Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

107results about How to "Play a stirring effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

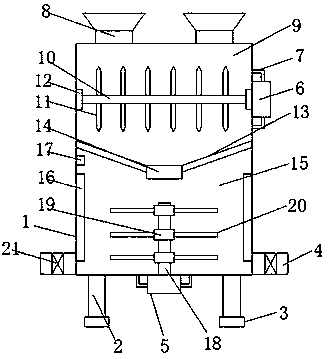

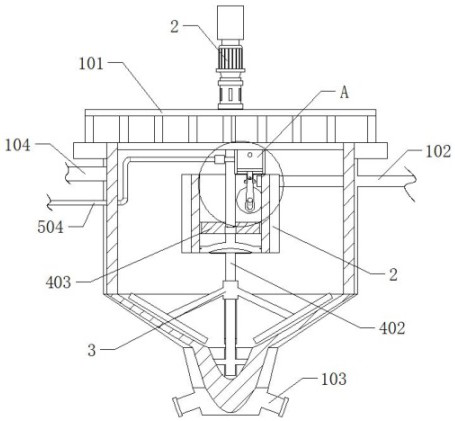

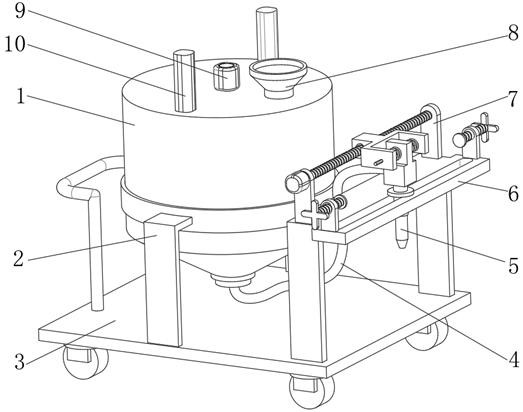

Drying device for chemical raw materials and medicine

ActiveCN104390439AGood dispersionWell mixedDrying gas arrangementsDrying chambers/containersEngineeringAir blower

The invention discloses a drying device for chemical raw materials and medicine. The drying device comprises a body which comprises a variable frequency motor, a feeding hole and a discharge hole. The base is arranged under the body; the variable frequency motor is arranged between the body and the base; the output part of the variable frequency motor is connected with a mixing shaft; the mixing shaft extends into the body; transverse mixing wheels are symmetrically arranged on the mixing shaft; the mixing shaft and the transverse stirring wheels are all of hollow structures; electric heating tubes are arranged inside the transverse stirring wheels and the mixing shaft; a screw scraper plate is further arranged on the mixing shaft; the feeding hole is formed in the top end of the body; a hot-air blower is connected with an air pipe arranged in the body by use of a guide pipe; a plurality of air holes are formed in the surface of the air pipe; a dry layer is arranged under the air pipe; an insulating layer is arranged on the inner wall of the body; an air pump is arranged on the outer surface of the body; the discharge hole is formed in the bottom of the body; a supporting bar is arranged between the body and the base. The drying device for chemical raw materials and medicine has the advantages of reasonable structural design, good drying effect, long service life and the like.

Owner:SHANGHAI LINKCHEM TECH CO LTD

Technology for recycling paraffin-resin mold material

InactiveCN102615244AQuick breakdownPlay a stirring effectPetroleum wax refiningFoundry mouldsParaffin waxSodium silicate

The invention discloses a technology for recycling a paraffin-resin mold material and particularly belongs to a technology for recycling a mold material of a precise mould. The technology for recycling the paraffin-resin mold material performs full reaction on hydrochloric acid and an alkali substance waterglass sodium silicate in a recycled paraffin-resin mold material to obtain a finished product in a steam heating way. The technology for recycling the paraffin-resin mold material has the advantages of simple process, convenience in operation, capability of effectively removing the alkali substance and granular impurities from the recycled paraffin-resin mold material, and reusability of the recycled paraffin-resin mold material.

Owner:SICHUAN DELI RAILWAY TECH

Cleaning device with drying function for production of agricultural byproducts

PendingCN108816918AImprove cleaning effectImprove drying efficiencyDrying gas arrangementsCleaning using liquidsElectrical controlAgricultural engineering

The invention belongs to the technical field of production of agricultural byproducts, in particular to a cleaning device with a drying function for the production of agricultural byproducts. Aiming at solving the problems that the existing cleaning device is simple in the structure, low in cleaning efficiency, and long in self hot air drying time after cleaning, the invention provides the following scheme. The cleaning device comprises a base and a rotating plate. First supports are fixedly arranged at the two edges of one end of the top outer wall of the base through screws, and fixed platesare fixedly arranged on the top outer walls of the two first supports through the screws. Servo motors are fixedly arranged on the top outer walls of the two fixed plate through the screws, and output shafts of the servo motors are connected with threaded rods through shaft couplers. By the arrangement of a fan and a resistance heating wire, the cleaning device can conveniently dry the agricultural byproducts with hot air after cleaning. By the mutual matching of the servo motors, the threaded rods and an electrical-control telescopic rod, a cleaning barrel can move up and down and left and right, the flexibility of the device is greatly improved, and the agricultural byproducts can be more conveniently cleaned and dried.

Owner:ANHUI YONSENT PHARMA

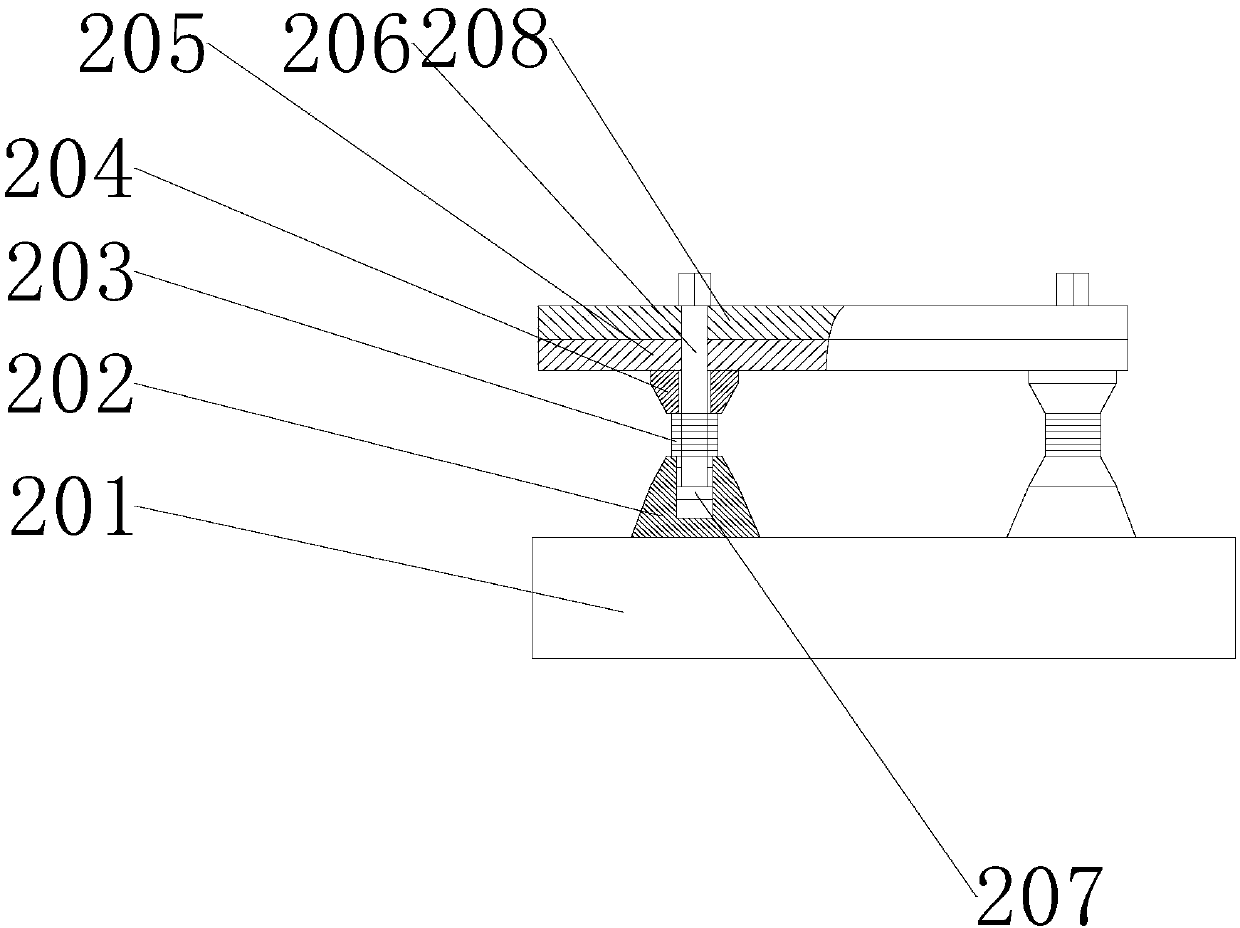

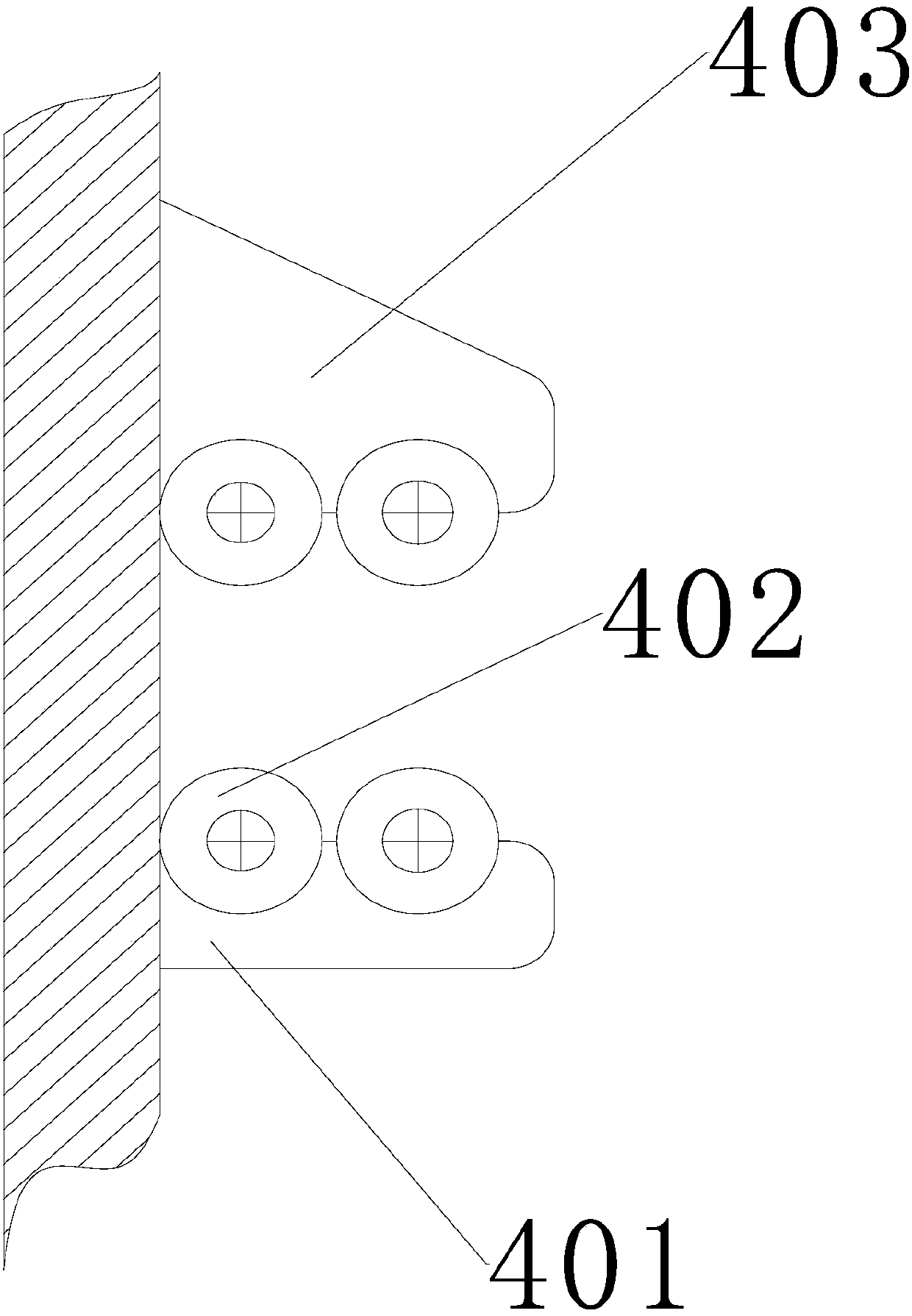

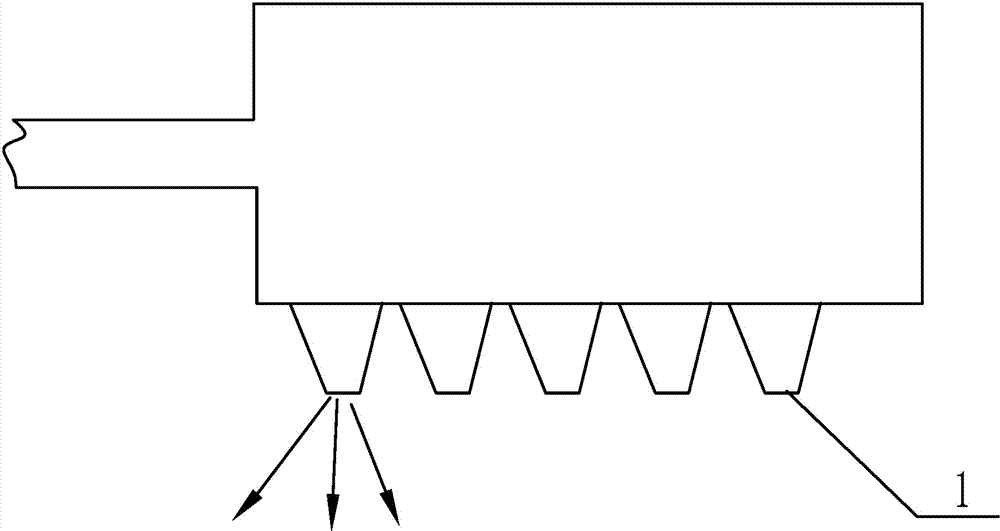

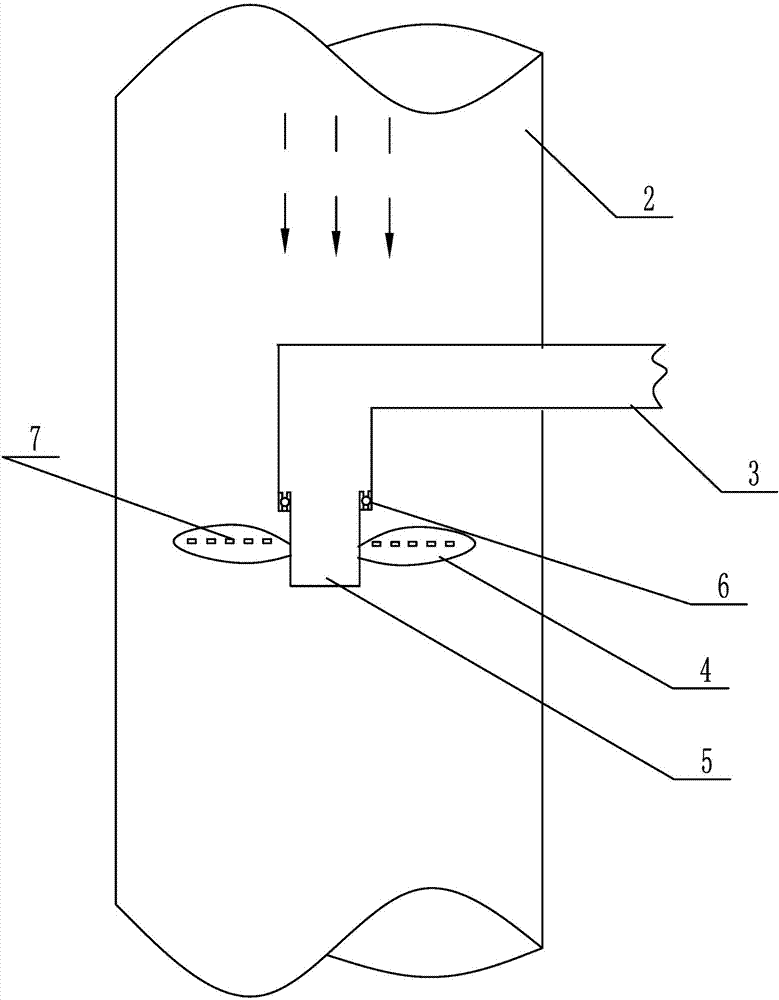

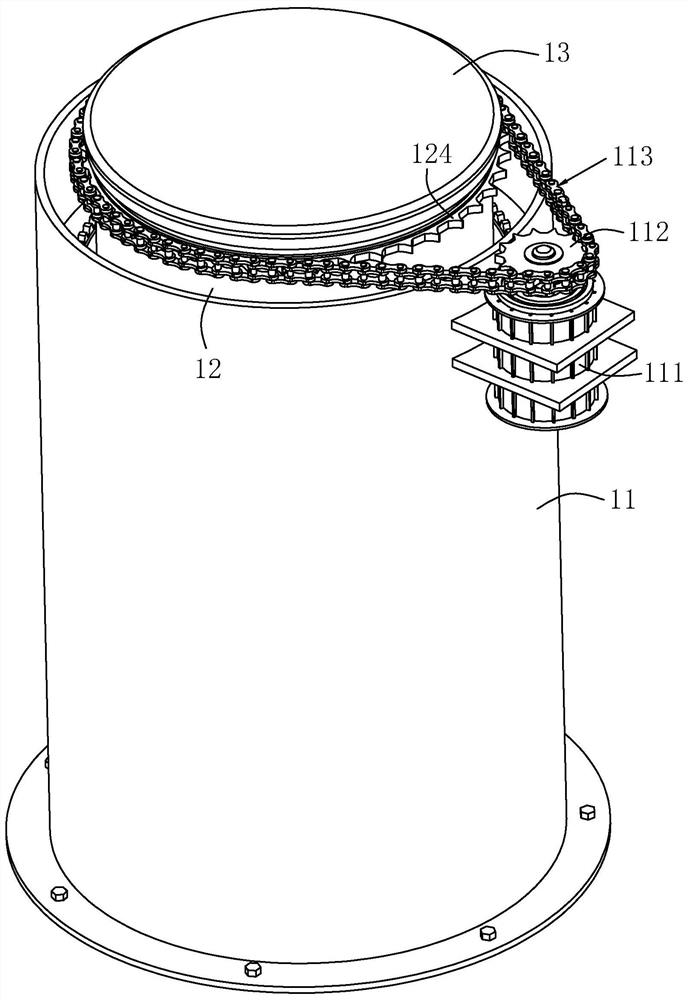

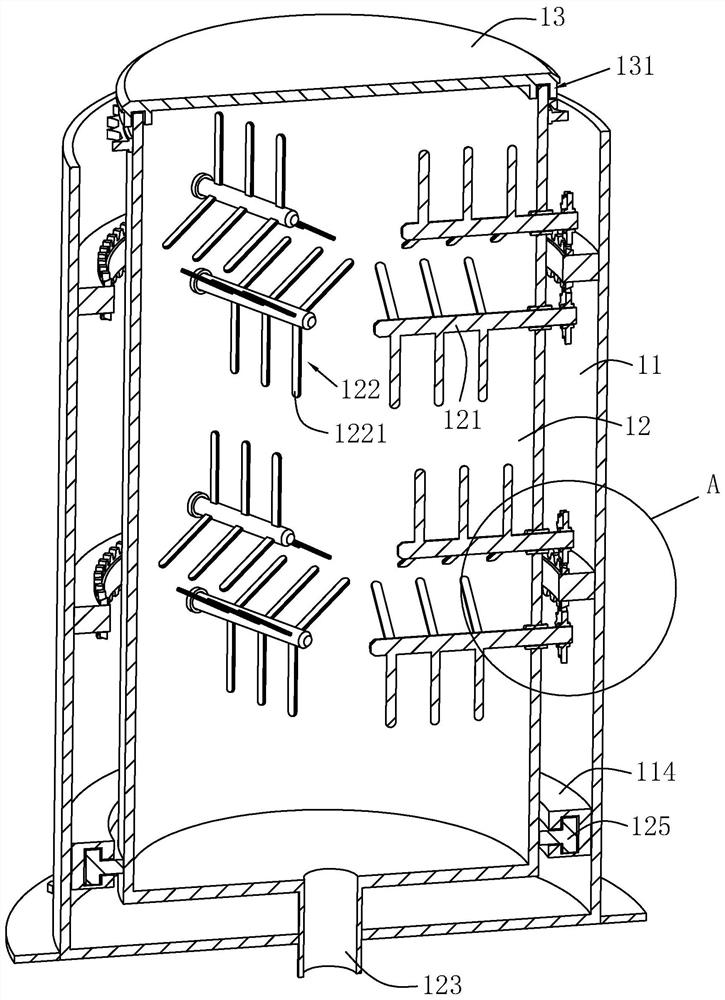

Highway marking machine

ActiveCN109183594APlay a stirring effectPrevent precipitationRoads maintainenceEngineeringHighway engineering

The invention relates to a highway marking machine, belonging to the technical field of highway engineering machinery, including a body, wherein a hopper is arranged on the body; a stirring bucket isarranged coaxially with the hopper in the hopper, and is rotatably connected with the hopper; the upper part of the hopper and the stirring bucket are provided with openings; a stirring device is arranged in the stirring bucket, and the stirring device comprises a plurality of sets of stirring members arranged along the height direction of the stirring bucket; each set of stirring members includesa plurality of stirring shafts circumferentially and uniformly distributed on the stirring bucket; a plurality of stirring blades are arranged on the stirring shaft along the length direction of thestirring shaft in the stirring bucket; a plurality of agitating shafts in each set of agitating members are located at the same height; the driving member drives the stirring bucket to rotate in the hopper, and the bottom wall center of the stirring bucket is communicated with a discharge pipe which is arranged through the hopper and extends to the outside of the hopper; and the driving member drives the stirring bucket to rotate in the hopper, so that the stirring blades have the stirring effect on the paint, thereby preventing the paint in the stirring bucket from precipitating or agglomerating.

