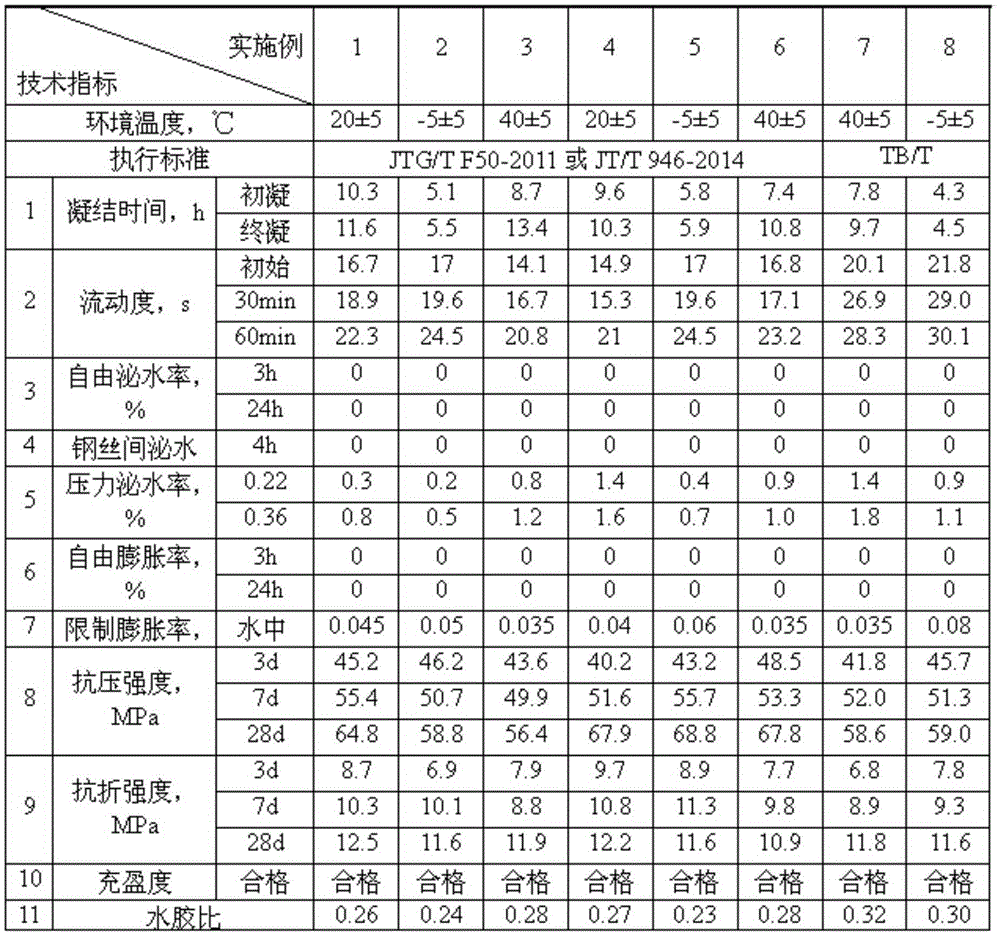

Examples

Embodiment 1

[0025] Weigh the raw materials according to the weight ratio, specifically: polycarboxylate water reducer 4%, microbead physical water reducer 2%, Brunei gum 0.4%, defoamer 0.6%, 200 mesh quartz powder 34%, clinker 19%, 16% dihydrate gypsum, 16% anhydrous anhydrite, and 8% fly ash, which are ground and mixed uniformly by a ball mill to make a grouting agent.

[0026] Weigh 8% of grouting agent and 92% of 52.5 grade ordinary Portland cement by weight, and mix them evenly with a dry powder mixer to make a grout.

[0027] The ambient temperature is 20±5°C, the water-binder ratio is 0.26, after adding water to the mixer, turn on the mixer, the mixer speed is 1000r / min, the line speed is 15m / s, and then evenly add the press slurry to the mixer, and stir for 5 minutes after the powder is added. After the pulping is completed, the grouting is carried out. The prepared cement slurry was tested according to "Technical Specifications for Highway Bridge and Culvert Construction" JTG / TF5...

Embodiment 2

[0029] Weigh the raw materials according to the weight ratio, specifically: 6% of naphthalene-based water reducer, 4% of microbead physical water reducer, 0.2% of white carbon black, 0.8% of defoamer, 16% of 400 mesh alum stone powder, and 23% of clinker , 14% of hemihydraulic gypsum, 20% of dihydrate gypsum, 6% of slag powder, 8% of micro-silica fume, and 2% of aluminum sulfate, and use a ball mill to grind and mix evenly to make a grouting agent.

[0030] Weigh 10% of the grouting agent and 90% of 52.5R grade Portland cement by weight, and mix them evenly with a dry powder mixer to make the grout.

[0031] Ambient temperature -5±5°C, water-binder ratio 0.24, after adding water to the mixer, turn on the mixer, the mixer speed is 1000r / min, the line speed is 15m / s, then evenly add the press slurry to the mixer, and stir for 3 minutes after the powder is added , After the pulping is completed, press the pulp. The prepared cement slurry was tested according to "Technical Specif...

Embodiment 3

[0033] Weigh the raw materials according to the weight ratio, specifically: polycarboxylate water reducer 3%, organically modified bentonite 0.4%, defoamer 0.6%, 600 mesh limestone powder 44%, clinker 26%, anhydrite 23% %, 3% slag powder, use a ball mill to grind and mix evenly to make a grouting agent.

[0034]Weigh 12% of the grouting agent and 88% of 42.5 grade ordinary Portland cement by weight, and mix them evenly with a dry powder mixer to make the grout.

[0035] The ambient temperature is 40±5°C, the water-binder ratio is 0.28, after adding water to the mixer, turn on the mixer, the mixer speed is 1000r / min, and the line speed is 15m / s, then evenly add the press slurry to the mixer, and stir for 5 minutes after the powder is added. After the pulping is completed, the grouting is carried out. The performance of the prepared cement slurry was tested according to "Technical Specifications for Highway Bridge and Culvert Construction" JTG / TF50-2011 and "Highway Engineering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com