Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Energy saving materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene-modified antibacterial anticorrosive paint

ActiveCN109777262ASolve practical problems in the field of antibacterial and antisepticEnergy saving materialsAntifouling/underwater paintsPaints with biocidesEpoxyMarine equipment

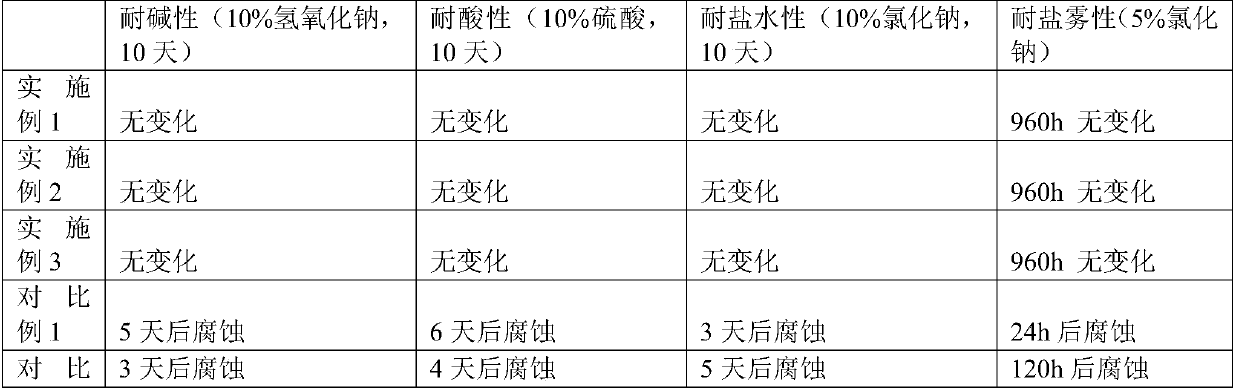

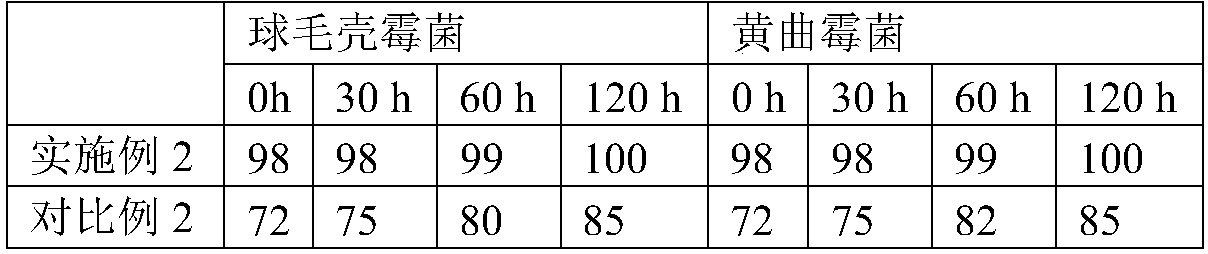

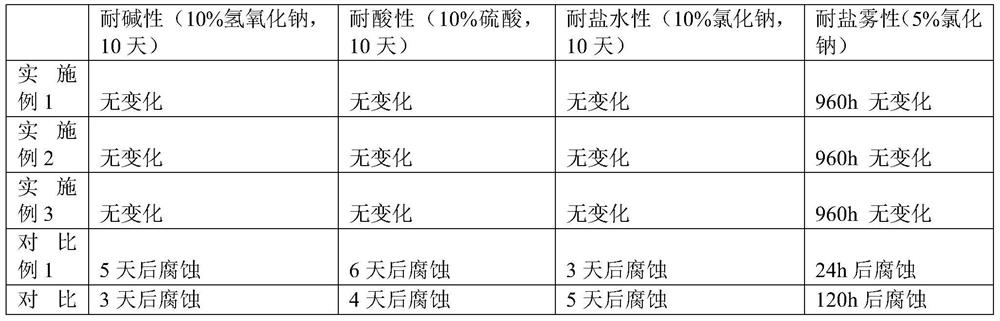

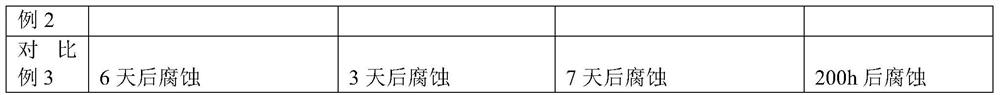

The invention relates to the field of antibacterial anticorrosive products, especially to a graphene-modified antibacterial anticorrosive paint. Raw materials of the antibacterial anticorrosive paintcomprise, by weight, 30-50 parts of epoxy resin, 15-35 parts of modified diatomite, 0.5-10 parts of a graphene material, 0.5-1 part of nano-silver particles, 8-20 parts of a filler, 1.5-6 parts of anauxiliary agent, 13-15 parts of nano-silver cooper-supported POSS-based resin and 16-25 parts of water. The prepared graphene-modified antibacterial anticorrosive paint can solve practical problems inthe fields of ship, marine equipment, granary, etc. which have antibacterial and anticorrosive requirements. The product has good economic benefit, and energy materials are saved. The product has excellent adhesion and good wear resistance in the aspects of steel structures, metal plates, etc., and can be resistant to high and low temperature, high salinity and bacterial corrosion to achieve theantibacterial and anticorrosive effect.

Owner:ZHEJIANG SCI-TECH UNIV

Polypropylene composition special for automobile bumpers and preparing method thereof

The invention discloses a polypropylene composition special for automobile bumpers and a preparing method thereof. The raw material formula of the polypropylene composition special for automobile bumpers is composed of, by weight, 30-50 parts of copolymerization polypropylene, 30-50 parts of copolymerization polypropylene reclaimed materials, 10-30 parts of calcium carbonate, 15-25 parts of flexibilizer, 0.1-0.5 part of antioxidant 1010, 0.1-0.5 part of antioxidant 168, 0.3-0.5 part of uvioresistant agent UV-531 and 0.08-0.1 part of diffusing powder ethylene bis stearamide (EBS). The polypropylene composition special for automobile bumpers can meet basic indexes of the automobile bumpers, has some indexes surpassing the world industrial level, has good characteristics of high rigidity, impact resistance, scratching resistance and low temperature resistance, can resist 95 DEG C high temperature and -30 DEG C low temperature, is solarization resistant and aging resistant, has service life as long as more than 15 years, can be recycled for reconstruction, and is an optimum material capable of protecting environment, being recycled, saving energy and reducing emission.

Owner:阜阳创启工艺品有限公司

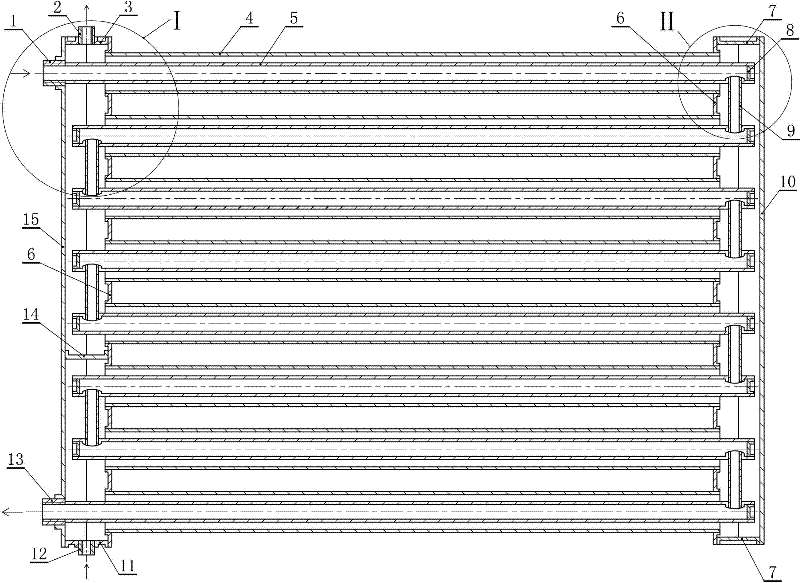

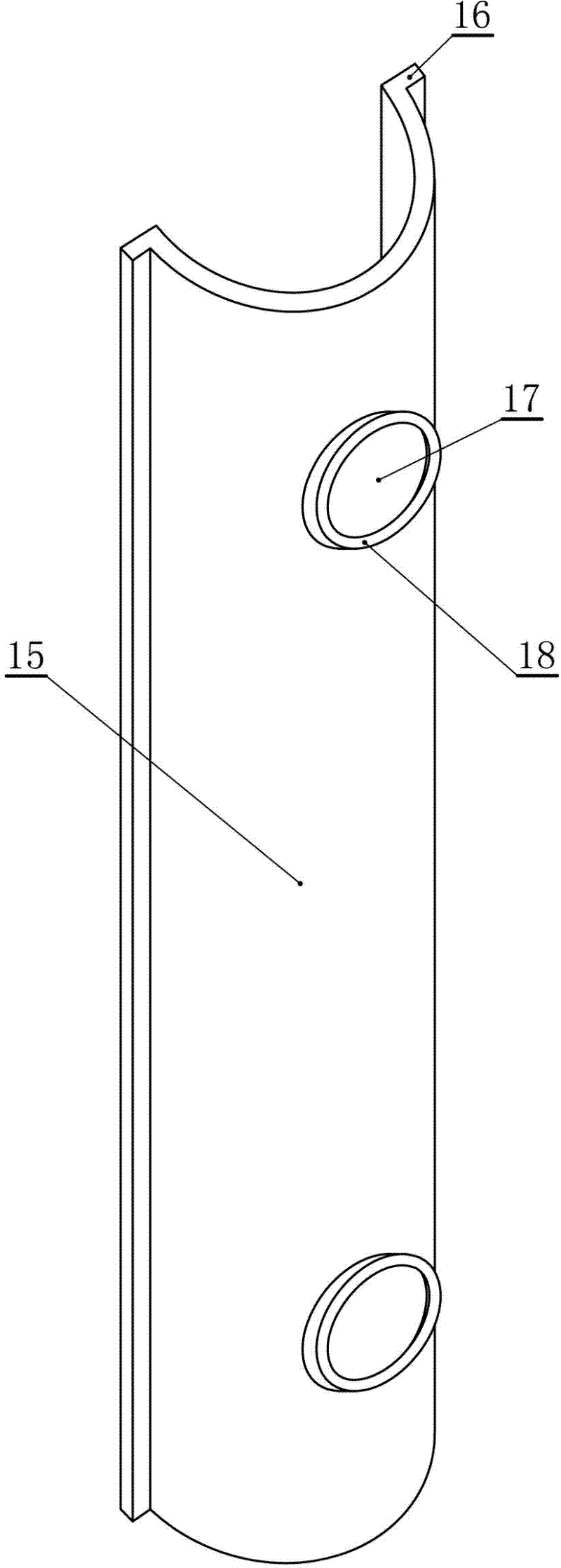

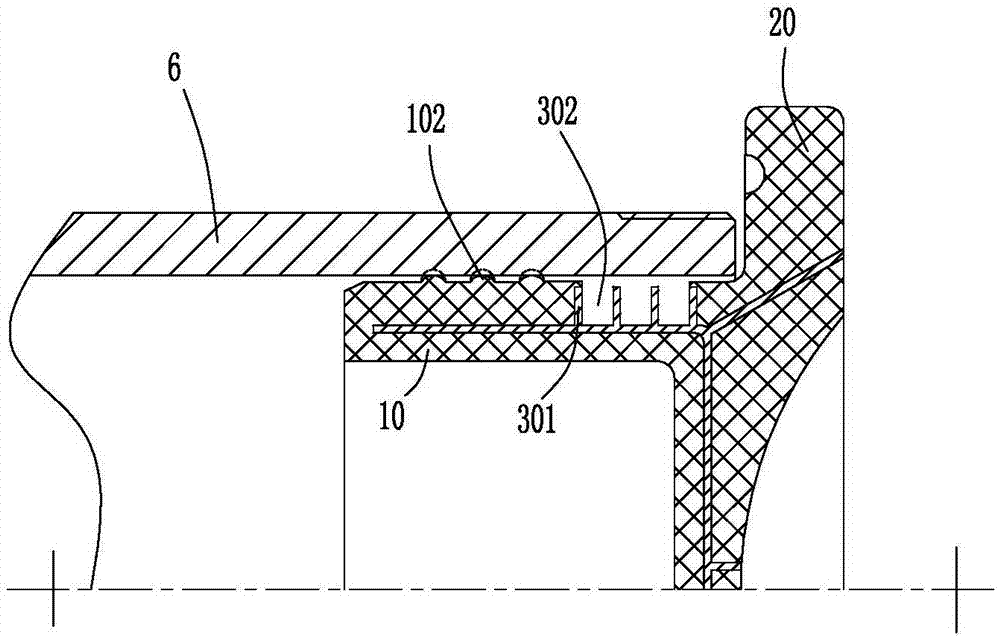

Circular pipe communicated, spliced, edge-pinched, and welded pressure-bearing heat exchanger, and manufacturing process thereof

ActiveCN102418956ASolve the problem of water leakage under pressureReduce difficultySpace heating and ventilation detailsHeat exchanger casingsPlate heat exchangerWater leakage

The invention discloses a circular pipe communicated, spliced, edge-pinched, and welded pressure-bearing heat exchanger, and a manufacturing process thereof. The heat exchanger comprises two headers, wherein a tap water communication pipe is fixedly connected between the two headers; a hot air heat supply pipe passes through the tap water communication pipe; each header is formed by welding two arc plates; the plate edges of the arc plates are flanged outwards; the plate edges of the two arc plates are aligned with each other and are subjected to edge-pinching and self-fluxing welding to form a circular tubular header cylinder body; head blocking plates of the headers are flanged outwards and are embedded at two ports of the circular tubular headers; and the two edges are aligned with a pipe wall surface, are spliced and are subjected to the edge-pinching and the self-fluxing welding to form the headers. An installation hole is punched on each arc plate; the installation hole is stretched inward an arc to form an edge; the aperture and the height of are stretched according to the arc plates; and the end surfaces of the two ends of the tap water communication pipe are subjected to R-angle cutting according to the stretching hole diameter and the stretching height of the arc plates, and then the tap water communication pipe is inserted into the installation holes stretched from the arc plates, are matched with each other, are spliced and are subjected to edge-pinching and self-fluxing welding connection. In the heat exchanger, welding seams are spliced, the edge-pinching welding is easy to realize, and water leakage is avoided; and the heat exchanger is good in pressure-bearing performance, and low in maintenance cost.

Owner:张伟

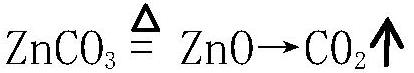

Composition used for preparing dumbbell and dumbbell preparation method using same

InactiveCN101619154AImprove economic efficiencyLow costDumb-bellsDomestic articlesSpecific gravityCast iron

The invention discloses a composition used for preparing dumbbells and a dumbbell preparation method using same. The composition comprises the following components according to the parts by weight: 2-4 parts of trans-isoprene, 5-8 parts of ethylene-vinyl acetate copolymer (EVA), 45-60 parts of iron ore powder and 45-60 parts of barite powder and performance additive. The invention also discloses a dumbbell preparation method using the composition. The invention is energy-saving and environmentally friendly; wherein, the preparation method can save more energy materials in the production process and generate no pollution to the environment, and the composition contains no toxic substance and can be recycled. The cast iron substitute prepared by the preparation method has bigger specific gravity with a density of 3-3.5g / m<3> and can satisfy the operating requirement of family fitness equipments.

