Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

441results about "Petroleum wax refining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

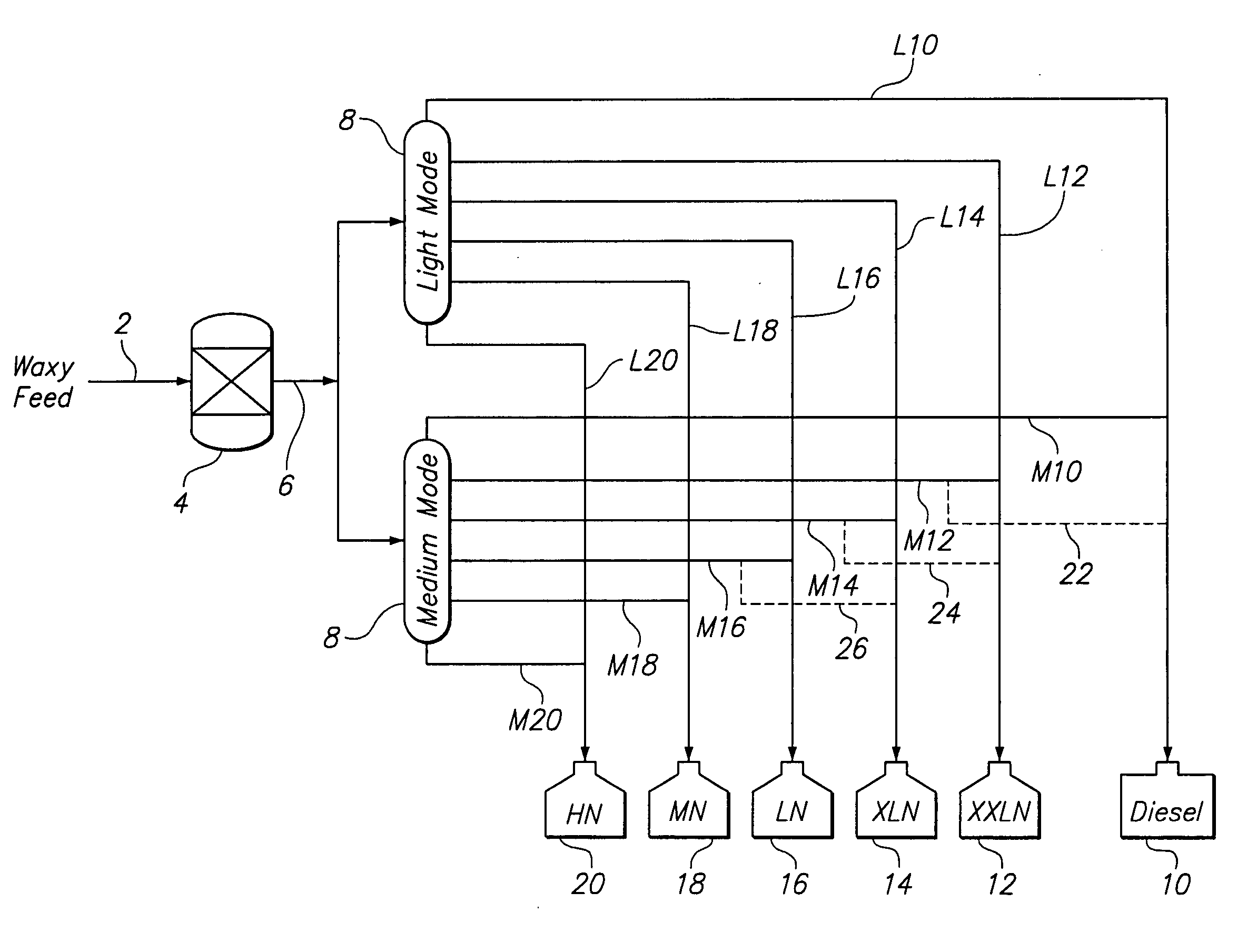

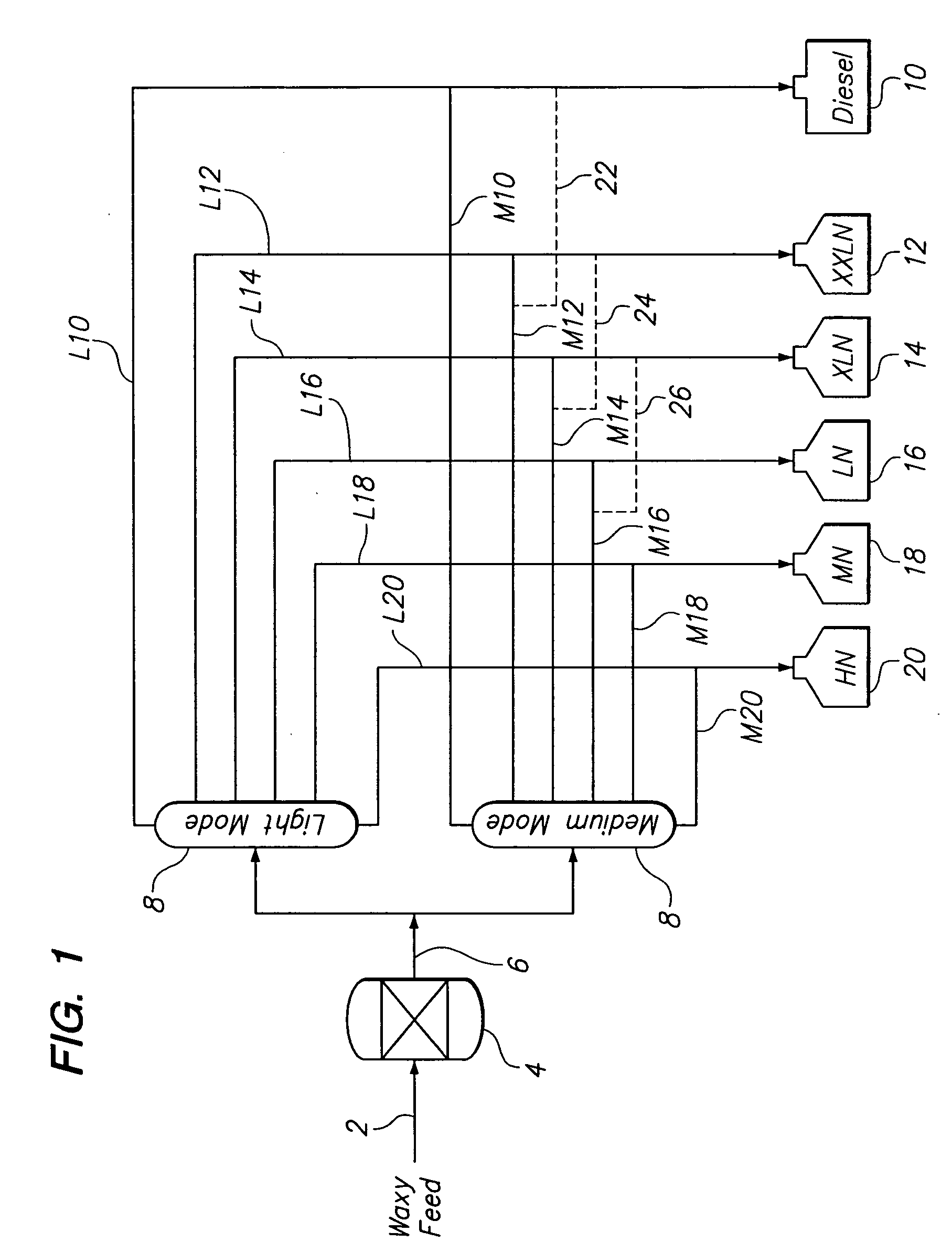

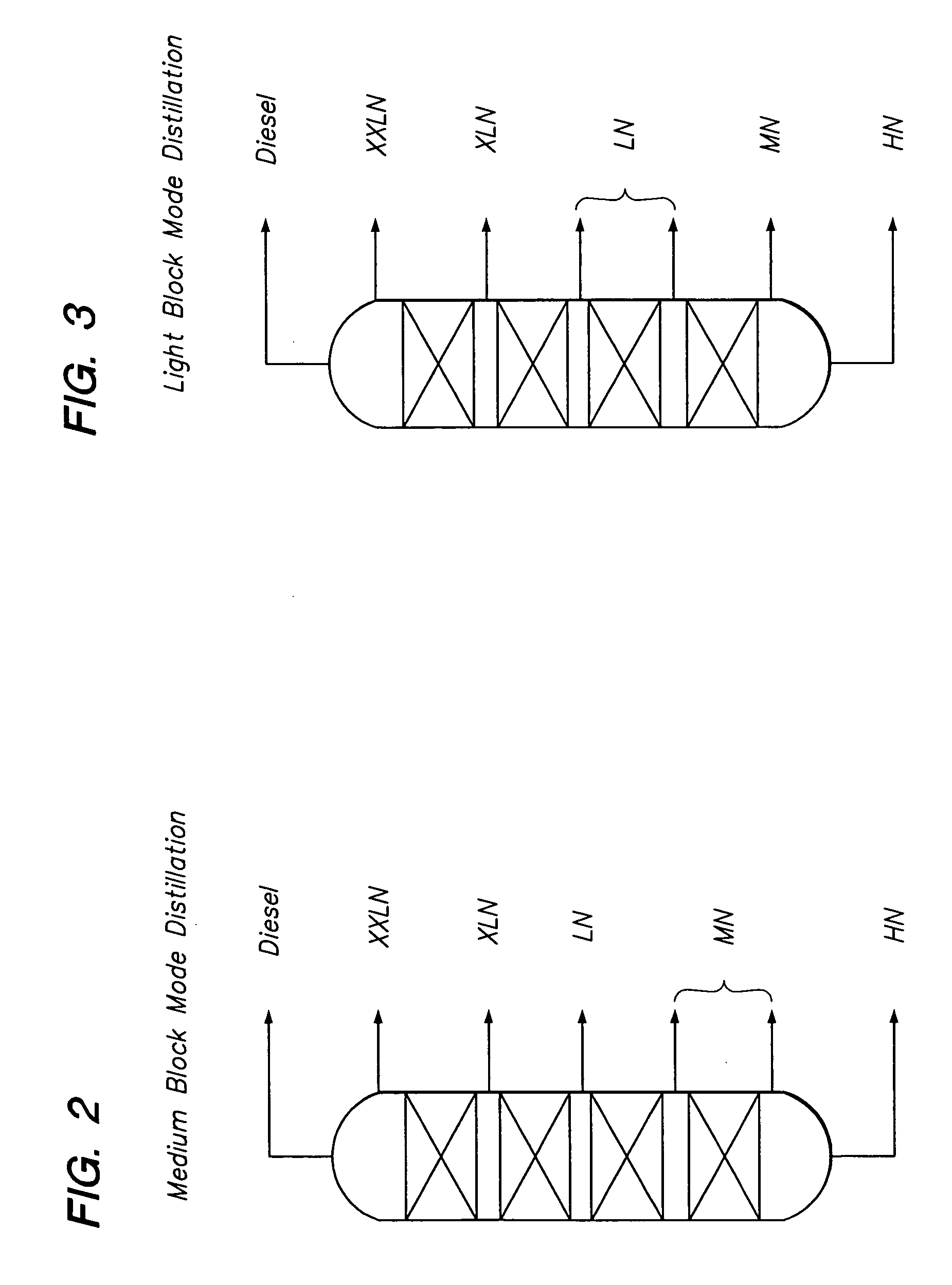

Multiple side draws during distillation in the production of base oil blends from waxy feeds

InactiveUS20060201851A1Refining to change hydrocarbon structural skeletonPetroleum wax refiningIsomerizationDistillation

A process for producing a product slate, which includes at least three base oil grades having kinematic viscosities at 100° C. within the range between about 1.8 cSt and 30 cSt, from a waxy feed having an initial boiling point of about 340° C. or less and a final boiling point of about 560° C. or higher, said process comprising (a) isomerizing at least a portion of the waxy feed, whereby the amount of isoparaffins present are increased; (b) distilling a first portion of the isomerized waxy feed in light block mode operation into at least three base oil fractions having different boiling ranges; (c) distilling a second portion of the isomerized waxy feed in medium block mode operation into at least three base oil fractions having different boiling ranges; and (d) blending at least one base oil fraction produced from light block mode with at least one base oil fraction produced from medium block mode to produce a lubricating base oil blend meeting a target value for at least one pre-selected property.

Owner:CHEVROU USA INC

Process for isomerization dewaxing of hydrocarbon streams

InactiveUS20030168379A1Yield maximizationReduce pointsMolecular sieve catalystsHydrocarbon by hydrogenationMolecular sieveIsomerization

A process for isomerization dewaxing of a hydrocarbon feed which includes contacting the hydrocarbon feed with a large pore size, small crystal size, crystalline molecular sieve and an intermediate pore size, small crystal size, crystalline molecular sieve to produce a dewaxed product with a reduced pour point and a reduced cloud point. In a preferred embodiment, the feed is contacted with the molecular sieves sequentially, first with the large pore sieve followed by the intermediate pore sieve.

