Three-dimensional gel network carrier and form-stable phase change composite material

A three-dimensional gel and network technology, applied in the field of new shape-setting phase change materials, can solve the problems of loss of phase change heat storage capacity of thermosetting polymers, difficult to control cross-link density, low thermal conductivity, etc., and achieve less phase change enthalpy loss. , The effect of good setting effect and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

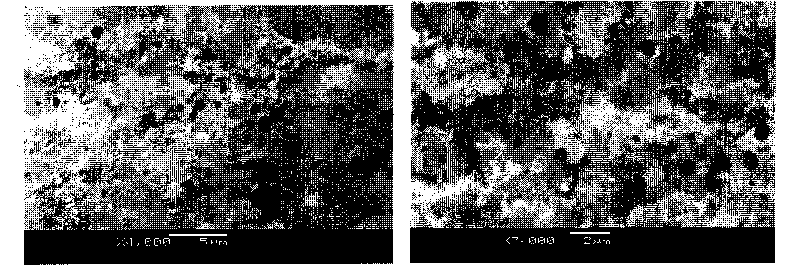

[0051] The preparation of embodiment 1 gel carrier

[0052] Using pure N-methylolacrylamide as the network agent monomer, N,N'-methylenebisacrylamide as the crosslinking agent, ammonium persulfate as the initiator, and ethanol as the solvent, carry out solution polymerization to form a three-dimensional network gel, of which

[0053] A. The molar ratio of crosslinking agent to monomer is 1:9

[0054] B. The mass ratio of monomer to solvent is 1:10

[0055] C. The initiator accounts for 1.5% of the mass fraction of the monomer

[0056] Weigh the reagents according to the above ratio, and then place them in the flask, and add the solvent last, raise the temperature of the ultrasonic disperser to 70°C, put the flask in the ultrasonic disperser to disperse, melt and disperse all kinds of reagents uniformly, and wait for the reaction After the gel appears in the system, turn off the ultrasound and continue the reaction in a constant temperature water bath at 70°C. After the reac...