Owner:青岛鑫三鸿塑胶制品有限公司

Anti-rust liquor and processing method therefor

The invention relates to antirust fluid. The invention also relates to a processing method of the antirust fluid. The antirust fluid made by the method is provided with obvious antirust function and has light even no pollution to the environment. The antirust fluid is generated mainly from the action of alkcnyl succinic acid and monoethanolamine. The mole ratio of alkcnyl succinic acid to monoethanolamine is 0.5-1 to 1. The main components of the antirust fluid are alkcnyl succinic acid dodecenylbutadioic, water and monoethanolamine.

Owner:马国伟 +1

3D printing building material

ActiveCN106186810AEasy constructionLow costAdditive manufacturing apparatusAntioxidantProviding material

The invention provides a 3D printing building material and belongs to the field of building materials. According to the technical scheme, the 3D printing building material is characterized by comprising raw materials in percentage by mass as follows: 10%-15% of polyethylene particles, 75%-85% of silicate powder and 5%-12% of an antioxidant. The 3D printing building material has the beneficial effects as follows: (1), the provided material is easy to operate, rapid printing, rapid forming, rapid warehousing and rapid use are realized, and a formed building wall is good in firmness, high in impact strength, high in ageing resistance and low in cost; (2), the material is easy to prepare and suitable for being widely popularized and applied, and the problem about recovery of the building material is solved.

