8-uril grease lubricant and its preparation method

A technology of lubricating grease and lubricating oil base oil, which is applied in the direction of lubricating composition, petroleum industry, thickener, etc., can solve the problem of few reports of octaurea lubricating grease, and achieve the effect of good extreme pressure performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

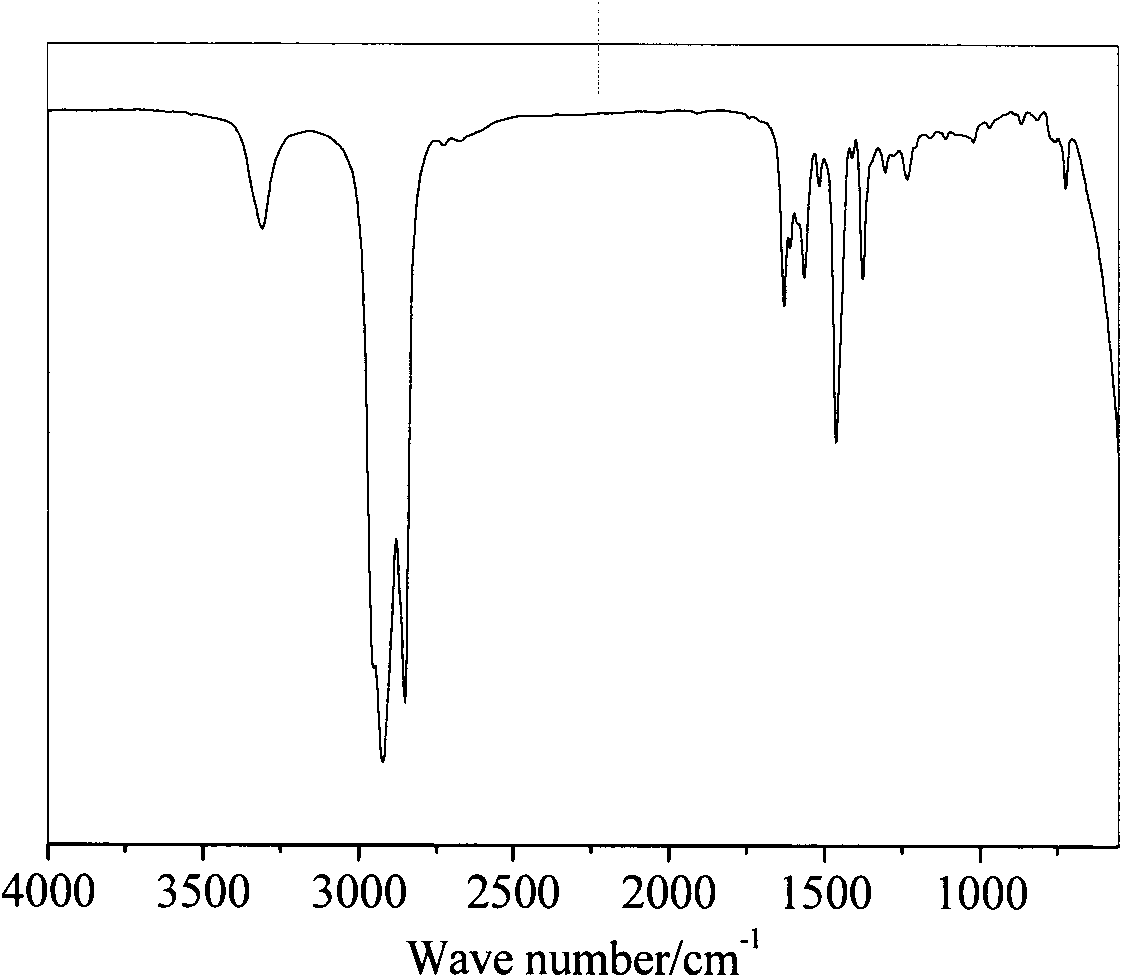

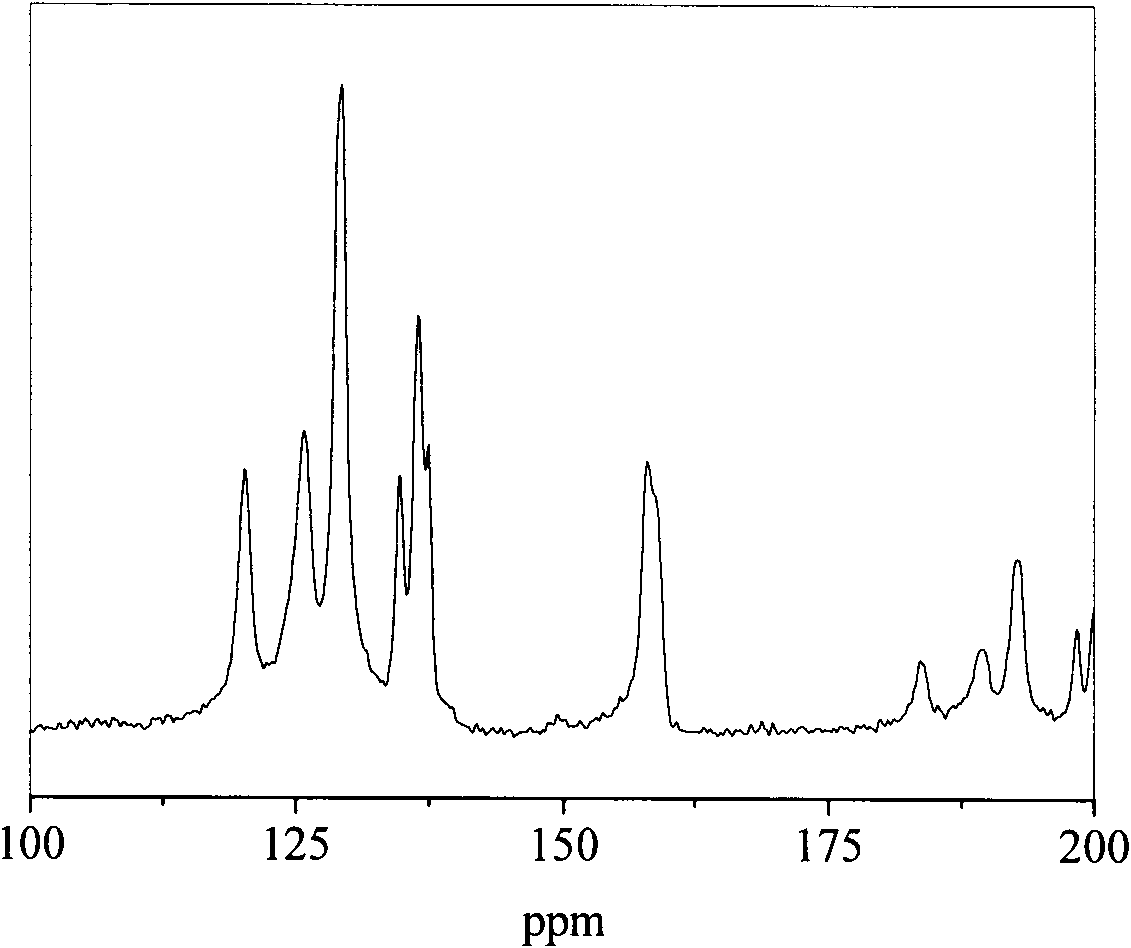

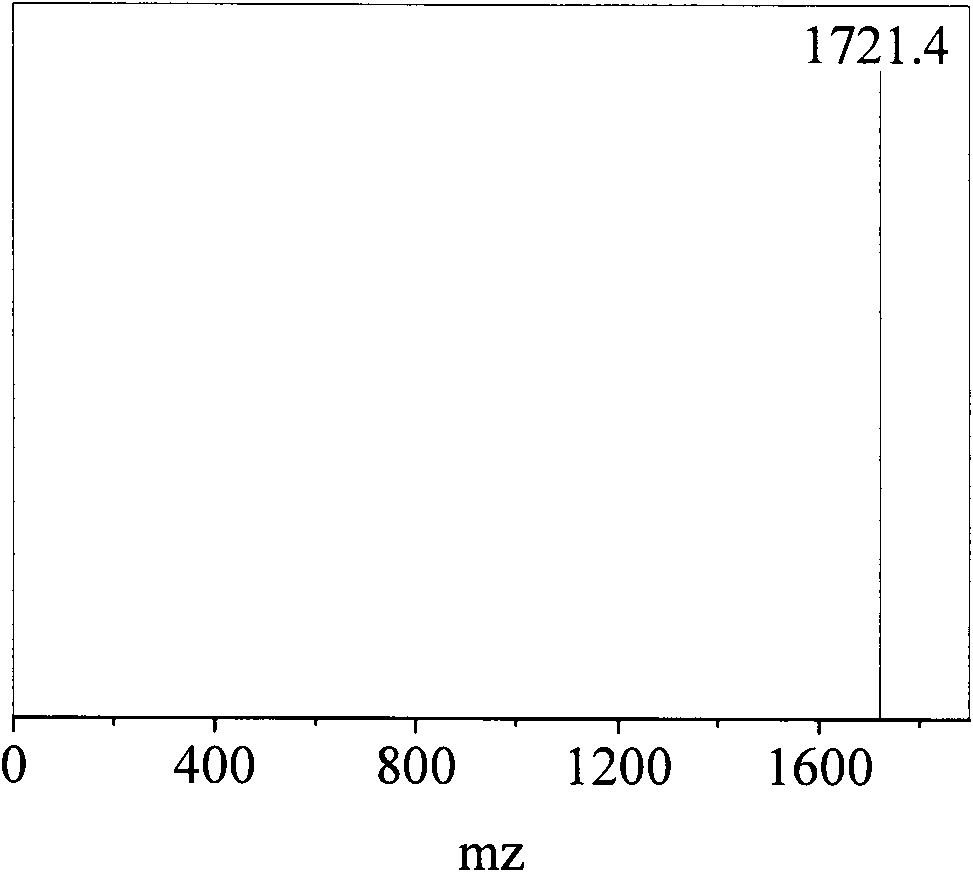

Method used

Image

Examples

Embodiment 1

[0039] First, mix about 145 grams of 500SN (kinematic viscosity at 40°C is 92-98cSt) and 37.8 grams of MDI and heat it to 50°C, slowly add 9.08 grams of ethylenediamine, raise the temperature to 80°C, react for 30 minutes, and slowly add 4.54 