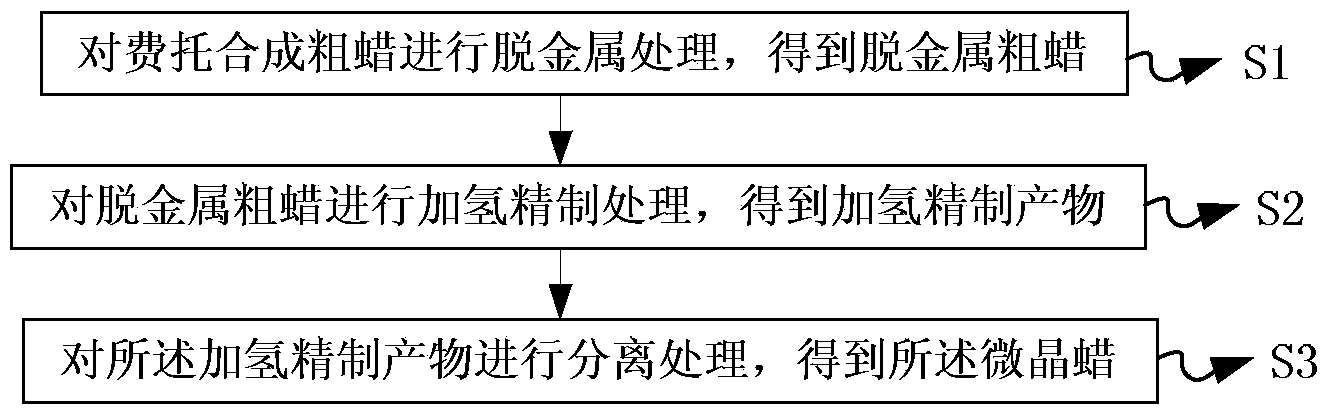

Method for producing microcrystalline wax from Fischer-Tropsch synthesis crude wax

A technology of Fischer-Tropsch synthesis and microcrystalline wax, which is applied in the refining of petroleum wax, can solve the problems of increasing processing costs, harsh cracking process conditions, and reducing the value of wax products, achieving the effect of reducing processing costs and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