Owner:河北玉蜘蛛智能科技有限公司

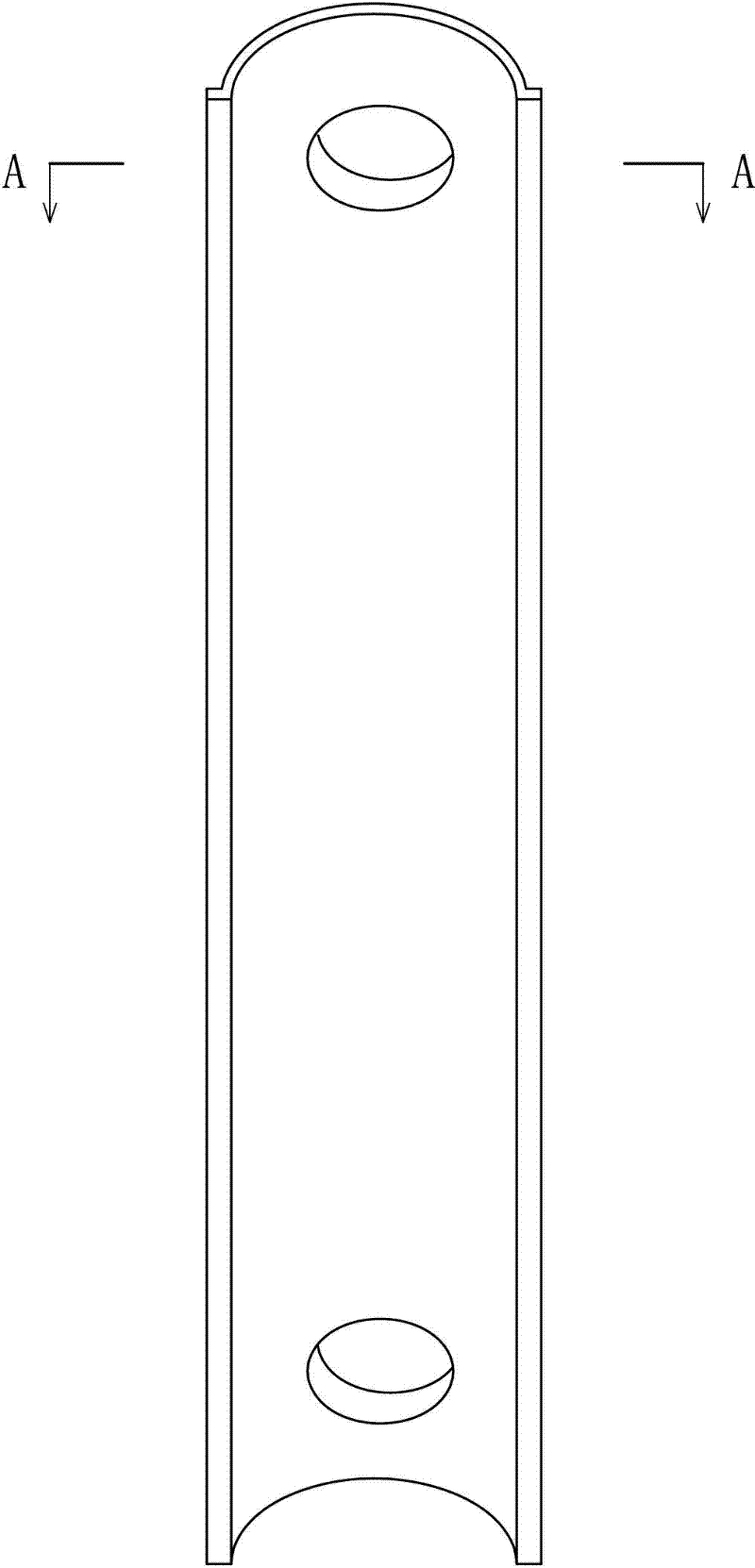

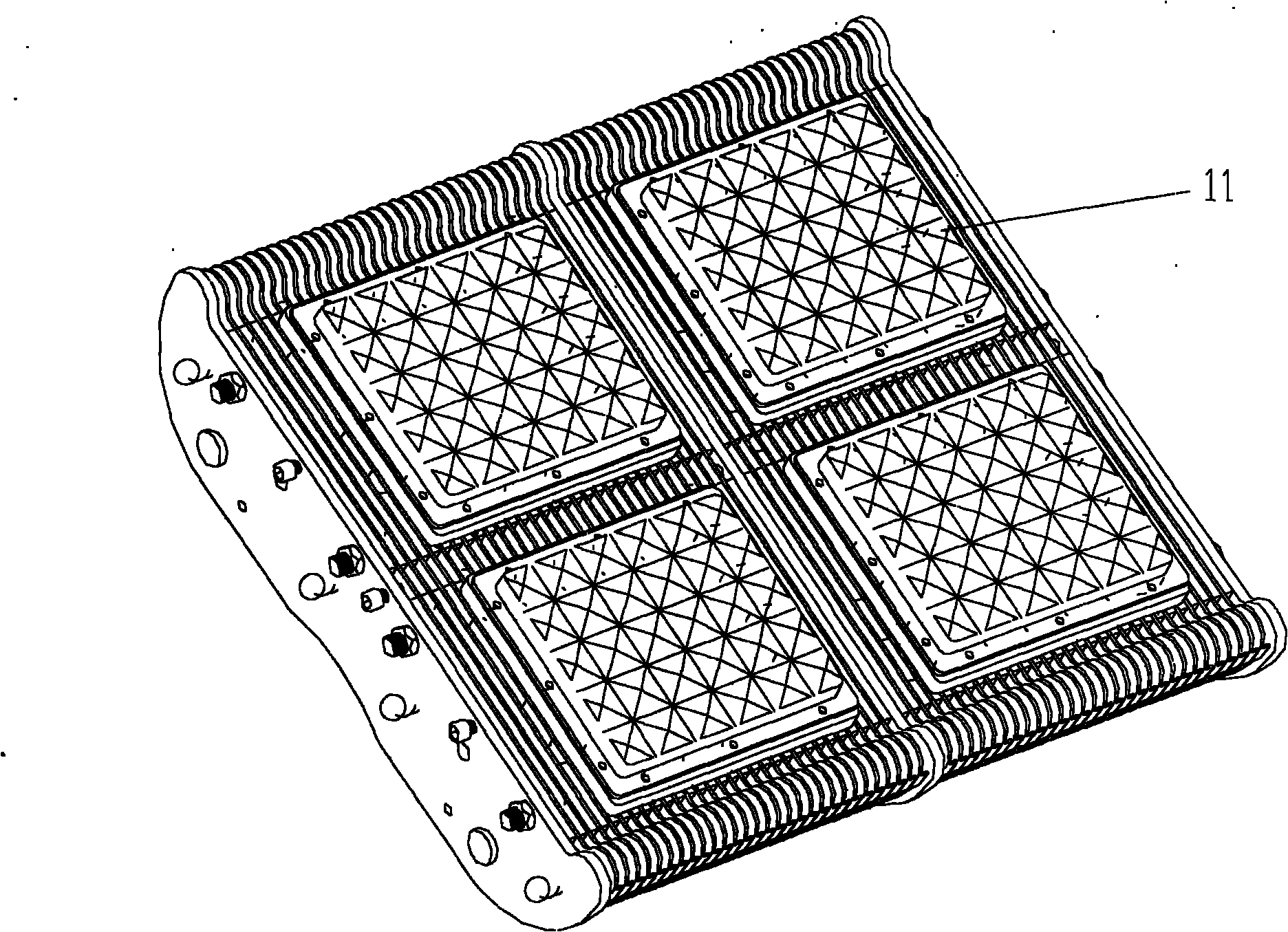

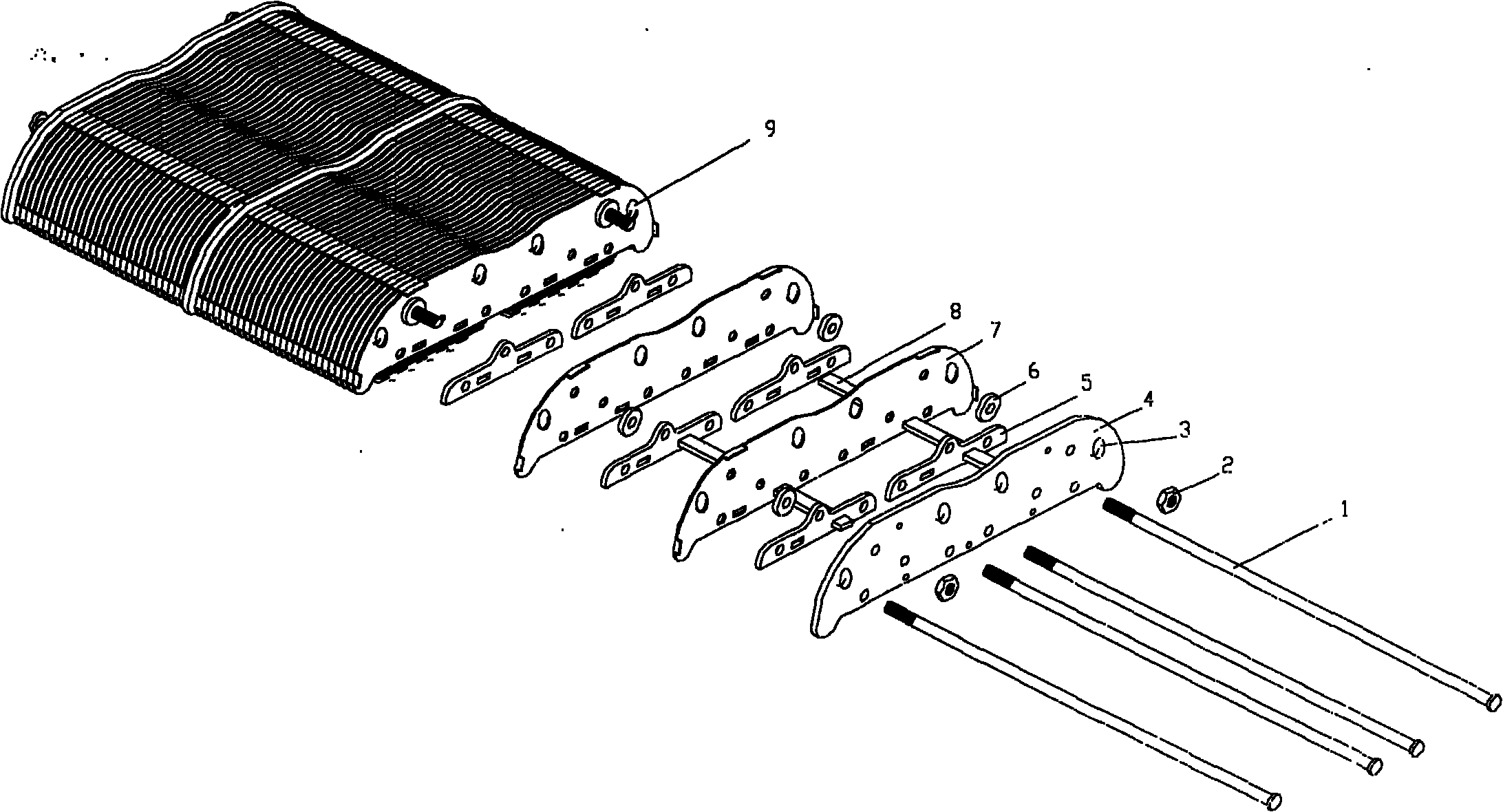

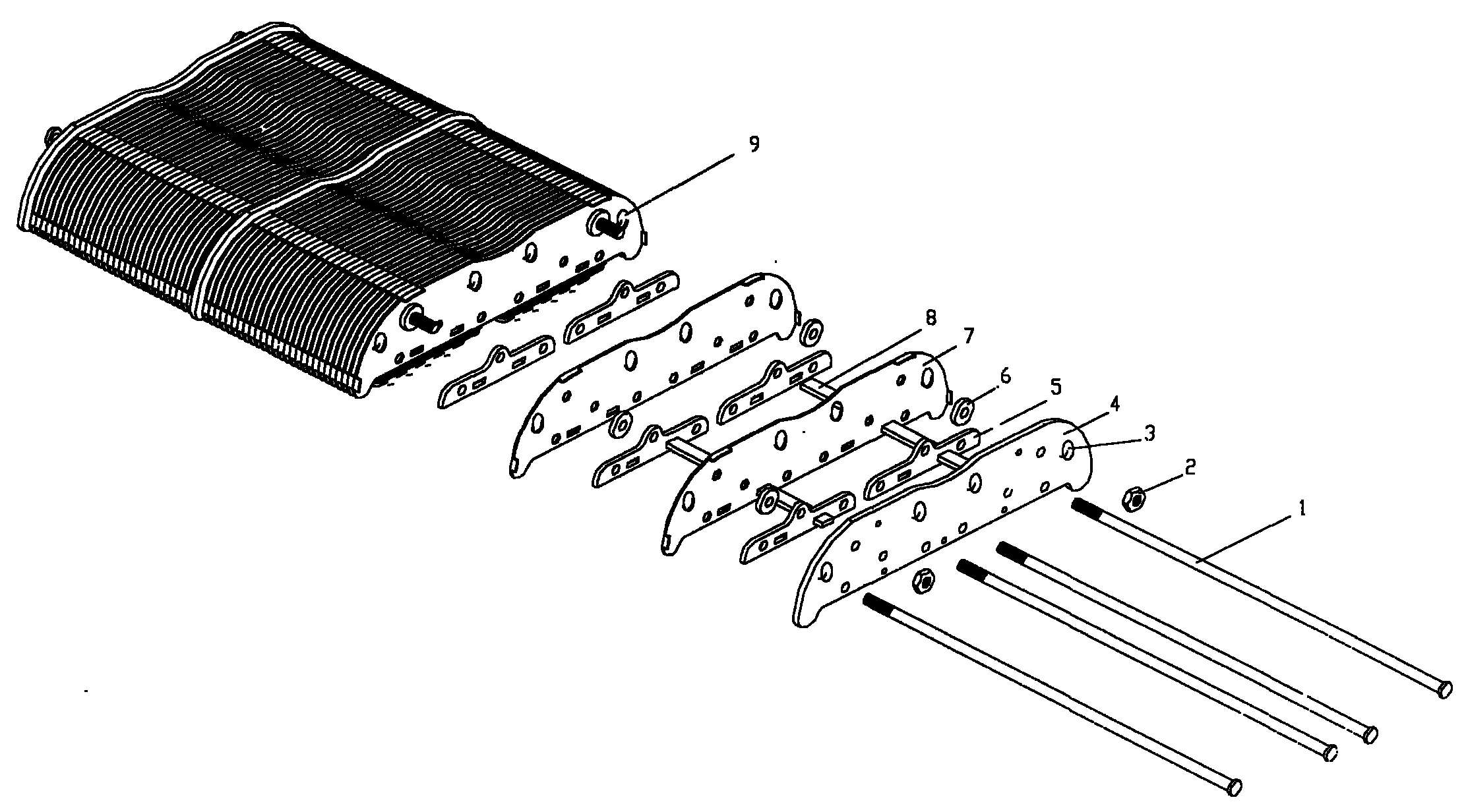

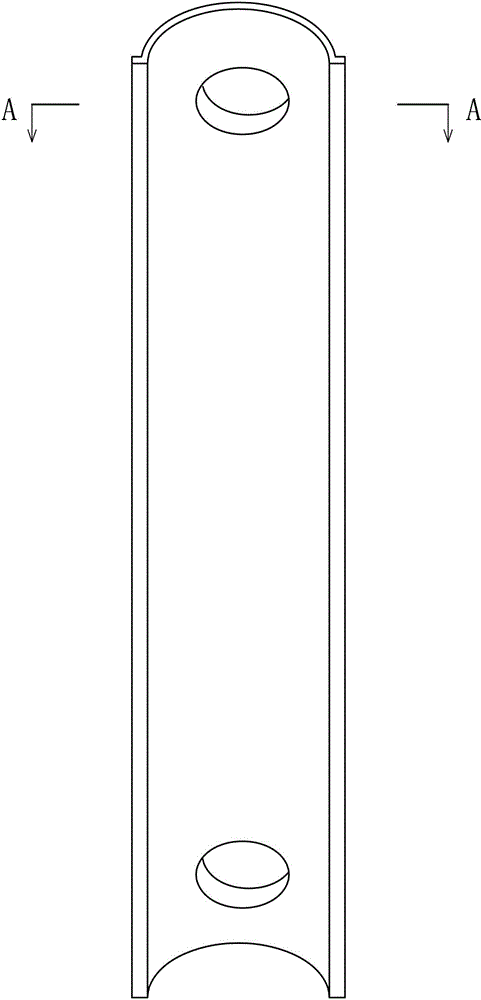

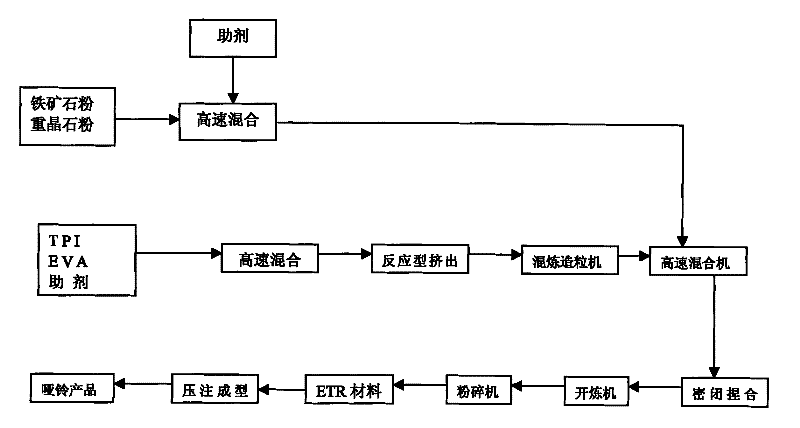

Method for manufacturing radiator of LED street lamp

InactiveCN102116461AIncrease productivityImprove recycling ratesPoint-like light sourceLighting heating/cooling arrangementsEconomic benefitsEngineering

The invention discloses a method for manufacturing a radiator of a light-emitting diode (LED) street lamp, by which the radiator is processed easily, the cost is low, and the finished product has a high heat radiation speed and high efficiency. The method comprises the following steps of: stamping sheets made of aluminum to form fins, and stamping installation through holes and elliptic through holes on the fins; stamping the sheets made of aluminum to form layer partition plates of which the areas are much smaller than those of the fins and stamping installation through holes on the layer partition plates; allowing bolts to pass through the installation through holes to superpose and fasten the fins and layer partition plates which are adjacent in pairs so as to form heat dissipation assemblies; and pressing the aluminum base plate provided with an LED circuit board against the heat dissipation assemblies for connection. By the scheme, the production efficiency is high, cost is low, and economic benefit is high; and specifically, the heat transfer effect is good, the assembly process is simple and the method is suitable for large-scale production and use.