grams of ethylenediamine , keep the temperature at 80°C, react for 30 minutes, mix about 145 grams of base oil and 20.37 grams of octadecylamine, heat it to 60°C and add it to the above mixture, keep the temperature at 80°C, react for 30 minutes, continue to heat up to 210°C, and then add about 145 grams of Cool the base oil to about 100°C and grind it.

Embodiment 2

[0041]First, mix about 146.67 grams of 150BS (kinematic viscosity of 29cSt at 100°C) and 23.77 grams of TDI and heat it to 40°C, slowly add 5.57 grams of propylenediamine, raise the temperature to 70°C, react for 30min, slowly add 2.79 grams of propylenediamine, and keep the temperature constant 70°C, react for 30 minutes, mix about 146.67 grams of base oil and 27.88 grams of dodecylamine, heat to 50°C and add to the above mixture, keep the temperature at 70°C, react for 30 minutes, continue to heat up to 200°C, and then add about 146.67 grams of base oil Cool to about 80°C and grind.

Embodiment 3

[0043] First, mix about 148.33 grams of PAO10 synthetic oil (kinematic viscosity at 100 °C is 9.8-10.2 cSt) and 31.27 grams of HDI and heat it to 45 °C, slowly add 10.05 grams of p-phenylenediamine, heat up to 75 °C, react for 30 minutes, and slowly add 5.03 gram of p-phenylenediamine, keep the temperature at 75°C, react for 30min, mix about 148.33g of base oil and 8.66g of aniline and heat it to 55°C, add it to the above mixture, keep the temperature at 75°C, react for 30min, continue to heat up to 205°C, then add 148.33 About one gram of base oil is cooled to about 90°C for grinding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com