Owner:EXXON RES & ENG CO

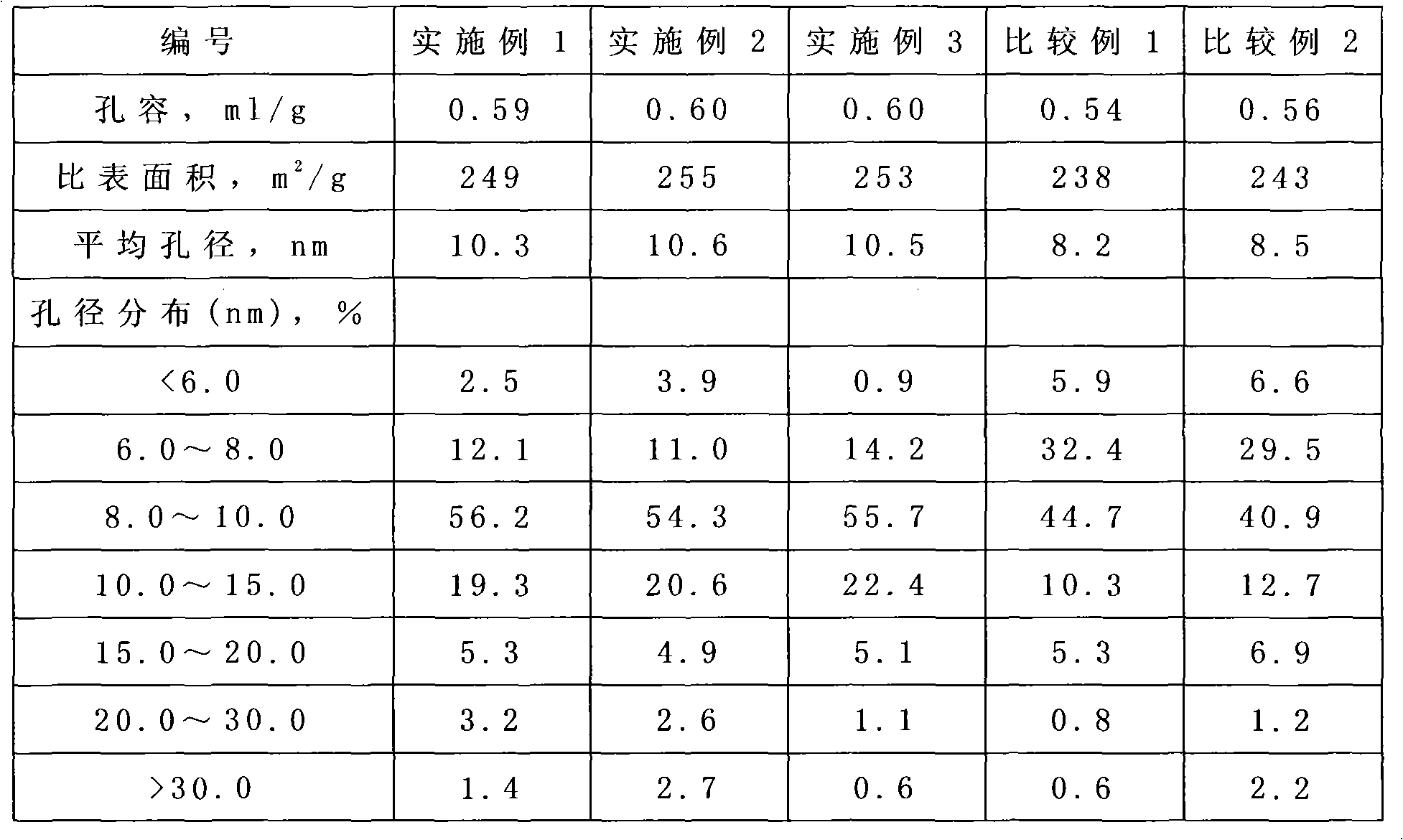

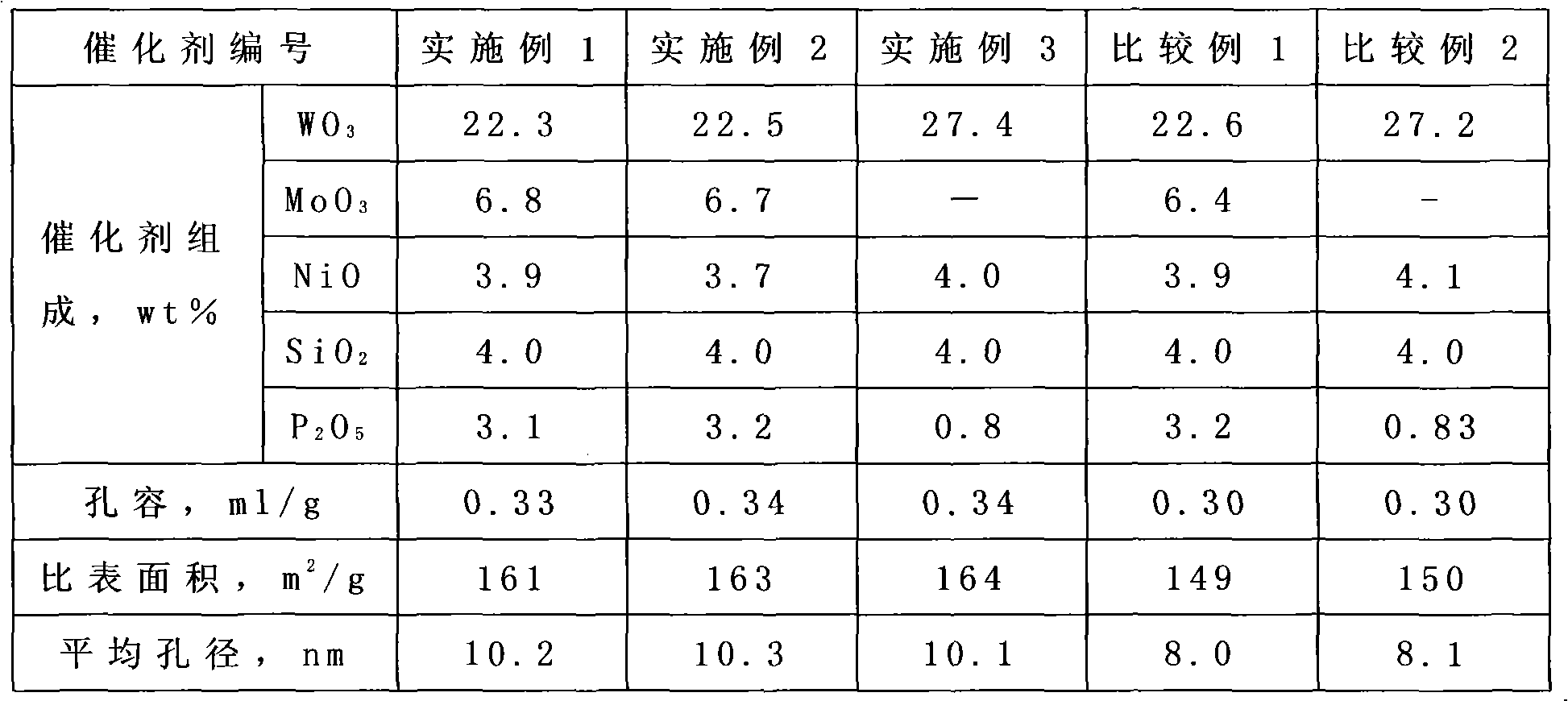

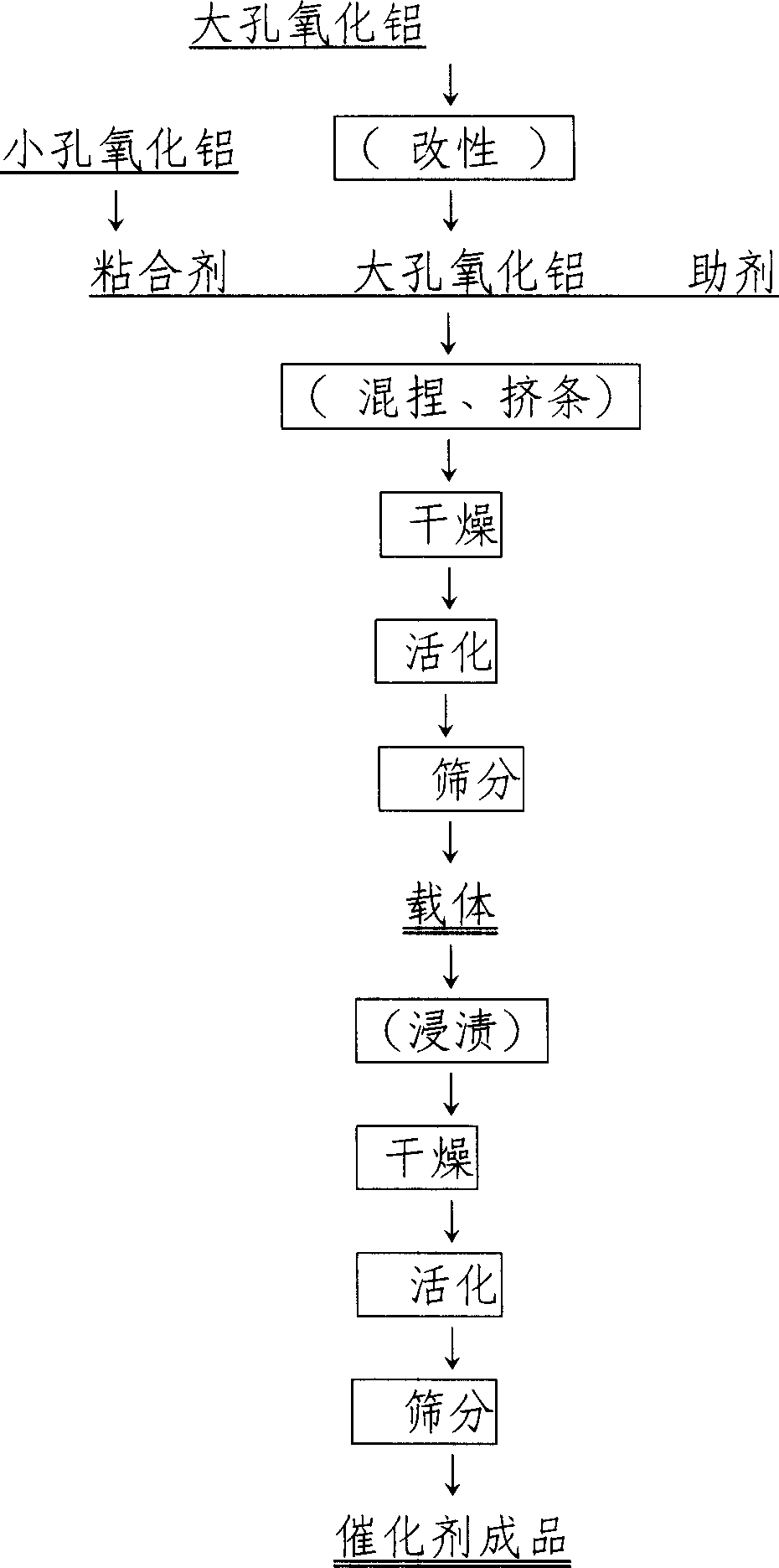

Method for preparing petroleum wax hydrofining catalyst

ActiveCN102039148AIncreased dispersionPore Structure ModulationCatalyst carriersPetroleum wax refiningCooking & bakingWax

The invention relates to a method for preparing a petroleum wax hydrofining catalyst. The method comprises the following steps of: weighing boehmite, adding a silicon-containing compound in an amount which is 6 to 17 percent based on the weight of the boehmite and phosphorus-containing organic compound solution in an amount which is 2 to 20 percent based on the weight of the boehmite, and extruding and forming on an extruder; drying at the temperature of between 100 and 120 DEG C; baking at the temperature of between 500 and 700 DEG C to obtain a gamma-Al2O3 carrier containing silicon and phosphorus, wherein the silicon-containing compound is silica solution of which SiO2 accounts for 30 percent based on the weight of the silica solution, or nano-silica; the active ingredients are one or two of NiO and Moo3, and WO3; NiO accounts for 2 to 7 percent based on the total mass of the catalyst, and MoO3 and / or WO3 account for 28 to 32 percent based on the total mass of the catalyst; the prepared catalyst has intensively distributed pores and appropriate surface acidity and still has high hydrogenation activity at a low reaction temperature and under a low reaction pressure.

Owner:PETROCHINA CO LTD

Hydrogenating refining catalyst for petroleum wax stuff and its preparation process

ActiveCN1597869AReasonable hole structureAppropriate pore volumePetroleum wax refiningCobaltPetroleum

The invention discloses a petroleum wax hydrofining catalyst and its preparing method, using Wu, Mo and Ni (or Co) as active metals and using the aluminum oxide containing Si and P auxiliaries to act as a carrier and its preparing method: it dips the aluminum oxide carrier in the Wu-Ni / Co water solution and the Mo-B water solution, respectively, so as to make it. The aluminum oxide carrier is prepared by using the Si-containing aluminum hydroxide prepared by CO2 neutralization process and then adding in the P-containing compound in the forming process. Its preparing process is simple and low-cost. The invention can effectively regulate the physico-chemical property of a catalyst by the cooperative regulation of the two compound auxiliaries, making the catalyst have reasonable aperture structure and proper surface acidic property. This catalyst can process the petroleum waxes including high-melting point petroleum wax and produce food-grade petroleum wax products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenating catalyst for petroleum wax and its preparation process

ActiveCN1597868AGood physical and chemical propertiesLarge aperturePetroleum wax refiningAluminateWax

The invention discloses a petroleum wax hydrogenation catalyst and its preparing method, adopting the Si- and P- containing aluminum hydroxide prepared by CO2 netur neutralization process to act as a carrier material of catalyst, where the Si and P auxiliaries are added in steps, some Si- and P- containing compounds mix with sodium meta-aluminate solution to form a glue, some Si-containing compounds are added after the glue is formed or in the ageing process, and most P-containing compounds are added in the process of peptizing or pulping the produced aluminum hydroxide after washed, thus making most Si and P are distributed on the surface of aluminum hydroxide, effectively give full play to the Si and P cooperatively regulating surface physico-chemical property and hole structure of the catalyst. Its preparing process is simple and low-cost. It has good activity and selectivity as processing petroleum waxes including high-melting point petroleum wax.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of paraffin for pharmaceutic adjuvants

InactiveCN102533333AAchieve decolorizationAchieve deodorizationPetroleum wax refiningPetroleum wax recoveryChemical industryParaffin wax

The invention discloses a method for refining and deoiling paraffin for pharmaceutic adjuvants, and belongs to the field of medical materials. The method disclosed by the invention comprises the following steps of: refining hydrogenant paraffin which is used as a raw material by adopting an active substance so that the paraffin is effectively deodorized, de-colored and deodorized and the paraffin is odorless and tasteless; 'sweating' the paraffin by using a deoiling box so that the paraffin is deoiled and the oil content of the paraffin is reduced, wherein the active substance is active carbon, diatomite and / or active floridin; and the deoiling box is a device which enable the paraffin to be sweated according to a principle that heating is performed by using different melting points of the paraffin so that oil is separated to be infiltrated to the surface of the paraffin, and the deoiling effect of the deoiling box is that the oil content is reduced from 0.5 percent to 0.3 percent, so that the oil content is effectively reduced and the paraffin is difficult to oxidize. The invention aims to widen the application field of the paraffin, and widen the application field of the paraffin from food industry and daily chemical industry to pharmaceutic adjuvant industry; and the paraffin is mainly used as an ointment base hard-enhancing component and a sustained-release material in medicaments.

