Method for controlling soil deformation in large rectangular pipe jacking

A technology for rectangular pipe jacking and soil deformation, which is applied in the field of anti-friction slurry to control soil deformation in large-scale rectangular pipe jacking excavation, and can solve the problems of accuracy fluctuation, filtration loss and pressure bearing capacity that cannot guarantee soil settlement deformation, etc. , to increase the consistency, ensure continuity and integrity, and lift the subsidence area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

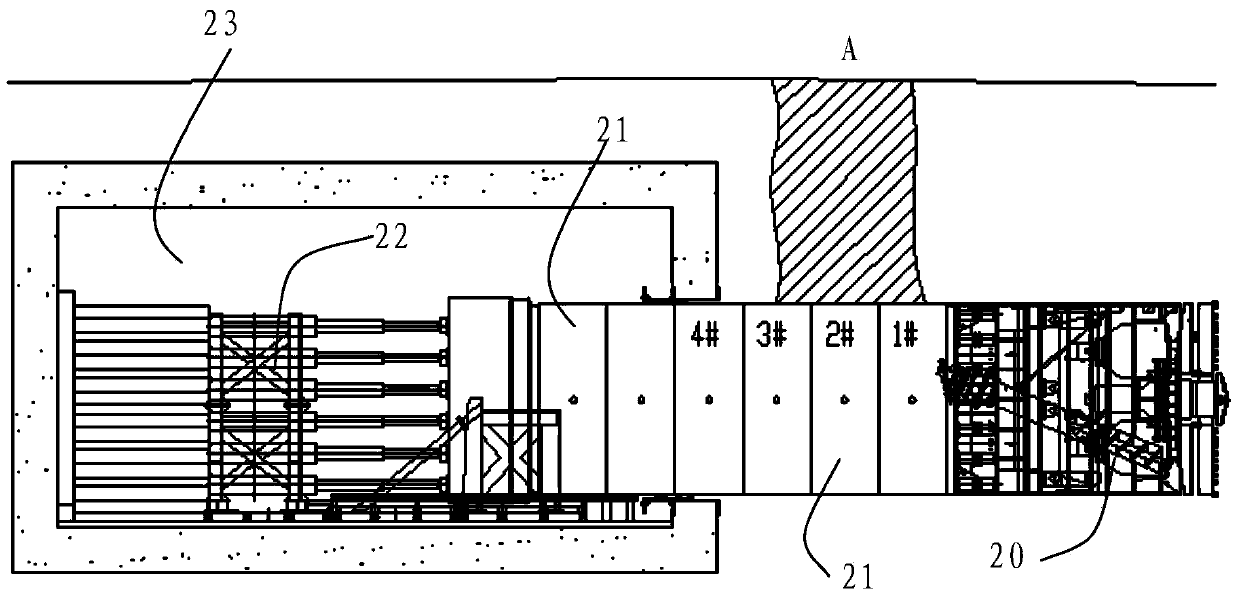

[0045] refer to figure 1 As shown, the machine head 20 of the rectangular pipe jacking is excavated in the soil. When the excavation reaches a certain distance, the machine head 20 stops advancing, and then uses the main jacking device 22 in the originating shaft 23 to push out the first annular pipe piece 21, By analogy, the machine head 20 and segment 21 are pushed forward in sequence until the tunnel is penetrated. The device for controlling soil deformation in large rectangular pipe jacking excavation of the present invention is used to reduce the frictional resistance between the segment and the soil during the advancement of the segment, prevent the phenomenon of backing the soil during the excavation process, and effectively reduce and control the construction Sectional soil deformation.