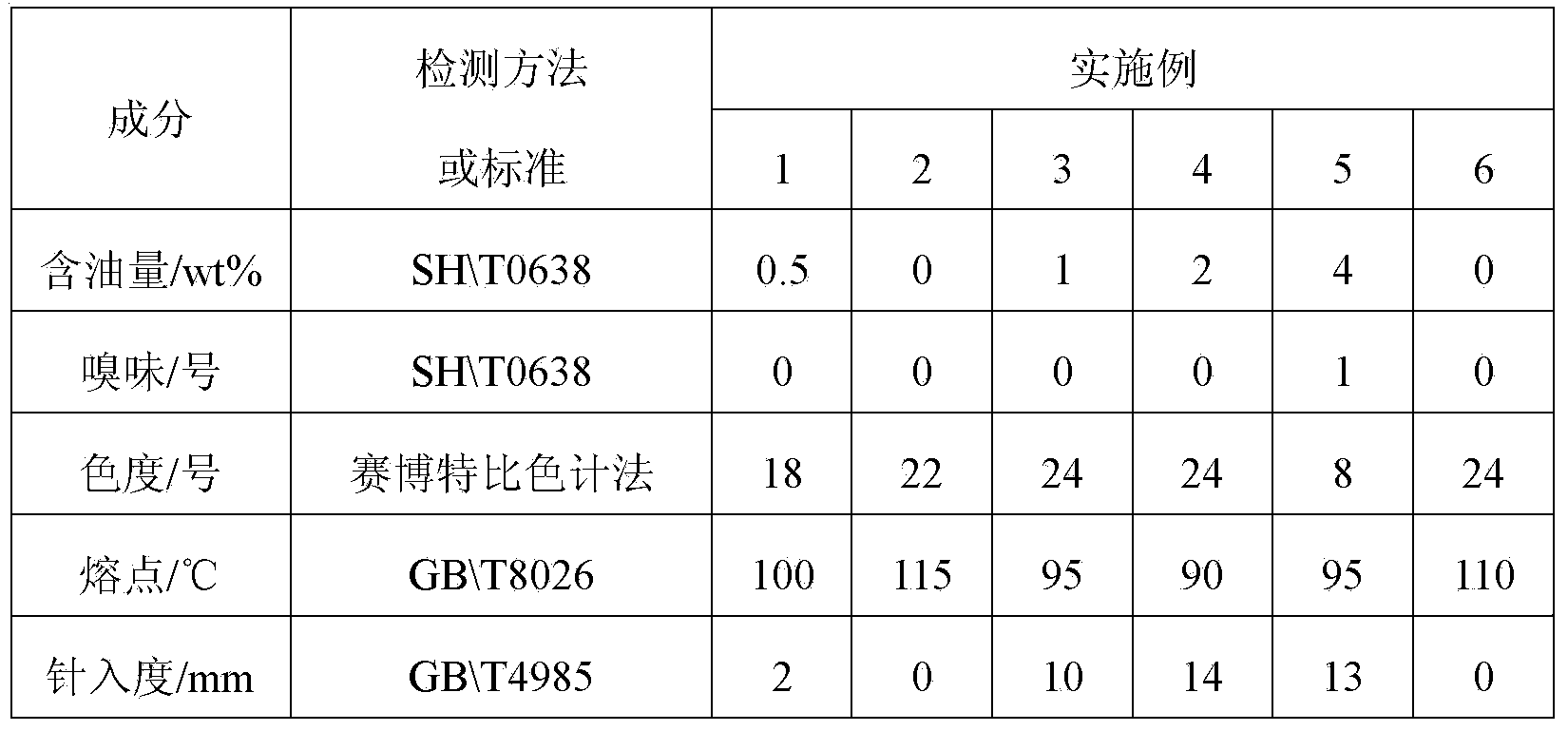

Examples

Embodiment 1

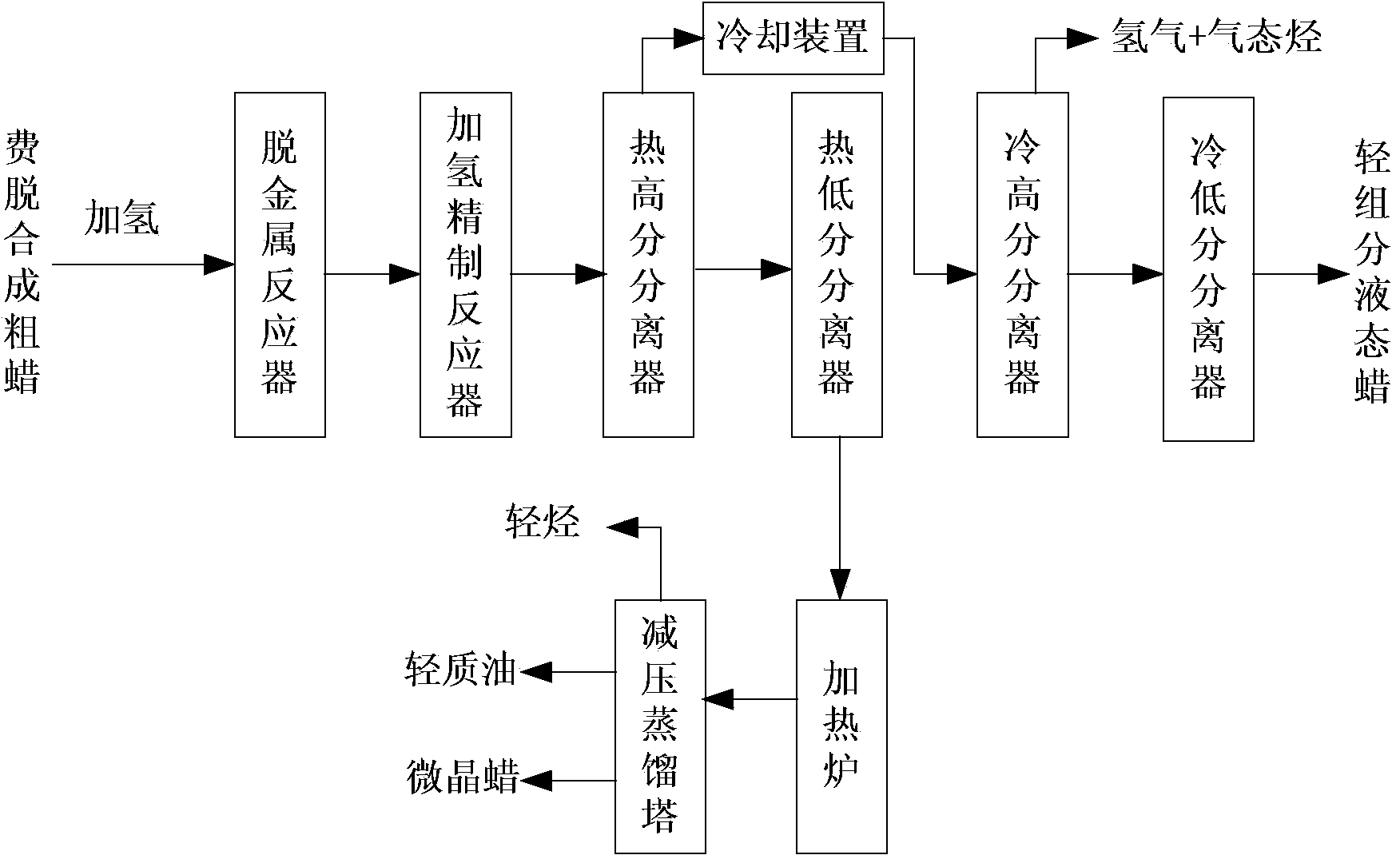

[0036] according to figure 2 The process flow processes the raw material. Using FZC-100, FZC-102B, FZC-103, FZC-204 demetallization catalysts, under the conditions of temperature 240 °C and pressure 2.0 MPa, the Fischer-Tropsch synthesis crude wax was subjected to demetallization reaction treatment to obtain demetallization crude wax ;

[0037] For demetallized crude wax, the pressure is 2.0MPa, the temperature is 240°C, the hydrogen-to-wax ratio is 600v / v, and the volume space velocity is 2h -1 Under certain conditions, the hydrofinishing reactor is carried out to remove oxygen-containing compounds and olefins to obtain hydrofinishing products.

[0038] The hydrorefined product is subjected to hot high-pressure separation, cold high-pressure separation, hot low-pressure separation, and cold low-pressure separation in sequence to separate hydrogen, remove light oil, and obtain heavy component liquid wax; the temperature of hot high-fraction separation is 160°C, The pressur...

Embodiment 2

[0041] according to figure 2 The process flow processes the raw material. Using RG-10, RG-10A, RG-10B, RDM-2 demetallization catalysts, under the conditions of temperature 280 °C and pressure 4.0 MPa, the Fischer-Tropsch synthesis crude wax is subjected to demetallization reaction treatment to obtain demetallization crude wax ;