Owner:四川志德公路工程有限责任公司

Plastic product recovery melting device

InactiveCN109333875APlay a stirring effectEfficient crushingPlastic recyclingMechanical material recoveryDrive motorProduct recovery

The invention discloses a plastic product recovery melting device comprising a shell. Discharge ports are formed in the bottoms of the two sides of the shell correspondingly. A first drive motor is arranged at the bottom of the shell. A second drive motor is arranged on the top of one side of the shell. First feed ports are formed in the two sides of the top of the shell correspondingly. A smashing cavity is formed in the top in the shell. A rotating shaft is arranged in the smashing cavity. Multiple sets of smashing blades are arranged on the rotating shaft. The two ends of the rotating shaftare connected with the inner wall of the smashing cavity through bearing pedestals correspondingly. One end of the rotating shaft penetrates the shell and is connected with the second drive motor. Apartition plate is arranged below the rotating shaft. The plastic product recovery melting device has the beneficial effects that the structure is simple, plastic particles can be effectively smashedbefore being molten, heating and stirring are conducted through a stirring shaft, the melting effect can be effectively improved, and the production efficiency and the product quality can be improved.

Owner:芜湖市崇兴乐塑胶有限公司

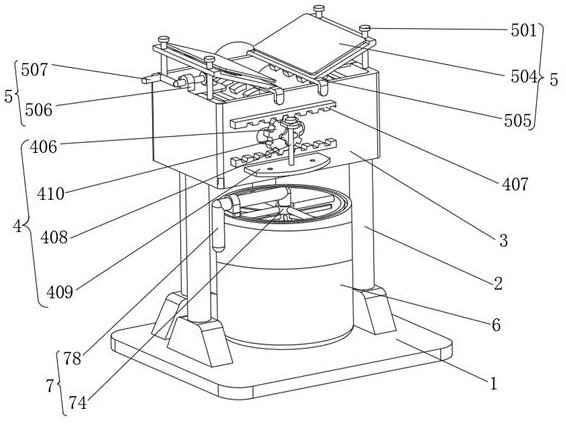

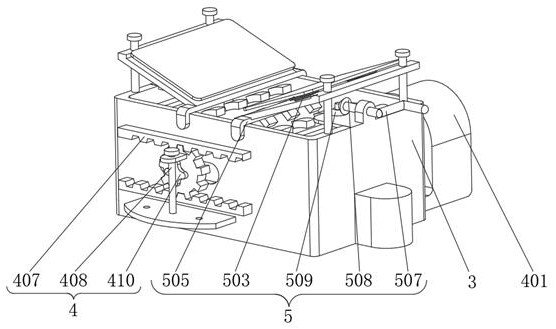

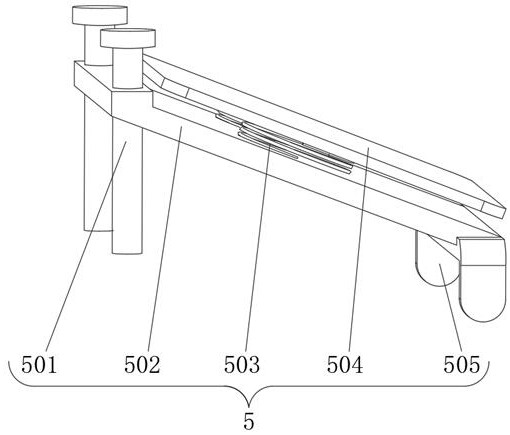

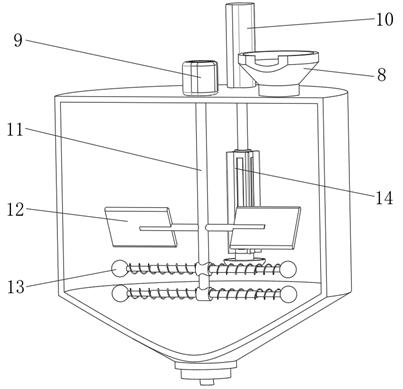

Raw material processing, crushing and quantitative mixing reaction device for Chinese patent medicine production

PendingCN112007722ATo the point of fragmentationAdjust the tilt angleSievingTransportation and packagingGear wheelPharmaceutical drug

The invention provides a raw material processing, crushing and quantitative mixing reaction device for Chinese patent medicine production and relates to the technical field of medicine processing. Thedevice comprises a base plate and a crushing device; supporting rods are fixedly connected to the upper surface of the base plate; a baffle is fixedly connected to the ends, away from the base plate,of the supporting rods; the crushing device is arranged in the baffle; the crushing device comprises a supporting frame; the surface of the supporting frame is fixedly connected with the baffle; a motor is fixedly connected to the inner wall of the supporting frame; and a first rolling shaft is fixedly connected to a rotating shaft of the motor. By means of the raw material processing, crushing and quantitative mixing reaction device, the problems that traditional medicine crushing is conducted through meshing rotation of large gears, and due to the fact that the crushing degrees needed by medicine are different, a traditional crushing machine has certain limitation, the later-period pharmaceutical effect is affected when the crushing degree is low, and the later-period pharmaceutical difficulty is increased when the crushing degree is high are solved.

Owner:王文思

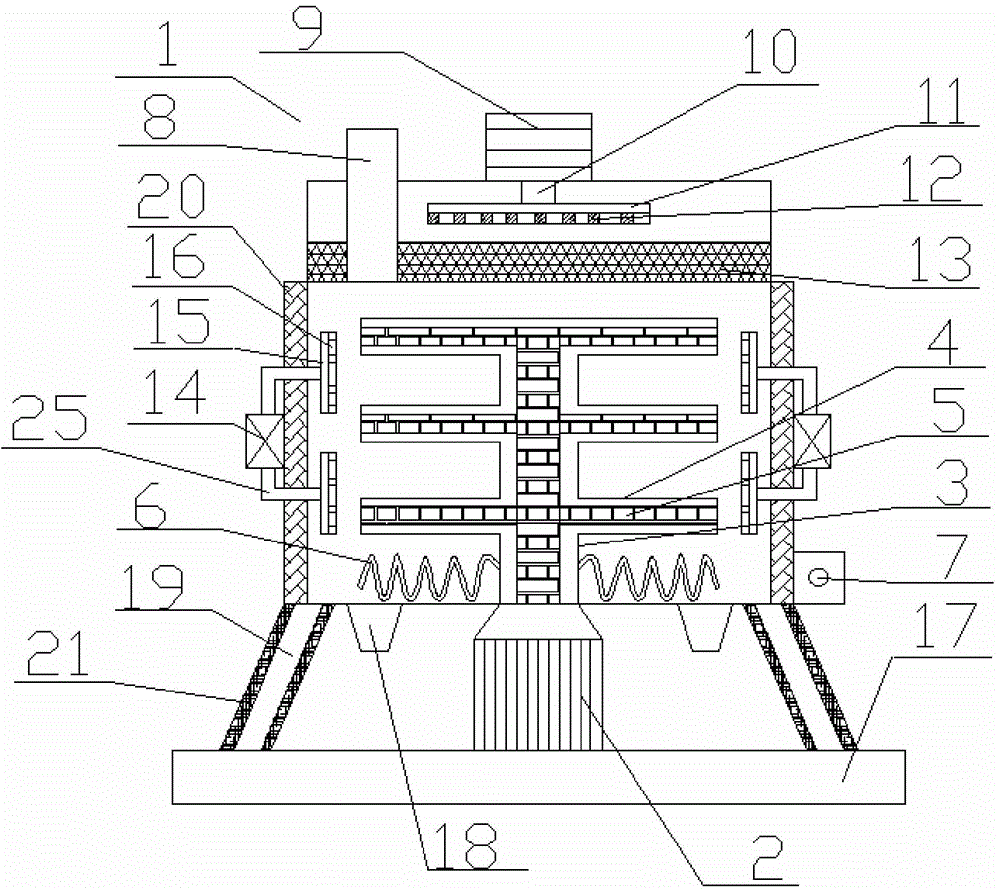

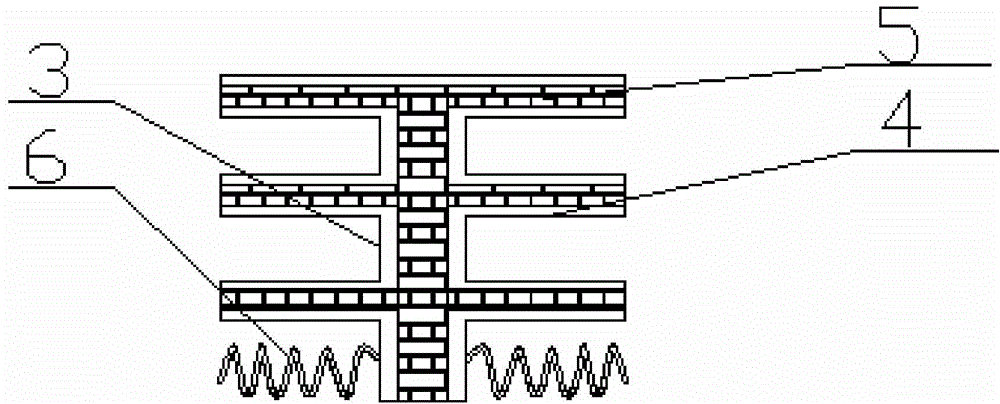

Efficient lubricating oil processing device

InactiveCN107812478APlay a stirring effectImprove the mixing effectRotary stirring mixersTransportation and packagingOil processingCoupling

The invention discloses an efficient lubricating oil processing device which comprises a base, a filtering tank and a stirring tank, wherein a plurality of damping mechanisms are arranged at the upperend of the base, and a first supporting column is fixedly connected to the upper ends of the damping mechanisms at the two sides of the upper end of the base, the stirring tank is fixedly connected to the upper end of the first supporting column, and a second supporting column is fixedly connected to the upper end of the damping mechanism in the middle of the upper end of the base, the filteringtank is fixedly connected to the upper end of the second supporting column, a motor is arranged in the middle of the upper end of the stirring tank, the motor is connected with the stirring shaft through a coupler, the two sides of the upper end of the stirring tank are respectively provided with an oil inlet pipe and a material inlet. In the working process, the base oil is added into the stirring tank through the oil inlet pipe, the stirring shaft is driven by a driving motor to rotate, so that the stirring effect on the lubricating oil can be achieved; the device is provided with a triple filtering device, the oil can be rapidly filtered and treated in all directions, better clean lubricating oil can be obtained, and control is easy.

Owner:WUXI FEITIAN GREASE

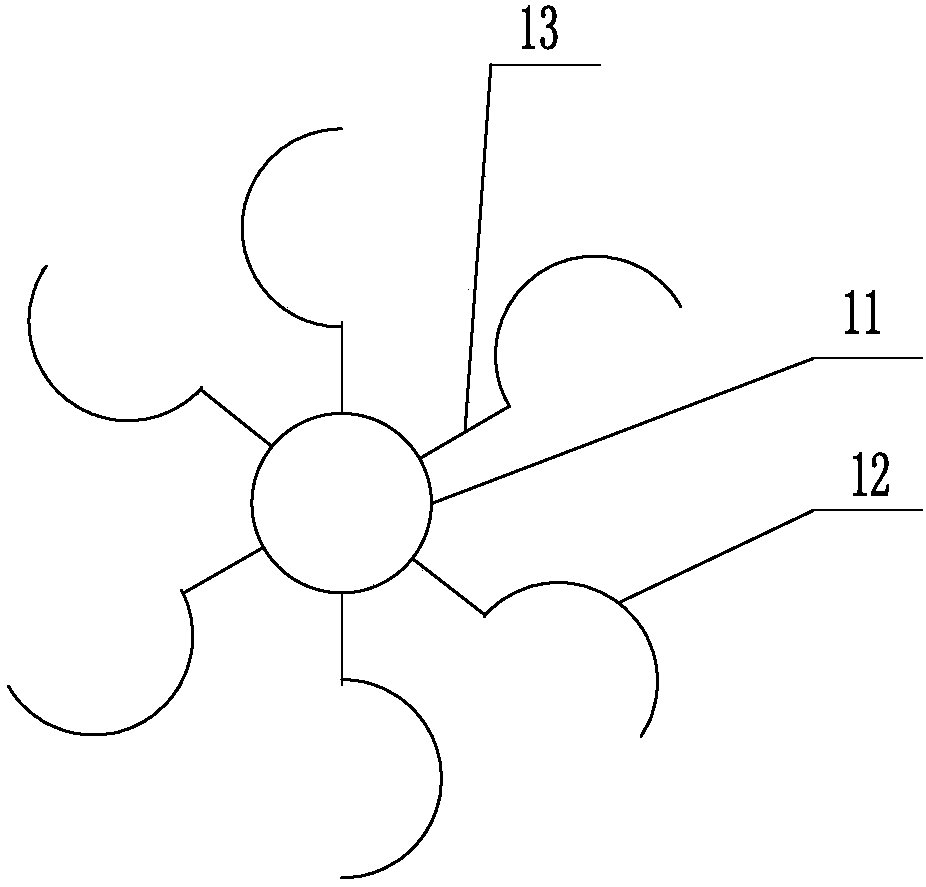

Mixed injecting mechanism

The invention discloses dairy product processing equipment, and particularly relates to a mixed injecting mechanism for processing a flavored dairy product. The mixed injecting mechanism comprises an output fan blade arranged in an original milk filling pipe, wherein an output fan blade comprises a center pipe and one group of long strip-shaped pipes, one end of the center pipe is closed, the other end of the center pipe is opened, the long strip-shaped pipes are circumferentially uniformly distributed on the side wall of the center pipe and are communicated with the center pipe, one group of spraying holes are uniformly formed in the long strip-shaped pipes along a length direction, the center pipe is further connected with an auxiliary material filling hole, and a spraying direction restrained by the spraying holes is perpendicular to a direction of the original milk filling pipe. The mixed injecting mechanism solves the defects of non-uniformity in mixing during filling and low manufacture cost in the prior art, and provides a mixed injecting mechanism capable of performing automatic mixing without mixing of a motor.

Owner:CHONGQING DAWOSI FOOD

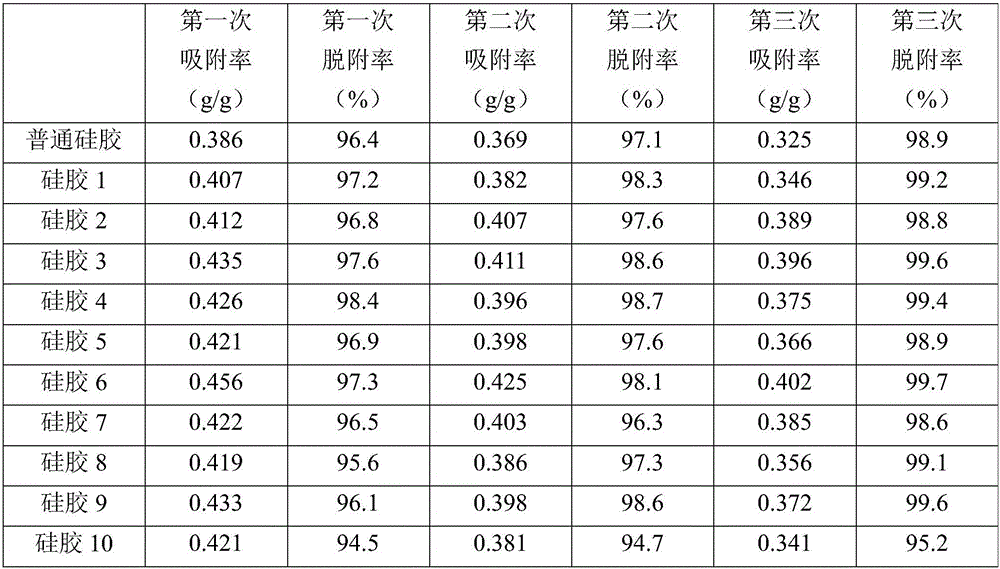

Hydrophobic modification method of silica gel under effect of ultrasonic waves

InactiveCN105771905AWide variety of sourcesEasy to operateOther chemical processesTrimethylsilyl chlorideUltrasound - action

The invention relates to a hydrophobic modification method of silica gel under the effect of ultrasonic waves. The hydrophobic modification method comprises the following steps: firstly performing vacuum drying and impurity elimination on common silica gel particles sold in the market, and then uniformly mixing normal heptane with ethanol and trimethyl chlorosilane according to a certain proportion in a three-neck flask so as to obtain a silane modifying agent; impregnating the silica gel particles after the operations of drying and impurity elimination in the silane modifying agent, and at the same time, modifying the silica gel under the effect of the ultrasonic waves so as to obtain lyophobic silica gel with good hydrophobic effects and good adsorption properties.

