Full life cycle operation mode of injectable/extractable liquid lithium battery

A technology of full life cycle and operation mode, which is applied in the field of full life cycle operation mode, can solve the problems of battery short circuit due to internal isolation layer, affecting the safety of lithium battery, battery fire, etc., to avoid electrolyte leakage and save battery cost and the effect of energy materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, the injectable / pumpable lithium battery is a liquid-injected lithium slurry battery, and the maintenance regeneration is an offline maintenance regeneration mode.

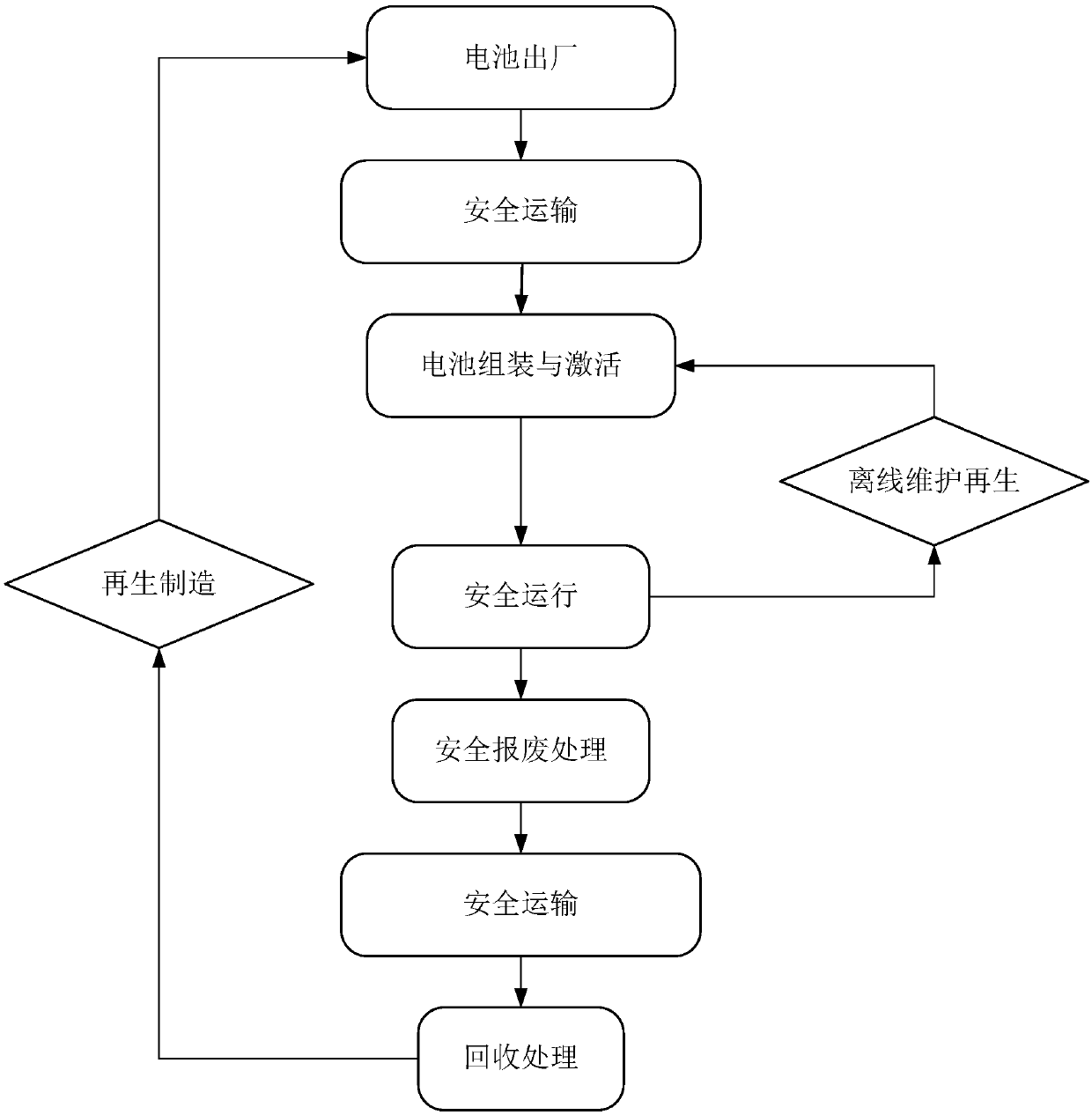

[0040] figure 1 It is a schematic diagram of the full life cycle operation mode of the liquid-injected lithium slurry battery in this embodiment. When the liquid-injected lithium slurry battery leaves the factory, the positive electrode sheet of the liquid-injected lithium slurry battery contains dry positive active conductive particles, wherein the positive active conductive particles are composites or mixtures of positive active materials and conductive components; liquid injection The anode sheet of the formula lithium slurry battery contains dry negative electrode active conductive particles, wherein the negative electrode active conductive particles are composites or mixtures of negative electrode active materials and conductive components. The above-mentioned dry state includes for...