Owner:JIANGXI MASHAN CHEM

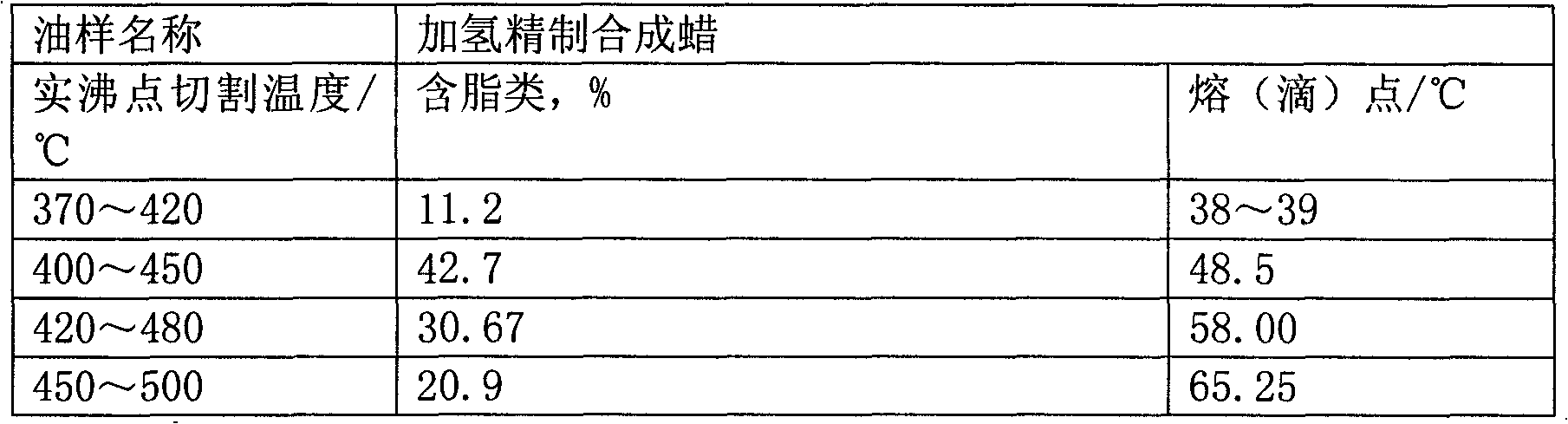

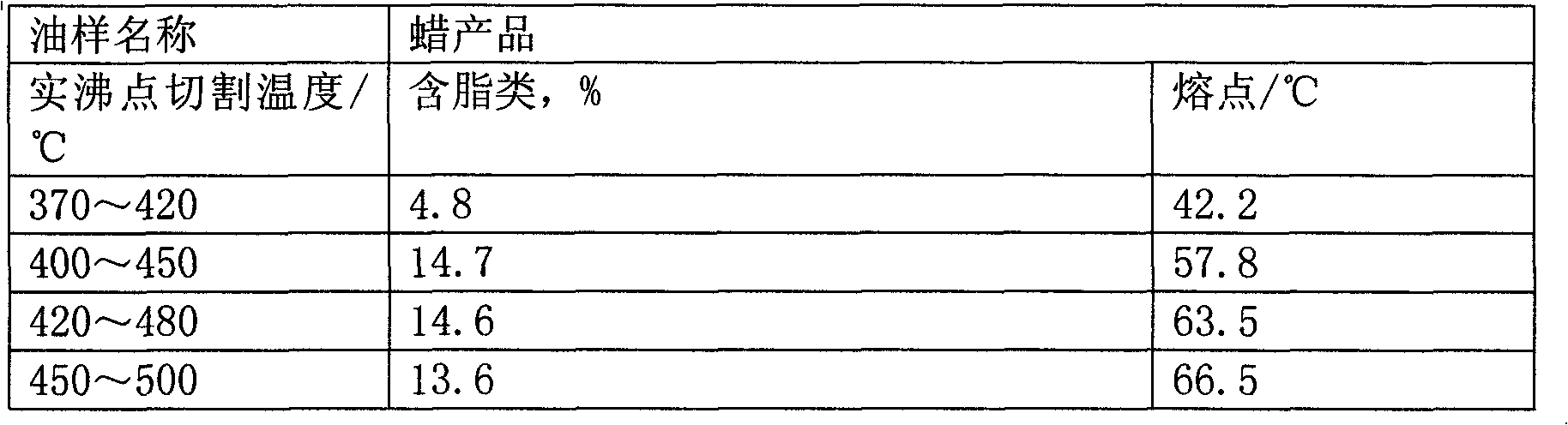

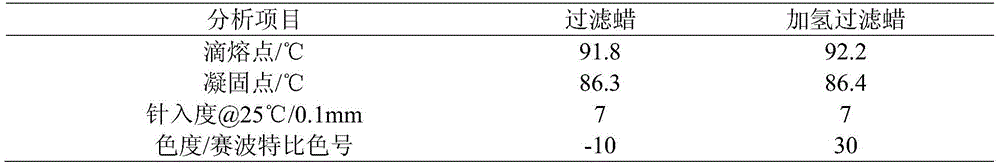

Fischer-Tropsch synthesis wax refinement method

InactiveCN102925214ALower lipid contentMeet more environmental requirementsPetroleum wax refiningWaxCandle

The invention relates to a Fischer-Tropsch synthesis wax refinement method, which comprises that: a crude wax component from a Fischer-Tropsch synthesis system is subjected to hydrogenation refinement, and then is conveyed to a sweating tank through a raw material pump, sweating is performed to remove lipid materials in the wax component, and the obtained material enters the next process device. According to the method, the sweating process is adopted to remove the lipid materials in the wax component, such that characteristics of simple process, low energy consumption and environment protection are provided; and candles produced by the raw material refined by the method have characteristics of smooth appearance, no toxicity, no odor and no smoke during burning, and no harm on human body.

Owner:苏喜红

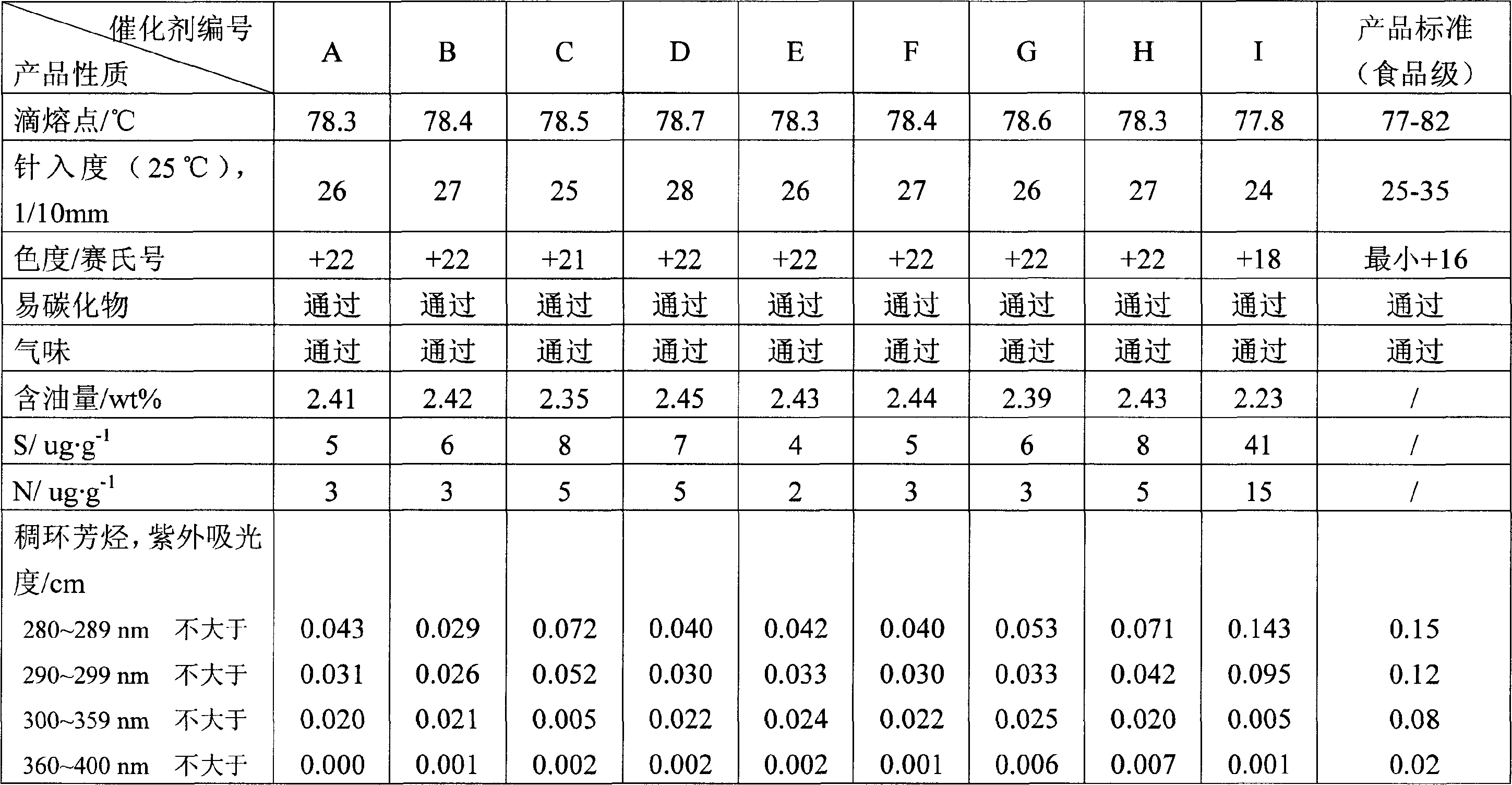

Method for producing micro crystal wax

InactiveCN1458244AHigh activitySolution to short lifePetroleum wax refiningState of artMicrocrystalline wax

The present invention discloses the hydrogenation process of producing white soft micro crystal wax. The said process has hydrodesulfurizing, dentrifying, deoxygenation and arene saturating reaction in optimal conditions to produce high quality white soft micro crystal wax product for food product and cosmetics. Compared with available technology, the said process is simple, long in operation period, and flexible in operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

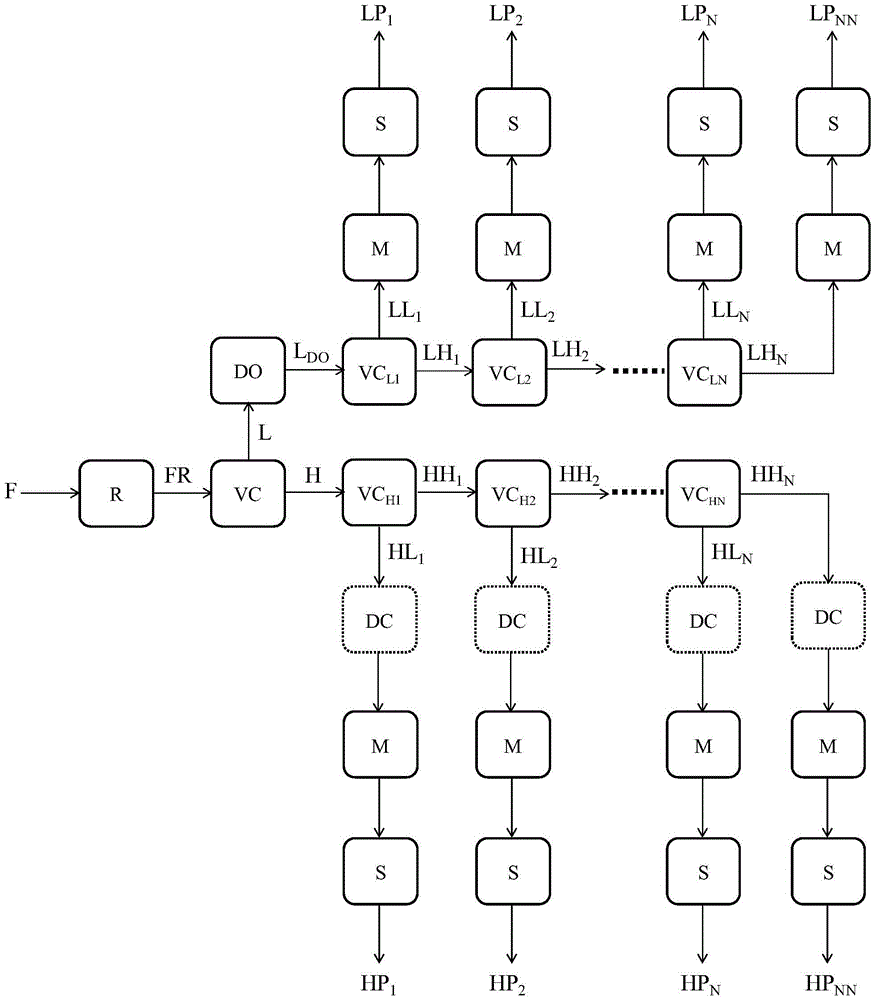

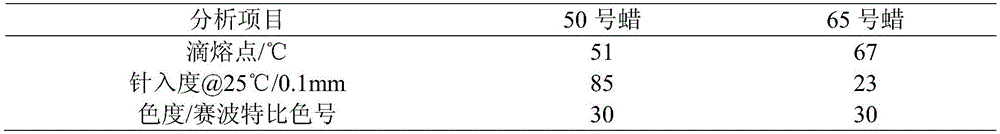

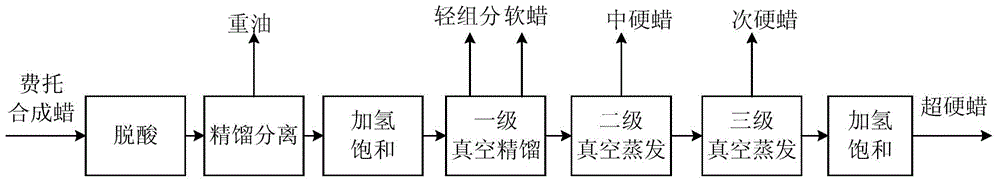

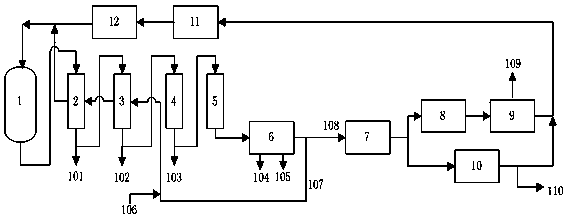

Method for processingFischer-Tropsch wax production series products

ActiveCN105542856ATake advantage ofRich product linePetroleum wax refiningMaterials scienceRaw material