[0042] For demetallized crude wax, the pressure is 4.0MPa, the temperature is 280°C, the hydrogen-to-wax ratio is 1000v / v, and the volume space velocity is 6h -1 Under certain conditions, the hydrofinishing reactor is carried out to remove oxygen-containing compounds and olefins to obtain hydrofinishing products.

[0043] The hydrorefined product is subjected to hot high-pressure separation, cold high-pressure separation, hot low-pressure separation, and cold low-pressure separation in sequence to separate hydrogen, remove light oil, and obtain heavy component liquid wax; the temperature of hot high-fraction separation is 180°C, The pressure is 4....

Embodiment 3

[0046] according to figure 2 The process flow processes the raw material. Using FZC-100, FZC-102B, FZC-103, FZC-204 demetallization catalysts, under the conditions of temperature 400 ℃ and pressure 10.0MPa, the Fischer-Tropsch synthesis crude wax is subjected to demetallization reaction treatment to obtain demetallization crude wax ;

[0047] For demetallized crude wax, the pressure is 10.0MPa, the temperature is 400°C, the hydrogen-to-wax ratio is 1500v / v, and the volume space velocity is 10h -1 Under certain conditions, the hydrofinishing reactor is carried out to remove oxygen-containing compounds and olefins to obtain hydrofinishing products.

[0048] The hydrorefined product is subjected to thermal high-pressure separation, cold high-pressure separation, hot low-pressure separation, and cold low-pressure separation in sequence to separate hydrogen, remove light oil, and obtain heavy component liquid wax; the temperature of thermal high-fraction separation is 240°C, Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com