Owner:CHANGZHOU UNIV +1

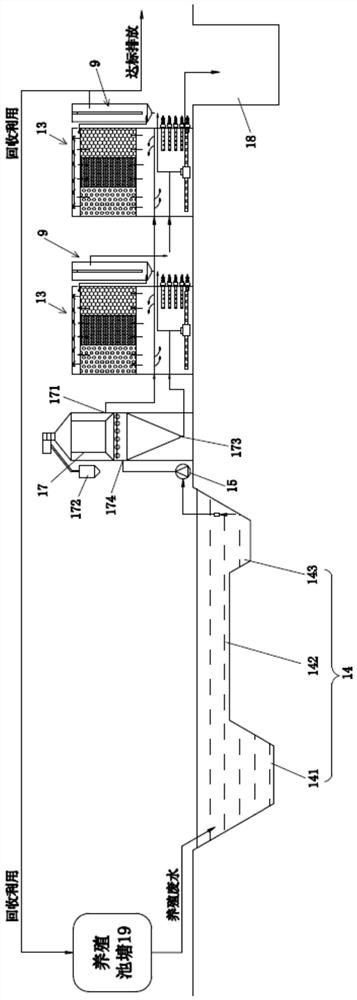

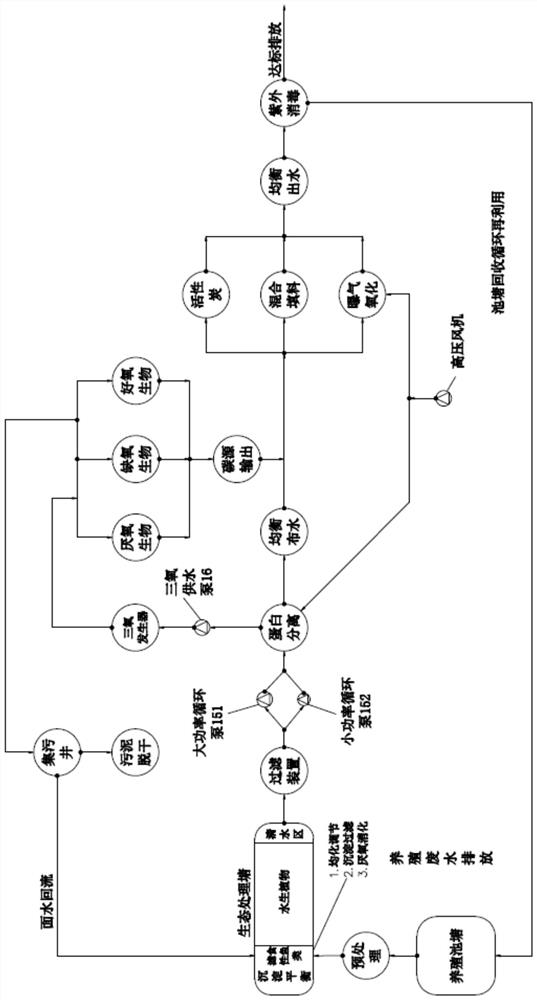

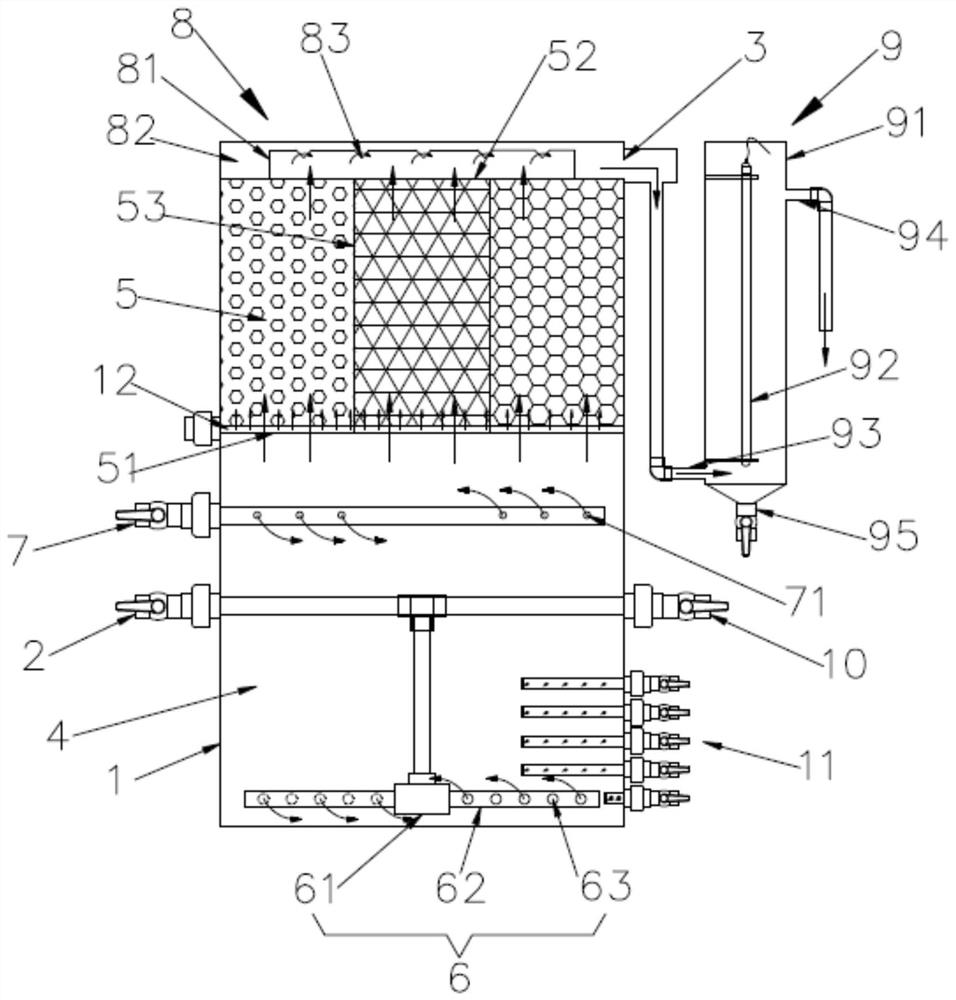

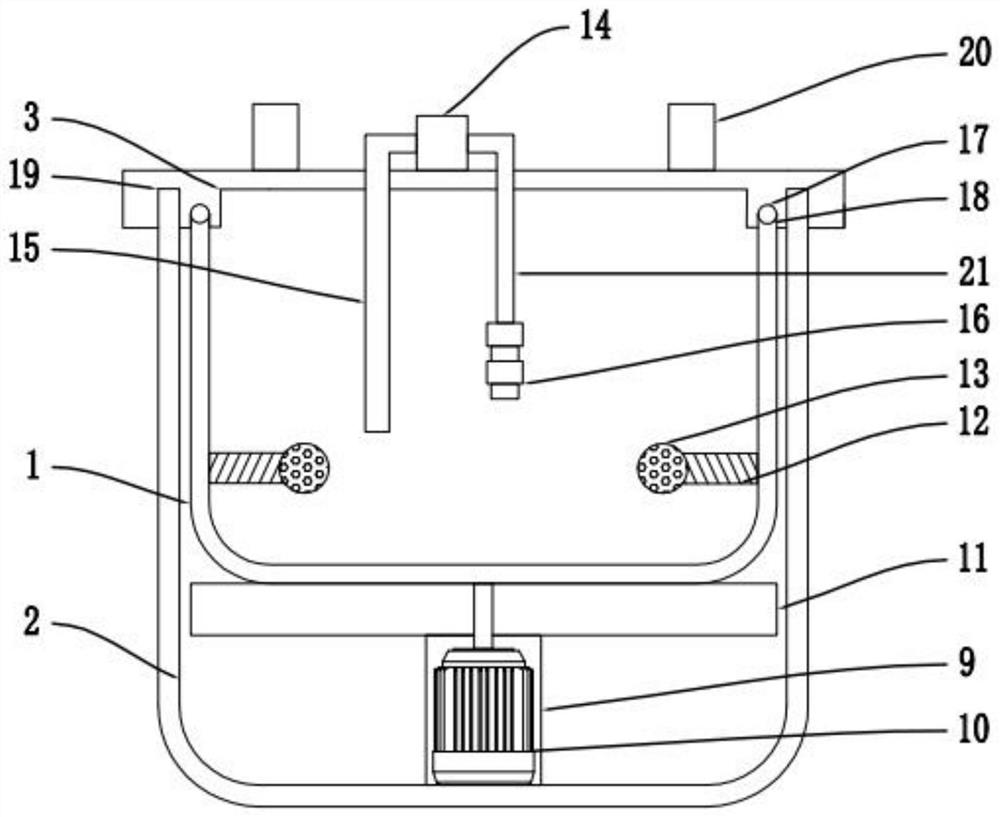

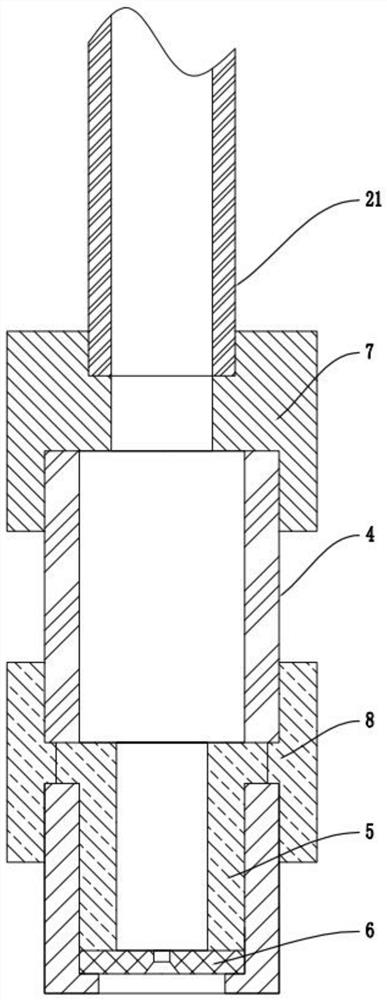

Culture wastewater purification treatment system and process

PendingCN112390467AIncrease dissolved oxygenIncrease diversityWater/sewage treatment by irradiationSpecific water treatment objectivesMicroorganismAmmoniacal nitrogen

The invention discloses a culture wastewater purification treatment system and process. The treatment system comprises an ecological treatment pond, a protein separator and a microbial nitrogen and phosphorus removal filter which are sequentially connected in the flow direction of wastewater. In the treatment process, after the culture wastewater in a culture pond is sequentially treated by the ecological treatment pond and the protein separator, circulating wastewater is introduced into a treatment container with anaerobic and anoxic microorganisms and aerobic microorganisms, and phosphorus in the circulating wastewater is subjected to denitrification reaction through the anaerobic and anoxic microorganisms; aerobic microorganisms are used for carrying out nitration reaction on ammonia nitrogen and nitrite in the circulating wastewater. According to the culture wastewater purification treatment system and process provided by the invention, ammonia nitrogen, nitrite, phosphorus and other substances in the wastewater are completely treated, and the treated water can be reused as culture water, so that water resources are saved.

Owner:GUANGZHOU CHUANGLING AQUATIC TECH CO LTD

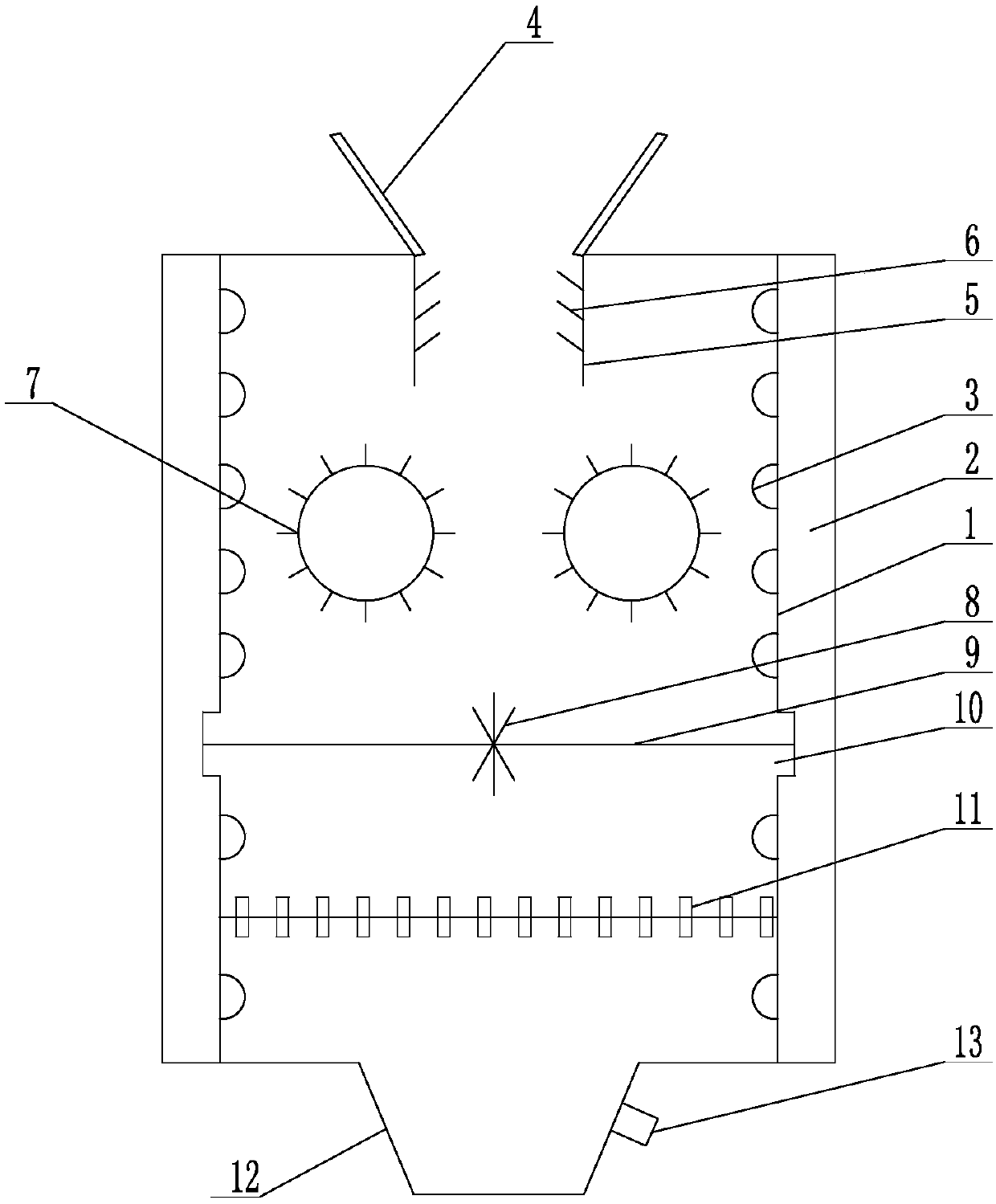

Iron ore crushing device

InactiveCN110496666AExtended stayPlay a stirring effectTransportation and packagingRotary stirring mixersIronstoneButt joint

The invention relates to a crushing device, in particular to an iron ore crushing device. The iron ore crushing device comprises a crushing box, wherein a water jacket is arranged on the outer side ofthe crushing box, a bulge is arranged on the inner wall of the crushing box, a feeding hopper is fixed at the top of the crushing box, an outlet of the feeding hopper is in butt joint with a feedingchute, the feeding chute is fixed on the inner surface of the upper plate of the crushing box, a baffle is arranged in an inner cavity of the feeding chute, two grinding crushing wheels are symmetrically arranged in the crushing box, an outlet of the feeding chute is located in the middle of the two grinding wheels, a stirring device is arranged below the grinding wheels, the stirring device is rotationally connected to a rotating shaft, the rotating shaft is fixed in a groove in the inner wall of the crushing box, crushing teeth are arranged below the stirring device, a discharging hopper isconnected to the bottom of the crushing box, and a vibrator is arranged on one side of the discharging hopper. According to the iron ore crushing device, the retention time of the iron ores in the crushing device is long, the crushing effect is good, blockage is avoided in the discharging process, the crushing device is cooled in the using process, the abrasion speed of the parts is reduced, and the service life is prolonged.

Owner:蒋秀荣

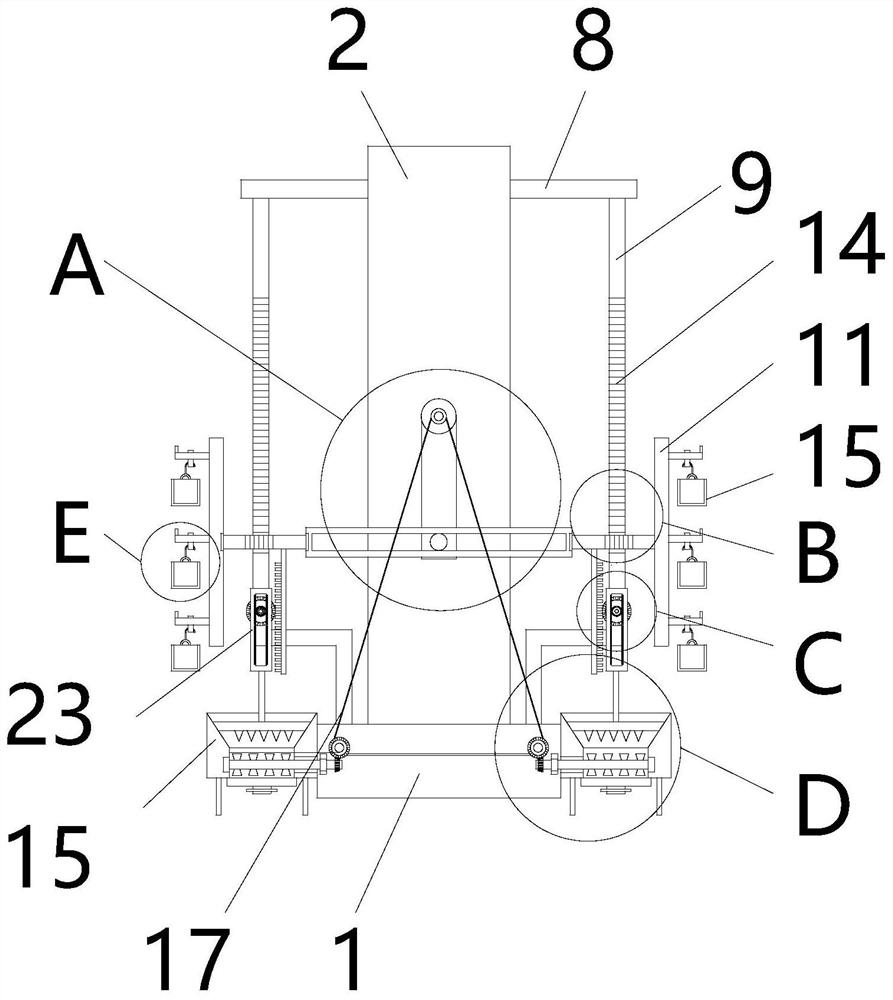

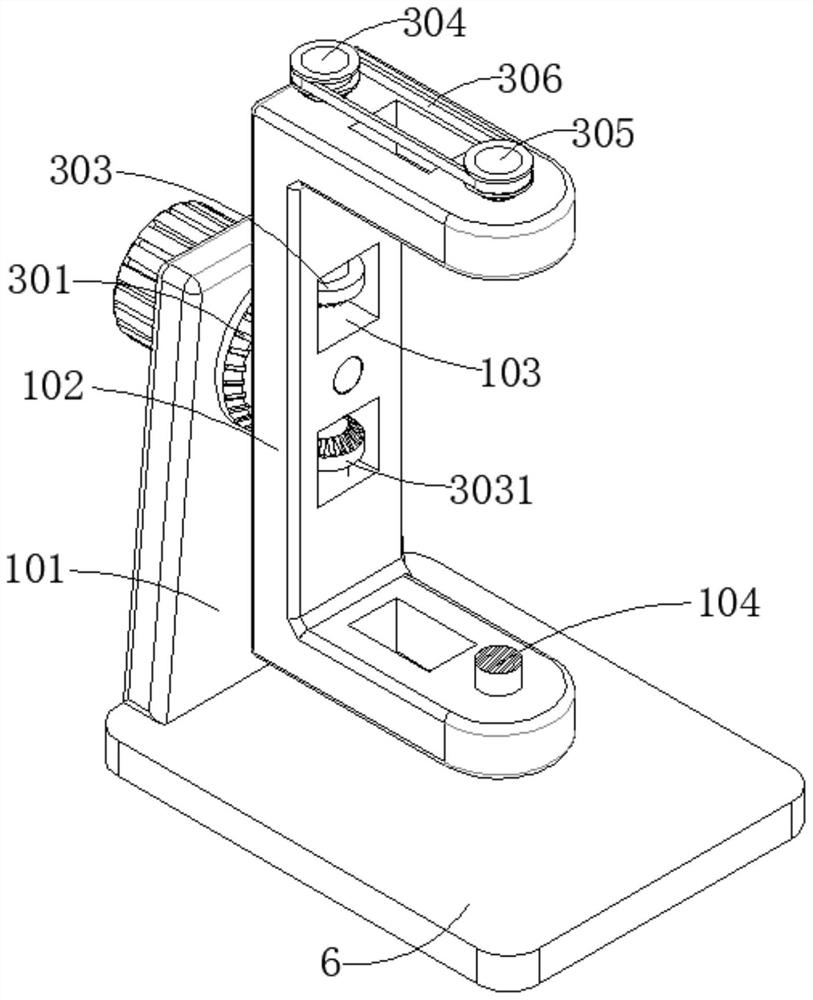

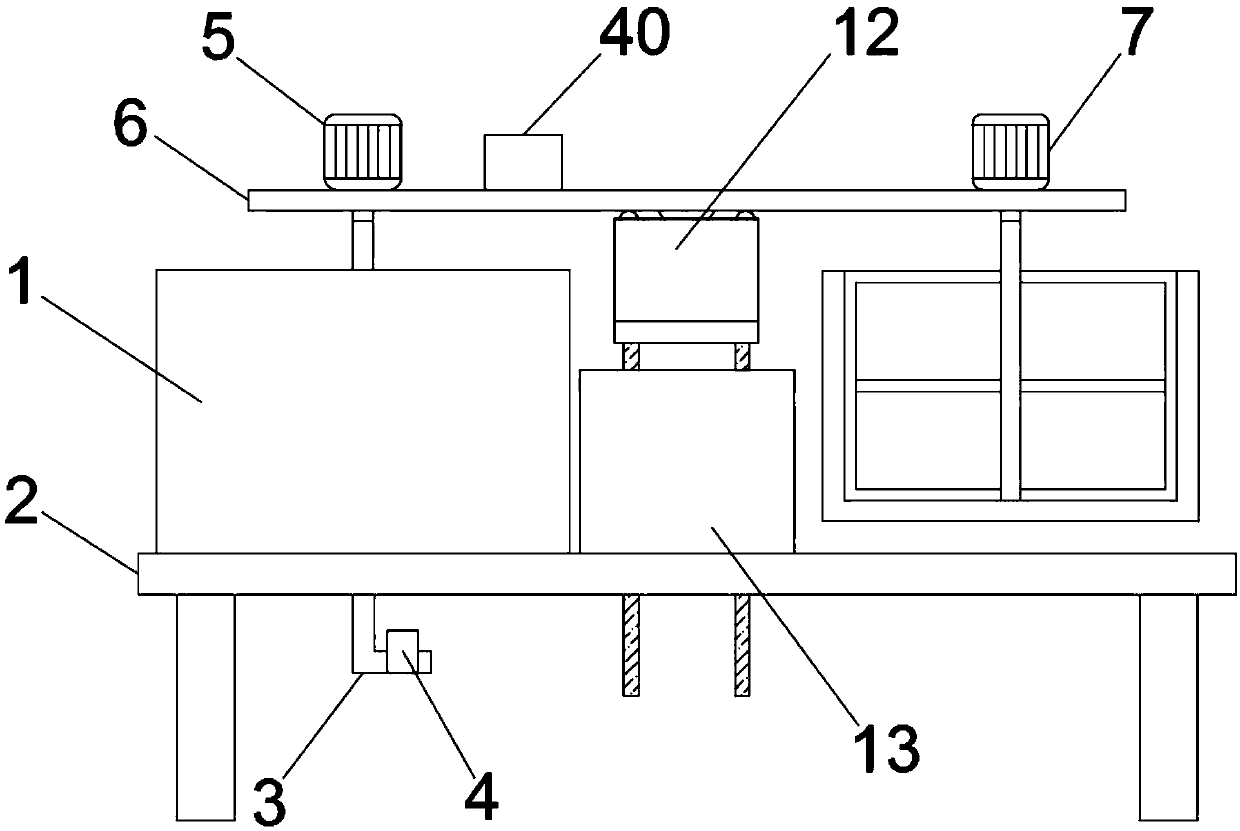

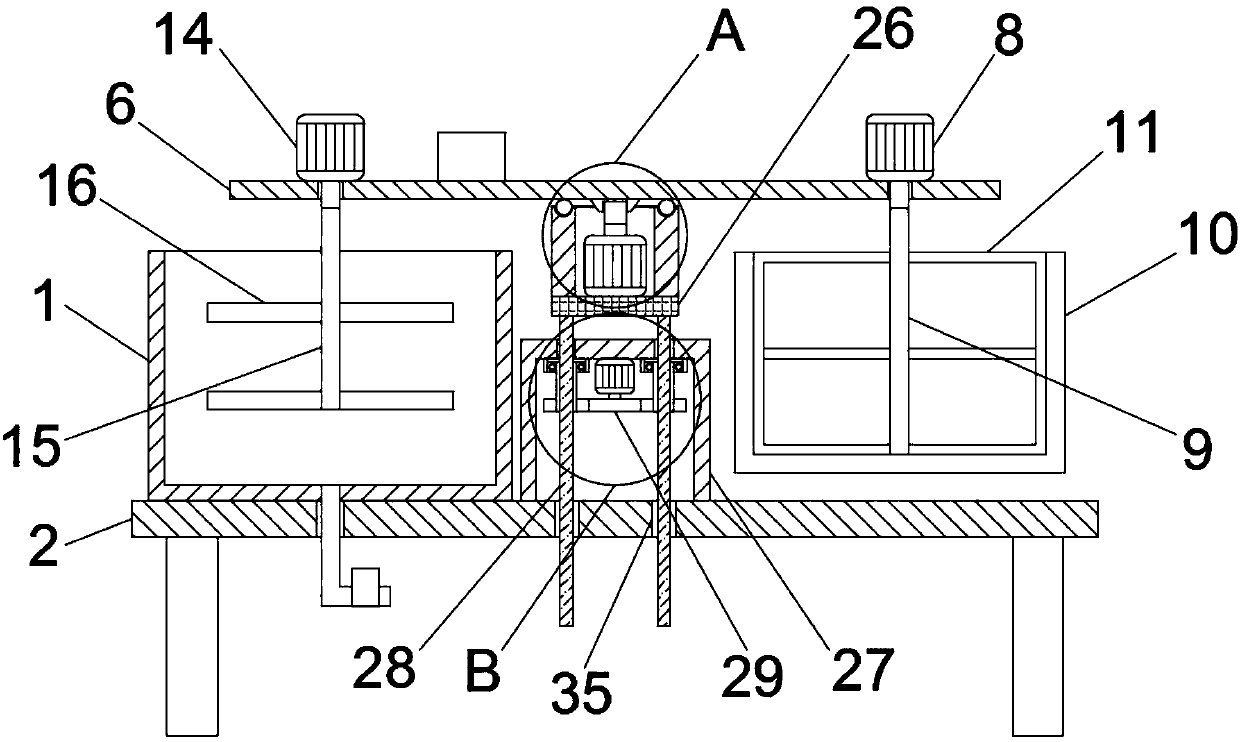

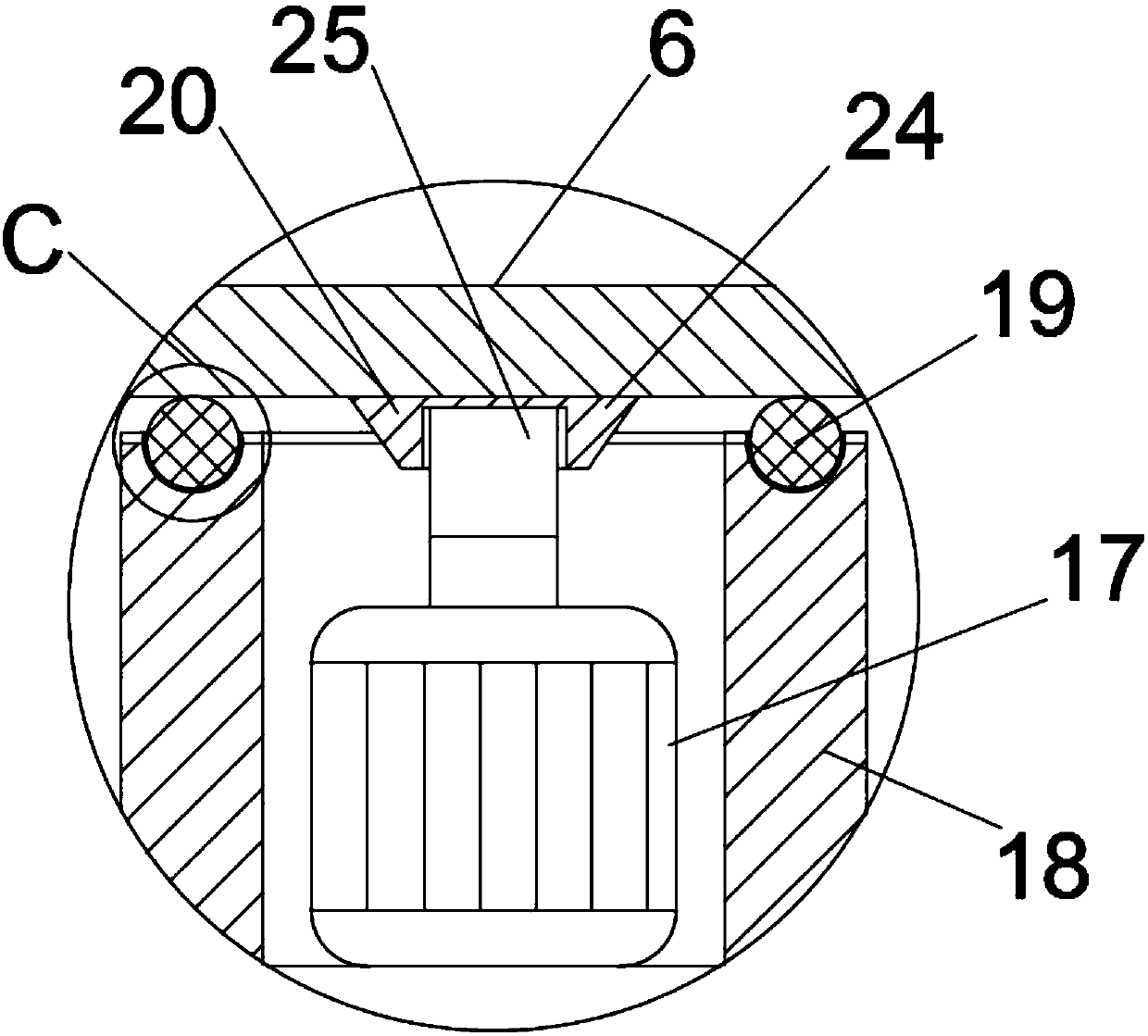

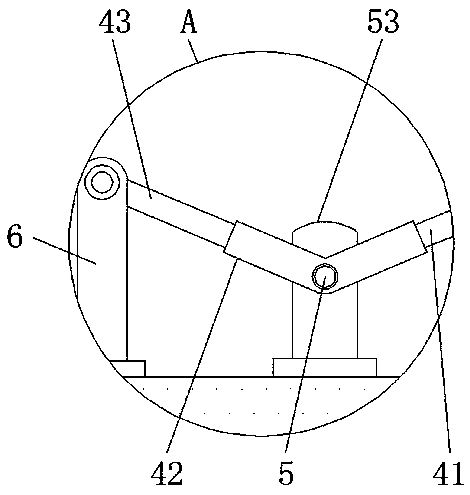

Building feeding device from high to low

InactiveCN111847310AGuaranteed efficiencyImprove transport efficiencyGearingLifting framesArchitectural engineeringStructural engineering