Owner:柯智慧

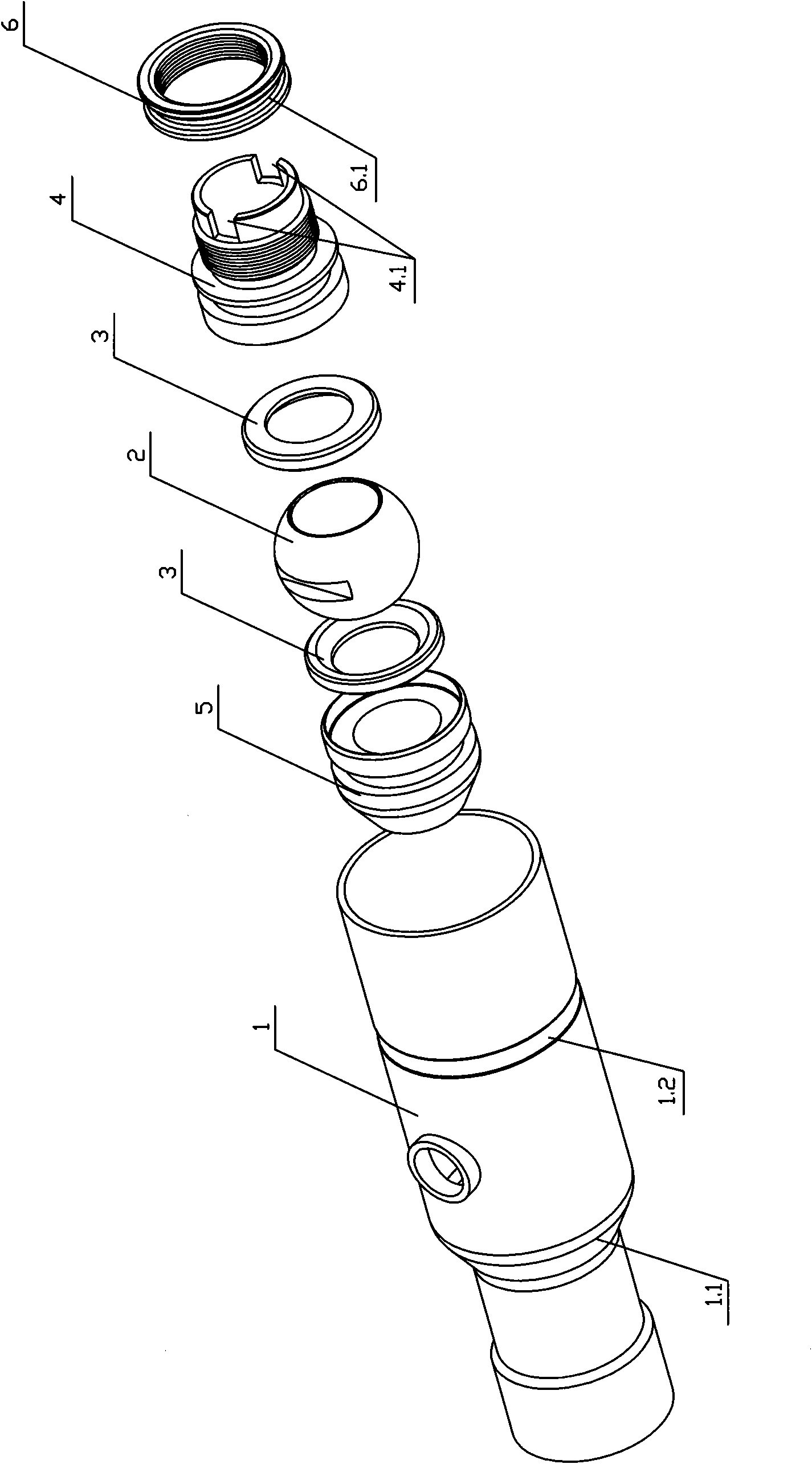

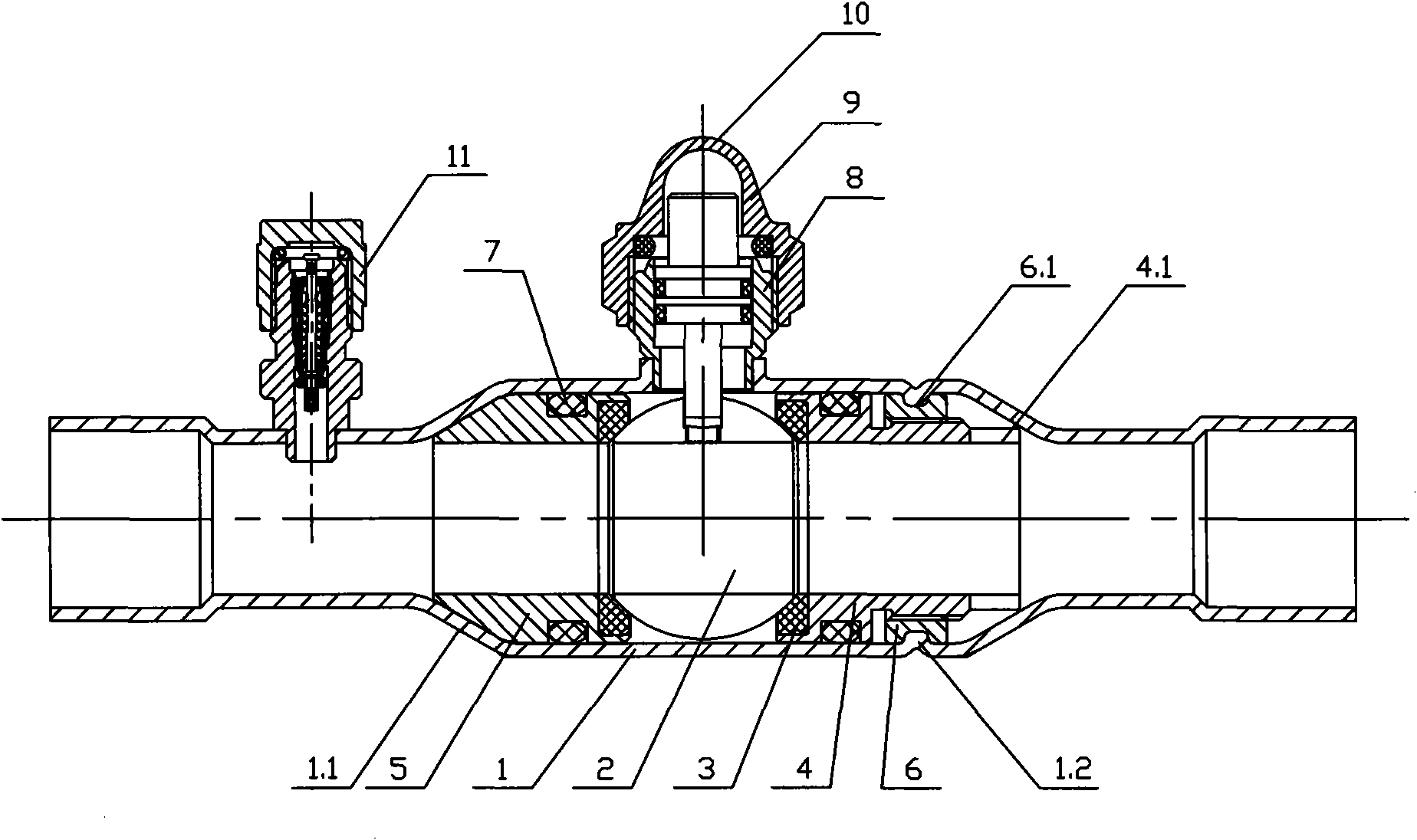

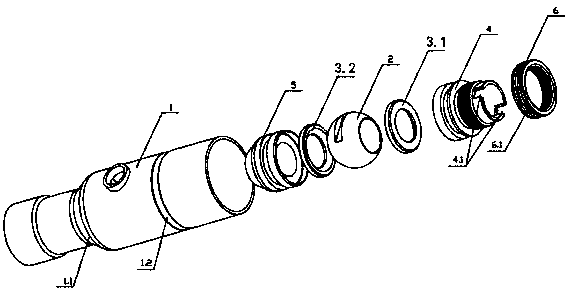

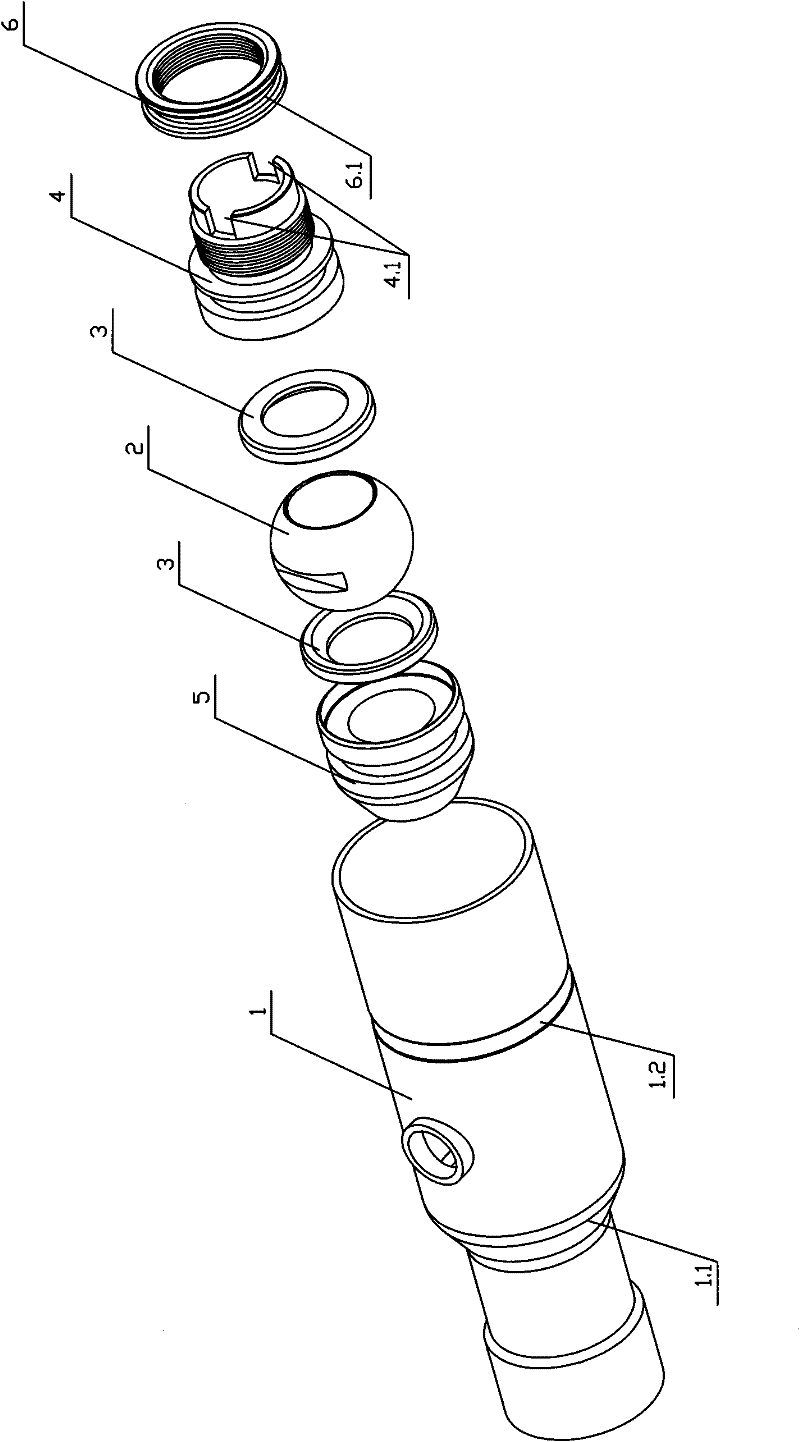

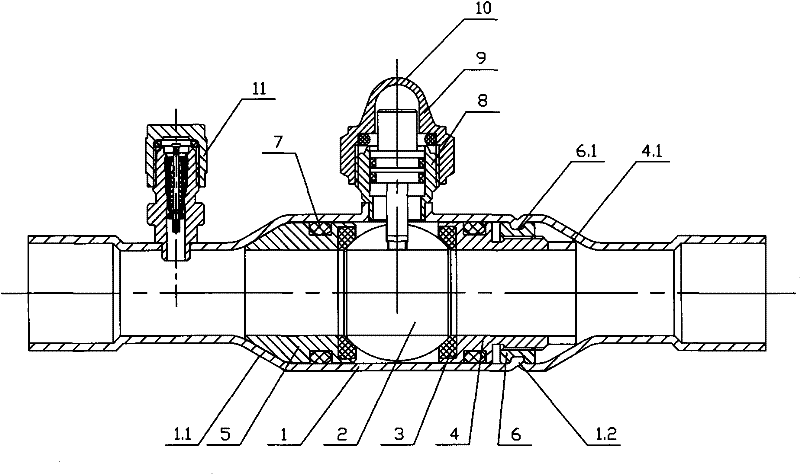

Ball valve

InactiveCN101839353AImprove the anti-leakage effectSave materialPlug valvesValve housingsEngineeringBall valve

The invention discloses a ball valve comprising a ball valve main body (1), a ball (2), two ball cushions (3), a first inner plugging body (4) and a second inner plugging body (5), wherein the ball valve main body (1) is an integrated whole and is provided with two throats (1.1) capable of limiting the corresponding inner plugging bodies in the ball valve main body (1); the other end of the first inner plugging body (4) and the other end of the second inner plugging body (5) are both abutted on the inner wall of the throats (1.1) of the ball valve main body (1); and an actuating device capable of adjusting tightness is arranged between one of the first inner plugging body (4) and the second inner plugging body (5) and the ball valve main body (1). The ball valve has favorable leakage-proof performance, material saving, high processing efficiency and low cost, does not affect internal parts when being assembled and does not leak when being adjusted.

Owner:宁波日月制冷设备有限公司

Method for planting trees in desert

InactiveCN101040596AImprove survival ratePlay the role of sand fixation and water retentionHorticulture methodsForestryLitterPotassium

The invention relates to a desert planting method, characterized in that covers a cover at edge of desert which can hold sand, water, fertilizer and temperature, in geometry shape, while the top of the cover is protruded and the cover is coated with a layer of waterproof material and the cover contains needed nutriment and chemical elements of plant, to supply water and nutriment to later planted plants. The inventive cover can be made from life waste and organic material, which contains chemical materials as potassium, magnesium and calcium needed by plants. The invention can cultivate plants in desert to protect former ground surface, and hold the plant position in cover, with which later planted plants can grow easily. The invention can be used to cultivate trees in desert first and then plant other dry-resistant farm crops to be used in desert edge and semi-dry area.

Owner:张小敏

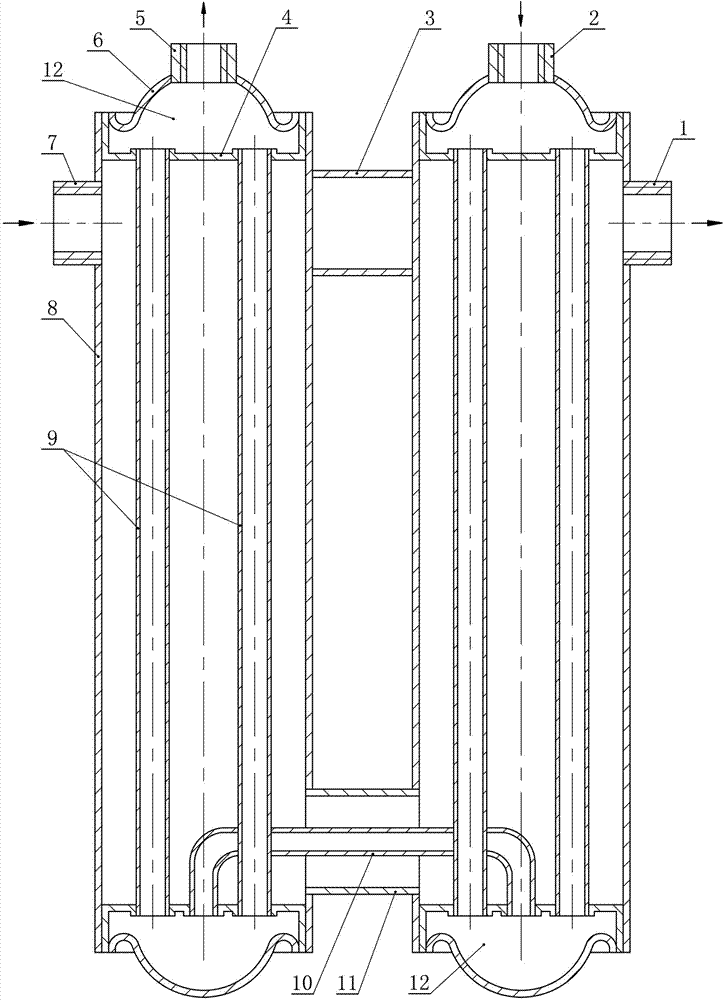

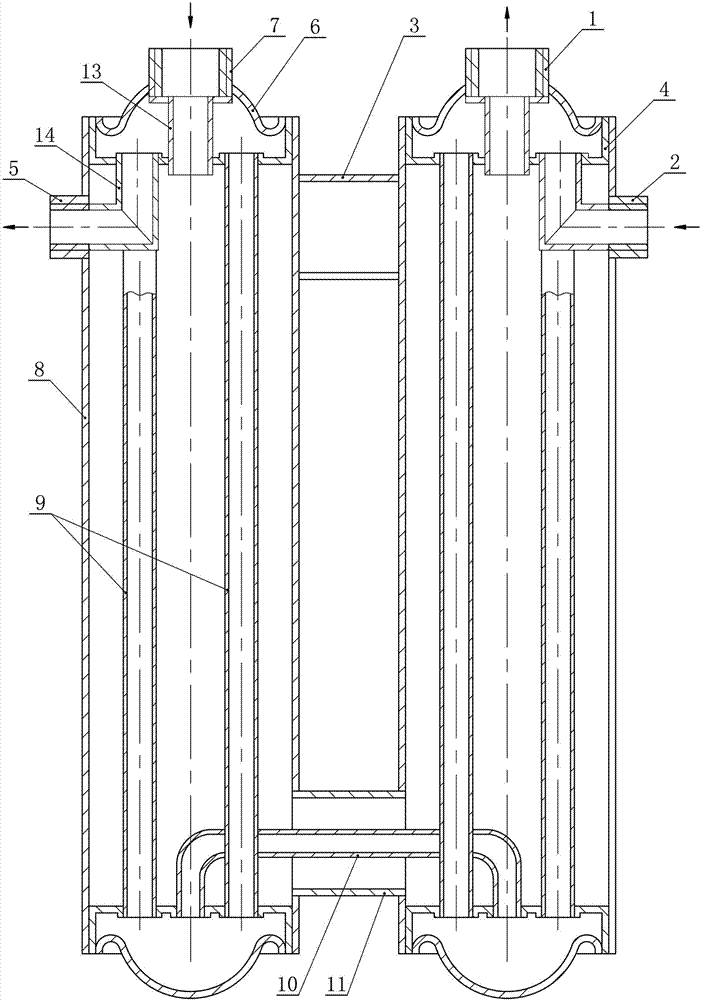

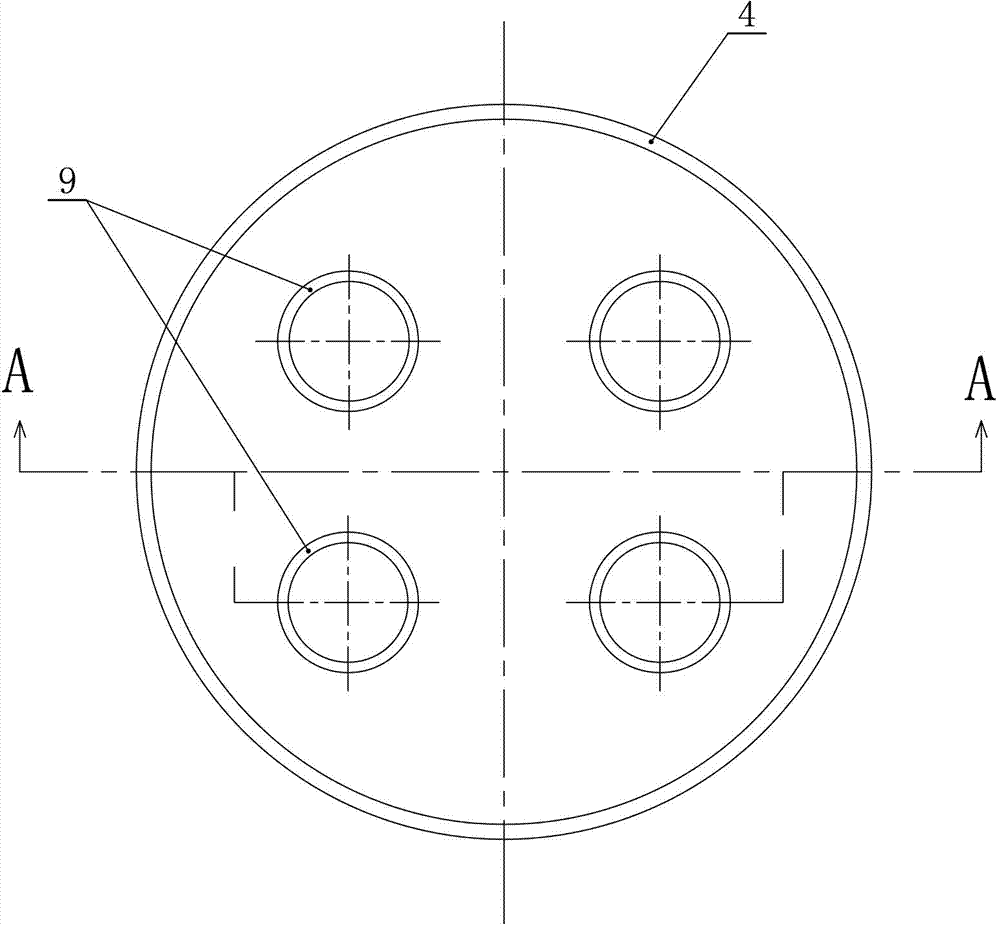

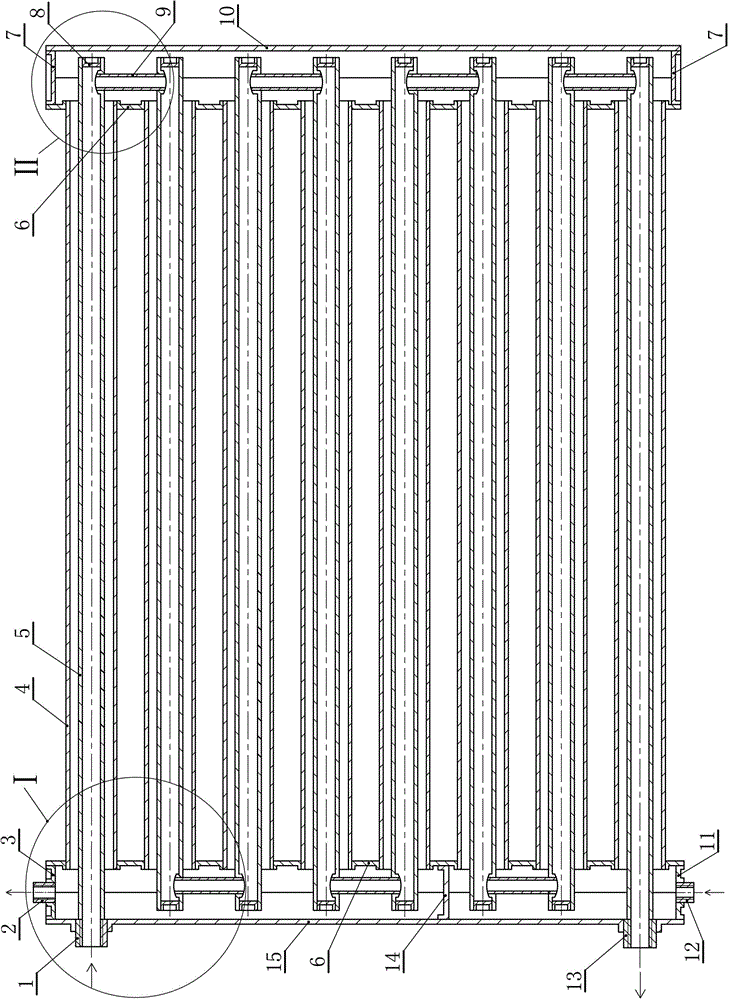

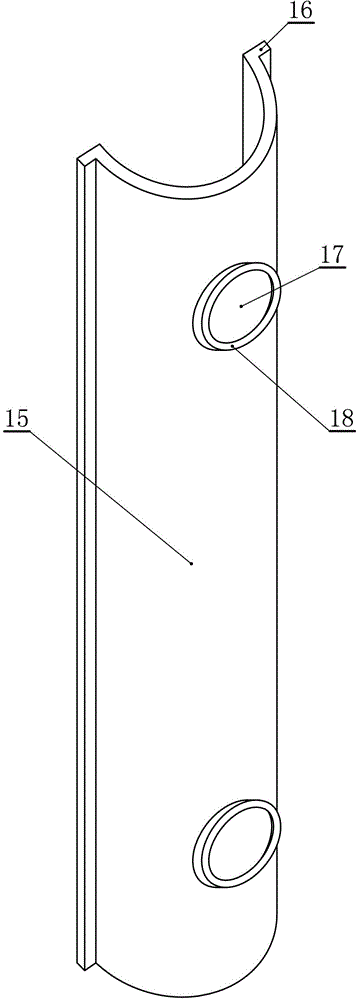

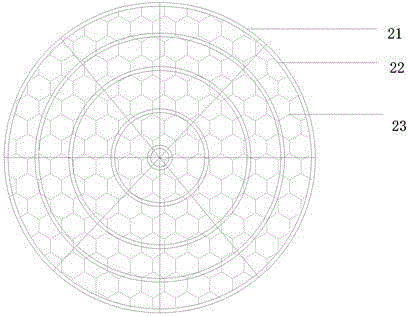

Multi-cold water pipe and multichannel heat absorption open-type communicating heat exchanger and manufacturing process thereof

