Hydrogenating catalyst for petroleum wax and its preparation process

A technology of hydrogenation catalyst and petroleum wax, which is applied in the refining of petroleum wax, which can solve the problems of catalyst cost increase, complicated preparation process, pollutant discharge, etc., and achieve suitable surface acidity and acidity, simple preparation process, and concentrated pores distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

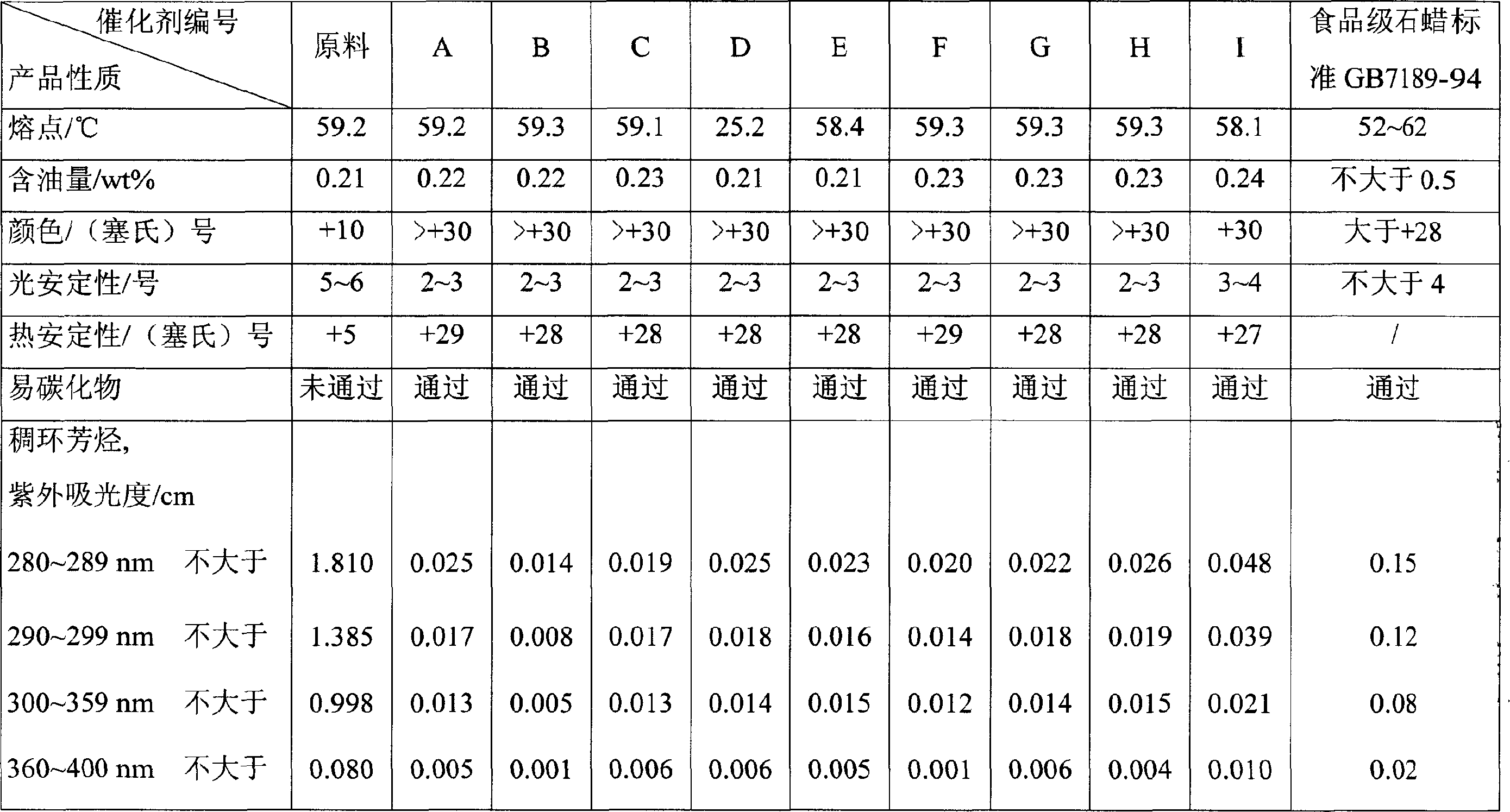

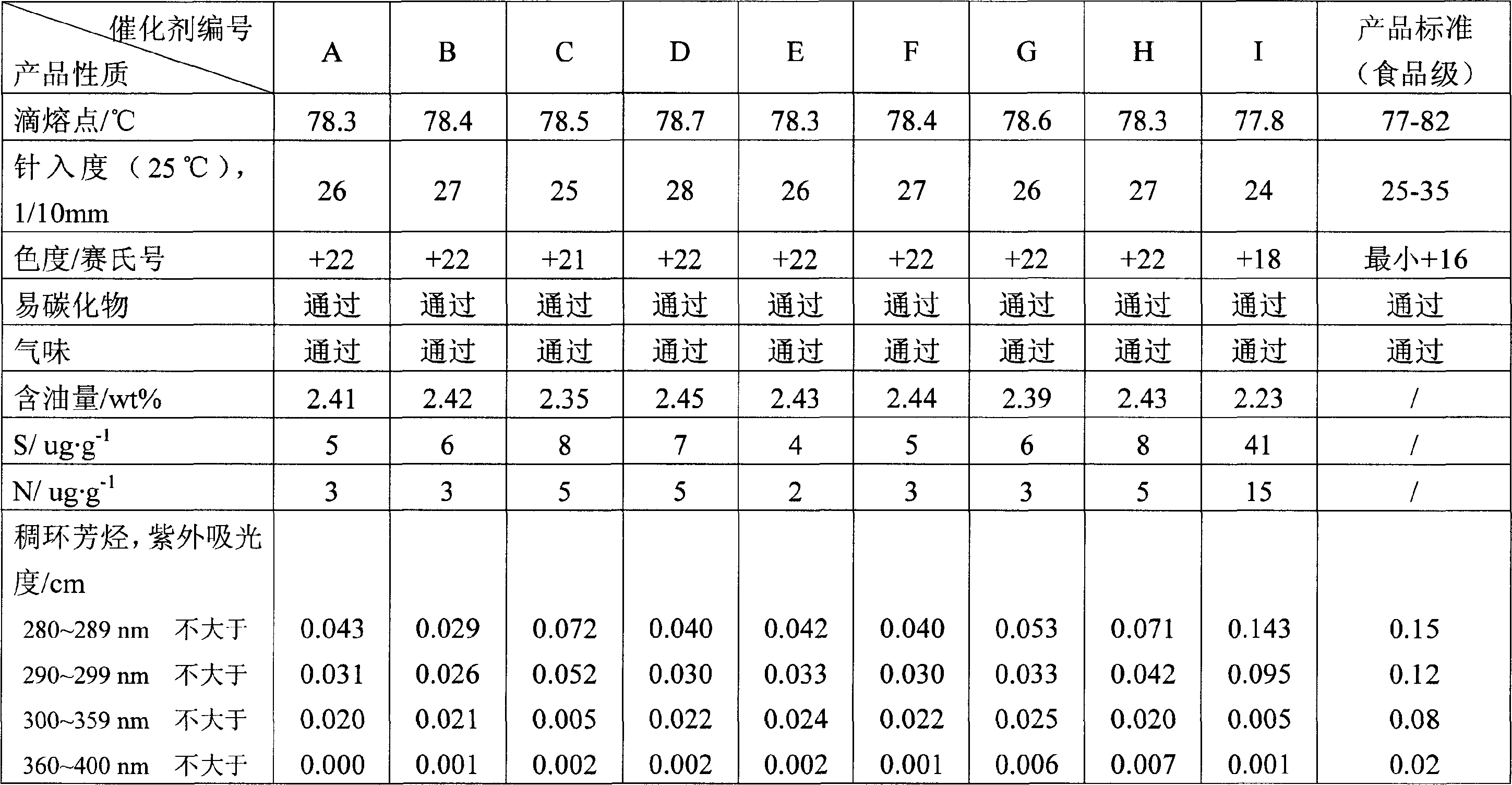

Examples

preparation example Construction

[0022] 1. Preparation of silicon and phosphorus aluminum hydroxide

[0023] In the preparation process of aluminum hydroxide containing silicon and phosphorus of the present invention, the concentration of the sodium metaaluminate solution used is 5gAl 2 o 3 / l~60gAl 2 o 3 / l. The silicon-containing compound is preferably an acidified sodium silicate (commonly known as water glass) solution, or a sodium silicate solution, so that the aluminum hydroxide is easy to dissolve Na + Washing can also be a low-sodium silica sol solution, and the silicon dioxide contained in the silicon-containing compound solution is adjusted to be 5g / l-40g / l. Acidified water glass is prepared by adding an acidic solution such as dilute hydrochloric acid solution or nitric acid solution to the water glass solution to prepare a clear, transparent and fluid acidified water glass solution, which is conducive to the high dispersion of silicon-containing compounds in the gel-forming system. 1 to 3; th...

Embodiment 1

[0037] (1) Preparation of silicon and phosphorus aluminum hydroxide