The invention provides a method for processing Fischer-Tropsch wax production series products. The method comprises: carrying out hydrofinishing on a Fischer-Tropsch wax raw material F to prepare a hydrofinished material FR; separating FR to obtain a light component material L and a heavy material H; carrying out oil removing operation on L to obtain an oil-removed light component material LDO; separating LDO to obtain a light component material LL1 and a remaining component material LH1; carrying out improvement of physicochemical properties on LL1 and forming so as to obtain a lightweight product LP1; treating LH1 according to the processes of the steps (4) and (5) to obtain a lightweight product LP2 and a remaining component material LH2; treating LH2 according to the processes of the steps (4), (5) and (6) to finally obtain a series of lightweight products LP3,..., LPN, and LPNN; separating H to obtain a light component material HL1 and a remaining component HH1; carrying out improvement of physicochemical properties on HL1 andforming so as to obtain a heavyweight product HP1; treating HH1 according to the processes of the steps (8) and (9) to obtain a heavyweight product HP2 and a remaining component material HH2; and treating HH2 according to the processes of the steps (8), (9) and (10) to finally obtain a series of heavyweight products HP3,..., HPN, and HPNN.

Owner:SYNFUELS CHINA TECH CO LTD

Process for making high viscosity index lubricating base oils

A process for making a lubricating base oil having a viscosity index of at least 110, comprising the steps of: combining a waxy light neutral base oil and a wax derived from pyrolyzing a plastics feed comprising polyethylene to form a blend; hydroisomerization dewaxing the blend; and recovering the lubricating base oil from an effluent from the hydroisomerization dewaxing step.

Owner:CHEVROU USA INC

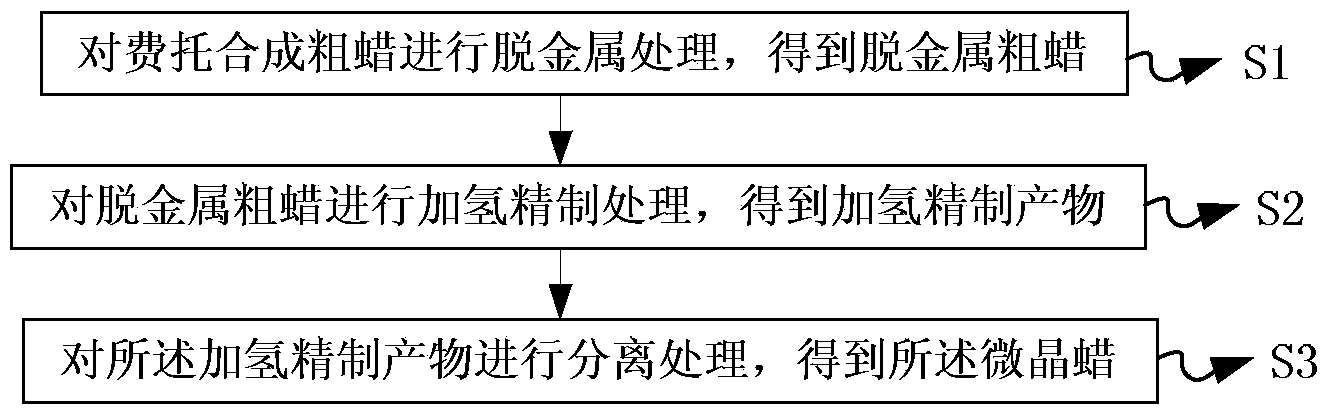

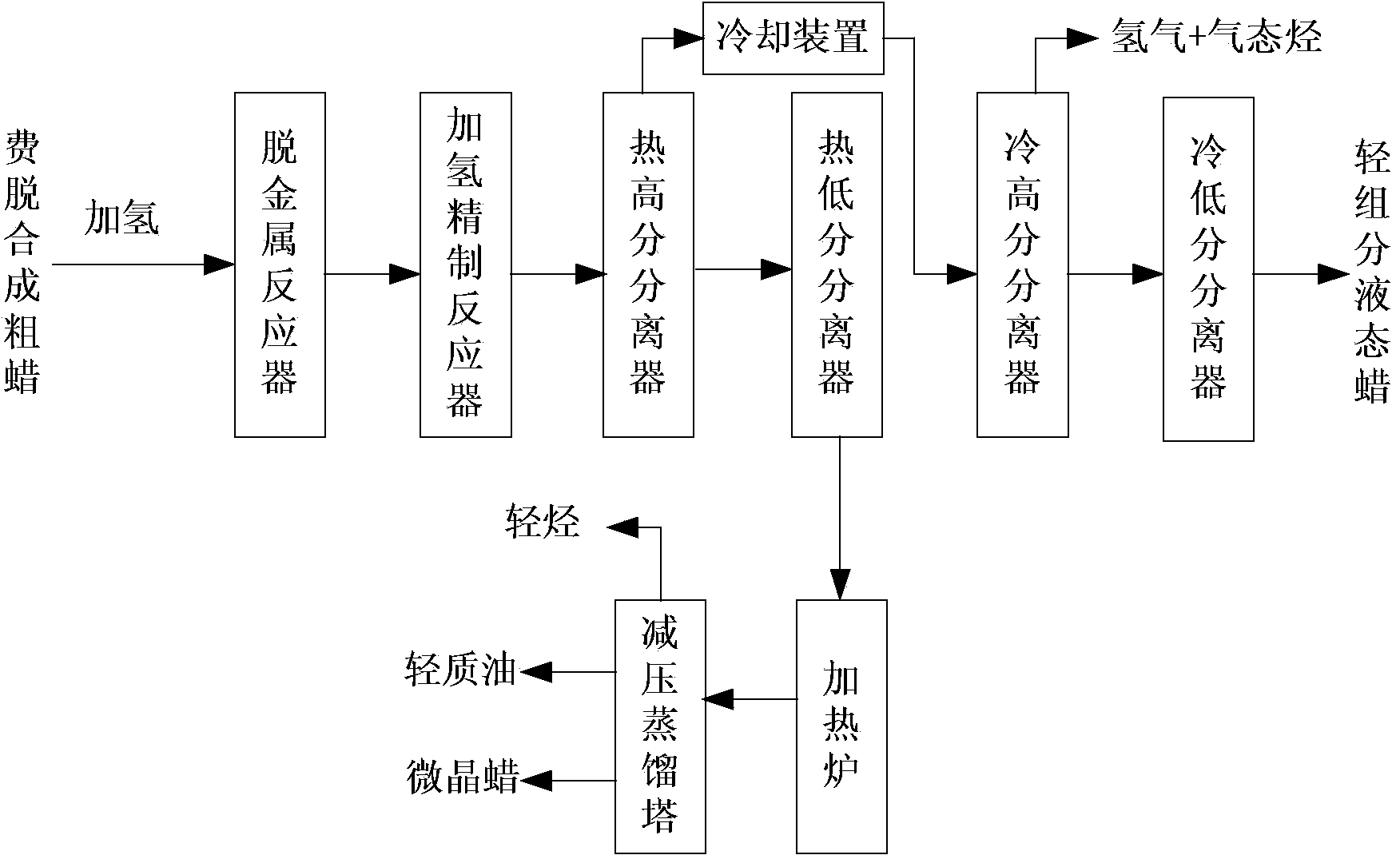

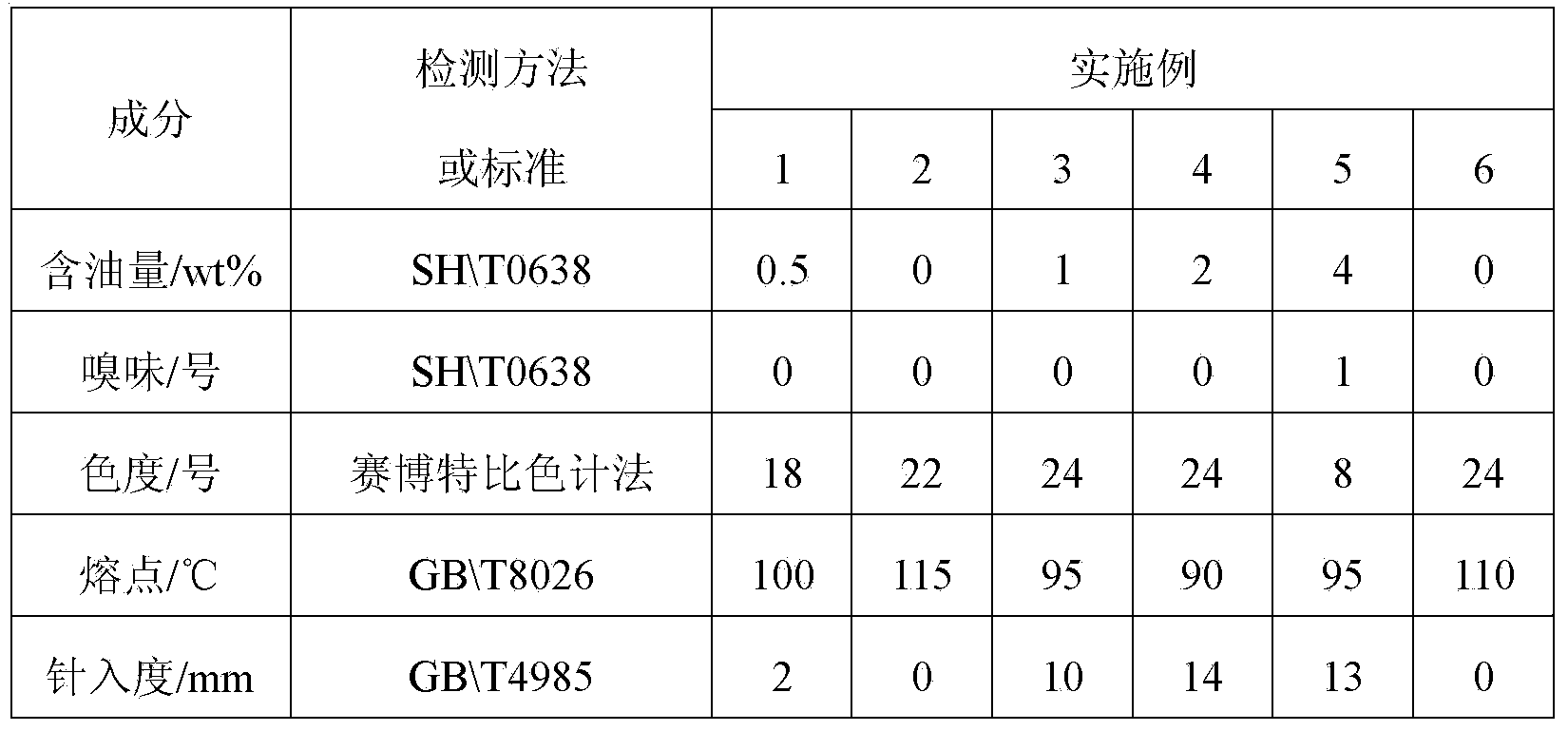

Method for producing microcrystalline wax from Fischer-Tropsch synthesis crude wax

ActiveCN104178219AIncrease added valueReduce oil contentPetroleum wax refiningMicrocrystalline waxMetal catalyst

The invention discloses a method for producing microcrystalline wax from Fischer-Tropsch synthesis crude wax. The method comprises the following steps of S1, carrying out metal removal treatment on Fischer-Tropsch synthesis crude wax to obtain metal-removed crude wax; S2, carrying out hydrorefining treatment on the metal-removed crude wax to obtain a hydrorefined product; and S3, carrying out separation treatment on the hydrorefining product to obtain the microcrystalline wax. The microcrystalline wax is produced from the Fischer-Tropsch synthesis crude wax as a raw material, steps of removing sulfur, nitrogen, aromatics and other impurities are not needed, a metal catalyst entrained in the Fischer-Tropsch synthesis crude wax is directly removed and then the hydrorefining treatment is carried out, and the light-wax component in the hydrorefined product is separated out to obtain the microcrystalline wax with low content of oil and fewer sulfur, nitrogen, oxygen and metal impurities components. The method disclosed by the invention provides a novel processing process for the Fischer-Tropsch synthesis crude wax, the processing cost can be reduced and the additional value of the Fischer-Tropsch synthesis crude wax can be improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Prepn process of paraffin hydrofining catalyst

InactiveCN1421511AReduce the amount requiredReduce manufacturing costPetroleum wax refiningParaffin waxPore distribution

The present invention relates to one kind of catalyst used in petroleum refining equipment and is especially the preparation process of one kind of paraffin hydrofining catalyst. The preparation process of the paraffin hydrofining catalyst includes modification with alumina, compounding of active component solution, soaking and forming. The catalyst prepared through the process has lower content of active component, low cost, high strength, optimized alumina pore distribution and high stability.