InactiveCN102788523AAchieve heat exchange effectSave materialArc welding apparatusStationary tubular conduit assembliesEngineeringThermal water

The invention discloses a multi-cold water pipe and multichannel heat absorption open-type communicating heat exchanger and a manufacturing process thereof and is used for changing cold water into hot water to take a bath in families. Porous inner plates are respectively and fixedly welded in both ends of more than two heat supply pipes; end sealing plates are fixedly welded outside both ends of each heat supply pipe; cold water heat collection distribution chambers are formed by the porous inner plates and the end sealing plates; each two heat supply pipes are welded to be communicated through a heat supply pipe communicating straight pipe; more than two cold water pipes are interpenetrated into each heat supply pipe; both ends of each cold water pipe and the porous inner plates are welded to be communicated in the manner of opening; a cold water communicating pipe penetrates through the heat supply pipe communicating straight pipe, and both ends of the cold water communicating pipe and the porous inner plates in the adjacent two heat supply pipes are welded to be communicated; a cold water inlet / outlet and the cold water heat collection distribution chambers of side pipes at both sides of the heat supply pipes are welded to be communicated; and a warm air inlet / outlet and the side pipes at both sides of the heat supply pipes are welded to be communicated. According to the multi-cold water pipe and multichannel heat absorption open-type communicating heat exchanger disclosed by the invention, the heat absorption area is increased by fully utilizing an effective heat source through multi-dividing wall heat absorption and stepped heat transfer, therefore, the heat absorption is rapid, and the heat exchange efficiency that the temperature is changed in the manner of gradient is high.

Owner:张伟

A 3D printing building material

ActiveCN106186810BEasy constructionLow costAdditive manufacturing apparatusMaterials preparationRapid prototyping

The invention provides a 3D printing building material, which belongs to the field of building materials. The technical solution adopted is: a 3D printing building material. The key is that the material includes the following mass percentages of raw materials: polyethylene particles 10-15%, silicon Acid powder 75‑85% and antioxidant 5‑12%. The beneficial effects are: (1) The material provided by the present invention is easy to construct, realizes rapid printing, rapid prototyping, rapid storage, and rapid use. The formed building wall has good firmness, high impact strength, and strong anti-aging ability. Low cost; (2) The material preparation is simple, suitable for widespread promotion and application, and solves the problem of recycling building materials.

Owner:河北玉蜘蛛智能科技有限公司

Circular pipe communicated, spliced, edge-pinched, and welded pressure-bearing heat exchanger, and manufacturing process thereof

ActiveCN102418956BSolve the problem of water leakage under pressureReduce difficultySpace heating and ventilation detailsHeat exchanger casingsPlate heat exchangerWater leakage

The invention discloses a circular pipe communicated, spliced, edge-pinched, and welded pressure-bearing heat exchanger, and a manufacturing process thereof. The heat exchanger comprises two headers, wherein a tap water communication pipe is fixedly connected between the two headers; a hot air heat supply pipe passes through the tap water communication pipe; each header is formed by welding two arc plates; the plate edges of the arc plates are flanged outwards; the plate edges of the two arc plates are aligned with each other and are subjected to edge-pinching and self-fluxing welding to form a circular tubular header cylinder body; head blocking plates of the headers are flanged outwards and are embedded at two ports of the circular tubular headers; and the two edges are aligned with a pipe wall surface, are spliced and are subjected to the edge-pinching and the self-fluxing welding to form the headers. An installation hole is punched on each arc plate; the installation hole is stretched inward an arc to form an edge; the aperture and the height of are stretched according to the arc plates; and the end surfaces of the two ends of the tap water communication pipe are subjected to R-angle cutting according to the stretching hole diameter and the stretching height of the arc plates, and then the tap water communication pipe is inserted into the installation holes stretched from the arc plates, are matched with each other, are spliced and are subjected to edge-pinching and self-fluxing welding connection. In the heat exchanger, welding seams are spliced, the edge-pinching welding is easy to realize, and water leakage is avoided; and the heat exchanger is good in pressure-bearing performance, and low in maintenance cost.

Owner:张伟

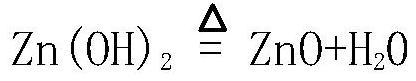

Method for producing zinc oxide for ceramic glaze by using hot-dip galvanized ash

The invention discloses a method for producing zinc oxide for ceramic glaze by using hot-dip galvanizing ash, which comprises the following steps: wet ball milling, filtering to remove iron, wet dechlorination, drying and calcining, wherein zinc in the hot-dip galvanizing ash is recovered in the form of zinc oxide which can be directly applied to the ceramic glaze. According to the method, the dechlorinated zinc ash is directly dried and calcined to prepare a zinc oxide product, high-temperature reduction volatilization and reoxidation are not needed, the recovery rate of zinc is increased and can reach 99%, meanwhile, a large amount of energy materials such as high-quality anthracite (or coke powder) are saved, the production cost is reduced, and good economic benefits are achieved; and the production process is clean and environment-friendly, no solid waste is generated in the whole process, no smoke is discharged, zero wastewater is discharged, good environment-friendly benefits are achieved, and the prepared zinc oxide is large in specific gravity, good in flowability, low in volatile matter and capable of being directly applied to the ceramic glaze industry.

Owner:李发武

Building material applied to three-dimensional printing technology

InactiveCN107555934AEasy constructionEasy to makeAdditive manufacturing apparatusSodium phosphatesFreeze-drying

The invention discloses a building material applied to a three-dimensional printing technology. The building material is prepared from the raw materials in parts by weight: 60 to 70 parts of cement, 40 to 50 parts of industrial sludge, 30 to 40 parts of ceramic waste, 10 to 20 parts of kaolin compound, 30 to 40 parts of filler, 6 to 12 parts of magnesium oxide, 2 to 4 parts of aluminum sulfate, 1.5 to 2.5 parts of sodium phosphate, 15 to 25 parts of binder, 1 to 2 parts of water reducing agent and 60 to 80 parts of water. The kaolin compound is prepared by the following technology: mixing lauryl sodium sulfate, ammonium acetate, kaolin, water and manitol; warming; stirring; dropwise adding into normal hexane in a stirring state; adding tetrachloro-silicane and tetraethyl orthosilicate after dropwise adding; stirring; washing by normal hexane; vacuum freeze-drying to obtain the kaolin compound.

Owner:WUHU LINYI ELECTRONICS SCI & TECH

Composition used for preparing dumbbell and dumbbell preparation method using same

InactiveCN101619154BNo pollutionEnergy saving materialsDumb-bellsDomestic articlesToxic materialPollution

The invention discloses a composition used for preparing dumbbells and a dumbbell preparation method using same. The composition comprises the following components according to the parts by weight: 2-4 parts of trans-isoprene, 5-8 parts of ethylene-vinyl acetate copolymer (EVA), 45-60 parts of iron ore powder and 45-60 parts of barite powder and performance additive. The invention also discloses a dumbbell preparation method using the composition. The invention is energy-saving and environmentally friendly; wherein, the preparation method can save more energy materials in the production process and generate no pollution to the environment, and the composition contains no toxic substance and can be recycled. The cast iron substitute prepared by the preparation method has bigger specific gravity with a density of 3-3.5g / m<3> and can satisfy the operating requirement of family fitness equipments.

Owner:青岛鑫三鸿塑胶制品有限公司

Polypropylene composition special for automobile bumpers and preparing method thereof

The invention discloses a polypropylene composition special for automobile bumpers and a preparing method thereof. The raw material formula of the polypropylene composition special for automobile bumpers is composed of, by weight, 30-50 parts of copolymerization polypropylene, 30-50 parts of copolymerization polypropylene reclaimed materials, 10-30 parts of calcium carbonate, 15-25 parts of flexibilizer, 0.1-0.5 part of antioxidant 1010, 0.1-0.5 part of antioxidant 168, 0.3-0.5 part of uvioresistant agent UV-531 and 0.08-0.1 part of diffusing powder ethylene bis stearamide (EBS). The polypropylene composition special for automobile bumpers can meet basic indexes of the automobile bumpers, has some indexes surpassing the world industrial level, has good characteristics of high rigidity, impact resistance, scratching resistance and low temperature resistance, can resist 95 DEG C high temperature and -30 DEG C low temperature, is solarization resistant and aging resistant, has service life as long as more than 15 years, can be recycled for reconstruction, and is an optimum material capable of protecting environment, being recycled, saving energy and reducing emission.

Owner:安徽龙和电力集团有限公司

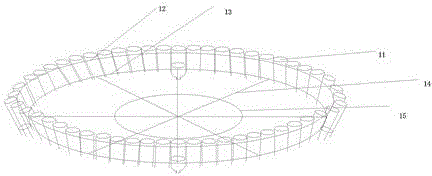

Ecological floating bed prepared from waste plastic bottles

InactiveCN106145362ANo pollutionSolve technical problems that are not conducive to energy conservation and environmental protectionBiological water/sewage treatmentEngineeringVertical axis

The invention especially relates to an ecological floating bed prepared from waste plastic bottles, belonging to the field of environmental protection. The ecological floating bed comprises plastic bottles, a lightweight framework, a binding material and a cushion net, wherein the lightweight framework is formed by firmly binding an outer framework, an inner framework and a chassis framework via a binding material; the plastic bottles are nontoxic intact waste plastic bottles, sealed mouths of the plastic bottles are placed upside down in water, and the plastic bottles are closely arranged on a side surface located between the outer framework and the inner framework; the parts, close to the bottom ends and the mouth ends, of the plastic bottles are separately fixed on the outer framework and the inner framework by using the binding material, and the vertical axis of each plastic bottle forms an angle of 0 to 180 DEG with the plane of the inner framework; a floating rack of the floating bed is composed of the plastic bottles, the inner framework and the outer framework; and the cushion net is laid on the chassis framework according to the shape of the chassis of the floating bed. The nontoxic intact plastic bottles discarded in daily life are used as a floating body material for preparation of the ecological floating bed, so the waste is turned into the valuable, everything is made the best use of, energy materials are saved, and pollution is not posed to environment.

Owner:项小飞

Carbon steel ball valve

The invention discloses a carbon steel ball valve. The other ends of a first inner cock body and a second inner cock body are pressed against an inner wall of a contracting opening of a ball valve body; a plurality of first grooves are formed in end surfaces, close to a ball, of a first seal member and a second seal member; a plurality of second grooves are formed in end surfaces, away from the ball, of the first seal member and the second seal member; first seal strips are arranged in the first grooves; second seal strips are arranged in the second grooves; the first seal strips are pressed against outer peripheries of the first grooves and the ball; and the second seal strips are pressed against outer peripheries of the second grooves and the ball. The ball valve body is formed integrally, fit tolerance and seams can be avoided, leakage can be avoided, and the leakage-proof performance is excellent. The ball valve body is integrally formed by a copper tube without cutting or casting, materials can be saved, energy can be saved, and the processing efficiency is high; and an adjustment device is arranged in the ball valve body, and the leakage-proof performance of the ball valve will not be influenced.

Owner:LIANGGANG VALVE GRP

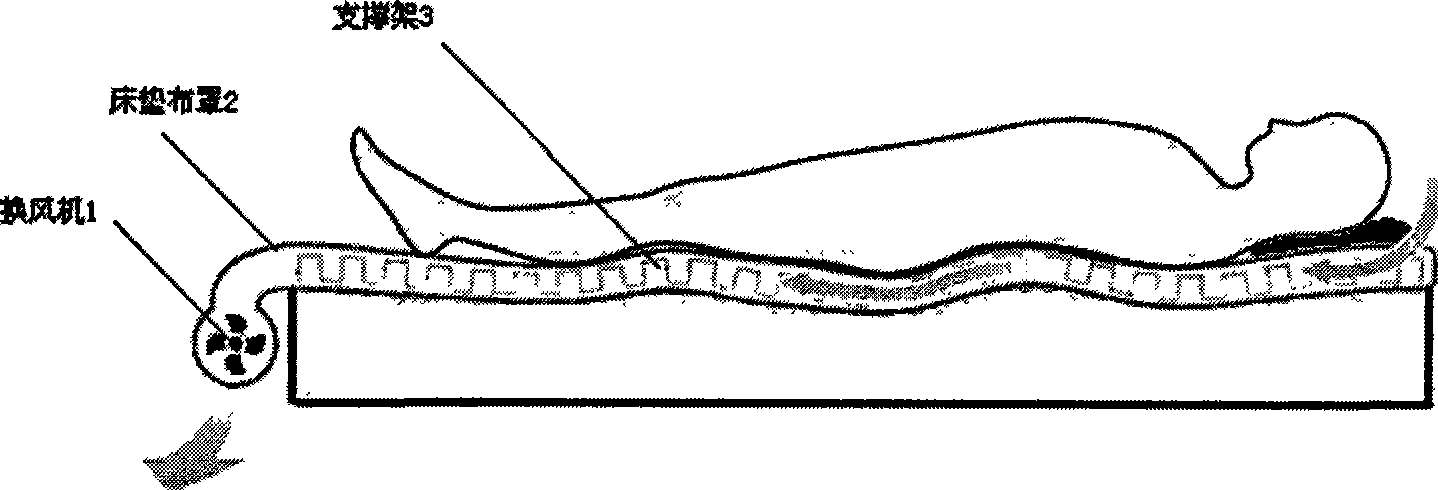

Mattress

The invention belongs to a household sleeping product, which relates to a wind transfer device, that is, a mattress provided with the function of health care, comfort and energy saving. The mattress can improve the sleep quality of human beings and discomfort feeling caused by the contact of human body with the mattress in hot days, and mainly consists of a wind transfer machine (1), a mattress fabric cover (2) and a support frame (3).