The invention relates to the technical field of buildings, and discloses a building feeding device from high to low. The building feeding device from high to low comprises a base, a support plate, a servo motor and charging baskets. The support plate is fixedly installed at the bottom of the base, and the servo motor is fixedly installed in the middle of the rear side wall surface of the support plate; a rotating column is fixedly installed at the output end of the servo motor, and rotating rods are fixedly installed at the bottom of the rotating column; clamping rods are fixedly installed onthe front side wall surfaces of the rotating rods, and the outer walls of the clamping rods are clamped in a rectangular lifting frame; and linkage rods are fixedly installed on the right and left sides of the lifting frame. According to the building feeding device from high to low, through rotation of a power source servo motor, a plurality of groups of machines are driven to cooperate with cement slurry conveyed to a low position from a high position in a linkage mode; the use efficiency of the cement slurry is ensured while the building feeding device facilitates workers to take and fill the cement slurry, and the transfer efficiency of the cement slurry is improved; the building feeding device is simple in structure, and a plurality of groups of movements cooperate with each other; andthe building feeding device is higher in practicability and creativity.

Owner:安徽广成建设工程有限公司

Nanometer material mixing device and using method thereof

InactiveCN111841363AImprove the mixing effectEffective stirringTransportation and packagingRotary stirring mixersElectric machineGear wheel

The invention discloses a nanometer material mixing device. The device comprises a base and a cylinder body, wherein a first supporting plate is connected to the top wall of the base; the outer wall of the first supporting plate is connected with a driving motor; the output end of the driving motor penetrates through the first supporting plate and is then connected with a driving bevel gear; the outer wall of the driving bevel gear is connected with a U-shaped support frame; a transmission assembly is connected to the U-shaped support frame; the output end of the transmission assembly penetrates through the U-shaped support frame and is then connected with the cylinder body; the outer wall of a third rotating shaft is connected with a transmission gear set; the output end of the transmission gear set is connected with a first stirring rod and a second stirring rod separately; the outer wall of the third rotating shaft is connected with a stirring assembly; and the end, away from the third rotating shaft, of the stirring assembly is connected with a brush plate. The mixing device is novel in structure and convenient to use; through the arrangement of a driving assembly, the transmission assembly and the stirring assembly, the mixing uniformity and the mixing efficiency of nanometer materials can be effectively improved; and meanwhile, the interior of the cylinder body can be conveniently cleaned in a later period.

Owner:绍兴市梓昂新材料有限公司

Stirring and cleaning integrated equipment for processing vermicelli powder syrup

InactiveCN108041573ARealize mechanized cleaningImprove cleaning efficiencyFood shapingFixed frameArchitectural engineering

The invention discloses stirring and cleaning integrated equipment for processing vermicelli powder syrup. The equipment comprises a stirring barrel, a support platform, a mounting plate, a rotating device and a lifting device, wherein the stirring barrel is fixed at one side of the top of the support platform; a discharge pipe is fixed at the bottom of the stirring barrel; an electric valve is fixed at the outer side of the discharge pipe; a stirring device is arranged at the inner side of the stirring barrel; the top of the stirring device is fixed with the mounting plate; a cleaning deviceis fixed at one end, away from the stirring device, of the bottom of the mounting plate; the cleaning device comprises a cleaning motor, a rotating shaft, a nylon brush and a fixing frame; the cleaning motor is fixed at the top of the mounting plate; the output shaft of the cleaning motor passes through the mounting plate and is fixed with the rotating shaft; and the output shaft of the cleaning motor is in slip connection with the mounting plate. The stirring and cleaning integrated equipment for processing vermicelli powder syrup simultaneously has stirring and cleaning functions, realizes mechanical cleaning of the stirring barrel, accelerates the cleaning efficiency of the stirring barrel, and reduces the labor force.

Owner:长沙金薯食品有限公司

High polymer material stirring device

InactiveCN111790308AAvoid accumulationPlay a stirring effectTransportation and packagingMixer accessoriesEngineeringDrive motor

The invention discloses a high polymer material stirring device, which comprises a stirring barrel, an outer barrel and an upper cover plate, wherein a motor placing shell is arranged at the bottom ofthe inner wall of the outer barrel, a driving motor is arranged in the motor placing shell, a supporting plate is arranged at the output end of the driving motor, the stirring barrel is fixedly arranged on the supporting plate, a vibration stirring spring is arranged on the inner side wall of the stirring barrel, a vibration stirring ball is arranged at the end portion of the vibration stirring spring, the upper cover plate is clamped at the tops of the outer barrel and the stirring barrel, a pressurizing pump is arranged on the upper cover plate, a liquid suction pipe is arranged in the stirring barrel, one end of the liquid suction pipe penetrates through the upper cover plate and is connected with the pressurizing pump, a liquid outlet pipe is arranged at the other end of the pressurizing pump, and a self-vibration pulse jet flow nozzle is arranged at the other end of the liquid outlet pipe. The invention belongs to the technical field of composite high polymer product production,and particularly relates to a high polymer material stirring device for uniformly stirring a high polymer material by combining vibration stirring and natural vibration jet flow stirring.

Owner:XUZHOU COLLEGE OF INDAL TECH

Cleaning mechanism for textiles

InactiveCN108505247AAchieve cleaningPlay the role of dryingLiquid/gas/vapor removalLiquid/gas/vapor fabric treatmentEngineeringTextile

The invention discloses a cleaning mechanism for textiles. The cleaning mechanism for textiles comprises a box, and a vertical reciprocating mechanism, a first fixed plate and a second fixed plate arearranged in the box; a plurality of pushing rods and first steel wires are arranged on the vertical reciprocating mechanism; a plurality of guiding holes are formed in the first fixed plate, and second steel wires are slidingly connected in the two adjacent guiding holes; the two ends of each second steel wire are each provided with an impact block and a balance weight; the second steel wires arefixedly connected with the first steel wires; a fixed shaft is rotationally connected on the second fixed plate, a plurality of blades are circumferentially arranged on the fixed shaft, each blade isprovided with a sliding groove, rubbing blocks are slidingly connected in the sliding grooves, and first springs are arranged between the rubbing blocks and the sliding grooves; an annular groove isformed in the fixed shaft, a vertical plate is slidingly connected in the annular groove, and a second spring is arranged between the vertical plate and the annular groove; a plurality of second through holes are formed in the vertical plate. By means of the cleaning mechanism for textiles in the technical scheme, the problem that the efficiency of the current cleaning mode of textiles is low is mainly solved.

Owner:NINGBO WENZE TEXTILE CO LTD

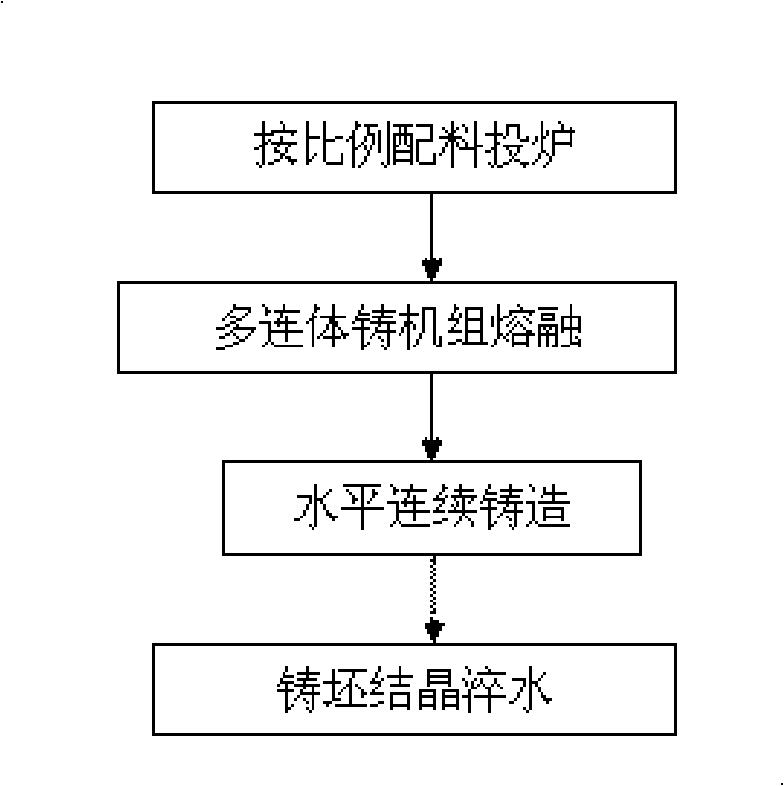

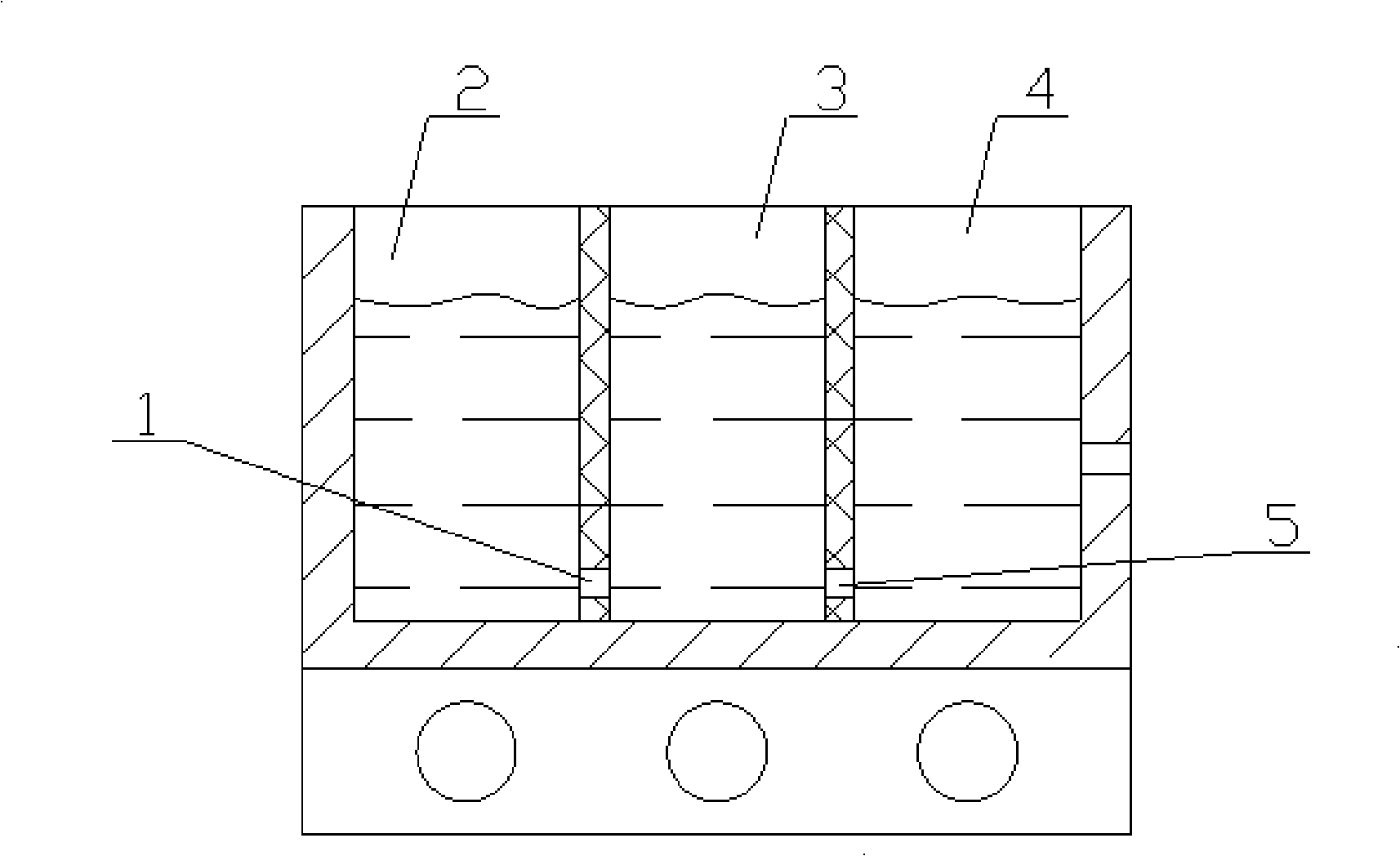

Casting method for producing copper strip without oxygen or with low oxygen content

The invention discloses a casting method for the production of oxygen free or low oxygen copper strips. The process flow of the invention is that: multi-connected casting machines are adopted for fusion-horizontal continuous casting-crystallizing and hardening the casting blank, wherein, the fusion by multi-connected casting machines is that a melting furnace, a blending furnace and a holding furnace are arranged in the cavity of one furnace body; a channel is arranged in a position adjacent to bottom of the furnace to separated the three furnaces; the copper liquid is supplemented by flowing through along the channel; the temperature of the melting furnace is kept at 1200 DEG C to 1250 DEG C; the copper liquid in the blending furnace is kept in a state of boiling and the temperature of the holding furnace is kept at 1160 DEG C to 1180 DEG C. Compared with the prior art, the casting method of the invention can reduce energy consumption and the oxygen content of the products, render the processed products easy for subsequent procession, thus being applicable to processing the pure copper strip products or alloy copper strip products.

