Lubricating grease for shear-resistant bearings, and preparation method thereof

A technology of bearing lubrication and shear resistance, which is applied in the field of grease, can solve problems such as reducing vibration and grease performance defects, and achieve the effects of simple production equipment, improved anti-wear and anti-corrosion performance, and high shear stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

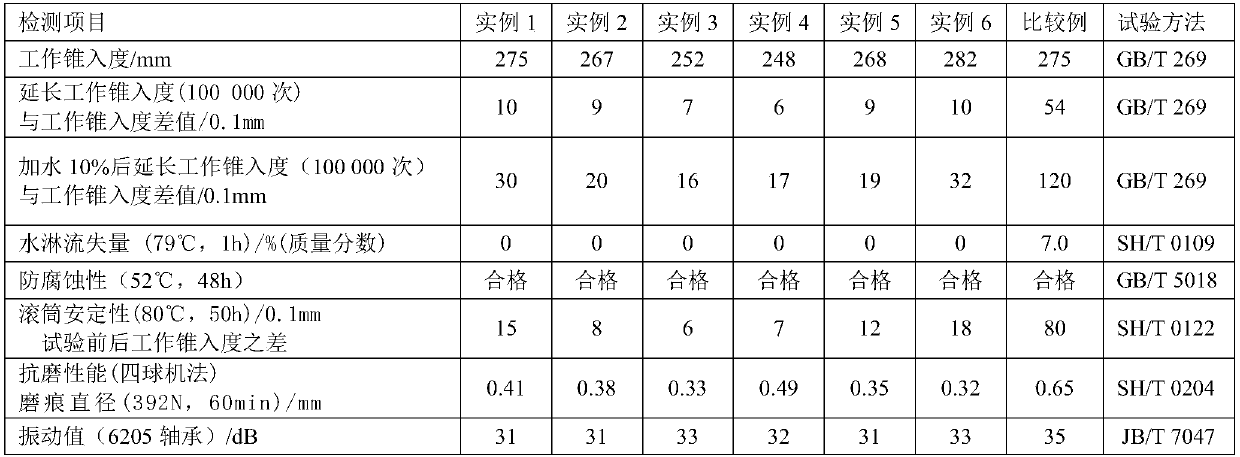

Examples

Embodiment 1

[0030] Add 2.9g of diphenylmethane diisocyanate and 270g of PAO base oil to reactor A and heat up to 50°C. After diphenylmethane diisocyanate is completely melted, add 9.2g of stearylamine melted in 270g of PAO base oil and cyclic Hexylamine 7.9g. After the reaction, raise the refining temperature to 90°C. After constant temperature for 1h, add 280g of PAO base oil and 160g of lauryl hydroxystearic acid to the B reaction kettle, raise the temperature to 80°C, and wait for the dodecyl hydroxystearic acid After the fatty acid is completely melted, it is poured into the A reactor, and at the same time, 22.4 g of LiOH aqueous solution is started to be added dropwise to the A reactor, and the control time is 0.5 h. After the end, add 1g of water and rise to the highest refining temperature to 185°C. After constant temperature for 1 hour, add 5g of diisooctyldiphenylamine and 5g of diphenylamine, cool down to 85°C naturally, add 10g of triphenyl phosphate and 10g of barium dinonylna...

Embodiment 2

[0032] Add 2.9g of diphenylmethane diisocyanate and 260g of PAO base oil to reactor A and heat up to 50°C. After diphenylmethane diisocyanate is completely melted, add 9.2g of octadecylamine melted in 260g of PAO base oil and cyclic Hexylamine 7.9g. After the reaction, the refining temperature was raised to 90°C. After the temperature was kept constant for 1 hour, 280g of PAO base oil and 180g of lauryl hydroxystearic acid were respectively added to the B reactor, and the temperature was raised to 80°C. After the fatty acid is completely melted, it is poured into the A reactor, and at the same time, 25.2 g of LiOH aqueous solution is started to be added dropwise to the A reactor, and the control time is 0.5 h. After the end, add 1g of water and rise to the highest refining temperature to 185°C. After constant temperature for 1 hour, add 5g of diisooctyldiphenylamine and 10g of 2,6-di-tert-butyl-p-cresol, cool down to 85°C naturally, add 10g of tricresyl phosphate and 5g of bar...

Embodiment 3

[0034] Add 2.9g of diphenylmethane diisocyanate and 250g of PAO base oil to reactor A and heat up to 50°C. After diphenylmethane diisocyanate is completely melted, add 9.2g of octadecylamine melted in 250g of PAO base oil and cyclic Hexylamine 7.9g. After the reaction, the refining temperature was raised to 90°C. After constant temperature for 1 hour, 200g of lauryl hydroxystearic acid melted from 280g of PAO base oil was added to the reactor B, and the temperature was raised to 80°C. After the stearic acid is completely melted, it is poured into the A reactor, and at the same time, 28g of LiOH aqueous solution is added dropwise to the A reactor, and the control time is 0.5h. After the end, add 1g of water and rise to the highest refining temperature to 185°C. After constant temperature for 1 hour, add 5g of diisooctyldiphenylamine, cool down to 85°C naturally, add 5g of tricresyl phosphate and 10g of barium sulfonate and stir well. After the three-roll machine grinds for one...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com