Embodiment 2

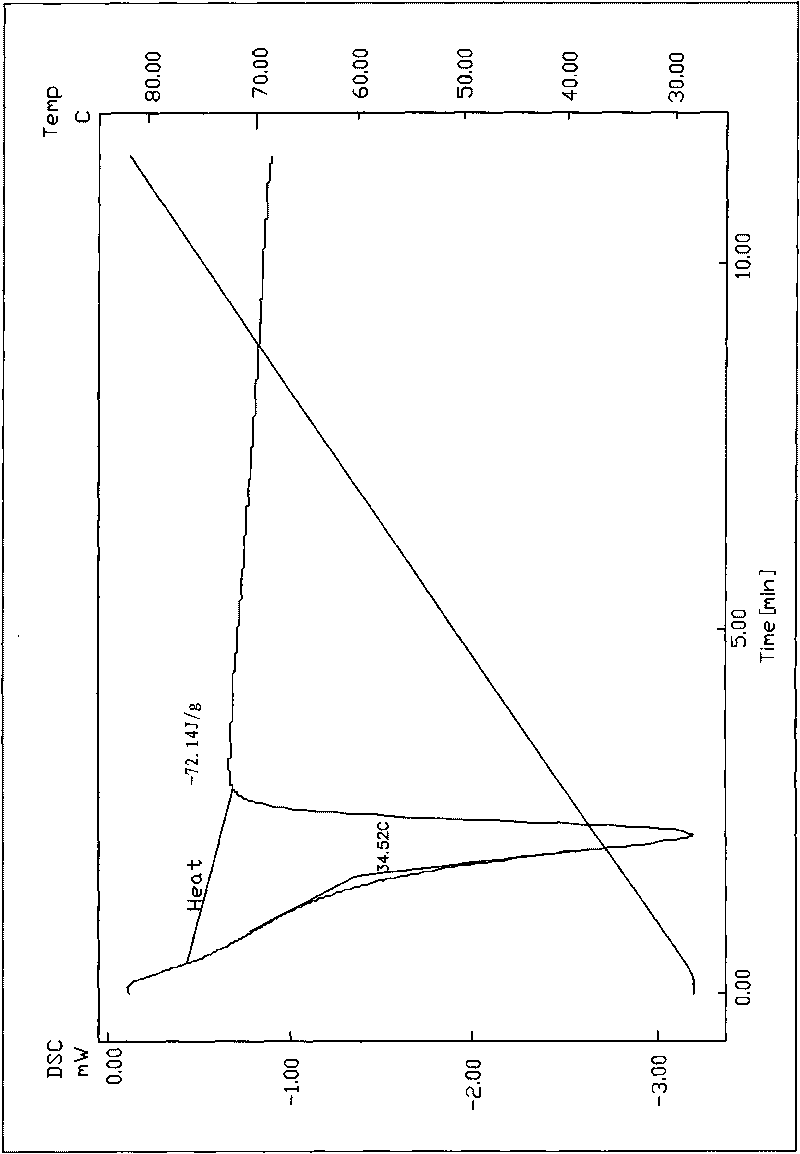

[0060] (1) Preparation of binary phase change materials suitable for tempering textiles with phase change temperature

[0061] It is prepared by blending 41% of lauric acid and 59% of cetyl alcohol in mole fraction respectively, and the phase transition temperature is 34°C. The specific process is to take 41% lauric acid and 59% cetyl alcohol respectively in mole fractions, add them into a water bath at a constant temperature of 60° C. to melt them, and then continuously stir for 30 minutes.

[0062] (2) Using pure N-methylolacrylamide as a network agent monomer, N, N'-methylenebisacrylamide as a crosslinking agent, ammonium persulfate as an initiator, and ethanol as a solvent to carry out solution polymerization, To generate a three-dimensional network gel, weigh the above reagents according to the following ratio:

[0063] A. The molar ratio of crosslinking agent to monomer is 1:9

[0064] B. The mass ratio of monomer to solvent is 1:10

[0065] C. The initiator accounts ...

Embodiment 3

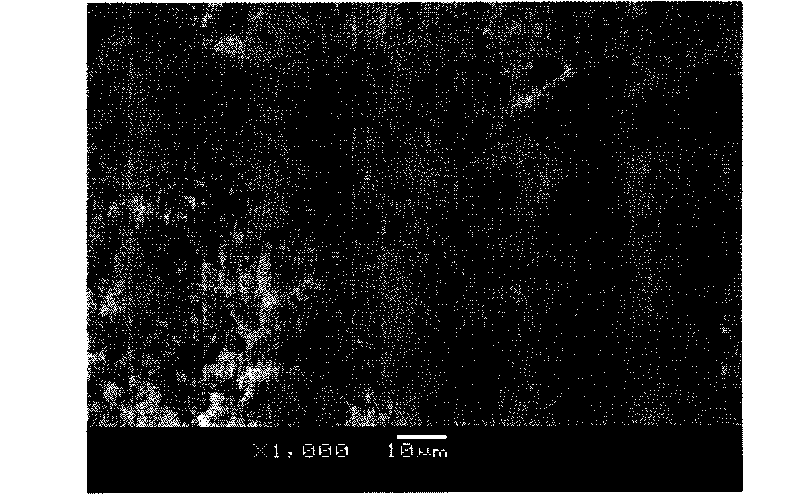

[0072] The preparation of embodiment 3 gel carrier

[0073] Using pure N-methylolacrylamide as the network agent monomer, N,N'-methylenebisacrylamide as the crosslinking agent, ammonium persulfate as the initiator, and ethanol as the solvent, carry out solution polymerization to form a three-dimensional network gel, of which

[0074] A. The molar ratio of crosslinking agent to monomer is 1:5

[0075] B. The mass ratio of monomer to solvent is 1:10

[0076] C. The initiator accounts for 3% of the mass fraction of the monomer

[0077] Weigh the reagents according to the above ratio, and then place them in the flask, and add the solvent last, raise the temperature of the ultrasonic disperser to 70°C, put the flask in the ultrasonic disperser to disperse, melt and disperse all kinds of reagents uniformly, and wait for the reaction After the gel appears in the system, turn off the ultrasound and continue the reaction in a constant temperature water bath at 70°C. After the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com