Owner:GUIZHOU GAOKE COPPER IND

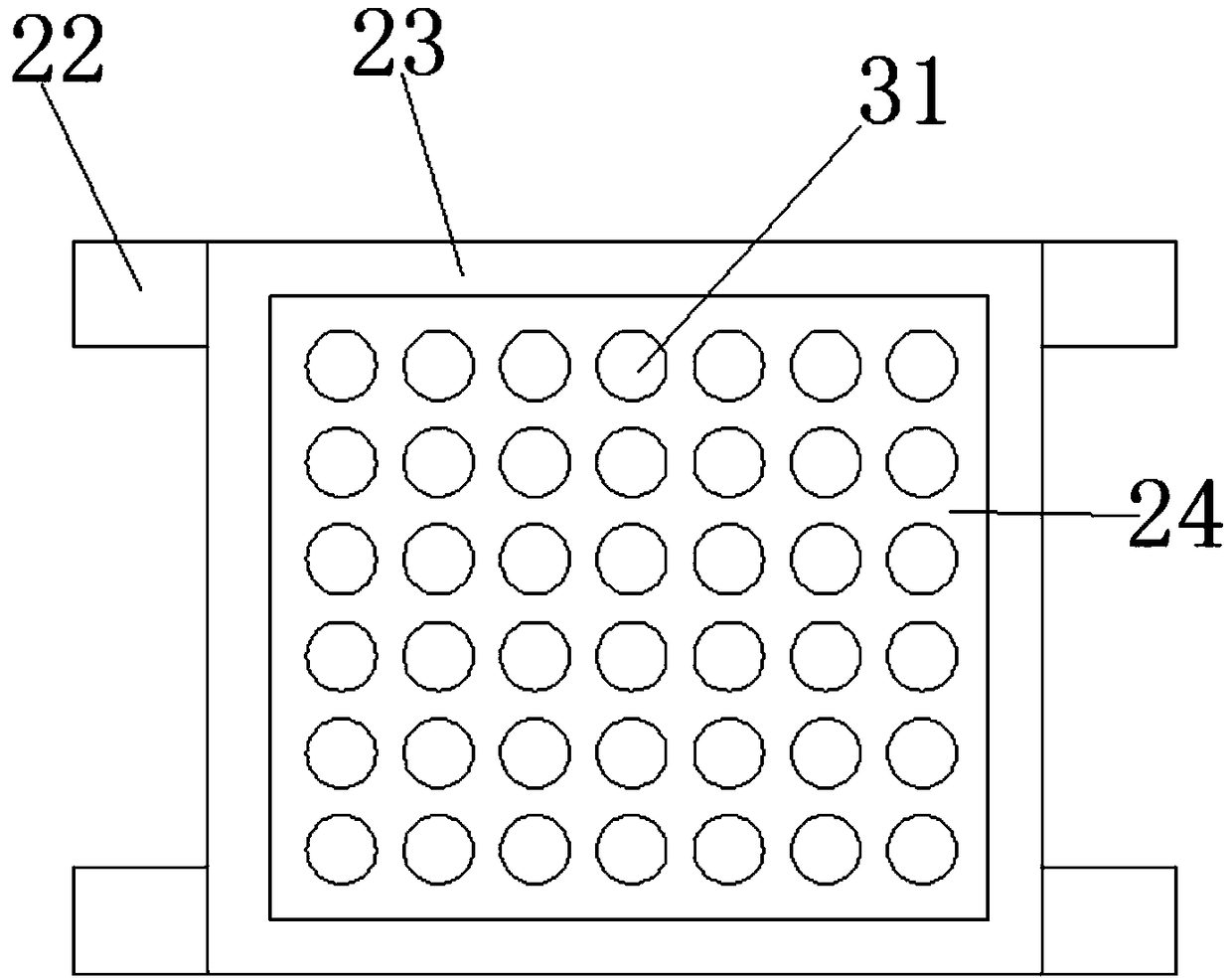

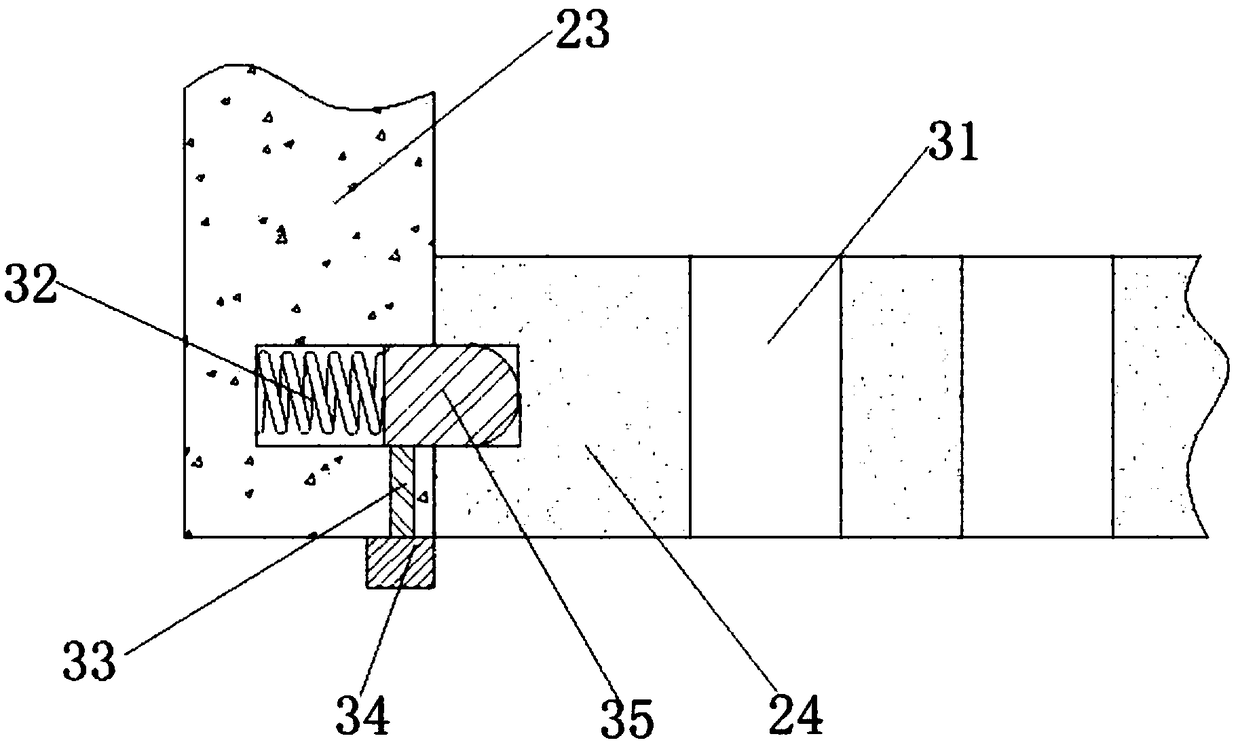

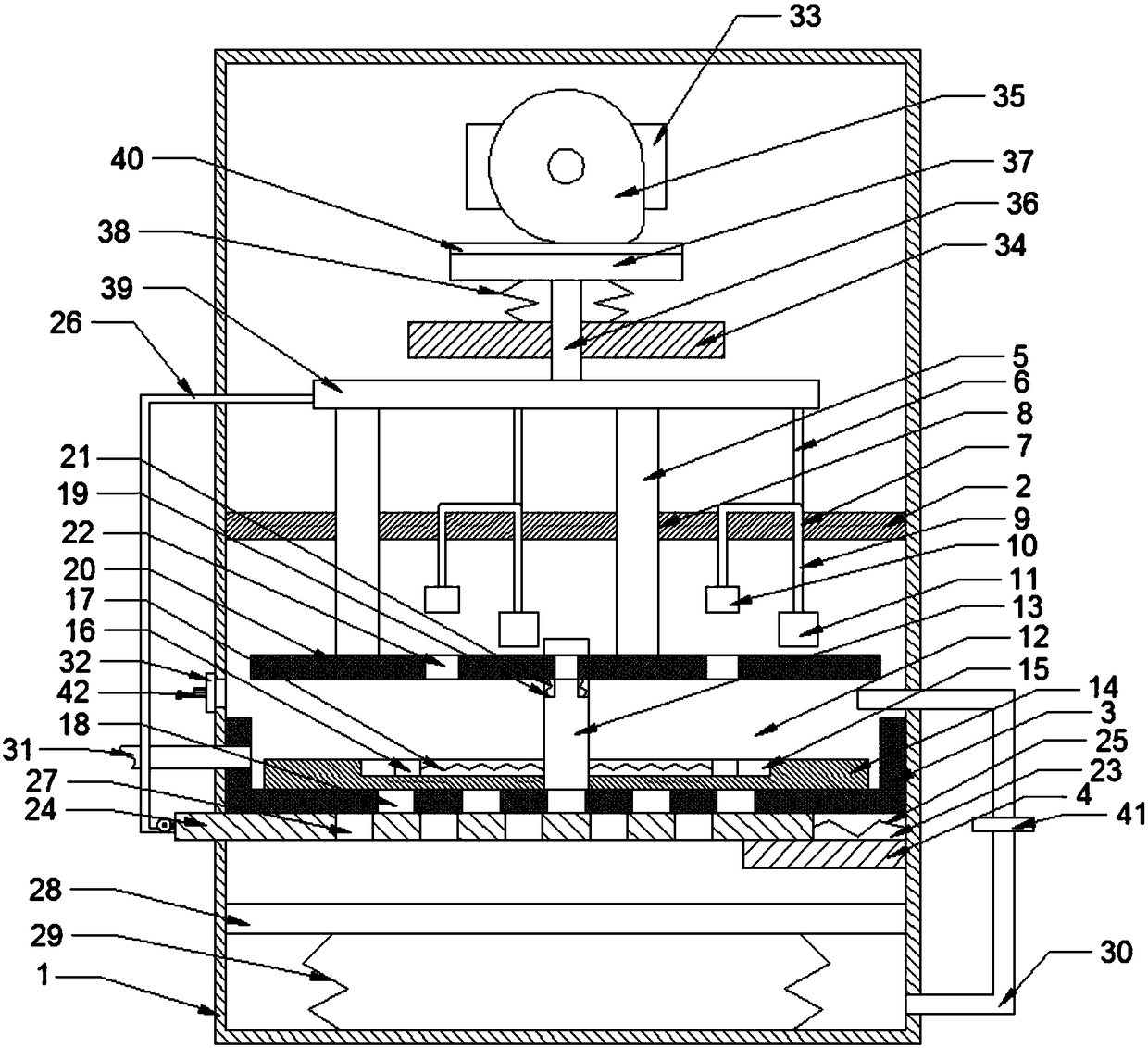

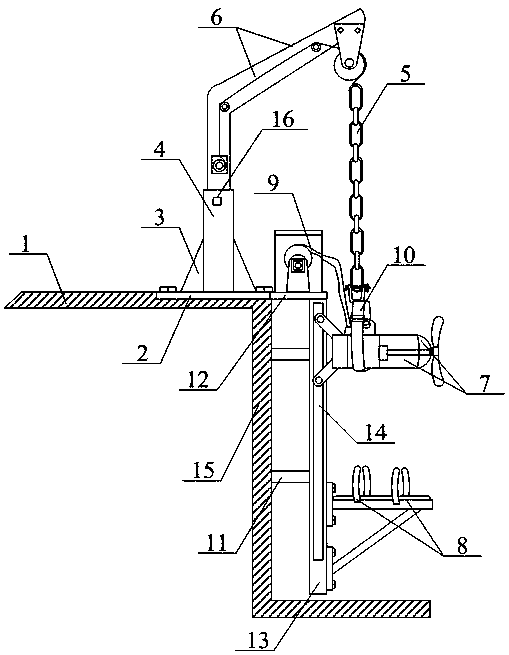

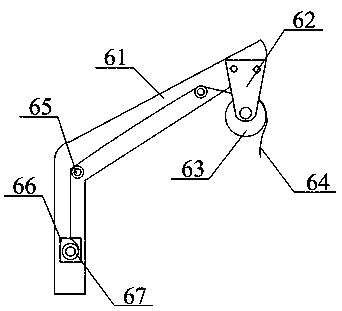

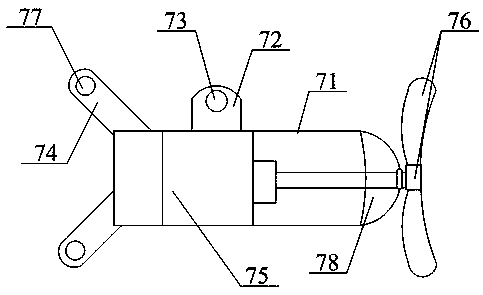

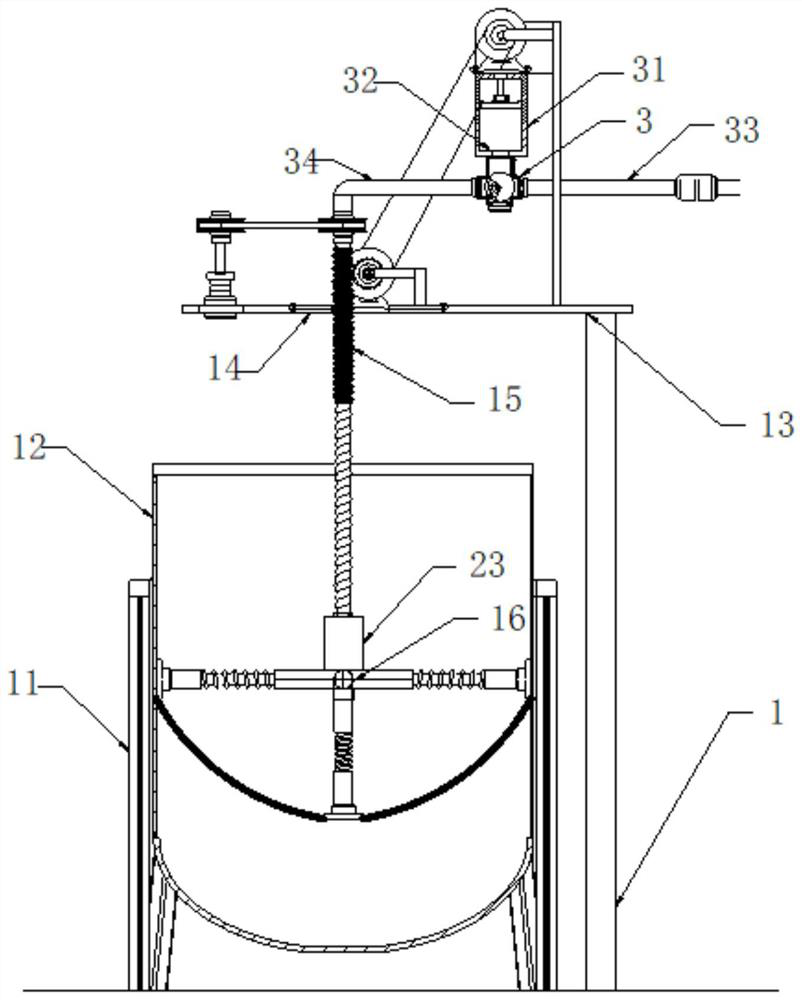

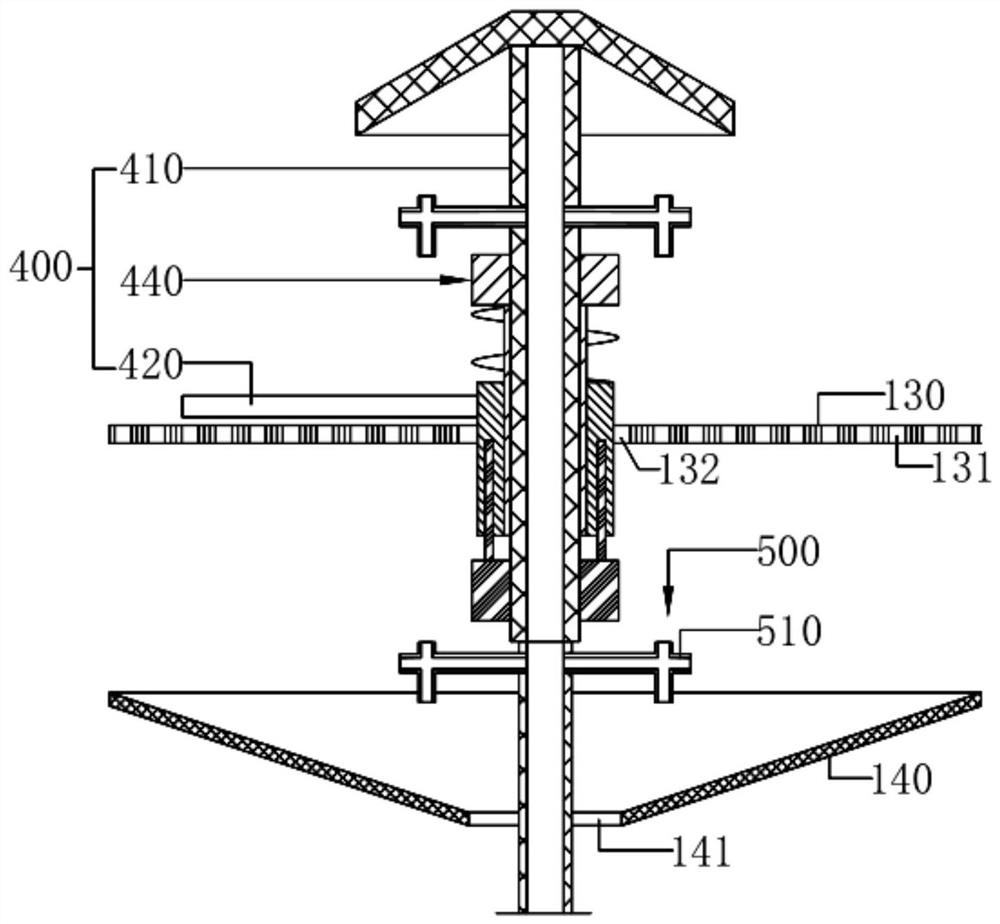

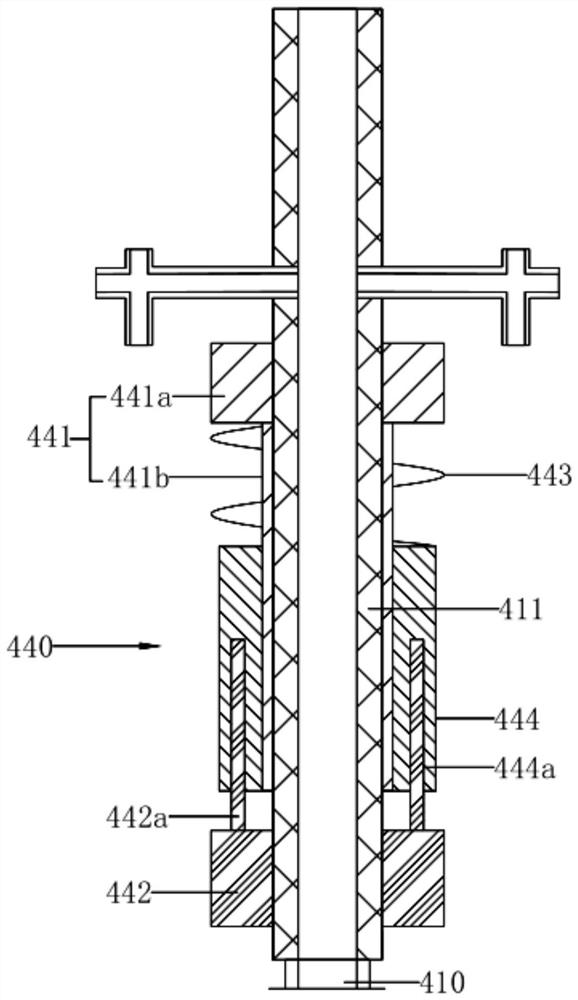

Comprehensive mixing treatment equipment for sludge settling tank

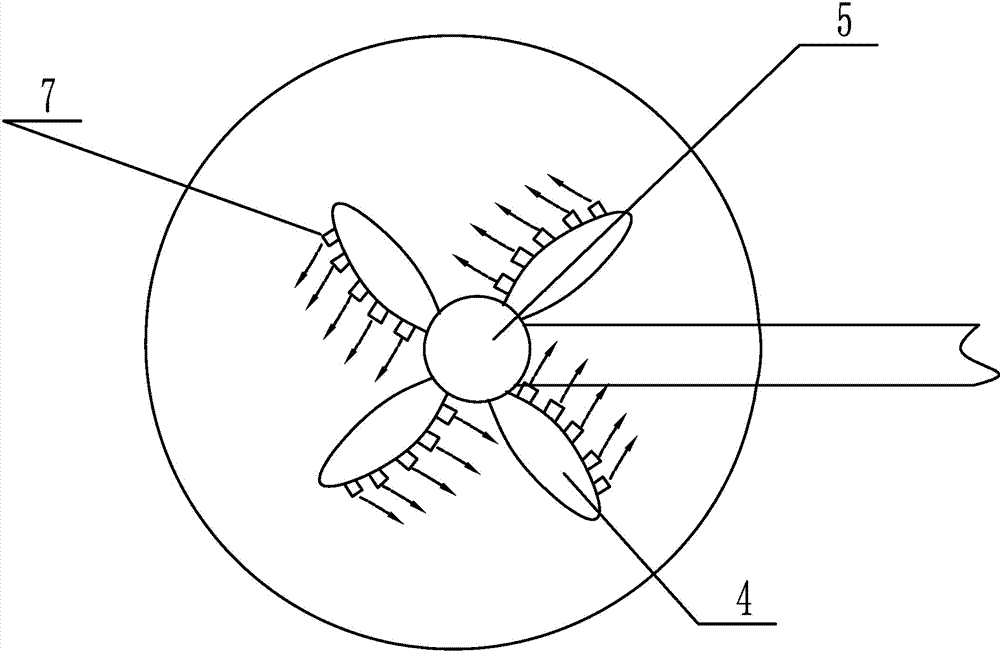

ActiveCN108751366AConducive to decentralizationMeet the mixing needsSedimentation separationWater/sewage treatment by flocculation/precipitationImpellerSludge

The invention provides comprehensive mixing treatment equipment for a sludge settling tank. The comprehensive mixing treatment equipment comprises a formation surface, an embedded steel plate, a hanger bracket, a hanger supporting pillar, a stainless steel lifting chain, an electric traction lifting bracket device, a conveniently-fixed stirrer structure, a stirring fixed limiting seat structure, acable retracting box structure, a falling prevention buckling structure, cross stay bars, a connecting plate, a supporting guide rod, a sliding chute, a sludge settling pond wall and a control switch, wherein the embedded steel plate is in bolted connection with the right-side position of the upper surface of the foundation surface. According to the comprehensive mixing treatment equipment provided by the invention, by arrangement of a hand-drive block, a pulling rope, a guide roller and a winding motor, the stirrer is beneficially released, and the stirring requirements on the sludge settling ponds with different depths can be met; by arrangement of a driving motor and a stirring impeller, sludge in the sludge settling pond is favorably stirred and a stirring effect is realized; a falling prevention strap is arranged to beneficially realize a secondary protecting effect on a submersible stirrer enclosure and the stirring impeller and enhance the fall prevention function.

Owner:徐文峰

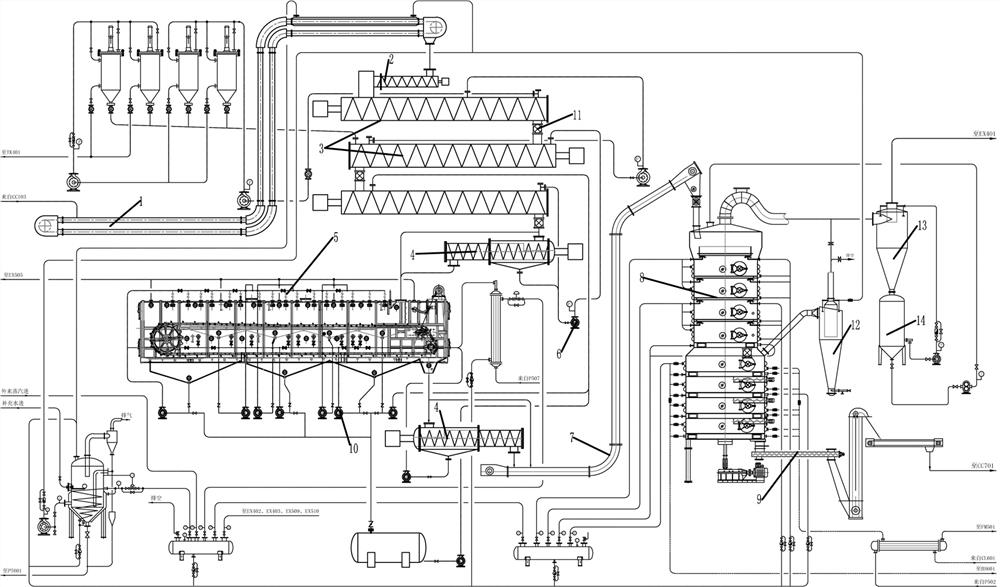

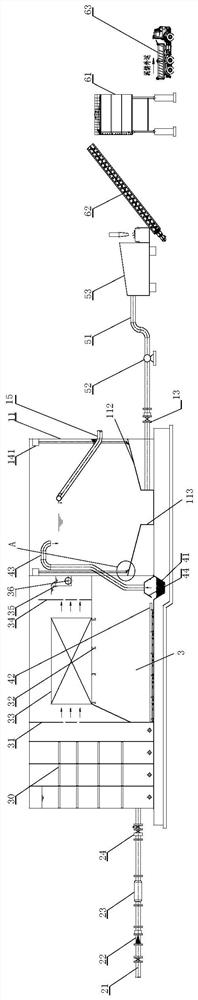

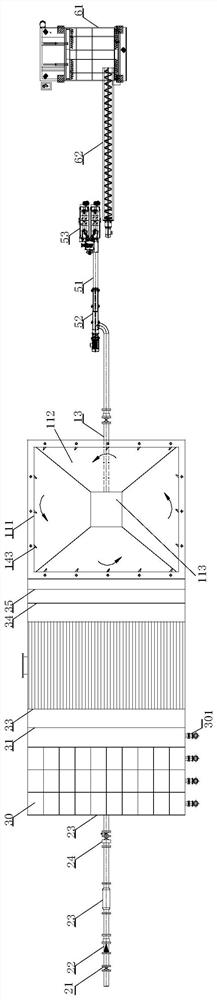

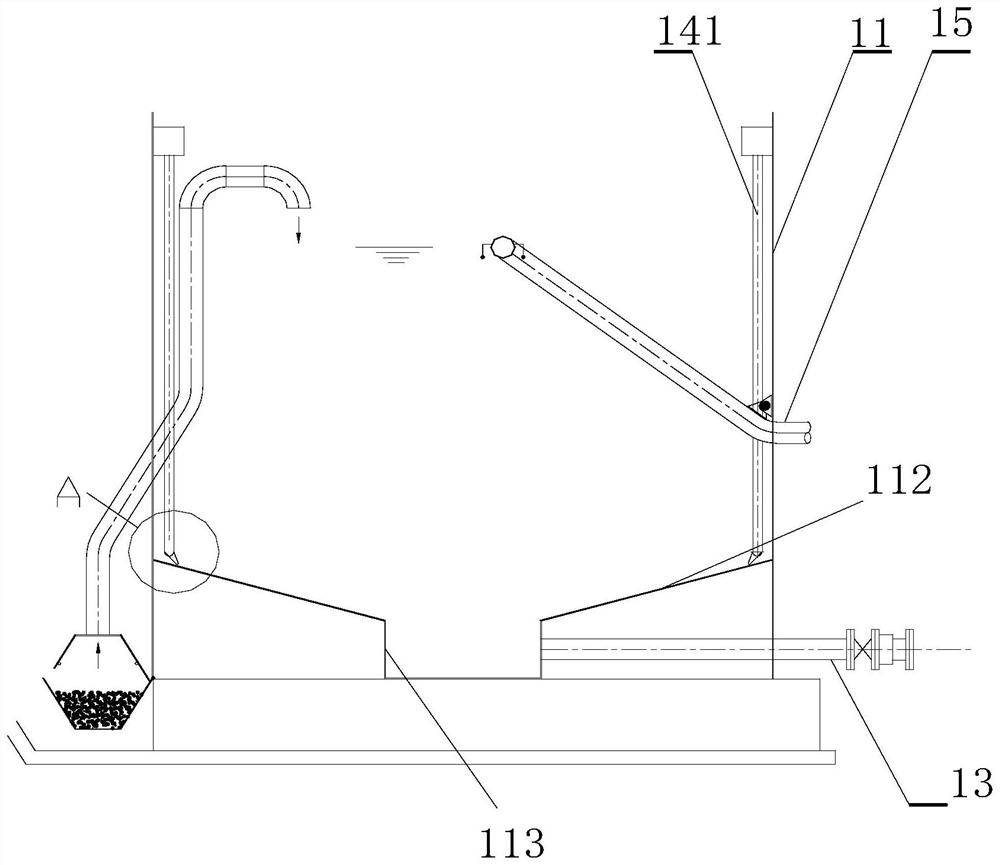

Continuous countercurrent extraction desolventizing system and process

PendingCN114748889AGuaranteed isolationGuaranteed Concentration GradientSolid solvent extractionPalm kernelProcess engineering

The invention belongs to the technical field of material extraction, and particularly discloses a continuous counter-current extraction desolventizing system and a continuous counter-current extraction desolventizing process, which are suitable for squeezing fish meal, palm kernel cakes, tea seed cakes, saponin polysaccharide extracted from tea seed cakes, pigment extracted from corn protein powder and the like, and comprise a conveyor, a feeder connected with the conveyor, and a horizontal multi-stage counter-current extractor connected with the feeder, a discharge hole of the horizontal multi-stage counter-current extractor is directly connected with the drag chain type extractor or is extruded by the extrusion separator, a solid is connected with the drag chain type extractor, and a liquid is conveyed to the last stage for cyclic extraction through the extract circulating pump; a material outlet in the bottom of the extraction device is conveyed to a desolventizing machine through a scraper conveyor or passes through an extrusion separator and then is conveyed to the desolventizing machine through the scraper conveyor, liquid is conveyed to the last-stage extraction section for circulation through a solvent circulating pump, and an outlet of the desolventizing machine is conveyed to a finished product warehouse through a conveyor. And the permeation effect of the solvent in the material is good.