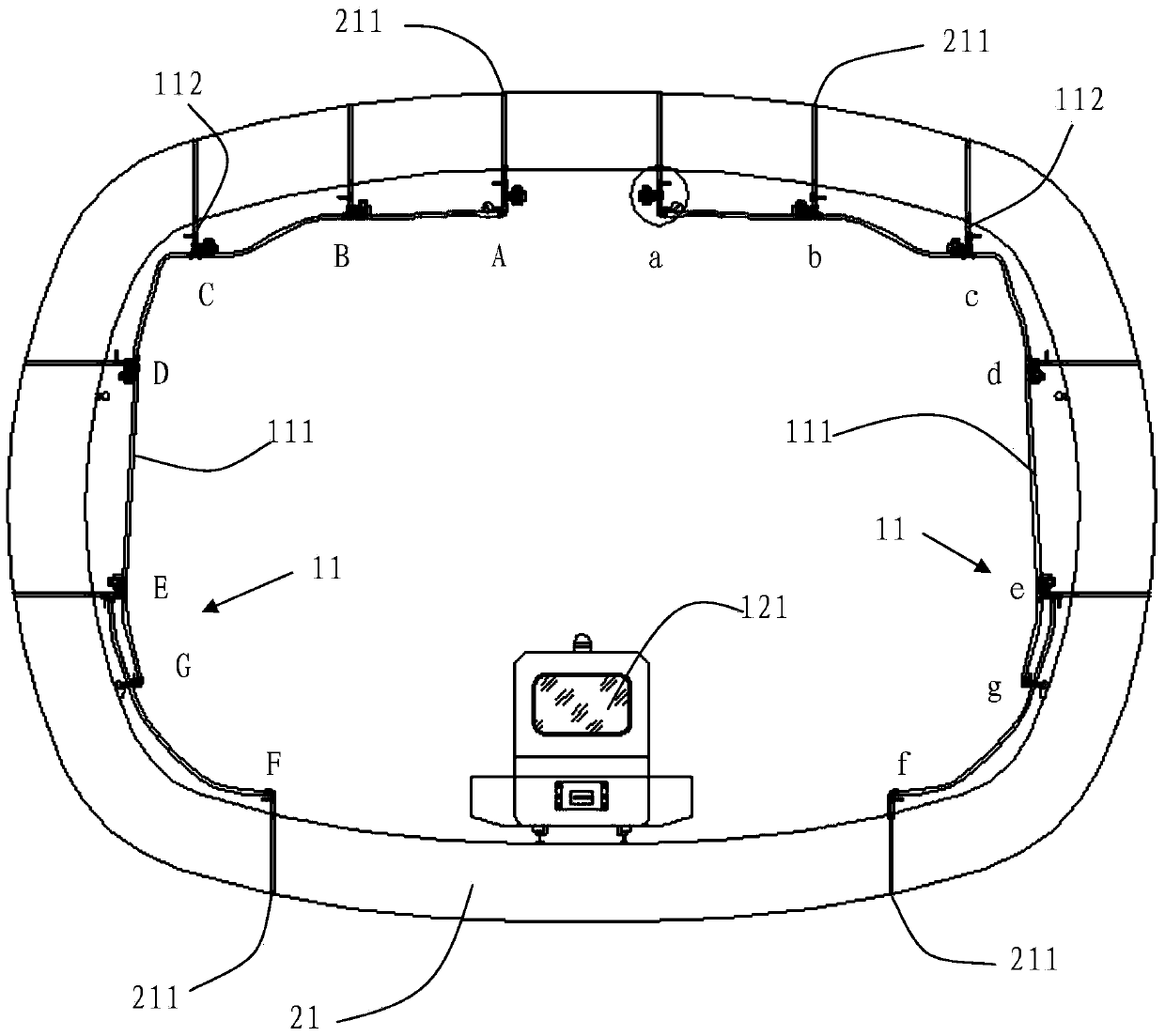

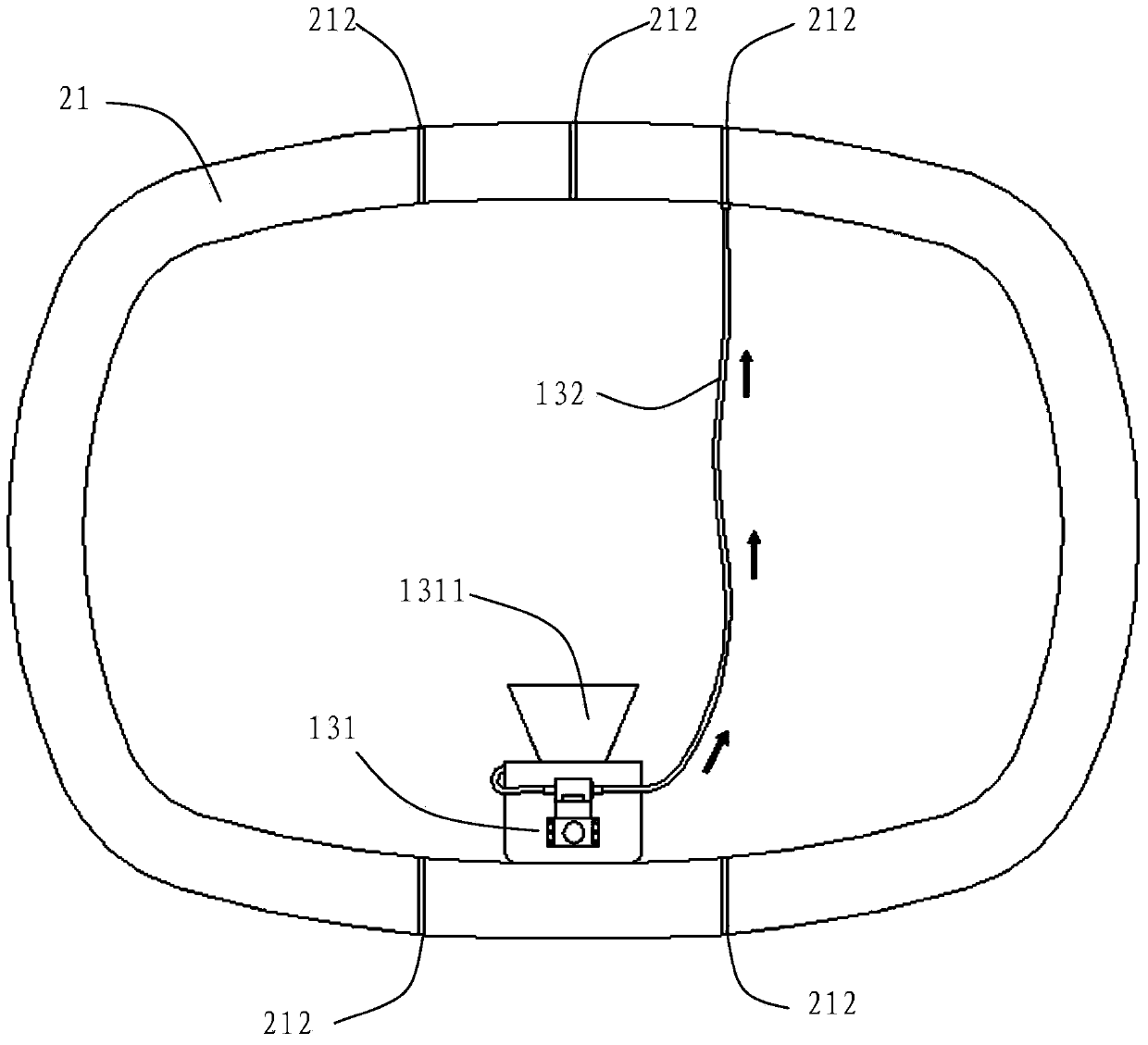

[0046] Cooperate figure 2 and im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com