Owner:何红波

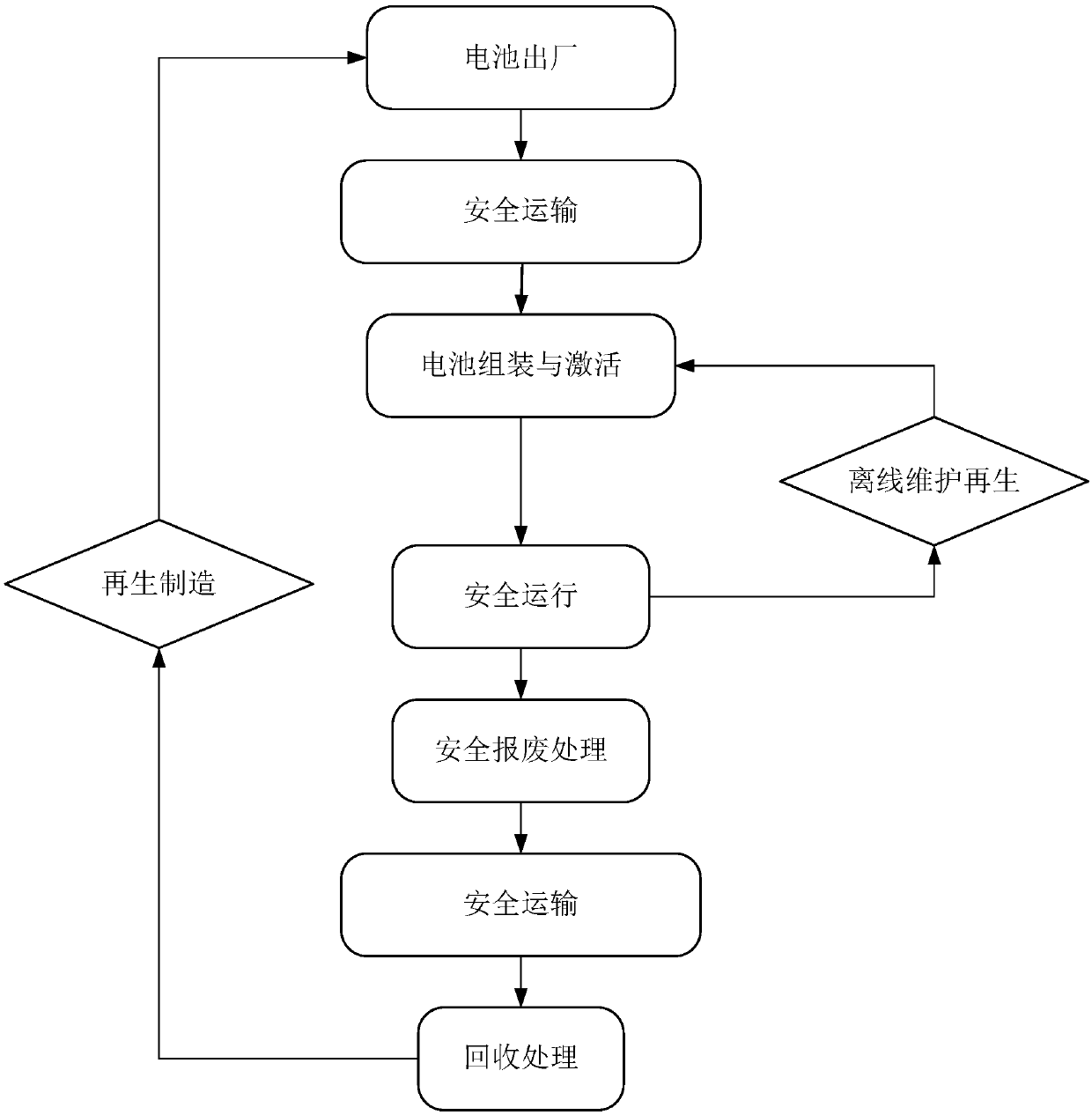

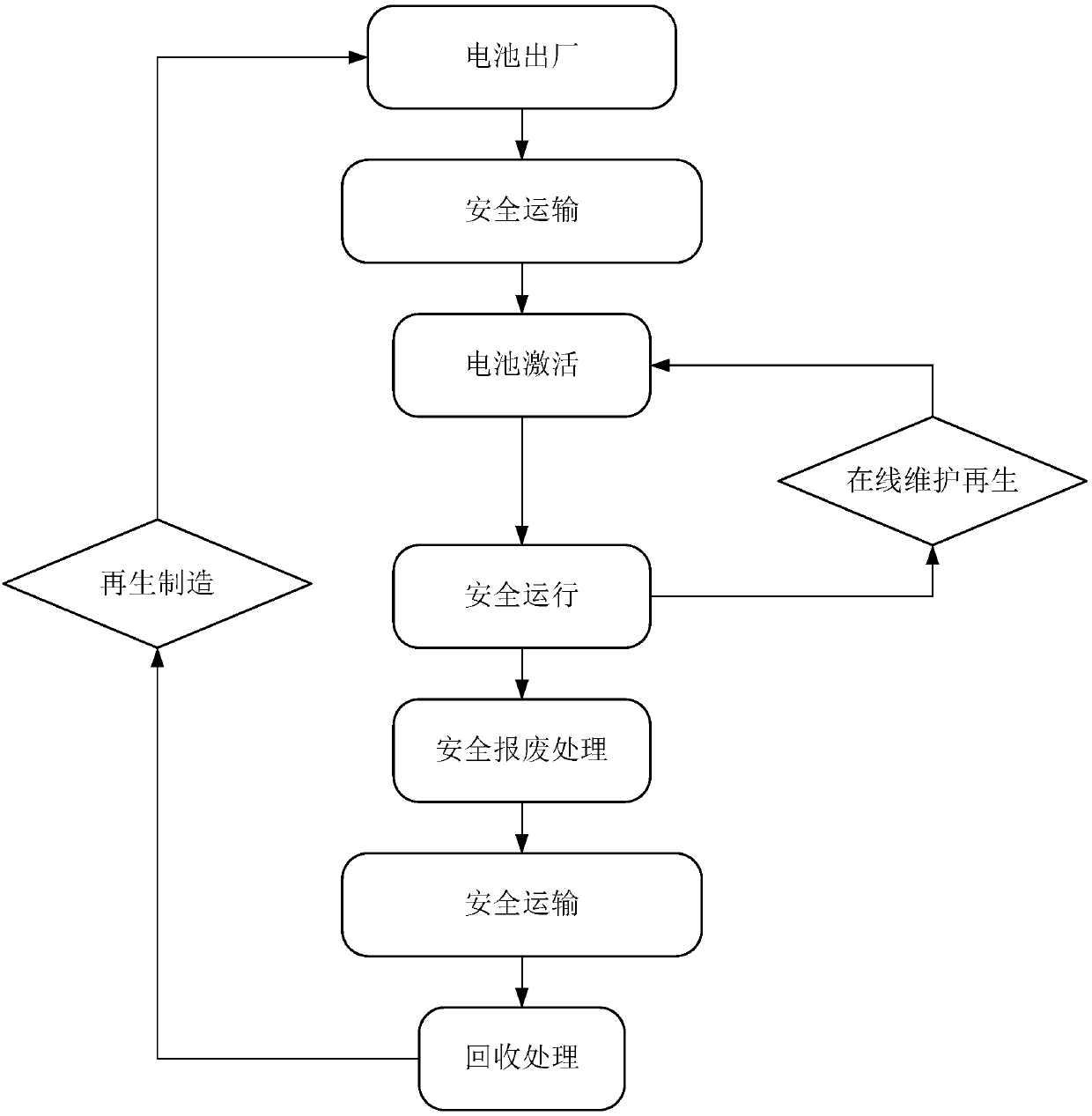

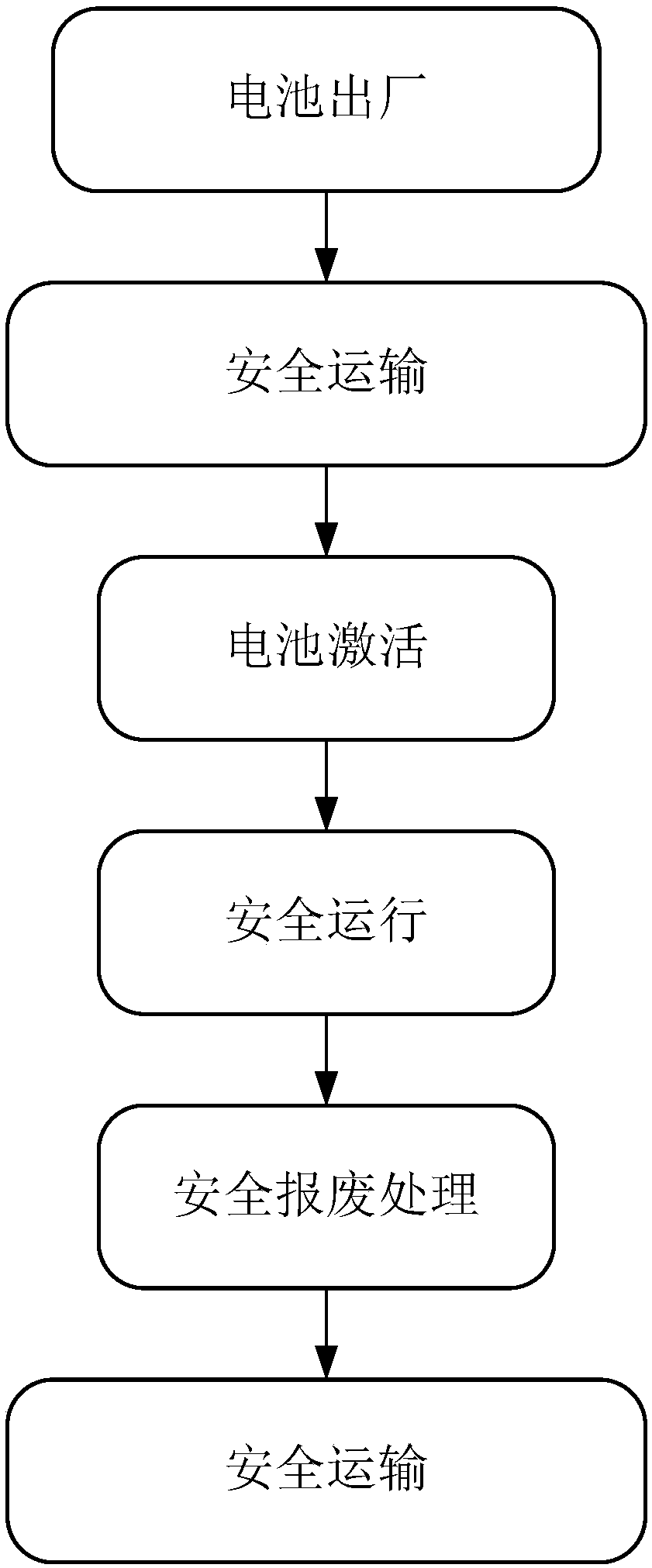

Full life cycle operation mode of injectable/extractable liquid lithium battery

ActiveCN110556504ANo electrochemical reactionAvoid flatulenceWaste accumulators reclaimingCell component detailsElectrochemical responseFull life cycle

The invention provides a full life cycle operation mode of an injectable / extractable lithium battery. With combination of the characteristics of the injectable / extractable lithium battery, no electrolyte is contained in the battery isolation layer when the battery leaves the factory so that no electrochemical reaction occurs inside the battery when the battery is transported to a user end or a transfer station and the battery can be safely transported as a non-dangerous product; meanwhile, the electrolyte in the battery is extracted out through a liquid extraction port and the safety agent isinjected when the life of the battery is terminate and scrap treatment is required so that the scrap battery does not generate electrochemical reaction in the process of transportation to the recycling station and can be safely transported as the non-dangerous product. The full life cycle operation mode of the injectable / extractable liquid lithium battery comprises a series of steps such as "battery leaving the factory-safe transportation-battery activation-safe operation-maintenance regeneration / safe scrap-safe transportation-recovery treatment-regeneration manufacturing" and the like.

Owner:BEIJING HAWAGA POWER STORAGE TECH

Ball valve

InactiveCN101839353BImprove the anti-leakage effectSave materialPlug valvesValve housingsBall valveEngineering

The invention discloses a ball valve comprising a ball valve main body (1), a ball (2), two ball cushions (3), a first inner plugging body (4) and a second inner plugging body (5), wherein the ball valve main body (1) is an integrated whole and is provided with two throats (1.1) capable of limiting the corresponding inner plugging bodies in the ball valve main body (1); the other end of the firstinner plugging body (4) and the other end of the second inner plugging body (5) are both abutted on the inner wall of the throats (1.1) of the ball valve main body (1); and an actuating device capable of adjusting tightness is arranged between one of the first inner plugging body (4) and the second inner plugging body (5) and the ball valve main body (1). The ball valve has favorable leakage-proof performance, material saving, high processing efficiency and low cost, does not affect internal parts when being assembled and does not leak when being adjusted.