Owner:上海永鸿机电设备科技有限公司 +1

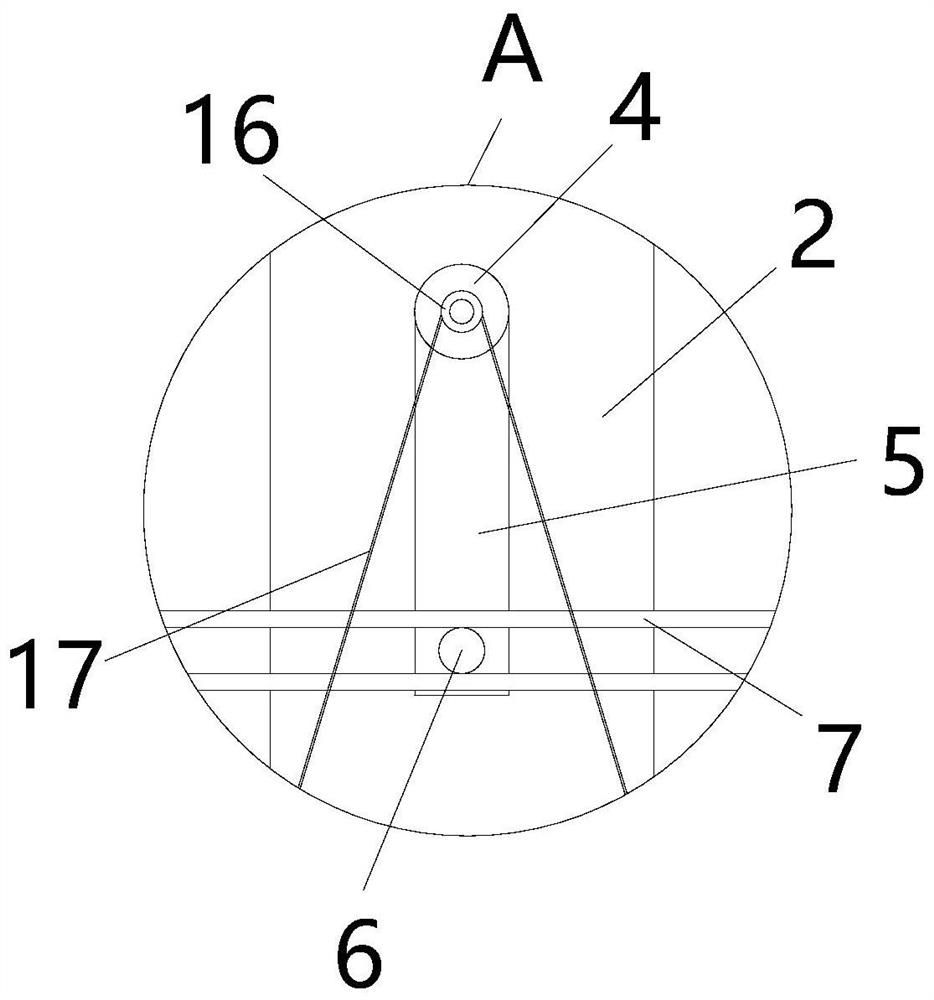

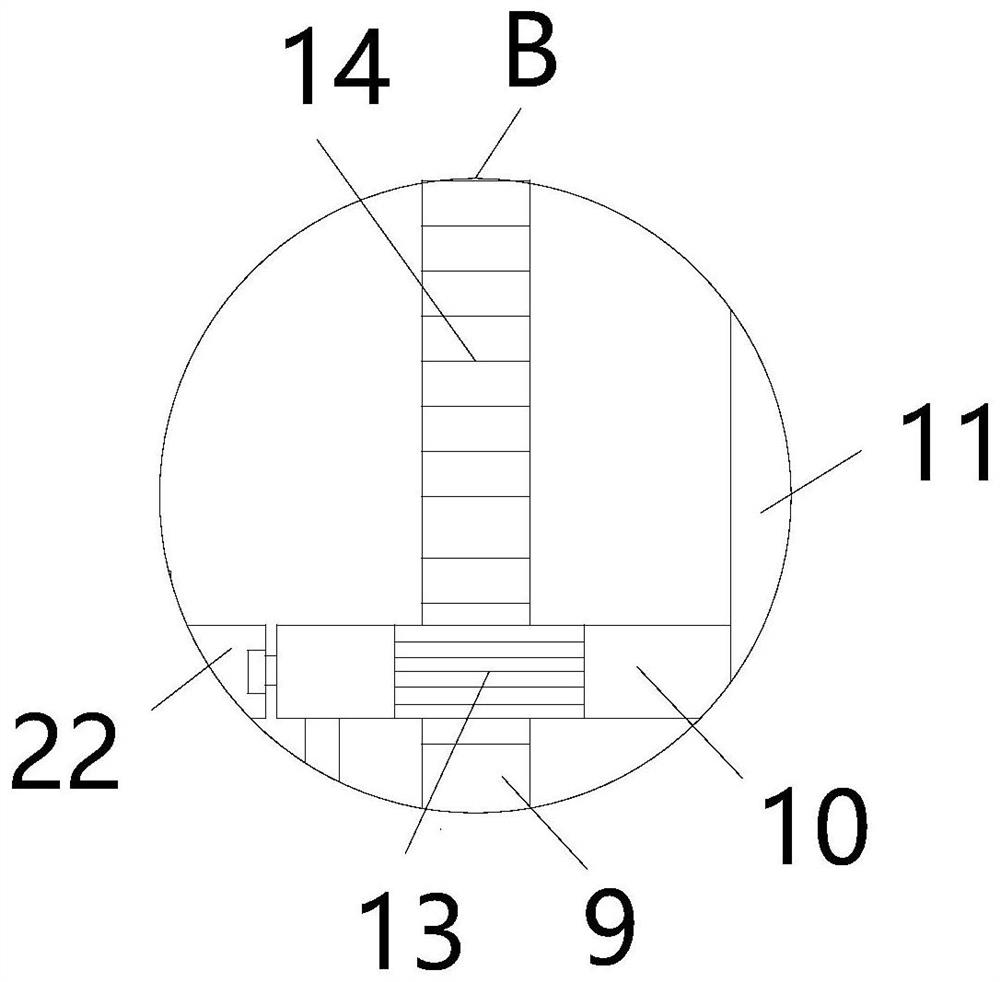

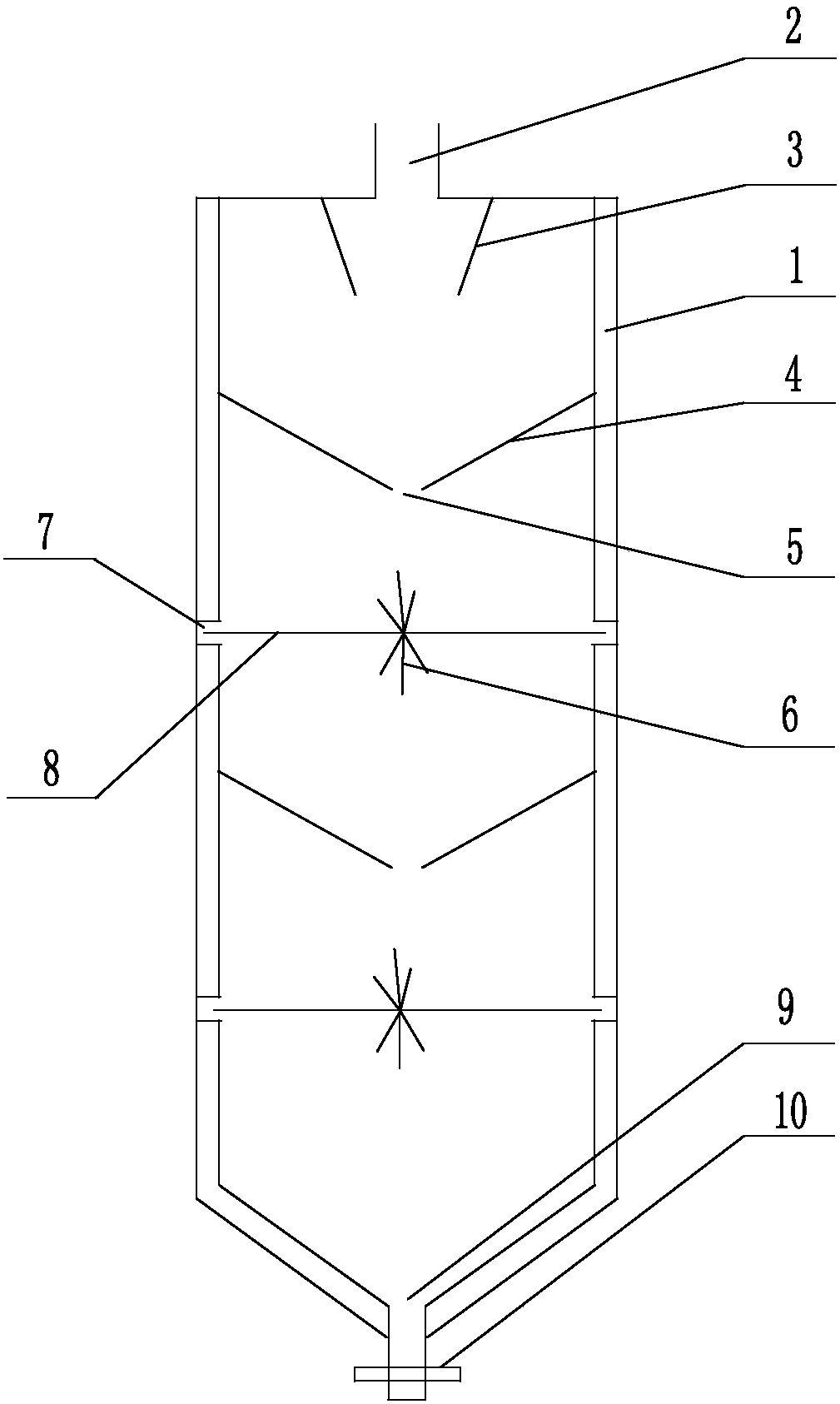

Segregation-prevention vertical sand silo

The invention relates to a sand silo, in particular to a segregation-prevention vertical sand silo. The segregation-prevention vertical sand silo comprises a silo body. The silo body mainly comprisesa cylindrical barrel body on the upper portion and a conical barrel body on the lower portion. A sand discharge port is formed in the lower end of the conical barrel body. A sand discharge valve is arranged on the lower portion of the sand discharge port. A feed chute is fixed to the center position of an upper cover plate of the silo body. An outlet of the feed chute is connected with a feed hopper in a butt joint manner. The feed hopper is fixed to the inner surface of the upper cover plate of the silo body. Drainage plates are fixed to the inner side wall of the silo body. A hole is formedin the center position of each drainage plate. A stirring device is arranged at the lower end of each hole. Each stirring device is connected to a rotating shaft in a rotating manner. The rotating shafts are fixed in grooves in the inner side wall of the silo body. The segregation-prevention vertical sand silo is provided with the drainage plates and the stirring devices, stirring paddles are driven to rotate under the effect of gravity of dry sand materials so that the stirring effect can be achieved, and the dry sand materials in the silo body can be evenly distributed without adding other power devices. The segregation-prevention vertical sand silo is simple in structure, good in segregation prevention effect, convenient to use and high in reliability.

Owner:ZIBO HUAYUAN MINING CO LTD

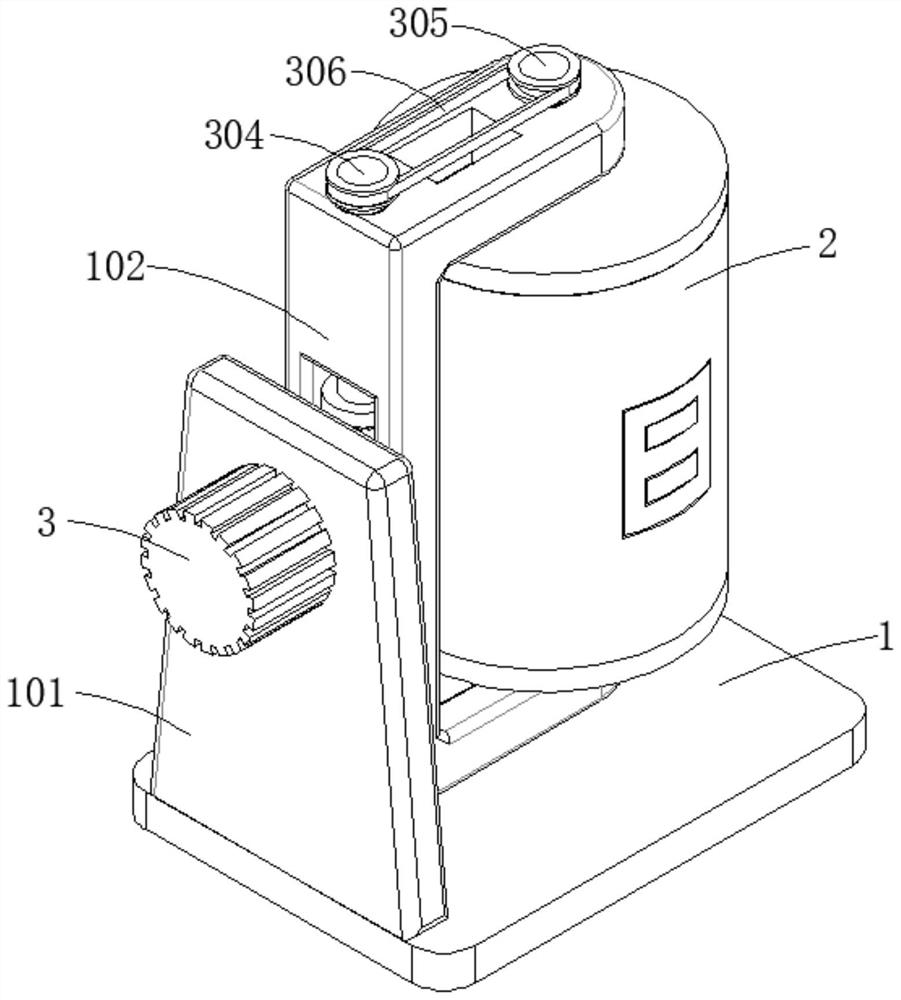

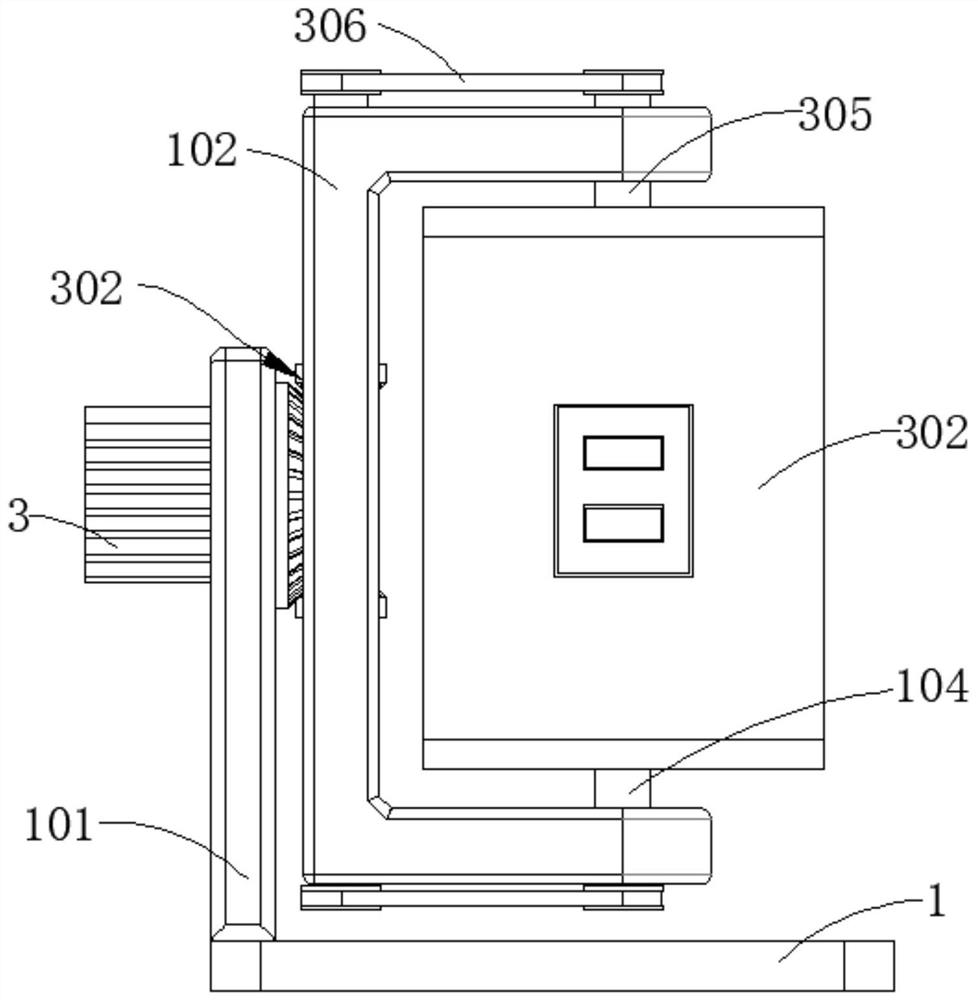

Chemical barrel cleaning device for multistage driving type line body operation

InactiveCN112452980AEasy to operateThe process is convenient and fastHollow article cleaningWater dischargeStructural engineering

The invention relates to the technical field of chemical engineering, in particular to a chemical barrel cleaning device for multistage driving type line body operation. The chemical barrel cleaning device comprises an equipment frame, wherein a supporting frame is arranged on the equipment frame, a chemical barrel is erected on the supporting frame, a driving frame is arranged at the top of the chemical barrel, a mounting base is arranged at the top of the driving frame, and a cleaning rod part is mounted in the mounting base; a cleaning frame is arranged at the bottom end of the cleaning rodpart, the cleaning rod part comprises an external driving rod part and an internal lifting rod part, the external driving rod part and the internal lifting rod part are each provided with an inner hollow structure, and threads are arranged on the inner wall and the outer wall of the external driving rod part; and an external lifting rod part is arranged in a pipe inner cavity of the external driving rod part in a penetrating manner and connected with the pipe inner cavity through internal threads, and a water discharging cylinder is arranged at the joint between the bottom end of the internallifting rod part and the cleaning frame. According to the chemical barrel cleaning device, the chemical barrel can be comprehensively and effectively cleaned, sewage does not need to be discharged from the chemical barrel, and the modern high-efficiency line body operation process is met.

Owner:李洋

Pigpen feeding machine for livestock raising with cleaning structure

InactiveCN109662038AVersatileEasy to cleanAnimal watering devicesTransportation and packagingLivestockWater loading

The invention discloses a pigpen feeding machine for livestock raising with a cleaning structure. The pigpen feeding machine comprises a feed chamber, an electrical push rod, a material charging portand a liquid loading pipe, wherein the feed chamber is arranged in a box body; the electrical push rod is vertically arranged at a side of the box body; an adjusting block is arranged in the feed chamber and is tightly attached to the inner wall of the box body; the material charging port is arranged above the feed chamber; the feed chamber is communicated with a feeding trough through a materialdischarging port; a water loading chamber and a dirt collecting chamber are arranged at a side of the feed chamber and are positioned in the box body; counterweight blocks are horizontally distributedin the water loading chamber; the liquid loading pipe is positioned at a side edge of the box body. The pigpen feeding machine for livestock raising with the cleaning structure has the advantages that by designing internal and external structures of the device, drinking water can be added into the device while the feed is charged, so that the functions are improved; after the device is used, thecleaning of the whole device is more convenient.