Embodiment 2

[0046] In this embodiment, the injectable / pumpable lithium battery is a slurry-injected lithium slurry battery, and the maintenance regeneration is an online maintenance regeneration mode.

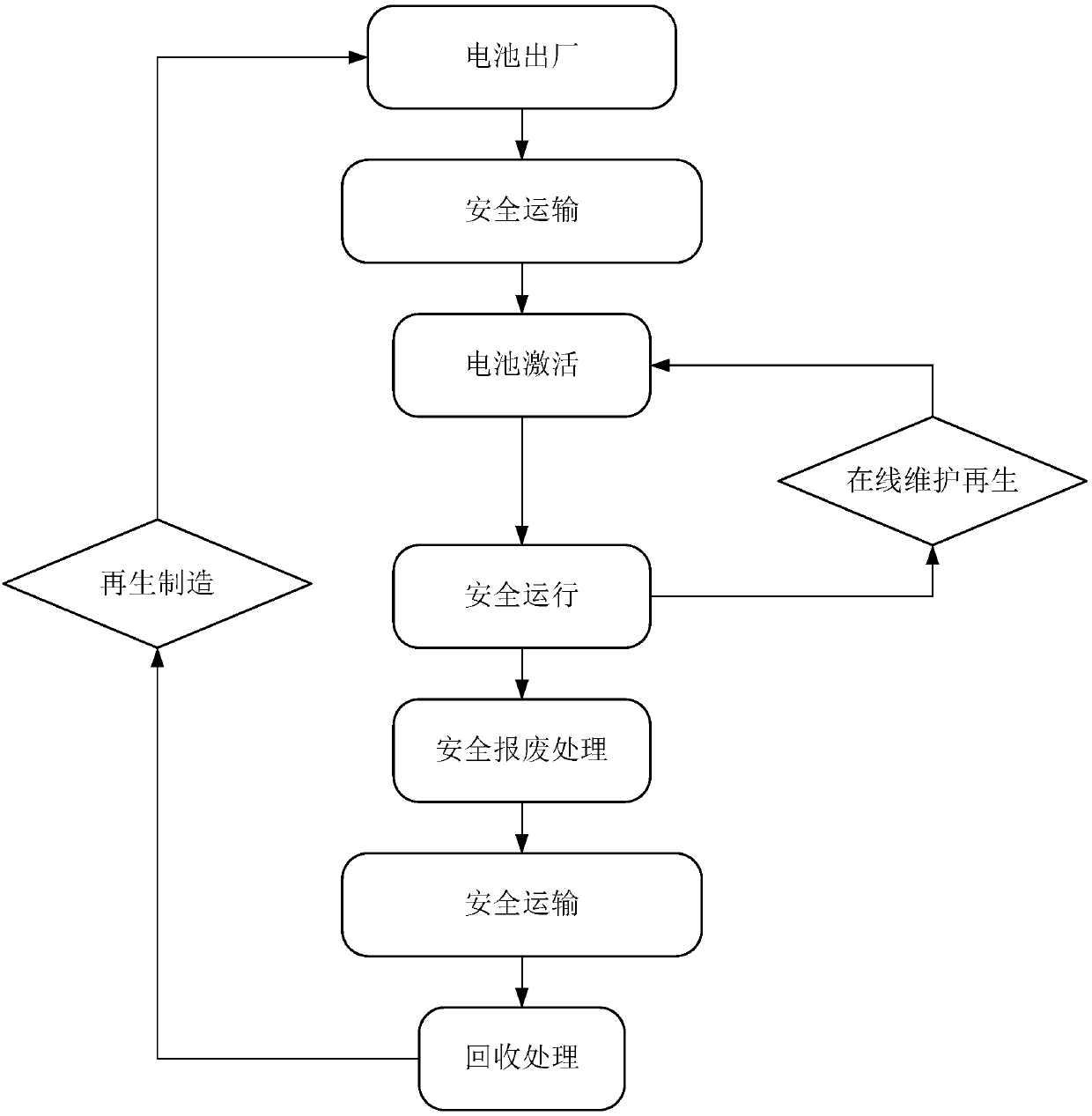

[0047] figure 2 It is a schematic diagram of the full life cycle operation mode of the grouting lithium slurry battery in this embodiment. When the grouting type lithium slurry battery leaves the factory, the positive electrode composite powder material and the negative electrode composite powder material of the grouting type lithium slurry battery are mixed with the non-reactive electrolyte respectively to form a slurry state, wherein the positive electrode composite powder material is The compound or mixture of the positive electrode active material and the conductive component, the negative electrode composite powder material is the compound or mixture of the negative electrode active material and the conductive component, and the non-reactive electrolyte is the aqueous or non-aqueous ...