Owner:BC P INC CHINA NAT PETROLEUM CORP

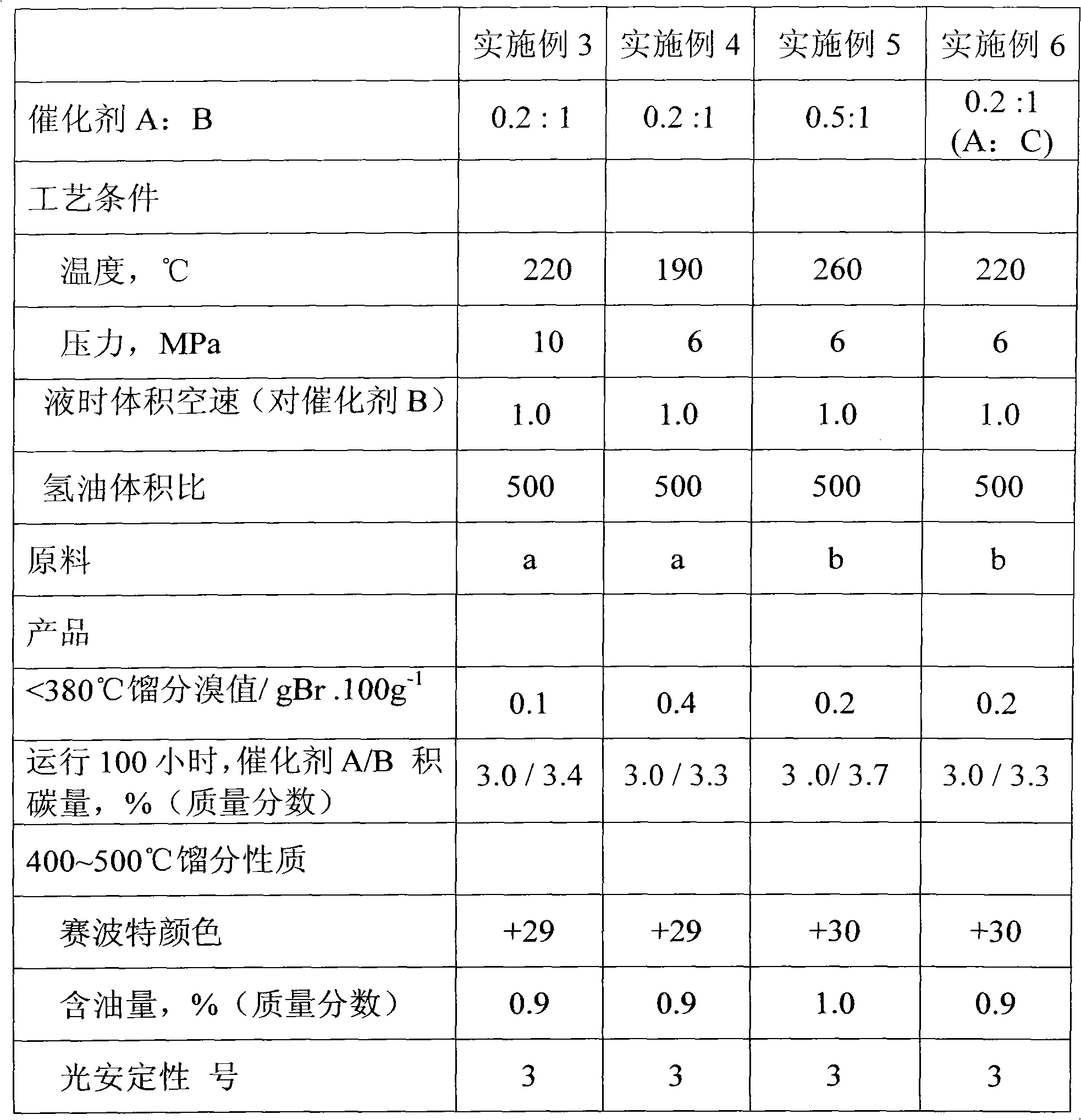

Hydrofining method for Fischer-Tropsch oil

ActiveCN102041067AReduce carbon depositionLess severePetroleum wax refiningTreatment with hydrotreatment processesHydrodeoxygenationFixed bed

The invention discloses a hydrofining method for Fischer-Tropsch oil. In the method, a fixed bed reactor is used, and the Fischer-Tropsch oil is contacted with the diolefins hydrogenation saturation catalyst so as to hydrogenate and saturate diolefins and then is contacted with the hydrogenated deoxidized catalyst in order to carry out olefin saturation and hydrodeoxygenation reactions, so as to obtain the hydrofined products. Compared with the method using a single catalyst, the method disclosed by the invention can reduce the coke and deposited carbon formed by polymerizing dienes. Compared with the method using a double reactor, the method disclosed by the invention simplifies the process flow.

Owner:CHINA PETROLEUM & CHEM CORP +1

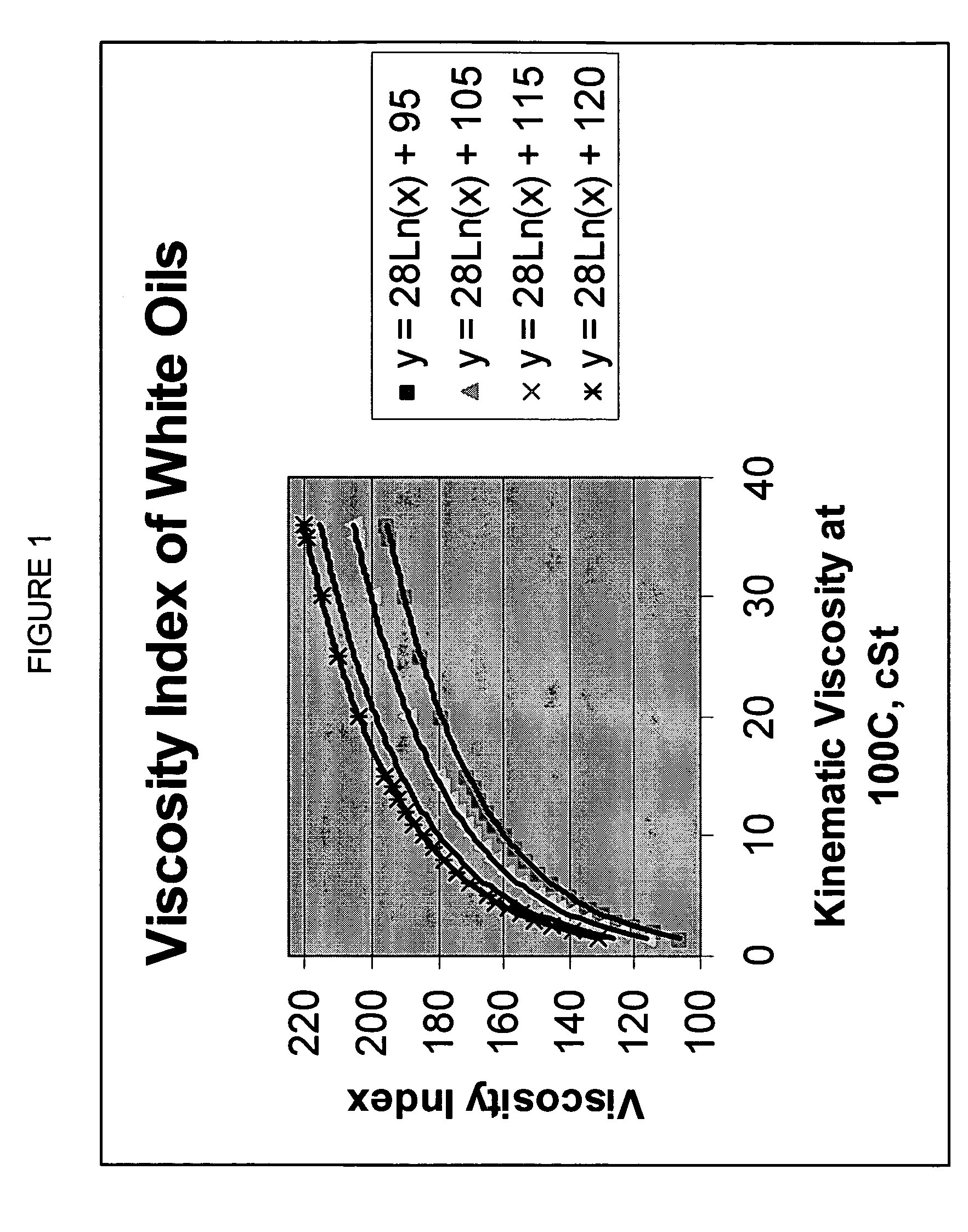

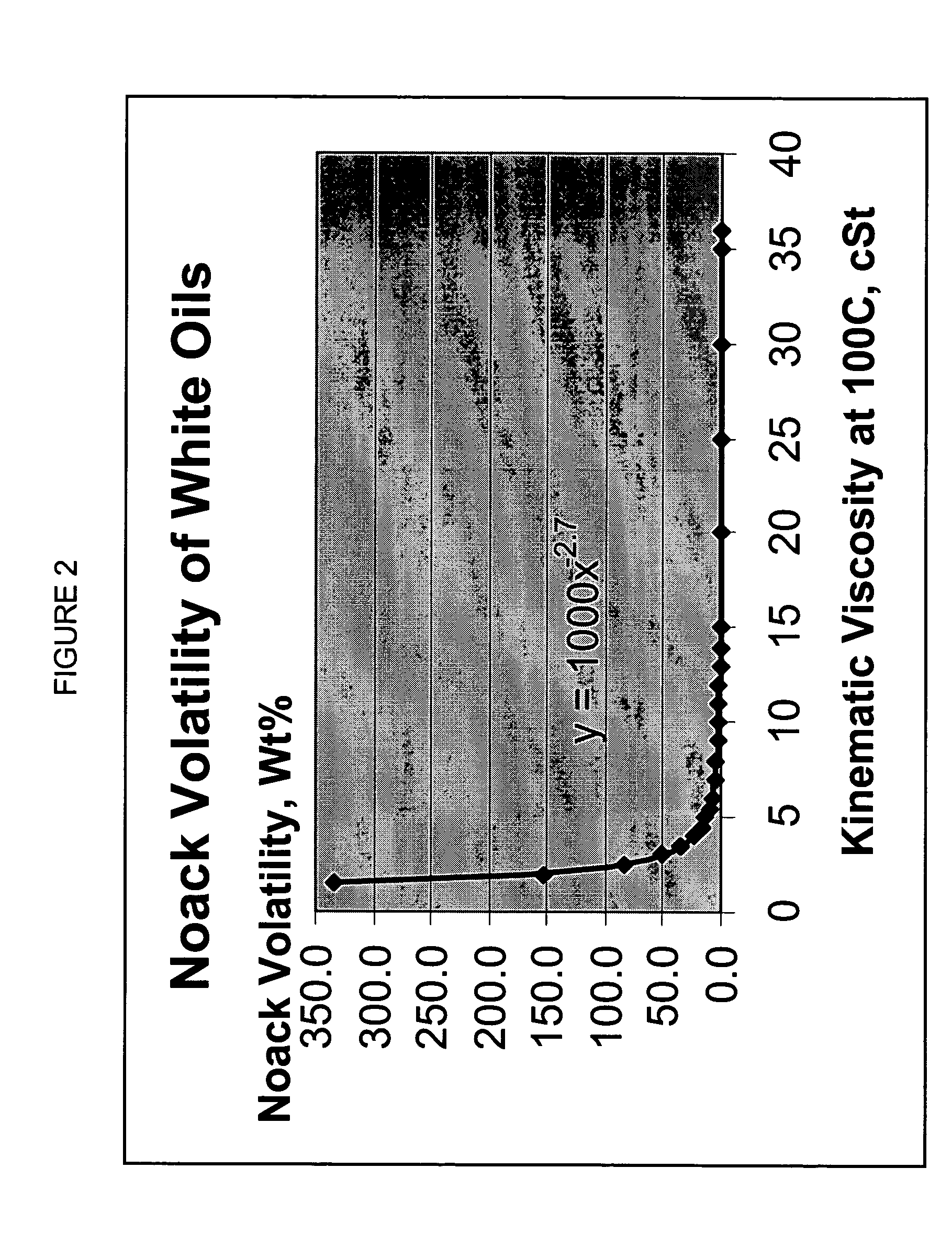

Process to make white oil from waxy feed using highly selective and active wax hydroisomerization catalyst

A process for producing one or more white oils, by: a) hydroisomerization dewaxing a waxy feed with a defined composition over a highly selective and active wax hydroisomerization catalyst with a defined composition under conditions sufficient to produce a white oil; and b) collecting one or more white oils, wherein the yield of white oils is high, and they have a low pour point and a good Saybolt color. Also, a process for producing medicinal grade white oils, by a)hydroisomerization dewaxing a waxy feed with a defined composition over a highly selective and active wax hydroisomerization catalyst with a defined composition under conditions sufficient to produce a white oil, b) collecting technical grade white oils having a low pour point and good Saybolt color in high yield, and c) hydrofinishing the technical grade white oils at conditions sufficient to produce medicinal grade white oils that pass the RCS test.