Owner:苗培 +3

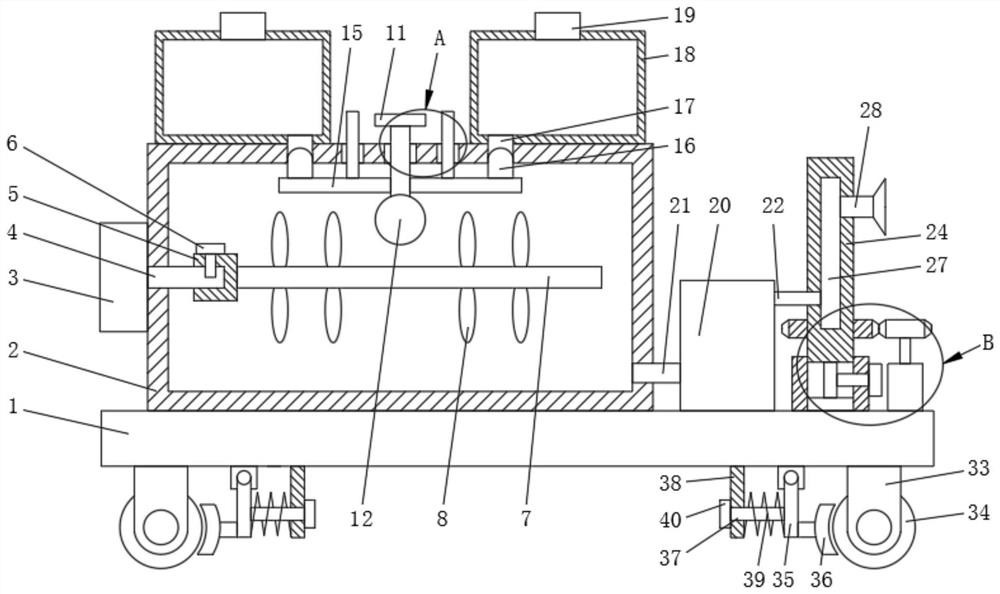

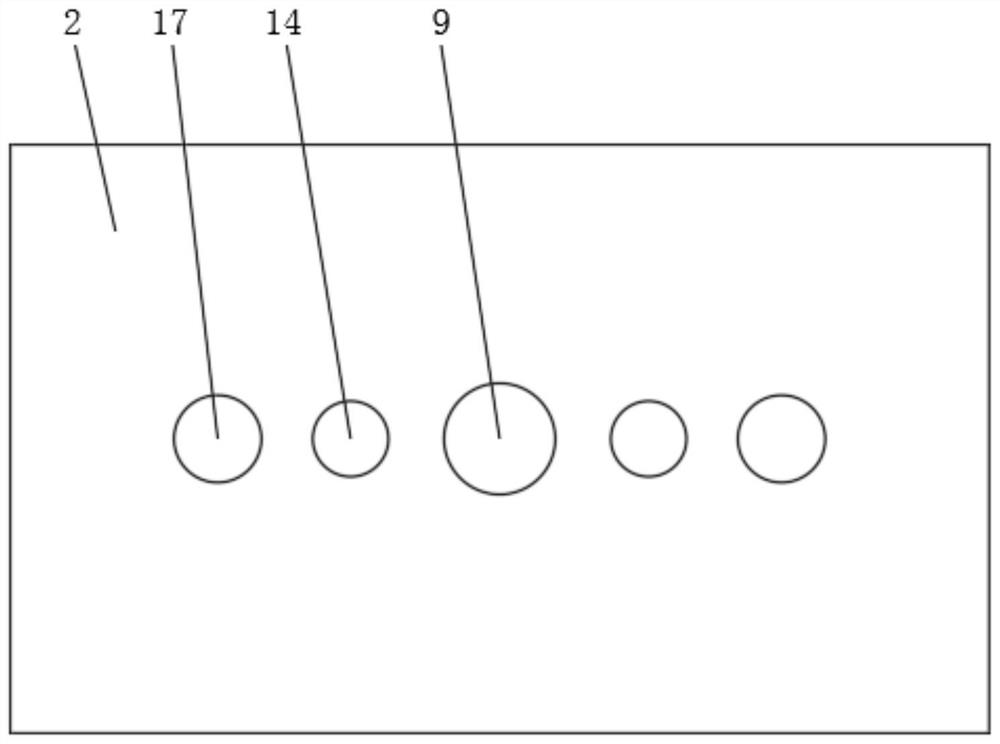

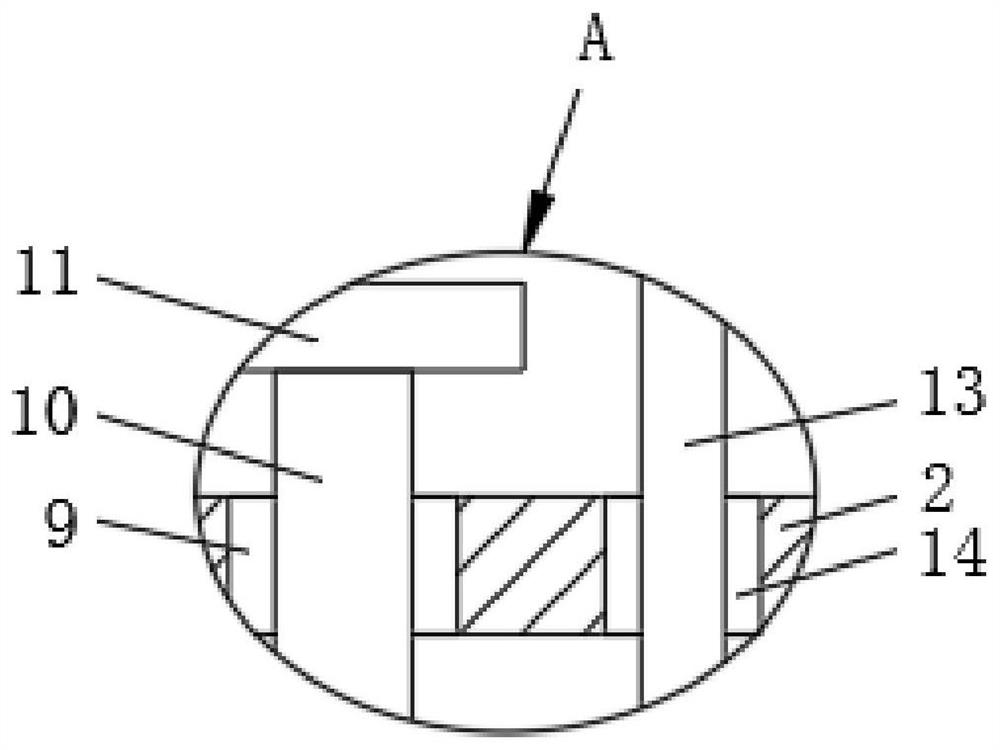

Pesticide spraying vehicle and working method thereof

PendingCN112841159APlay a stirring effectPrevent precipitationAgricultural machinesSpraying apparatusPesticideAgricultural engineering

The invention discloses a pesticide spraying vehicle. The pesticide spraying vehicle comprises a supporting plate; a pesticide box is arranged at the upper end of the supporting plate; a first motor is arranged on the pesticide box; a first rotating shaft of the first motor is rotationally connected with the pesticide box; the outer side of the first rotating shaft is sleeved with a connecting base; a connecting rod is fixedly connected to the connecting base; a through hole is formed in the pesticide box; a sliding rod is slidably connected to the interior of the through hole; a connecting ring is fixedly connected to the upper end of the sliding rod; a floating ball is fixedly connected to the lower end of the sliding rod; and a transverse rod is fixedly connected to the sliding rod. Through the effect of the designed motor, an effect of stirring liquid pesticide can be achieved, and the liquid pesticide can be effectively prevented from precipitating; through the effect of a pesticide adding box, the storage amount of the liquid pesticide in the pesticide spraying vehicle is larger; and through the effect of the floating ball, a plug can be driven to move up and down, so that the effect of automatically adding pesticide into the pesticide box is achieved.

Owner:王勇

Integrated sludge water treatment system

PendingCN112777801APlay a stirring effectLow costSludge treatmentTransportation and packagingFlocculationWater treatment system

The invention discloses an integrated sludge water treatment system which comprises a mixing device, a flocculation basin, a precipitation device, a concentration device, a sludge lifting device, adewatering device and a conveying device. The mixing device is used for mixing a flocculating agent into sludge water; the flocculation basin is connected with the mixing device through a pipeline and is used for flocculating the sludge water; the precipitation device is used for carrying out sludge water separation on the sludge water; the concentration device is used for concentrating sludge; the sludge lifting device is used for conveying the sludge in the precipitation device into the concentration device; and the dewatering device is used for drying the sludge.

Owner:ZHEJIANG LIANCHI WATER EQUIP

A raw material impurity removal and screening device for grain and oil processing

ActiveCN112718483BAvoid synchronous entryAvoid enteringSievingGas current separationOil processingBLENDER/MIXER

The invention relates to a raw material impurity removal and screening device for grain and oil processing, which belongs to the technical field of grain and oil processing equipment. Partition plate, the second partition plate, the side of the first partition plate near the discharge port, the side of the first partition plate near the discharge port forms the first impurity removal chamber; the first partition plate and the second partition plate A second impurity removal chamber is formed between them; a number of first discharge ports are arranged at intervals in the circumferential direction of the first partition; the first discharge port communicates with the second impurity removal chamber; A stirring mechanism for stirring the raw materials on the upper side of the first partition; a blowing mechanism for blowing air into the first impurity removal chamber and / or the second impurity removal chamber is arranged in the box; a suction mechanism is arranged outside the box , the suction mechanism sucks the air in the box. By adopting the above technical scheme, light and fine impurities in raw materials can be removed under closed conditions.

Owner:天长市天鑫粮油贸易有限责任公司

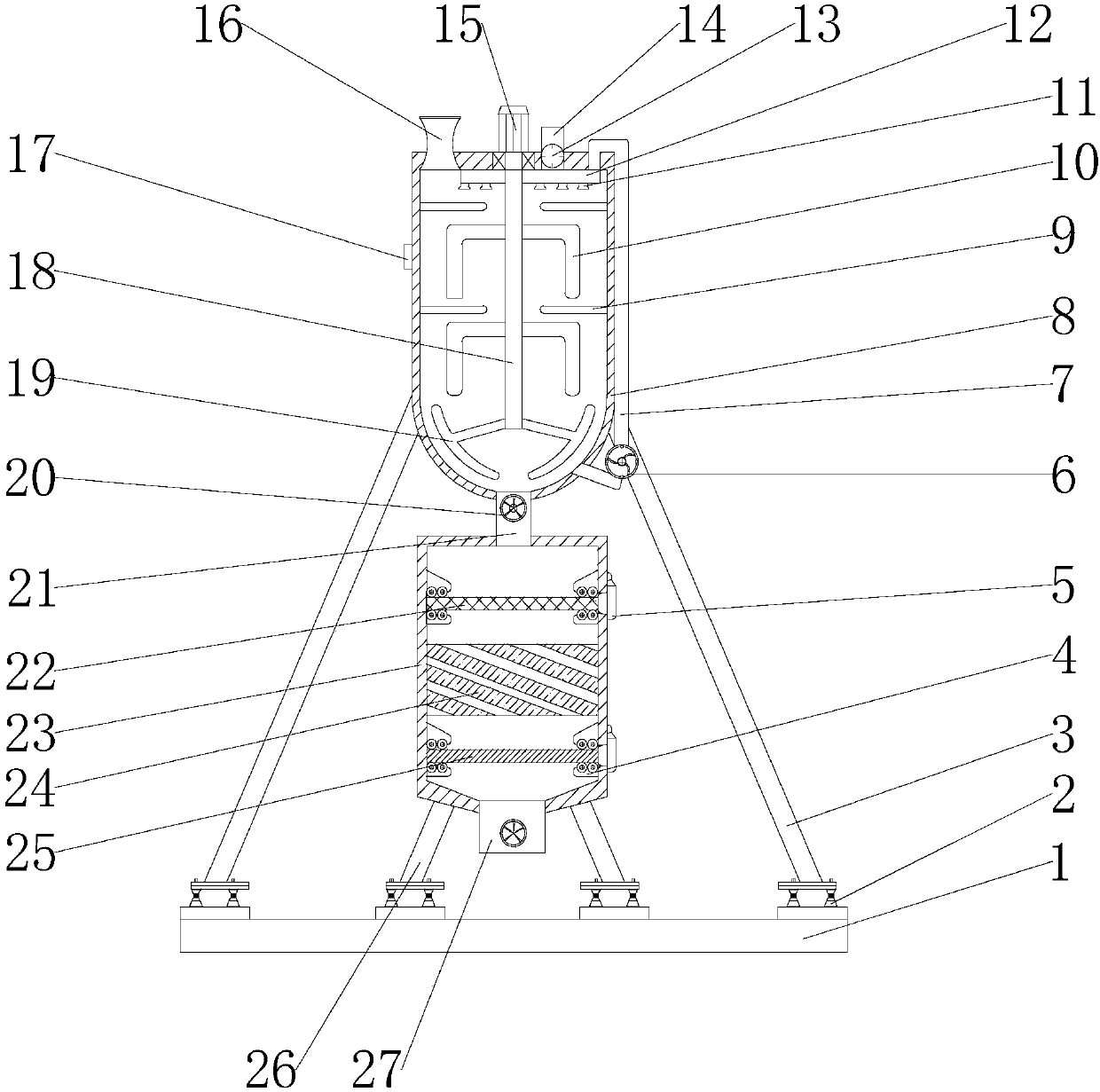

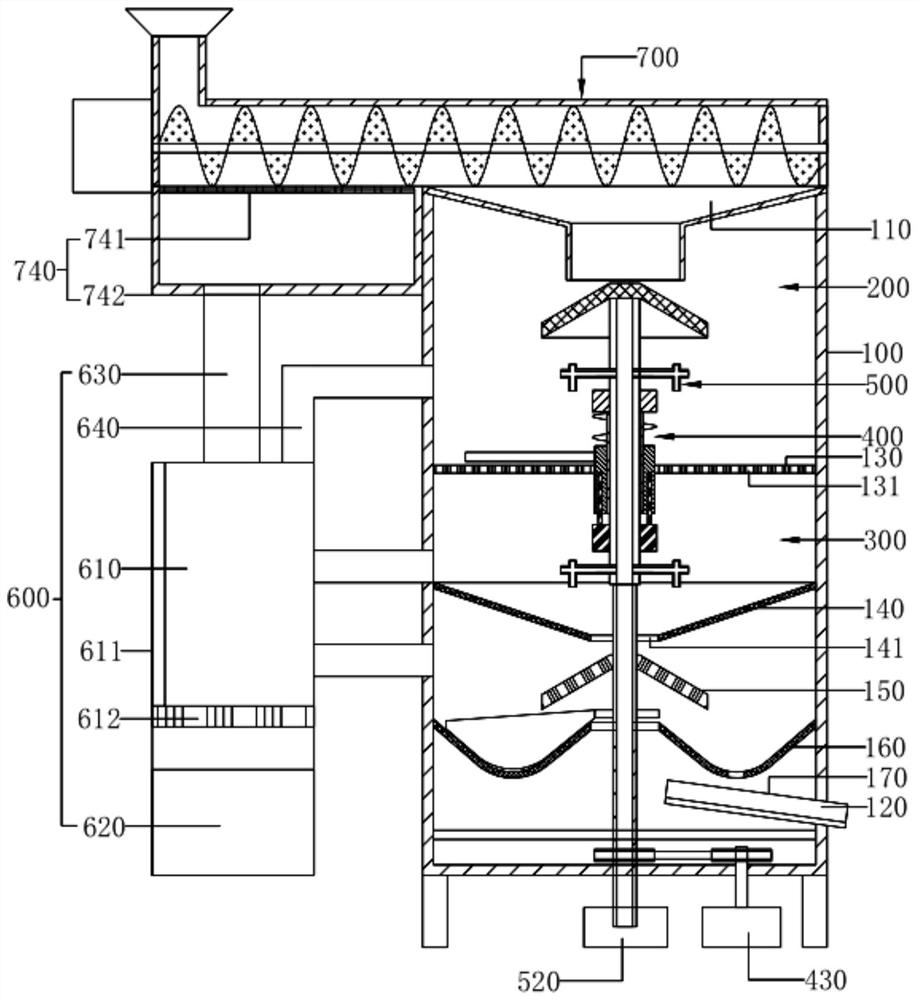

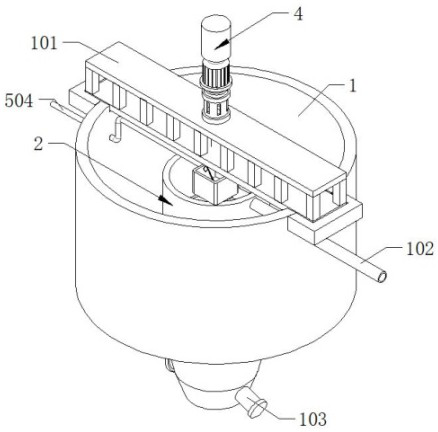

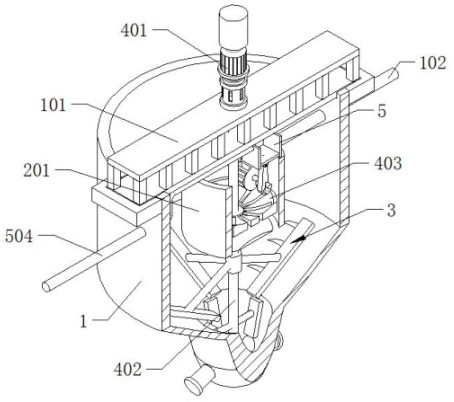

High-density paste type thickener with efficient treatment capacity

InactiveCN111620420AControl dischargeEasy dischargeWater/sewage treatment by flocculation/precipitationWater/sewage treatment apparatusFlocculationImpeller

The invention provides a high-density paste type thickener with efficient treatment capacity. The high-density paste type thickener comprises a tank body, a feeding device, a raking mechanism and a driving mechanism; the top wall of the tank body is connected with a bridge frame; the driving mechanism is connected to the top wall of the bridge frame; the feeding device is connected to the interiorof the tank body; the raking mechanism is connected to the interior of the tank body and matched with the inner wall of the tank body; the outer wall of the tank body is connected with a feeding pipeline; the feeding pipeline penetrates through the tank body and is communicated with the feeding device; the feeding device comprises a flow stabilizing barrel, an impeller is connected to the inner wall of the flow stabilizing barrel through a rotating shaft, the output end of the feeding pipeline is matched with the impeller, a flocculant storage box is connected to the bottom wall of the bridgeframe, a circulating mechanism is connected to the outer wall of the rotating shaft, and the output end of the circulating mechanism is matched with the flocculant storage box. The high-density pastetype thickener is simple in structure and convenient to use, the discharge amount of a flocculating agent can be effectively controlled according to the feeding speed, the cost of the flocculating agent can be effectively saved, and the flocculation effect of the flocculating agent can be effectively improved.

Owner:HUAIBEI KUANGHUAN WASHES EQUIP

A road marking machine

ActiveCN109183594BPlay a stirring effectPrevent precipitationRoads maintainenceAgricultural engineeringStructural engineering

Owner:四川志德公路工程有限责任公司

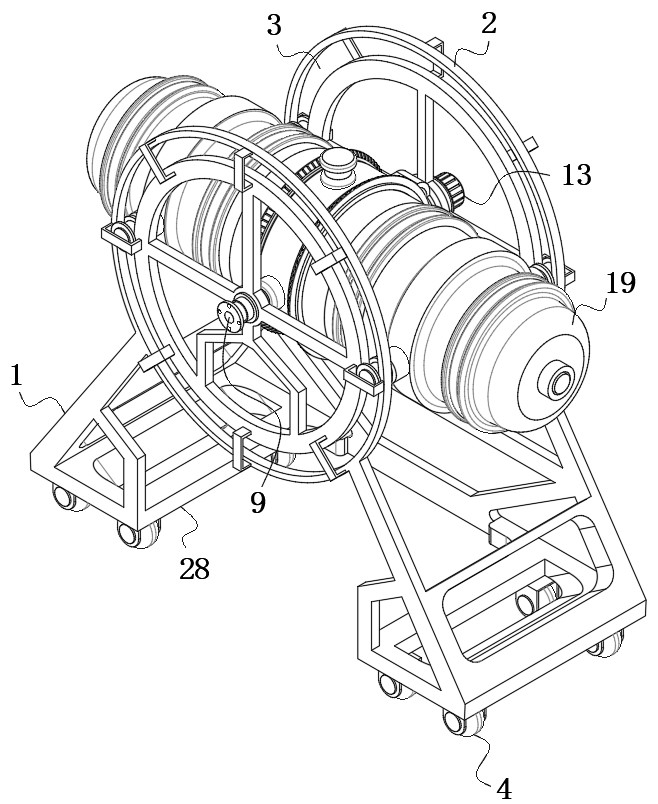

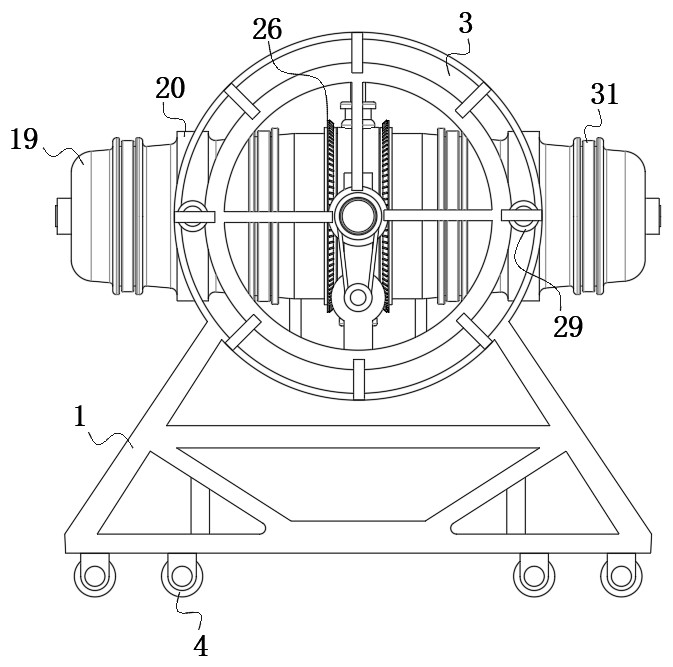

Multi-rotation-direction type building material processing system

ActiveCN112476774AWell mixedIncrease stirring speedCement mixing apparatusElectric machineConstruction engineering

The invention discloses a multi-rotation-direction type building material processing system, and belongs to the technical field of building material processing. The multi-rotation-direction type building material processing system comprises a bottom frame, wherein the top surface of the bottom frame is fixedly connected with two guide frames which are symmetrically arranged; guide ring grooves areformed in the surfaces of the two guide frames; a rotating mechanism is rotatably connected between the opposite surfaces of the two guide frames through bearings; the surface of one guide frame is fixedly connected with a main driving motor; one end of an output shaft of the main driving motor is in transmission connection with the rotating mechanism through a chain; the peripheral side surfaceof the rotating mechanism is in sliding fit with the two guide ring grooves; and the rotating mechanism comprises a fixed sleeve. According to the multi-rotation-direction type building material processing system provided by the invention, through the design of the rotating mechanism and a rotating roller, a static stirring structure of a traditional stirring device is changed into a movable stirring structure; during work, the main driving motor can drive the whole stirring mechanism to do 360-degree circular motion; and through the implementation of the motion effect, materials to be stirredare made to flow in a circulating and reciprocating mode.