Embodiment 3

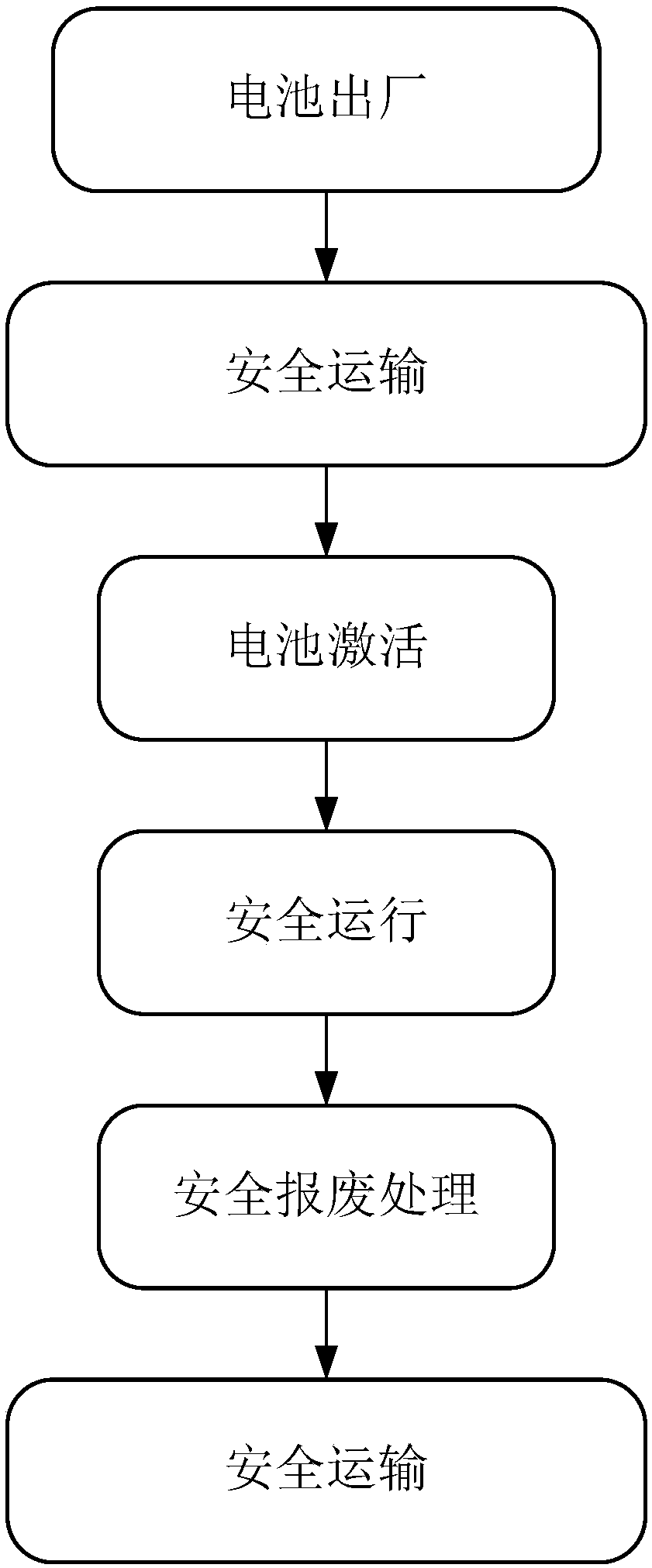

[0055] In this embodiment, the injectable / pumpable lithium battery is a bipolar lithium battery. Compared with Embodiment 1 and Embodiment 2, the full life cycle operation mode in this embodiment includes fewer steps.

[0056] image 3 It is a schematic diagram of the full life cycle operation mode of the bipolar lithium battery in this embodiment.

[0057] The bipolar lithium battery consists of several bipolar electrode sheets formed by coating the positive electrode material layer and the negative electrode material layer on both sides of the bipolar plate. A unipolar electrode sheet coated with a positive electrode material layer or a negative electrode material layer on one side, a bipolar electrode sheet and a unipolar electrode sheet are collectively referred to as an electrode sheet, and an isolation layer is provided between the electrode sheets. When the bipolar lithium battery leaves the factory, the electrode material layer and the separator are in a dry state wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com