Owner:CHEVROU USA INC

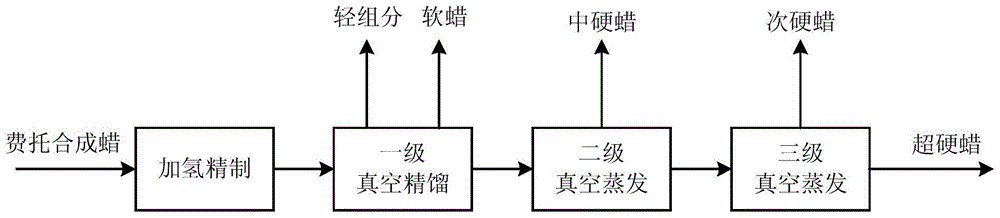

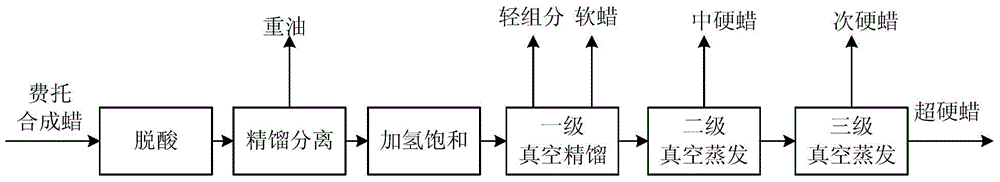

Method for preparing high-grade wax by Fischer-Tropsch synthesis crude wax

ActiveCN106554823AImprove qualityQuality improvementPetroleum wax refiningPetroleum chemical modificationGas phaseDistillation

The invention relates to the field of production of high melting-point wax, and discloses a method for producing high-grade wax by Fischer-Tropsch synthesis crude wax. The method comprises the following steps: A) a hydrogenation saturation step: performing hydrogenation saturation on a raw material; B) primary separation: placing the saturated raw material in the step A) in a primary rectification unit, rectifying the raw material under certain pressure and temperature effects to obtain a light component, soft wax and crude hard wax; C) secondary separation: placing the crude hard wax obtained in the step B) in a secondary distillation unit, evaporating the material under certain pressure and temperature to obtain a first gas phase and a liquid phase; and D) third separation: placing the liquid phase in a third distillation unit, evaporating the material under certain pressure and temperature to obtain a second gas phase and superhard wax; wherein the primary rectification unit is a vacuum rectifying tower. The method can reduce the hardware cost of the employed distillation units in the separation process and increases the economic performance of a Fischer-Tropsch device.

Owner:YASHENTECH CORP

Method for high value utilization of Fischer-Tropsch synthesis tail gas

ActiveCN103666518ASimple processEasy to operateOrganic chemistryPetroleum wax refiningAlkaneGas phase

The invention relates to a method for high value utilization of Fischer-Tropsch synthesis tail gas. The method comprises that: Fischer-Tropsch synthesis reaction products enter a first heat exchanger in a gas phase form so as to be subjected to heat exchange, and gas-liquid separation is performed to obtain hard wax; heat exchange is performed through a second heat exchanger, and gas-liquid separation is performed to obtain soft wax; and a water cooling device is adopted to separate heavy oil, an ammonia cooling device is adopted to separate to obtain light oil and synthesis water, one part of the non-condensable tail gas is adopted as the circulation gas, is pre-heated through the second heat exchanger and the first heat exchanger, and then enters the Fischer-Tropsch synthesis reactor, the other part is adopted as the relief gas so as to carry out low carbon alkane dehydrogenation to produce low carbon olefins, the low carbon olefins are subjected to aromatization to produce BTX or are subjected to polymerization to produce terminal olefins, and the lubricating oil poly alpha olefin is further synthesized. The method has advantages of low production cost, high product price, and good quality.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Technology for recycling paraffin-resin mold material

InactiveCN102615244AQuick breakdownPlay a stirring effectPetroleum wax refiningFoundry mouldsParaffin waxSodium silicate

The invention discloses a technology for recycling a paraffin-resin mold material and particularly belongs to a technology for recycling a mold material of a precise mould. The technology for recycling the paraffin-resin mold material performs full reaction on hydrochloric acid and an alkali substance waterglass sodium silicate in a recycled paraffin-resin mold material to obtain a finished product in a steam heating way. The technology for recycling the paraffin-resin mold material has the advantages of simple process, convenience in operation, capability of effectively removing the alkali substance and granular impurities from the recycled paraffin-resin mold material, and reusability of the recycled paraffin-resin mold material.

Owner:SICHUAN DELI RAILWAY TECH

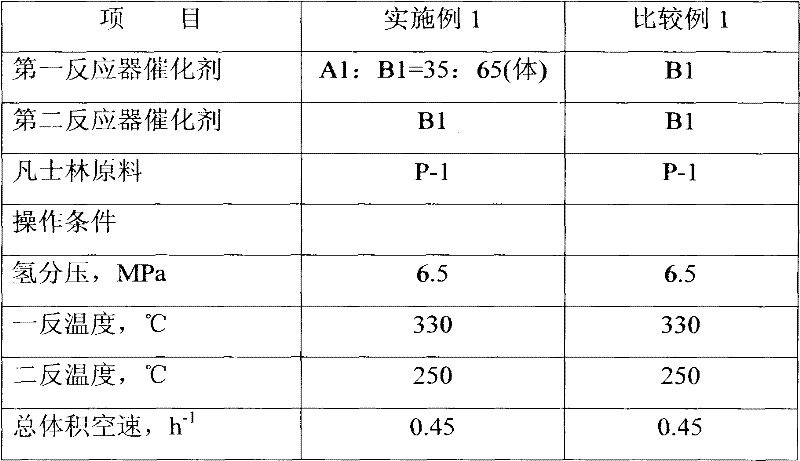

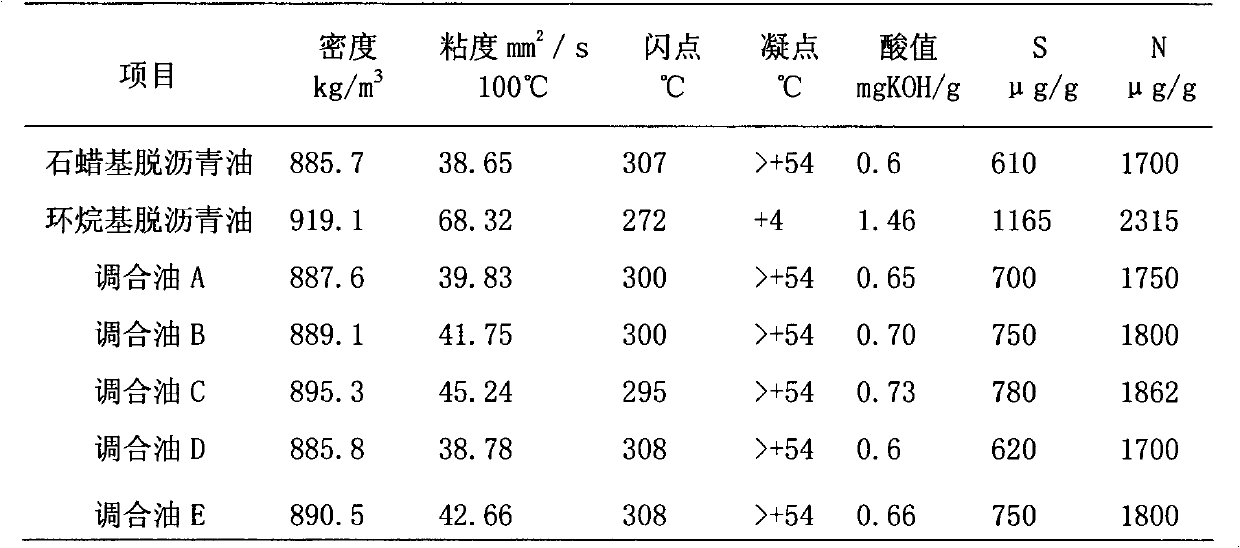

Method for in-depth hydrogenation and dearomatization of vaseline

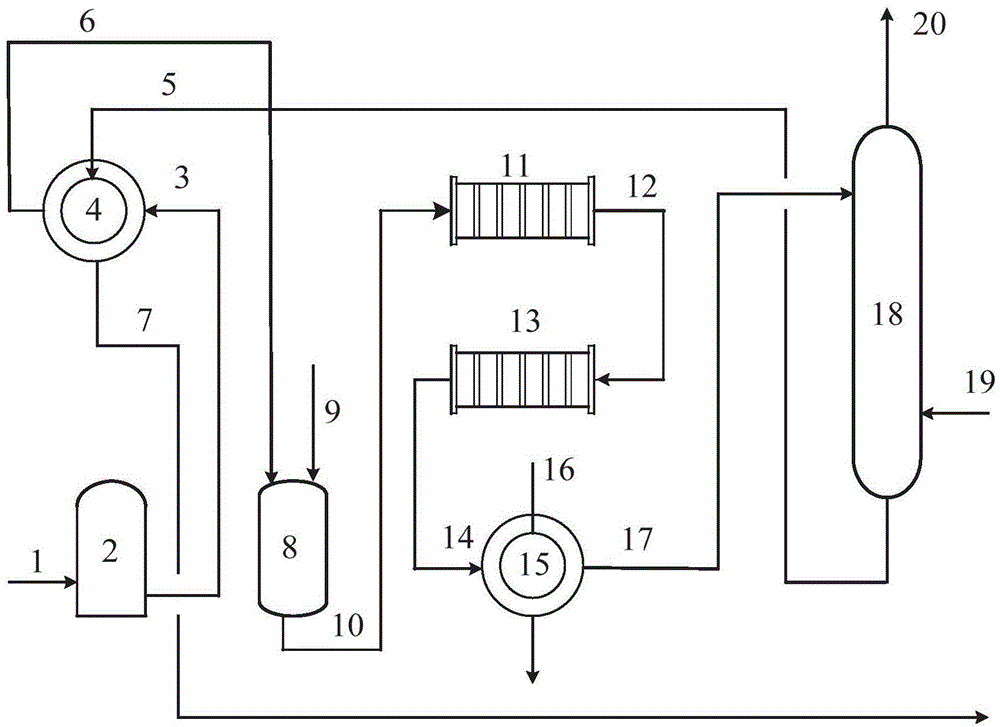

ActiveCN103102989AQuality improvementLow investment costPetroleum wax refiningTreatment with hydrotreatment processesGas phaseHigh pressure

The invention relates to a method for in-depth hydrogenation and dearomatization of vaseline. According to the method, a vaseline raw material and hydrogen enter into a first reactor at first and contact with a sulfided non-noble metal hydrorefining catalyst for desulphurization, denitrification, deoxidation and partial aromatic saturation; then a reaction product of the first reactor undergoes gas-liquid separation in a high pressure separator, and an obtained liquid phase and fresh hydrogen enter into a second reactor which employs a noble metal catalyst for aromatic saturation; a reaction product of the second reactor undergoes gas-liquid separation, an obtained liquid phase is subjected to removal of light hydrocarbon and odor so as to obtain a vaseline product, and an obtained gas phase enters into the first reactor and is used as supplementary hydrogen for the first reactor; and hydrogen partial pressure of the first reactor and the second reactor is 5 to 10 MPa. With the method provided by the invention, the high-quality vaseline product can be obtained at a low reaction pressure, and equipment investment and operation cost are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Paraffin hydrorefining catalyst and its prepn process

The present invention is paraffin hydrorefining catalyst and its preparation process. New type of gamma-Al2O3 carrier is first prepared via adding boron compound or boron-containing halide for excellent surface structure favorable to the dispersion of active metal. The carrier is then soaked in Mo-Ni-P solution, and through drying, roasting and other steps, Mo-Ni-P / B2O3-Al2O3 catalyst is prepared. During the preparation of the catalyst, the condition is controlled and optimized for homogeneous dispersion of the metals on the surface of B2O3-Al2O3, proper distribution of active components and even raised reducing performance. The catalyst has excellent paraffin hydrorefining performance, even if in reduced metal loading amount, and excellent paraffin decolorizing performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Phase-change paraffin preparation method

InactiveCN105505331AEfficient steam outReduce pollutionPetroleum wax refiningHeat-exchange elementsPhase change enthalpyHydrogenation reaction

The invention relates to a phase-change paraffin preparation method, and belongs to the technical field of pharmaceutical and chemical engineering. The phase-change paraffin preparation method is simple in technology; by means of the method, demand-based customized production can be achieved, waste can be reduced, cost can be lowered, and economic benefits can be effectively increased. According to the technical scheme, the phase-change paraffin preparation method includes the following steps that coal is subjected to gasification production to obtain synthesis feed gas, the feed gas is subjected to a Fischer-Tropsch synthesis reaction to obtain Fischer-Tropsch synthesis products, the Fischer-Tropsch synthesis products are subjected to a hydrogenation reaction to obtain a wide-fraction mixture, namely, Fischer-Tropsch synthesis paraffin, the Fischer-Tropsch synthesis paraffin is subjected to molecular short steaming and rectification to obtain refined paraffin products with different phase change enthalpy values, and NNO is added to obtain stable phase-change paraffin.