Owner:宁波日月制冷设备有限公司

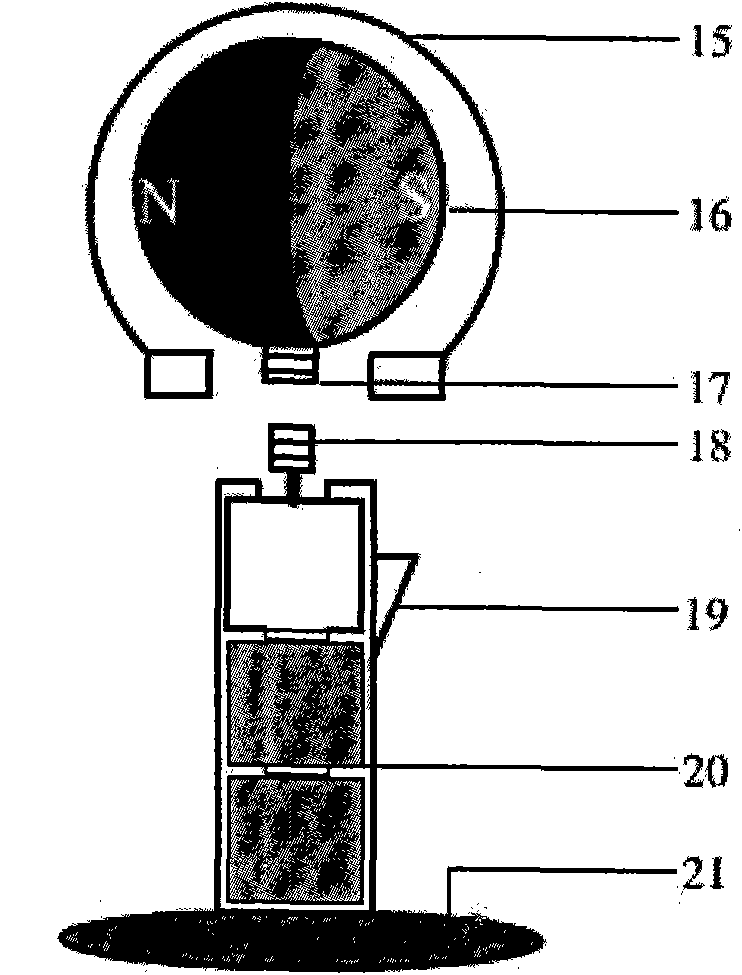

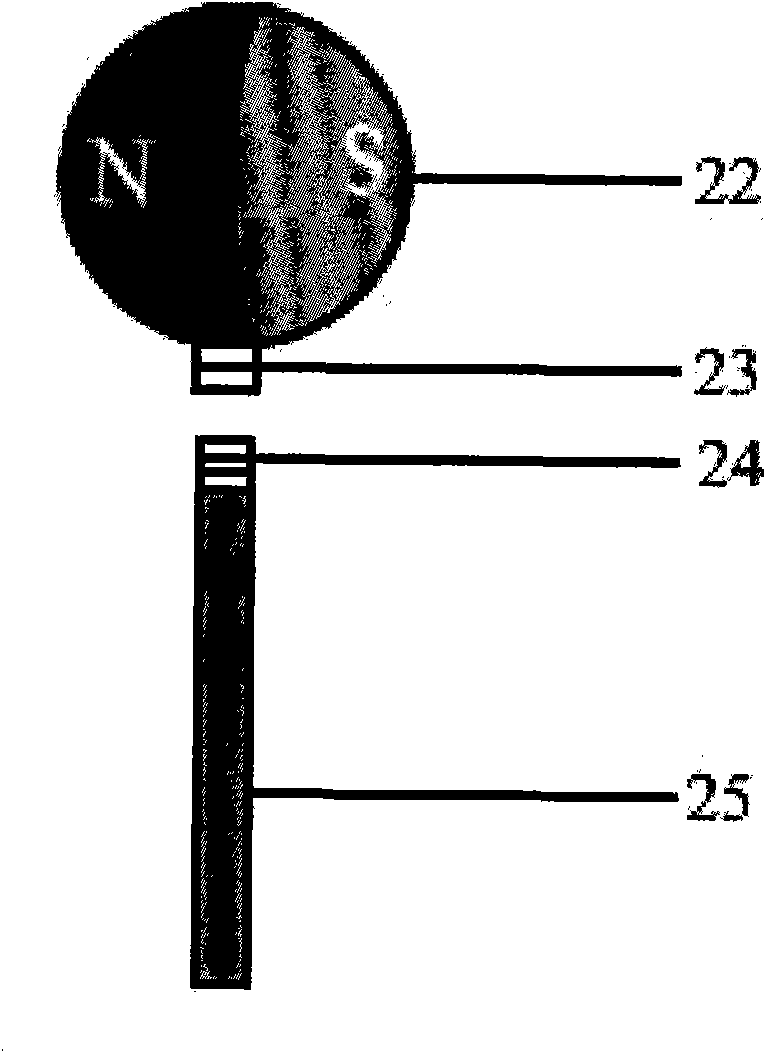

Interaction rotating device of permanent magnets and method

InactiveCN101951120ASolve the delivery problemHelp to understandDynamo-electric gearsPermanent magnet motorControl switch

The invention discloses an interaction rotating device and an interaction rotating method of permanent magnets. The interaction rotating device consists of the permanent magnets which are arranged on a support independently, a permanent magnet rotated manually and a permanent magnet rotated by a motor, wherein each of the permanent magnets which are arranged on the support independently comprises the permanent magnet, a rotating shaft and the support; the permanent magnet rotated by motive power comprises the permanent magnet, the motor, a variable speed control switch and a safety protective cover; and the permanent magnet rotated manually comprises the permanent magnet and a handle. The interaction rotating device has the advantages of: 1, establishing the relation between rotation and the permanent magnets as well as a magnetic field; 2, summarizing the fundamental law of synchronous rotation among two or more permanent magnets; 3, developing a novel field of rotation force transfer; 4, contributing to the further recognition and understanding on magnetic phenomena in teaching; 5, serving as auxiliary tools for further exploring the relation between the properties and the motion of the magnetic field and the permanent magnets; and 6, developing a new technical field for toy commerce.

Owner:仝卫明

Ecological floating bed

InactiveCN106145360AGreat usabilityA large amount of wasteBiological water/sewage treatmentEngineeringPollution

The invention especially relates to an ecological floating bed prepared from waste plastic bottles, belonging to the field of environmental protection. The ecological floating bed comprises plastic bottles, a plastic net cover, a lightweight framework, a binding material and a cushion net, wherein the plastic bottles are intact waste plastic bottles which are tightly sealed and then successively put into the cylindrical plastic net cover with a diameter almost equivalent to the diameters of the plastic bottles; the lightweight framework is formed by binding a lightweight material; the plastic net cover filled with the plastic bottles are bond on the lightweight material of the lightweight framework; and the cushion net is laid on the lightweight framework according to the shape of the floating bed. The nontoxic intact plastic bottles discarded in daily life are used as a floating body material for preparation of the ecological floating bed, so the waste is turned into the valuable, everything is made the best use of, energy materials are saved, and pollution is not posed to environment.

Owner:项小飞

Method for producing ecological floating bed with waste plastic bottles

InactiveCN106145358AGreat usabilityA large amount of wasteBiological water/sewage treatmentEngineeringVertical axis

The invention relates to the field of environmental protection, in particular to a method for producing an ecological floating bed with waste plastic bottles. The method comprises steps as follows: (1) production of a light frame: the light frame is formed by binding an outer frame, an inner frame and a base plate frame, and the shape of the light frame is determined according to the design; (2) binding of the plastic bottles: the plastic bottles are waste, non-toxic and intact plastic bottles, closed openings face the underwater position, the plastic bottles are closely arranged on the side surface between the outer frame and the inner frame, positions close to bottom ends and opening ends of the plastic bottles are bound and fixed on the outer frame and the inner frame respectively, and included angles formed by vertical axes of the plastic bottles and the plane of the inner frame range from 0 to 180 degrees; a buoyancy frame of the floating bed is formed by the plastic bottles, the inner frame and the outer frame; (3) laying of a cushion net: the cushion net is laid on the base plate frame as per the shape of a base plate of the floating bed. The ecological floating bed is produced from the non-toxic and intact plastic bottles wasted due to daily consumption and used as a floating body material, the waste is turned into wealth, materials are put to good use, energy materials are saved, and the environment is not polluted.

Owner:项小飞

Composite structure sealing plug for pipeline

Owner:北京市梵格橡塑技术有限公司

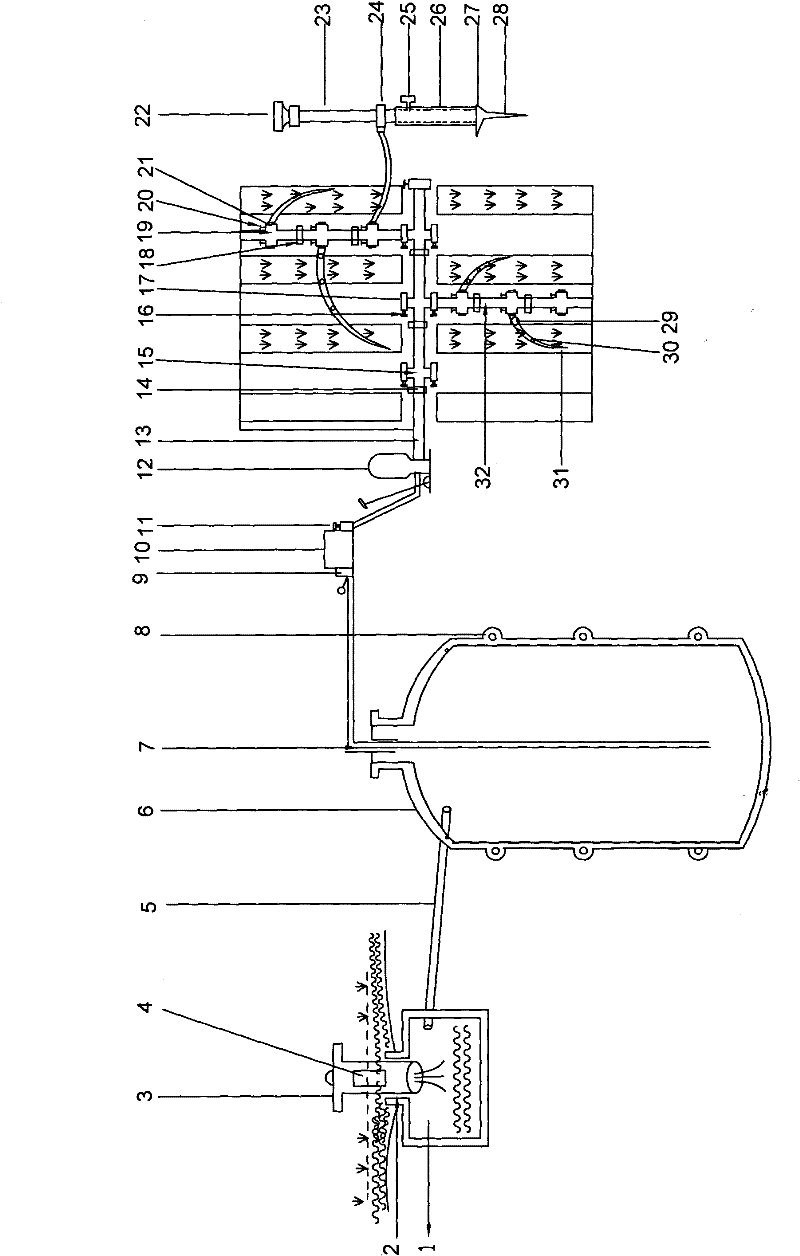

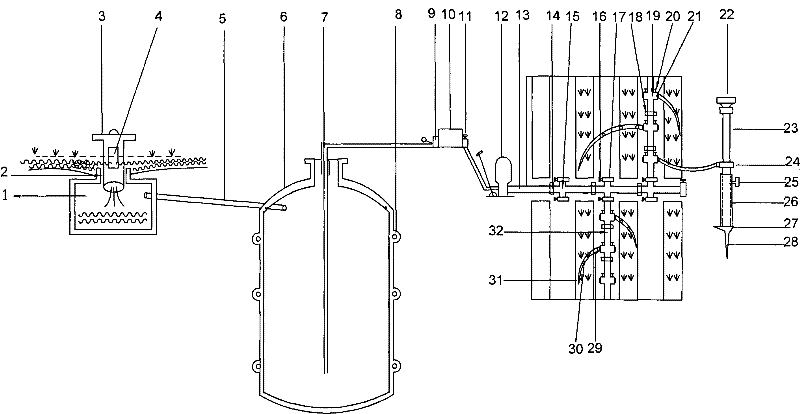

Rain-collecting double-energy water-saving irrigator

InactiveCN101904290BReduce wasteSpeed up the leapWatering devicesCultivating equipmentsWater volumeWater source

The invention discloses a rain-collecting double-energy water-saving irrigator, which consists of a settling tank, a rain collecting tank, a water pump, a water tank, a pressurizing air pump, a connecting water pipe and an irrigating device. In the invention, untimely and unbalance natural rain can be collected and converted into a water source which can be handled discretionary and used in a balance manner, irrigating method and water volume can be changed properly according to different crops or the different growth periods of the crops, and thus, the utilization rate of the collected wateris improved and the waste of water source is reduced. The irrigator, therefore, has the advantages of energy and water conservation, convenient and flexible use, labor conservation and high working efficiency. The rain collecting tank of the irrigator is made of waste plastic, so waste is changed into a valuable material. Thus, the irrigator has the advantages of energy source material conservation, low cost, convenient use and transport, investment and labor conservation and the like. The irrigator is an ideal substitute for modern brisk hybrid water collecting well. The irrigator is particularly suitable for developing dry-farming high-efficiency agriculture in droughty areas.