[0038] 1) Solution preparation

[0039] The preparation concentration is 30gAl 2 o 3 / l of sodium metaaluminate solution; add sodium silicate solution in dilute nitric acid solution, stir rapidly, and prepare acidified sodium silicate solution, so that the concentration of acidified sodium silicate solution is 20gSiO 2 / l, the pH value of the final solution is 1; the preparation concentration is 20.0gSiO 2 / l low-sodium silica sol solution; prepare ammonium dihydrogen phosphate solution with a concentration of 5.0gP / l.

[0040] 2) into glue

[0041] Put the sodium metaaluminate solution in the gel-forming tank, control the temperature at 20°C, slowly add the acidified sodium silicate solution at a certain flow rate, stir quickly and evenly, and add the sodium silicate as SiO 2 The content calculated in aluminum hydroxide is 4.0% by weight, and the carbon dioxide gas with a concentration of 30% (volume c...

Embodiment 2

[0048] (1) Preparation of silicon and phosphorus aluminum hydroxide

[0049] Compare with embodiment 1 (1), be mixed with the phosphoric acid solution containing phosphorus 8.0g / l, slurries add phosphoric acid solution and carry out peptization, aging 1.0 hour then, all the other are identical with embodiment 1 (1), obtain containing silicon and Phosphorous Aluminum Hydroxide Product B1.

[0050] (2) The preparation of the silicon- and phosphorus-containing alumina support is the same as in Example 1 (2).

[0051] (3) The preparation of the catalyst is the same as in Example 1 (3). That is, the cost example obtains product B of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com