Owner:SHANXI LUAN COAL BASED SYNTHETIC OIL +1

Catalyst for hydrogenation upgrading heavy and residual oil and application thereof

The heavy oil and residual oil hydromodifying catalyst contains oily colloid of Mo and W, with the average grain size of Mo and W being below 500 nm. The catalyst may be used widely the hydrogenating reaction, hydrocracking and other technological process of heavy oil and residual oil. In the said technological processes, the catalyst containing Mo and W is first dispersed inside heavy oil and residual oil, and in the presence of hydrogen, the inferior heavy oil and residual oil is hydrogenated. The present invention aims to raise the efficiency of heavy oil and residual oil hydrogenating reaction while lowering the cost of catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

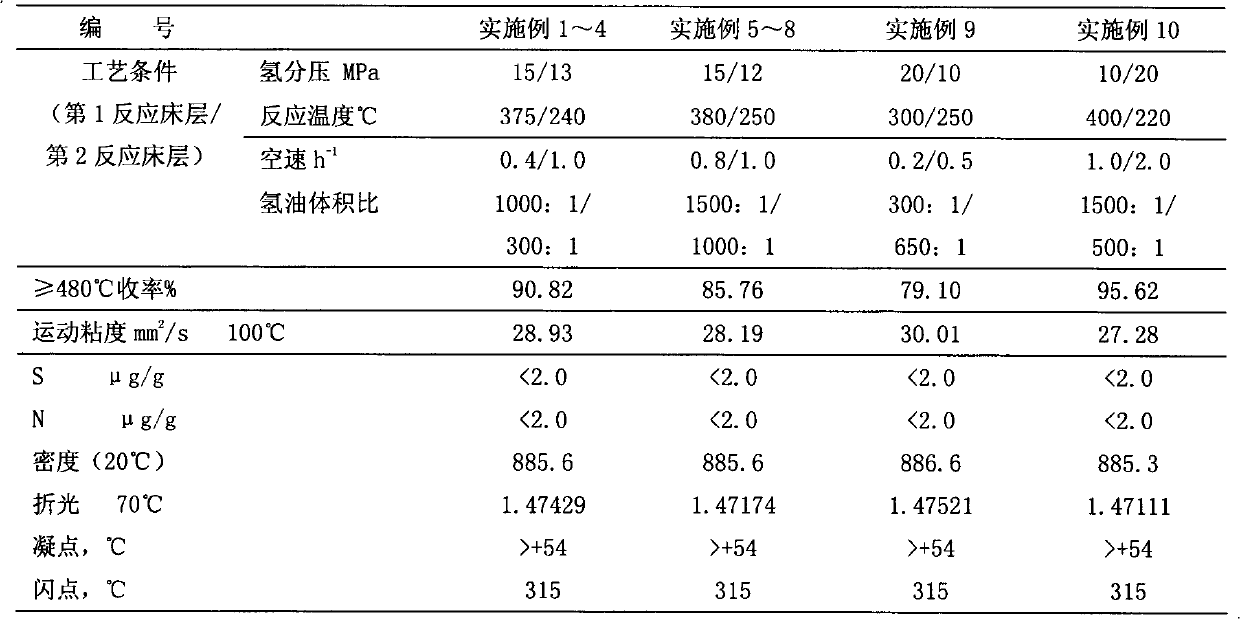

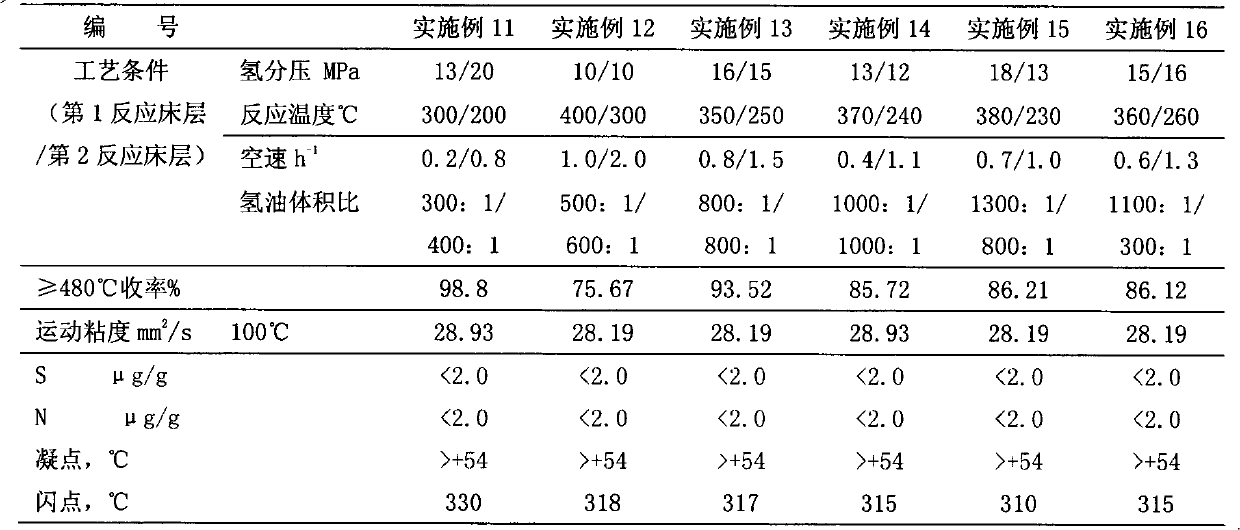

Preparation method of food-grade microcrystalline wax

InactiveCN103865580AExtended service lifeChange the rate of the hydrogenation reactionPetroleum wax refiningMicrocrystalline waxSlag

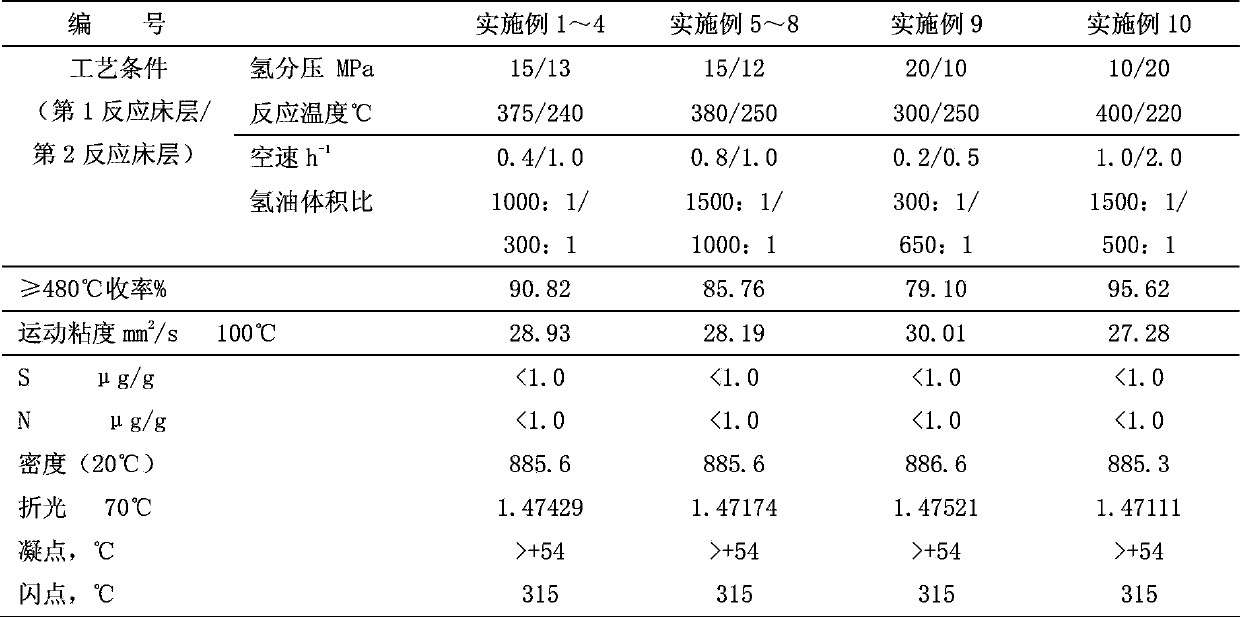

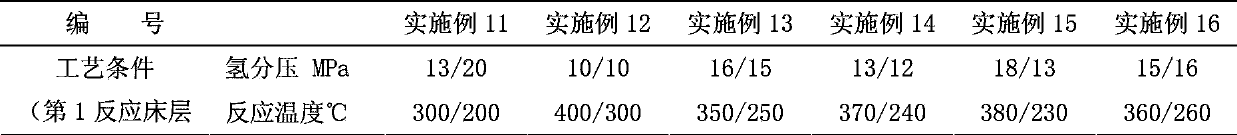

The invention relates to a preparation method of food-grade microcrystalline wax. The preparation method comprises the following steps that blended oil comprising paraffin-based slag-reduced deasphalted oil and naphthenic base slag-reduced deasphalted oil is used as a raw material, is fed into a first reaction bed layer and then undergoes a hydrotreatment modification reaction; the reaction product is fed into a stripping tower and the stripped product is fed into a second reaction bed layer and undergoes a hydrofining reaction to produce hydrofined product oil; the hydrofined product oil is cut by atmospheric and vacuum fractionation equipment to form a heavy lubricant component having a temperature of 480-750 DEG C; the heavy lubricant component and an acetone-benzol dewaxing solvent are mixed; the mixture is cooled to below -15 DEG C; the cooled mixture is filtered so that dewaxed filtrate and deoiled wax are obtained; the deoiled wax is mixed with carclazyte by stirring; and the mixture is filtered so that the carclazyte is removed and the food-grade microcrystalline wax is obtained. The food-grade microcrystalline wax has Seybolt color number greater than +25, a drop melting point of 67-92 DEG C, a needle penetration degree of 15-35(1 / 10mm), oil content of 0.85-3.0%, sulfur and nitrogen content less than 1 microgram per gram and heavy metal and arsenic content less than 1mg / kg.

Owner:PETROCHINA CO LTD

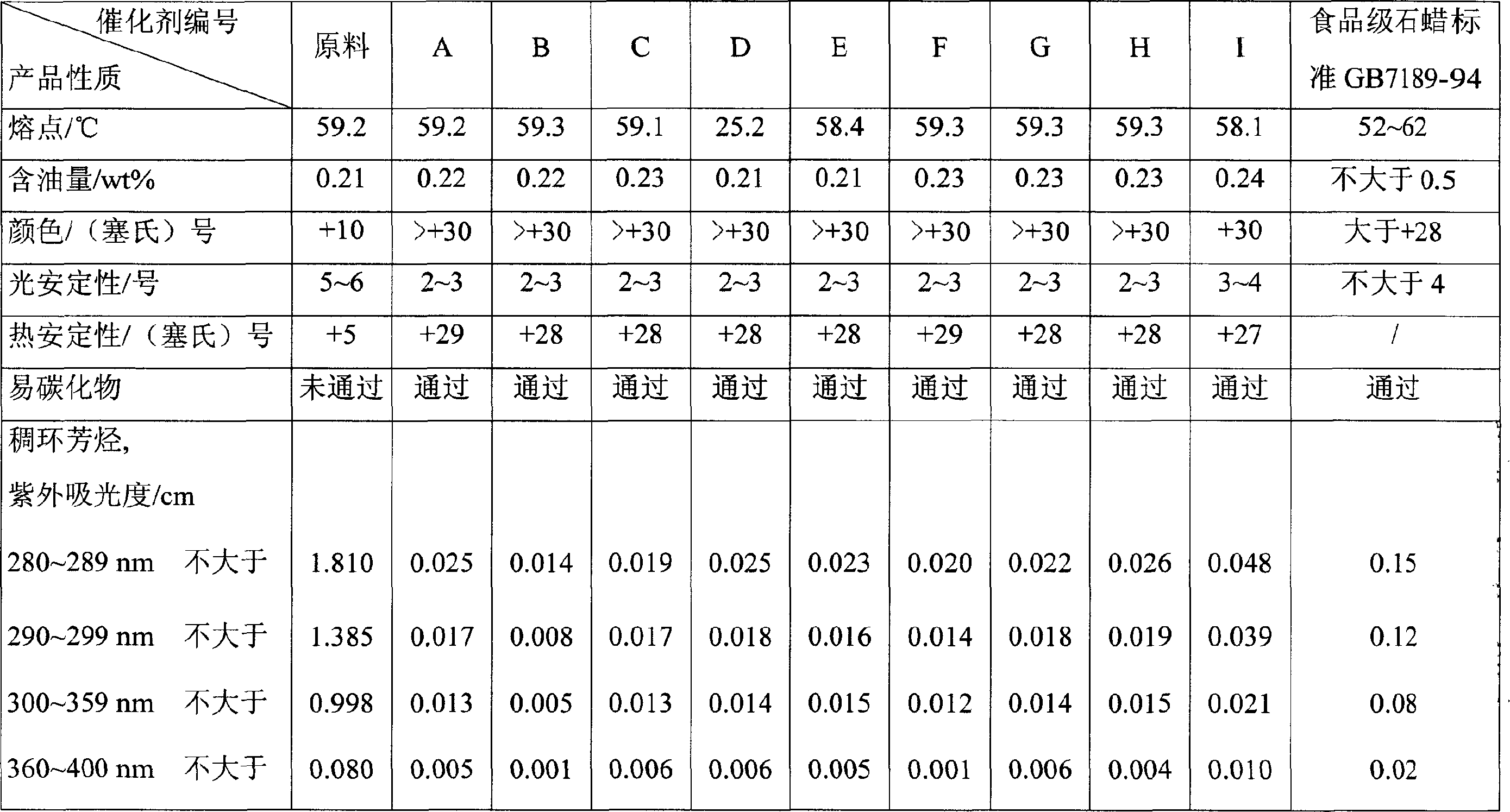

Paraffin-hydrogenating refining process

ActiveCN1952076AReduce n-paraffin contentImprove toughnessPetroleum wax refiningPolycyclic aromatic hydrocarbonParaffin wax

The invention disclosed a method of ozocerite hydrogenation refinement, which adopts ozocerite hydrogenation refining catalyst and hydrogenation isomerizing catalyst as the two main catalysts. Under the ozocerite hydrogenation refining conditions, the ozocerite contacts the two catalysts one by one. The invention can not only get refined ozocerite products with low sulphur and nitrogen content, low polycyclic aromatic hydrocarbon content, it can also decrease the content of ortho- diolefine in the ozocerite and overcome the defects of poor tenacity and brittleness. The ozocerite produced according to the invention can be used in food, medicine and cosmetics.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for production of high-melting-point petroleum wax

The invention relates to a method for production of high-melting-point petroleum wax. The method comprises the steps of: firstly making a deoiling raw material contact a petroleum wax hydrofining catalyst to undergo refining reaction under a hydrofining condition, subjecting the deoiling raw material undergoing hydrofining to deoiling by a solvent to produce deoiled wax. According to the method provided by the invention, the solvent used in the solvent deoiling process is a mixed solvent of tert-butyl-containing asymmetric ether and C3-C6 aliphatic ketone. Production of high-melting-point petroleum wax by the method provided by the invention can improve the filtration speed of solvent deoiling by 20%-35% and increase the yield of deoiled wax by 1%-3%.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for hjydrogenation refining petroleum wax

The petroleum wax hydrofining process is one process in single reactor with two kinds of graded and filled catalyst. Under hydrofining condition, the petroleum wax is first contacted with Mo-Ni catalyst, the refined product is then mixed with cold hydrogen and the mixture is finally contacted with W-Ni catalyst to obtain refined product with low S and N content and low fused ring arene content. The product has obviously improved stability. The said petroleum wax material includes paraffin and microcrystalline wax, and petroleum wax product of the present invention may be used in food product,medicine and cosmetics.