Owner:李富奎

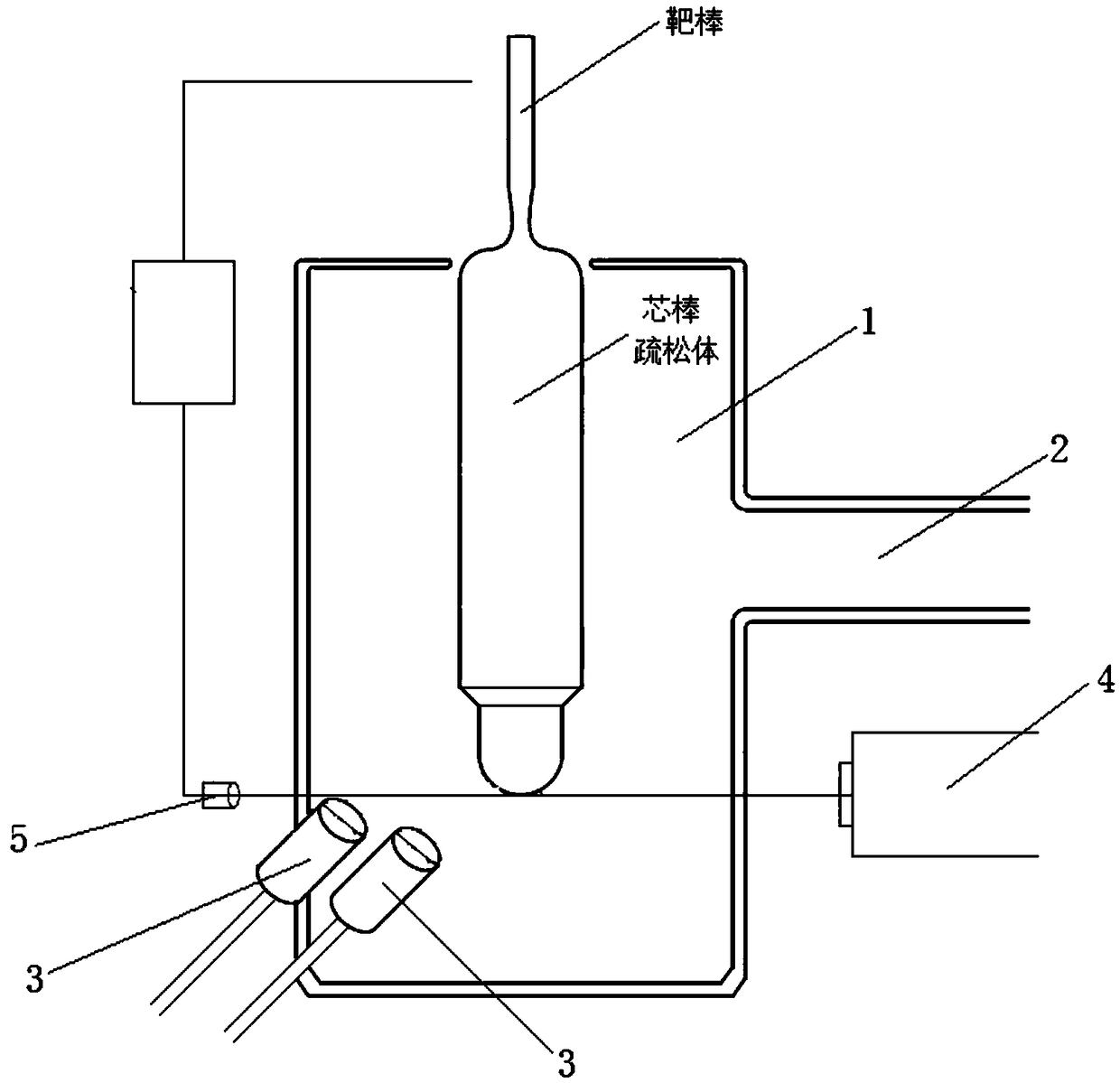

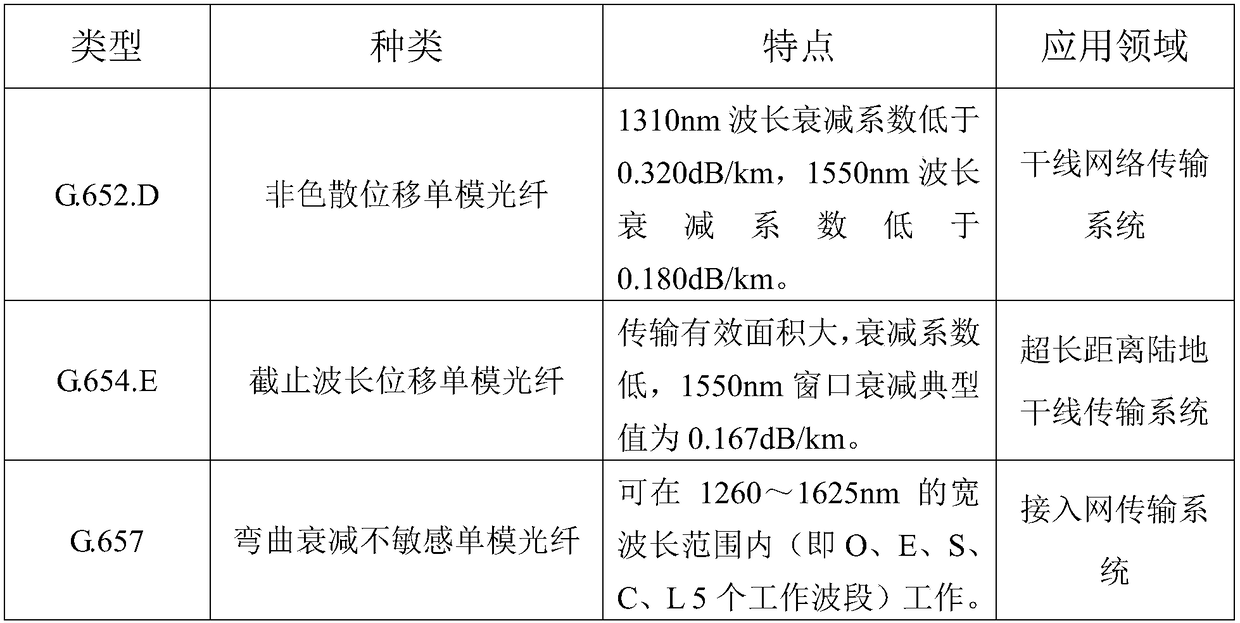

Method and device for preparing optical fiber preformed core rod

The invention provides a method and a device for preparing an optical fiber preformed core rod. The preparation method comprises the following steps: rotating a target rod serving as a guiding rod bytaking the axis of the target rod as the rotating shaft, and synchronously rising along the axial direction of the target rod; delivering steam containing organic siloxane and organic germane to a blast lamp through a pipeline, and reacting to generate dust of SiO2 and GeO2; depositing the generated dust of SiO2 and GeO2 onto the target rod to obtain a core rod loose body; and sintering the core rod loose body to obtain a compact transparent core rod, and extending to obtain the optical fiber preformed core rod. According to the preparation method, no chlorine pollutant is generated, the pollution problem of chloride ions can be solved, and the material is more environment-friendly.

Owner:HENGTONG OPTICAL MATERIAL CO LTD +1

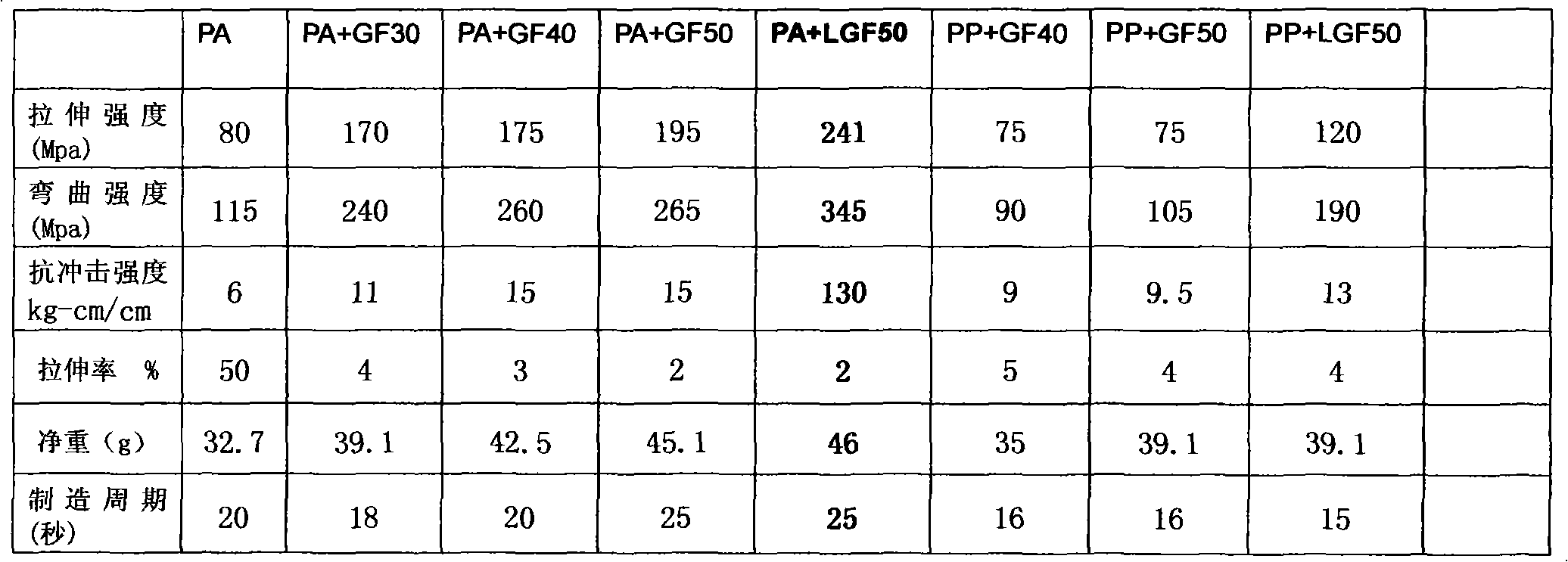

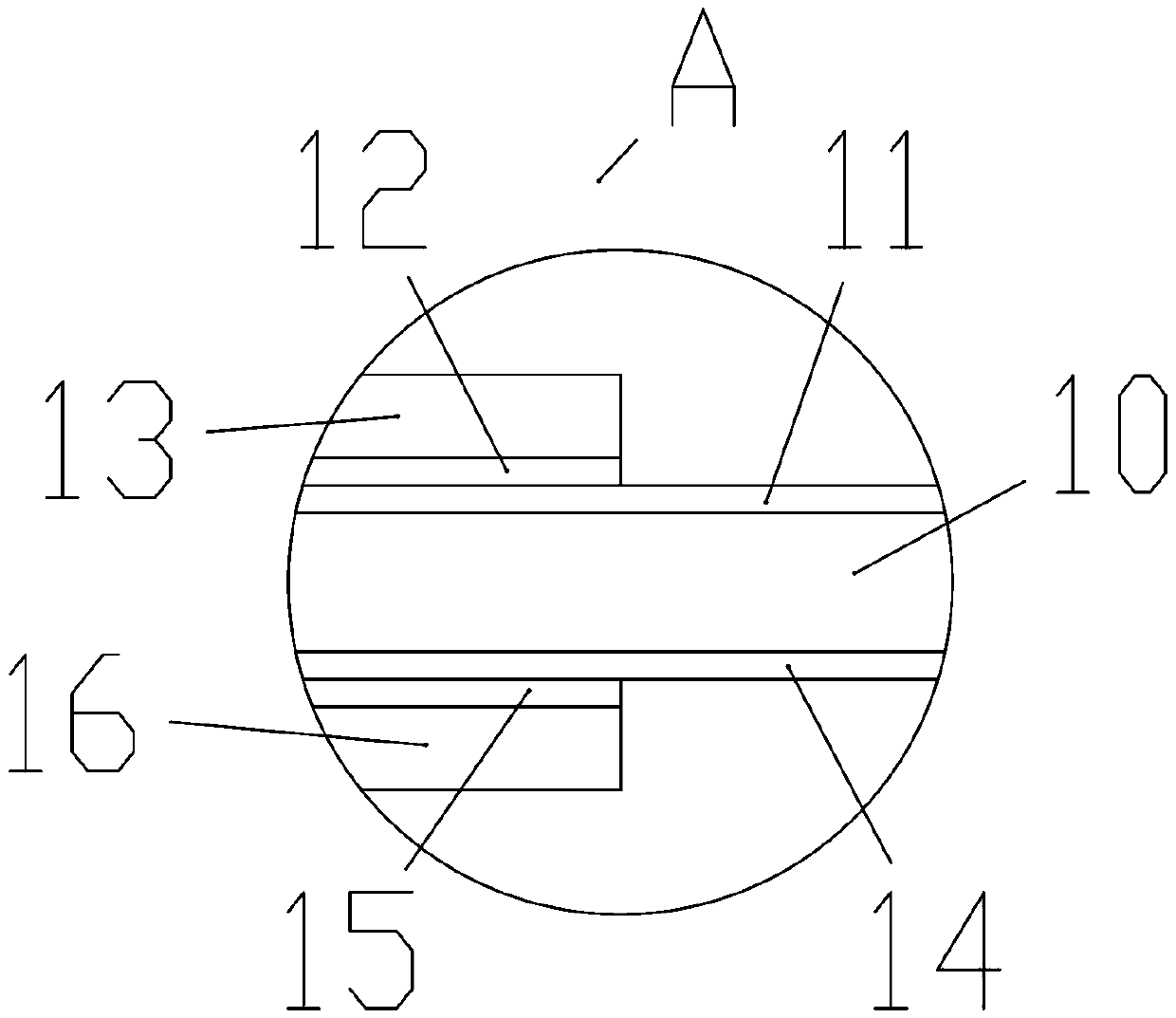

Manufacturing process of parts related to elbow and wrist joint of artificial upper limb

InactiveCN101927548ALight weightGuaranteed physical propertiesCoatingsInjection mouldingInjection molding machine

The invention discloses a manufacturing process of the parts related to the elbow and wrist joint of an artificial upper limb. The manufacturing method is that a novel composite material with mixed nylon and long glass fiber is used to perform the injection molding process instead of the traditional metal cutting machining process. The related parameters of the selected material and the related technological parameters are as follows: 1. the composite material with mixed nylon and long glass fiber comprises the following components by weight percent: 30%-50% of nylon (PA), 50%-65% of glass fiber, 2-3% of coupling agent, 1-2% of plasticizer and 1% of other components; 2. the injection process of the composite material is that the temperature of the material tube is 280-310 DEG C, the injection pressure is 40Mpa, the injection time is 15-35 seconds and the shaped parts are completely cooled at the room temperature; and 3. the parts are dried at 130 DEG C for 4-6 hours before shaped. An injection machine with the tonnage of 100-500 is used to inject the fused liquid raw material in the injection moulds through an injection machine, and the novel composite material is adopted to prepare the parts related to the elbow and wrist joint of the artificial upper limb through the process technology of injection molding.

Owner:李秀胜

Double-sided blood glucose test paper and double-numerical-value display blood glucose meter

PendingCN110940713ASmooth exhaustImprove siphon effectDiagnostic recording/measuringSensorsBlood glucose metersEngineering

The invention discloses double-sided blood glucose test paper and a double-numerical-value display blood glucose meter. The double-sided blood glucose test paper comprises a PET substrate, a first detection layer and a second detection layer, wherein the first detection layer and the second detection layer are arranged on the front surface and the back surface of the PET substrate; the double-value display glucometer comprises a shell, a first circuit board, a second circuit board, a microprocessor and a power supply module which are arranged in the shell, and a display screen, keys and a connector which are arranged on the surface of the shell. The blood glucose test paper disclosed by the invention is double-sided test paper, so that two blood glucose values can be detected on the basisthat a patient takes blood once, and the blood taking burden of the patient is reduced; the double-numerical-value display glucometer matched with the double-sided blood glucose test paper is not onlysuitable for the double-sided blood glucose test paper, but also can use the single-sided blood glucose test paper for detection, so that the use cost of a patient is reduced.

Owner:郑州信德医疗科技有限公司

A kind of graphene modified antibacterial anticorrosion coating

ActiveCN109777262BSolve practical problems in the field of antibacterial and antisepticEnergy saving materialsAntifouling/underwater paintsPaints with biocidesEpoxyMarine equipment

The present invention relates to the field of antibacterial and anticorrosion coating products, in particular to a graphene-modified antibacterial and anticorrosion coating. The raw materials of the antibacterial and anticorrosion coating include: 30-50 parts of epoxy resin, modified diatomite 15-35 parts, 0.5-10 parts of graphene material, 0.5-1 part of nano-silver particles, 8-20 parts of filler, 1.5-6 parts of additives, 13-15 parts of nano-silver copper loaded POSS base resin and 16-25 parts of water share. A kind of graphene modified antibacterial anticorrosion coating prepared by the present invention can solve the actual problems in the field of antibacterial anticorrosion of ships, marine equipment, granaries, etc., has good economic benefits, saves energy materials; in steel structures, metal plates, etc. On the one hand, it has excellent adhesion, good wear resistance, can withstand high and low temperature, high salinity, can well tolerate bacterial corrosion, and achieve antibacterial and antiseptic effects.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com