Owner:CHINA PETROLEUM & CHEM CORP +1

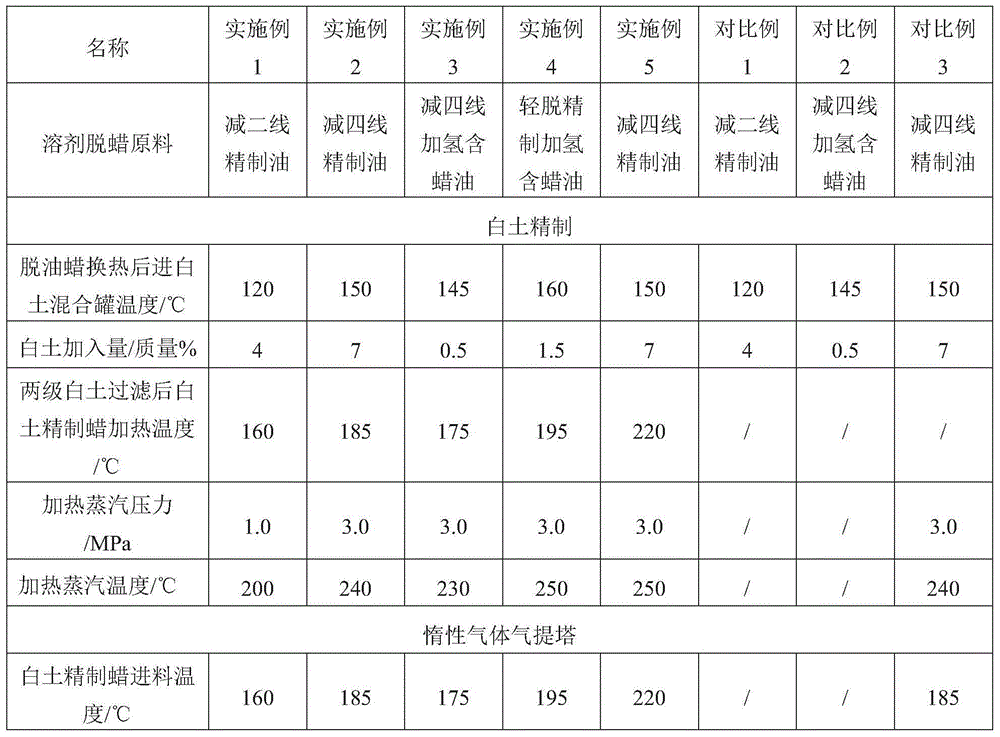

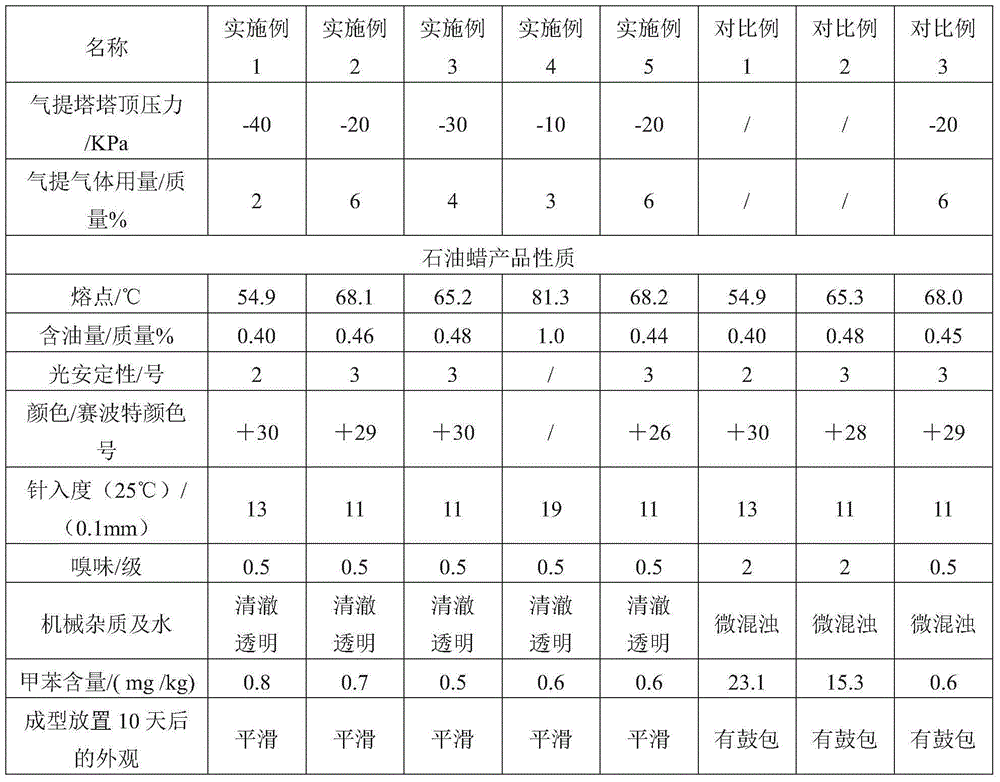

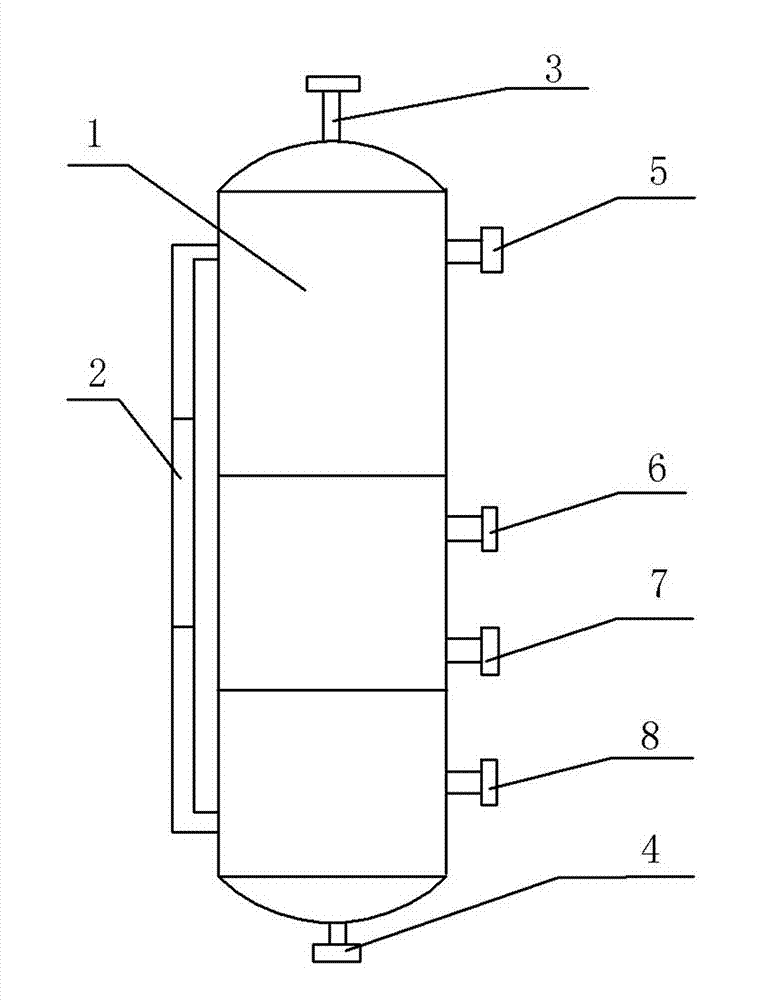

Method for improving petroleum wax smell and appearance

The invention discloses a method for improving petroleum wax smell and appearance. According to the method, deoiled wax obtained after a solvent recovery process of a solvent dewaxing device contacts clay; a mixture is separated, such that clay refined wax is obtained; through solvent dewaxing solvent recovery, the content of a toluene solvent in deoiled wax is no higher than 300mg / kg; the clay refined wax is subjected to inert gas stripping in a stripping tower, such that substances influencing the smell and appearance of the petroleum wax are removed, and a wax product meeting the petroleum wax standard requirement is obtained. After a period of time of storage, the petroleum wax obtained after clay refining and inert gas stripping is prevented from a bulge phenomenon.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and device for refining liquid paraffin

ActiveCN102888245ALow costAchieve the purpose of separationPetroleum wax refiningParaffin waxProcess engineering

The invention discloses a method for refining liquid paraffin and belongs to an important link in the industrial production process of chlorinated paraffin. Compared with the traditional silicon gel adsorption and dehydration process, the method has the advantages that moisture and impurities in the liquid paraffin are purified by fully utilizing characteristic differences between by-product hydrochloric acid generated in the chlorinated paraffin production process and liquid paraffin raw materials, and silicon gel is not required to be bought additionally, so that energy is saved, the cost is reduced, and pollutants namely waste silicon gels are reduced. The invention also provides a device, namely a liquid paraffin purifier which is used in the method for refining liquid paraffin. The liquid paraffin purifier is rational in design, easy to mount, low in cost and convenient to operate, the production efficiency can be guaranteed, and the product quality is improved.

Owner:沁阳市海世鸿工贸有限责任公司

Paraffin-hydrogenating refining process

ActiveCN100432193CReduce n-paraffin contentEasy to fillPetroleum wax refiningPolycyclic aromatic hydrocarbonParaffin wax

Owner:CHINA PETROLEUM & CHEM CORP +1

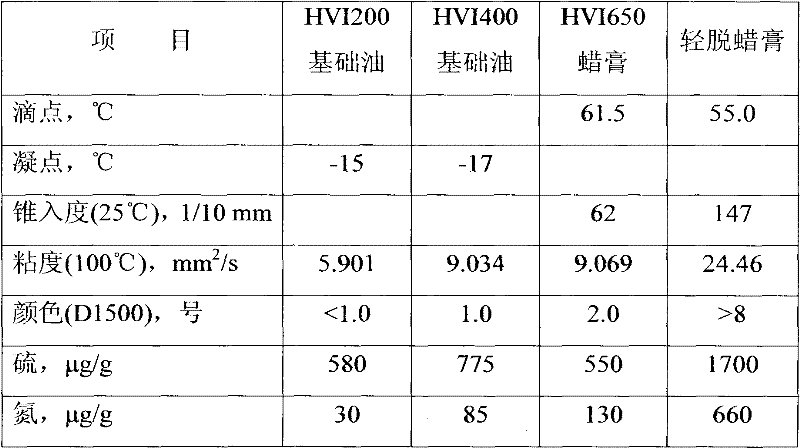

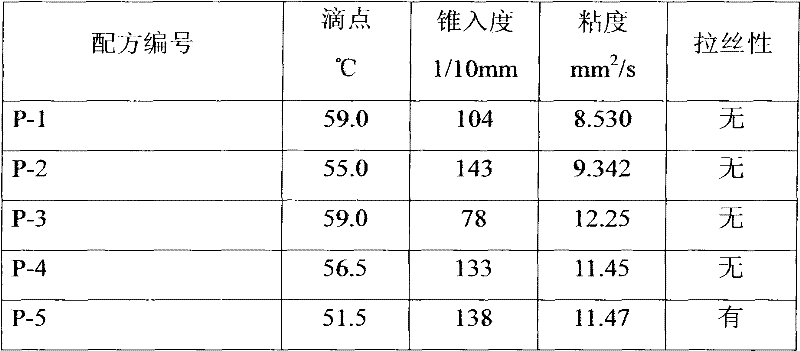

Production method of vaseline

The invention discloses a production method of vaseline. The method comprises the following steps: 1, blending HVI650 cerate, reduced pressure distillate oil base oil and selective reduced pressure residual oil light removal cerate which are treated as raw materials; 2, hydrotreating the obtained blended mixture through first-stage series hydrofinishing with a fixed bed; and 3, allowing the blended mixture to go through a first reactor and a second reactor under hydrofinishing conditions, wherein the first reactor is filled with a hydroisomerizing catalyst and a hydrofinishing catalyst, and the second reactor is filled with a hydrofinishing catalyst. The method of the invention allows high quality vaseline products to be obtained by treating raw materials which cannot be vaseline raw materials in the prior art as the vaseline raw materials, blending the raw materials with a proper process and hydrogenating the raw materials, so the vaseline raw material source is enlarged, the HVI650 cerate utilization approach is widened, and economic benefits are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing white micro-crystalline wax

The invention relates to a method for preparing white micro-crystalline wax. The method comprises the following steps of: feeding blended oil of paraffin base vacuum residue deasphalted oil and naphthenic base vacuum residue deasphalted oil serving as a raw material into a first reaction bed to perform hydrogenation modification reaction and feeding the raw material into a second reaction bed to perform hydrorefining reaction; cutting the obtained hydrogenated oil by using an atmospheric and vacuum fractionation device to obtain a heavy lubricating oil component of between 480 and 750 DEG C; mixing the heavy lubricating oil component and an acetone benzol dewaxing solvent; cooling the mixture to below -15 DEG C; and filtering to obtain dewaxed filtrate and deoiled wax, wherein the deoiled wax is the white micro-crystalline wax; the Saybolt color number of the white micro-crystalline wax is +20; the drip melting point ranges from 77 to 82 DEG C; the penetration is 23 to 30 (1 / 10mm); the oil content ranges from 0.85 to 3.8 percent; the sulfur / nitrogen content is below 2mu g / g; the heavy metal content and arsenic content are less than 1mg / kg; and the product quality can reach SH0009-90 cosmetic-grade paraffin industry standard.

Owner:PETROCHINA CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com