Owner:广东卓翰建设科技有限公司

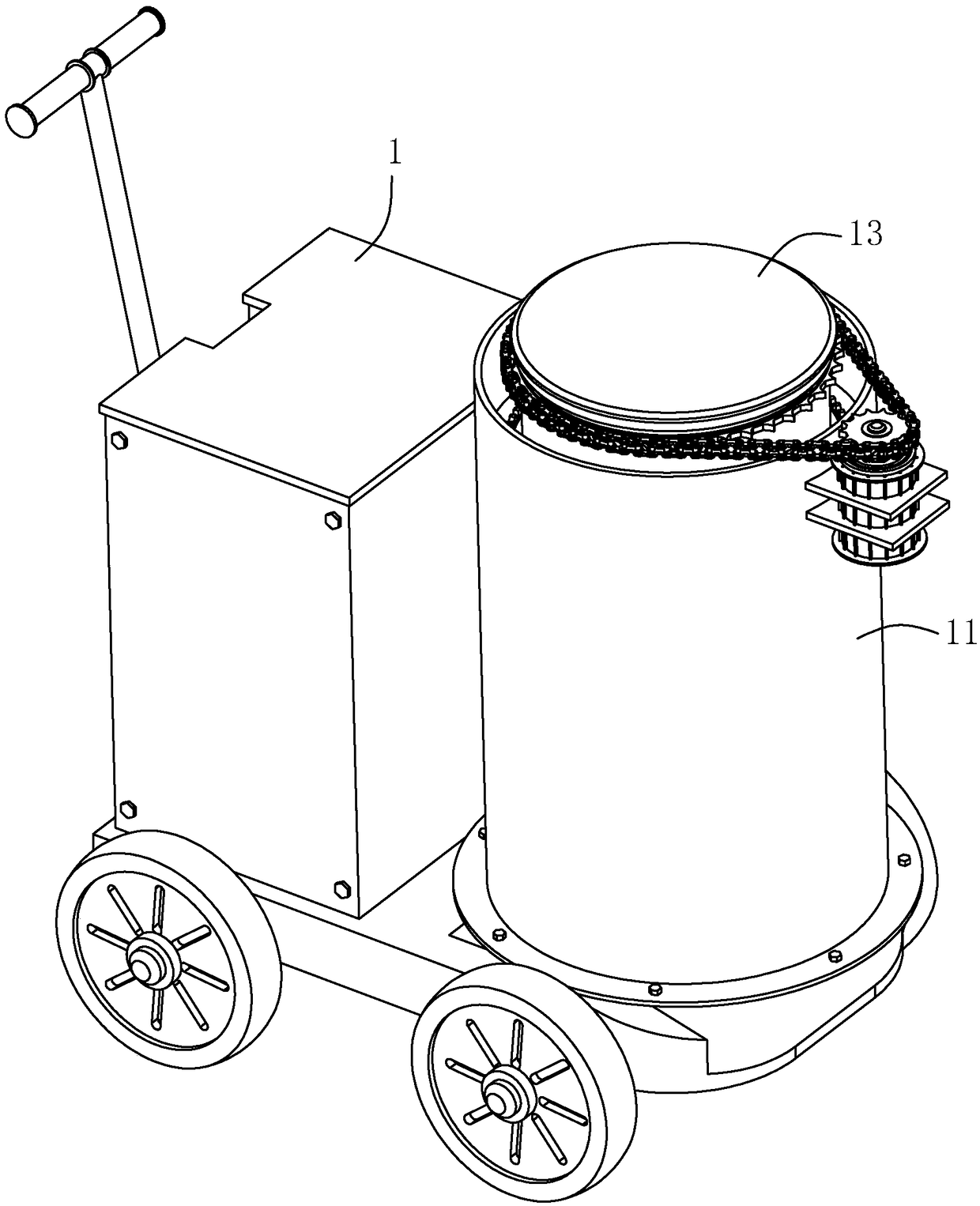

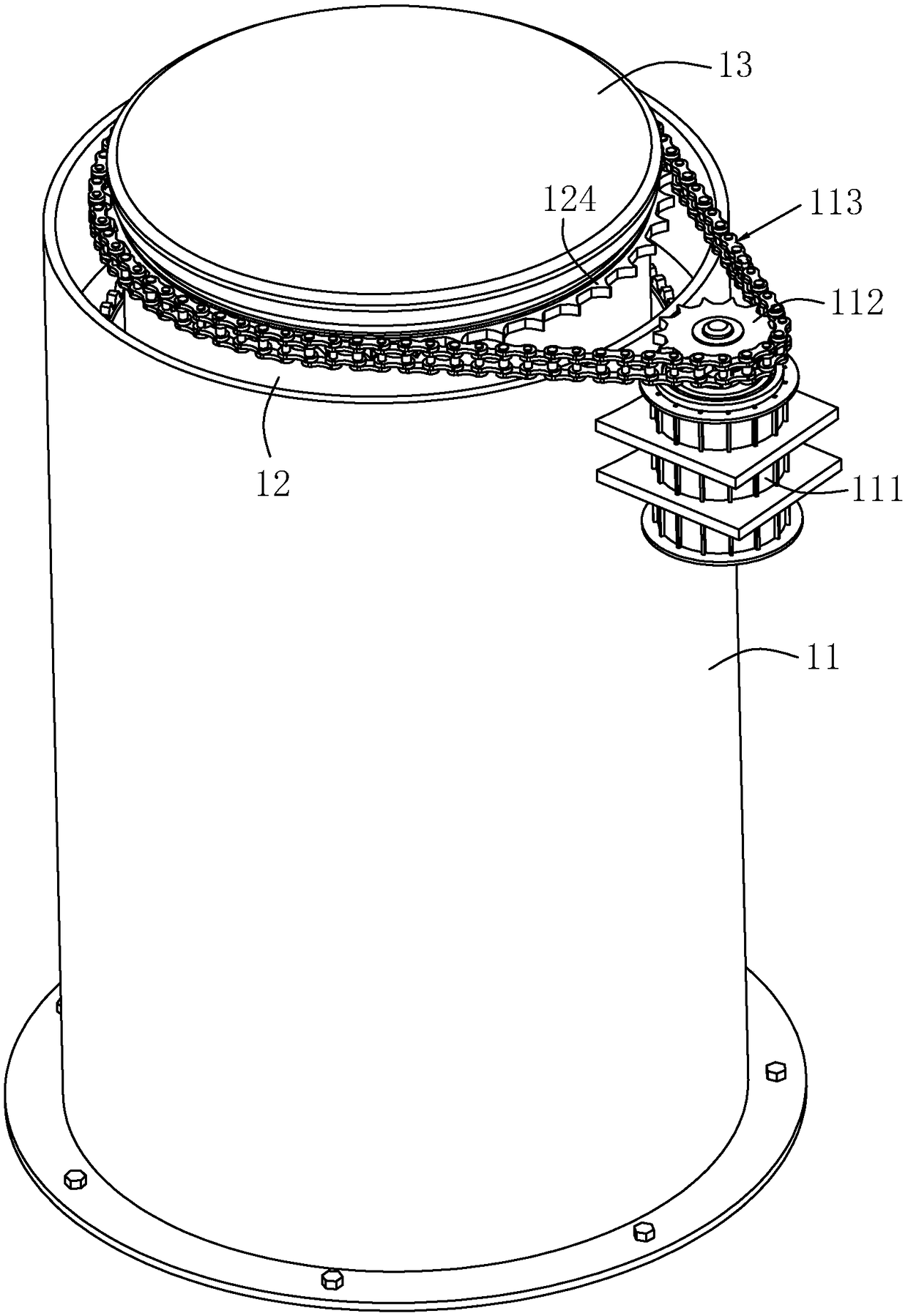

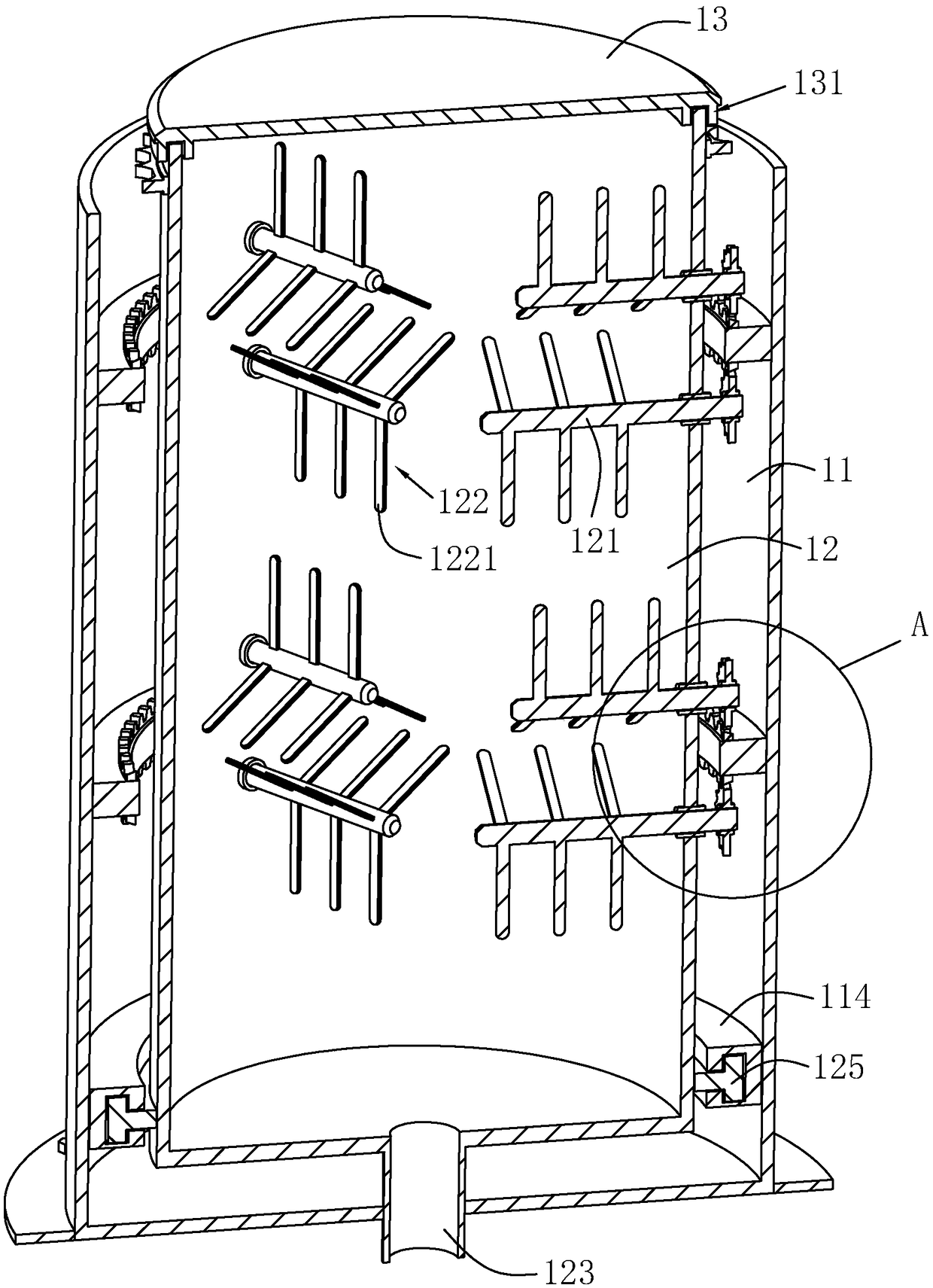

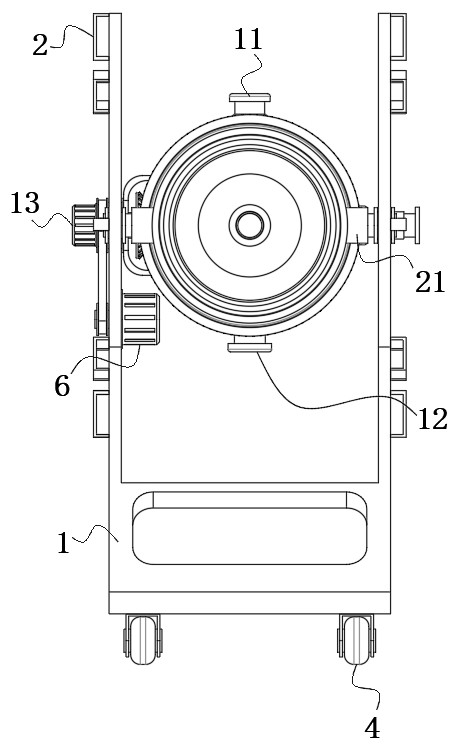

Mobile mortar production equipment for building and production method thereof

InactiveCN112025984AReduce resistanceImprove practicalityBuilding material handlingCement mixing apparatusElectric machineryStructural engineering

The invention discloses mobile mortar production equipment for a building and a production method thereof, relates to the technical field of mortar production equipment and aims at improving the stirring effect. The equipment comprises an agitator tank and a vehicle body, wherein a feed hopper is welded to the top of the agitator tank; the agitator tank is arranged on the outer wall of the top ofthe vehicle body through a mounting seat; and two symmetrical electric telescopic rods are fixed to the outer wall of the top of the agitator tank through screws. The application method of the equipment comprises the following steps of weighing mortar raw materials; adding the mortar raw materials into the agitator tank through the feed hopper; and controlling an agitator motor to work to rotatably stir the mortar. Through the arrangement of lifting frames, the electric telescopic rods and other structures, the electric telescopic rods can be used for driving the lifting frames to do verticalreciprocating motion, and a bowl-shaped seat ascends and descends along with the lifting frames; the resistance can be reduced due to the fact that the bottom of the bowl-shaped seat has radian; and the bowl-shaped seat is of a bowl-shaped structure and can drive bottom mortar to ascend during ascending, so that the special shape of the bowl-shaped seat is used for stirring the mortar.

Owner:武汉德创天成科技发展有限公司

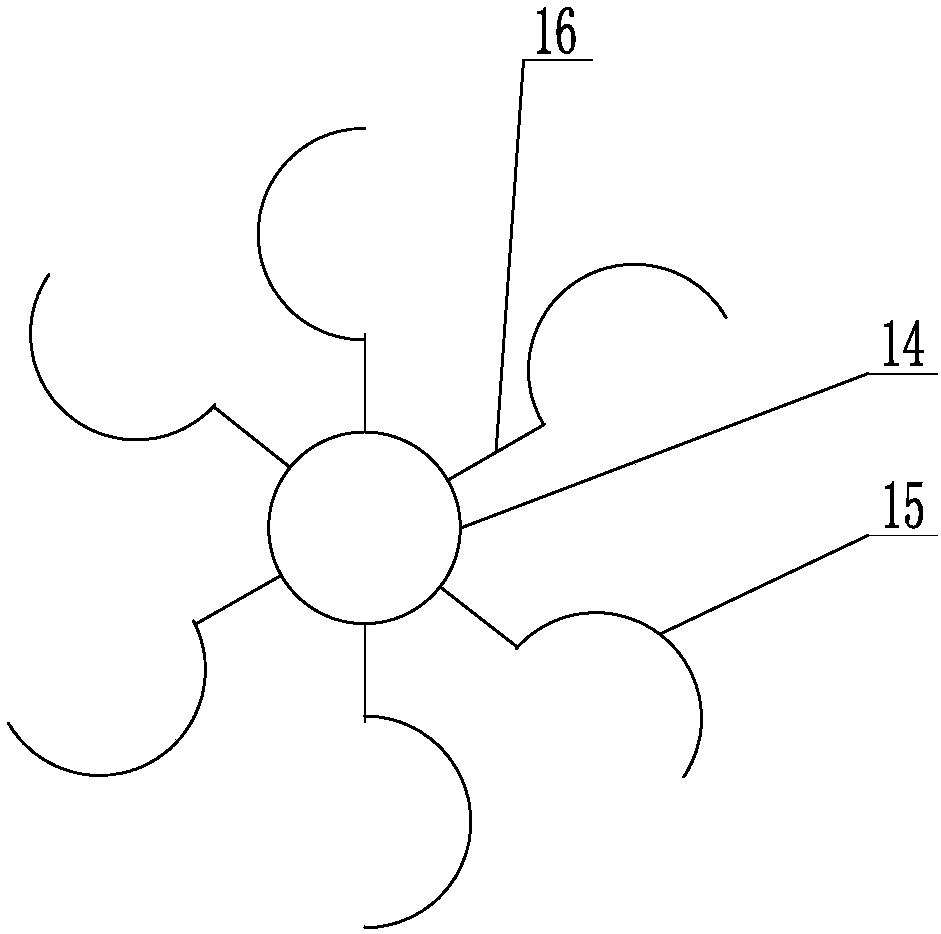

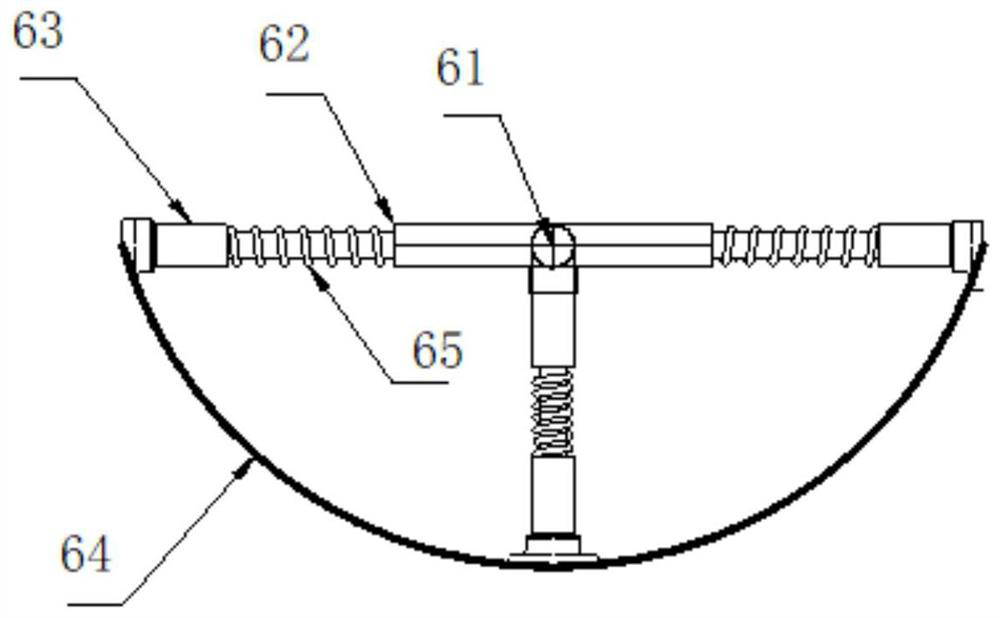

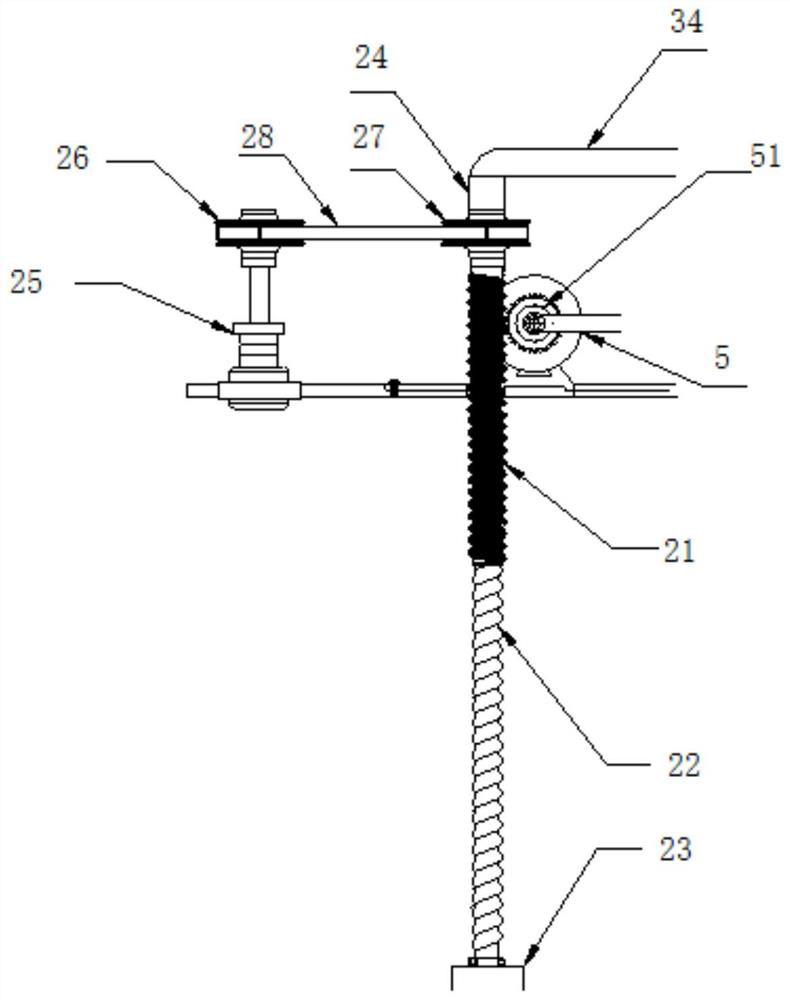

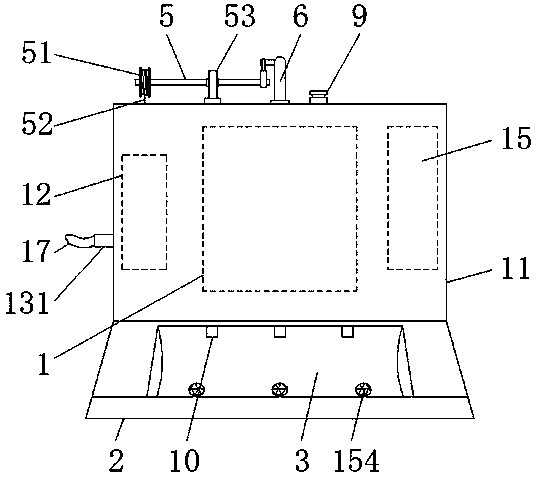

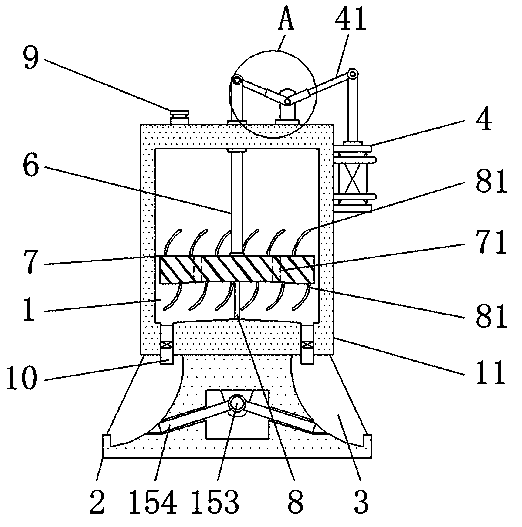

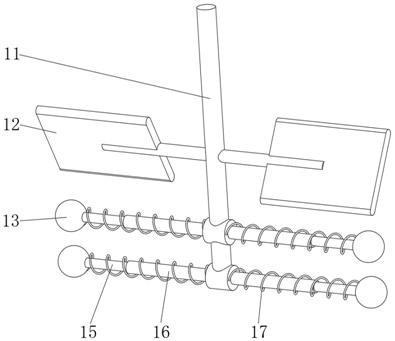

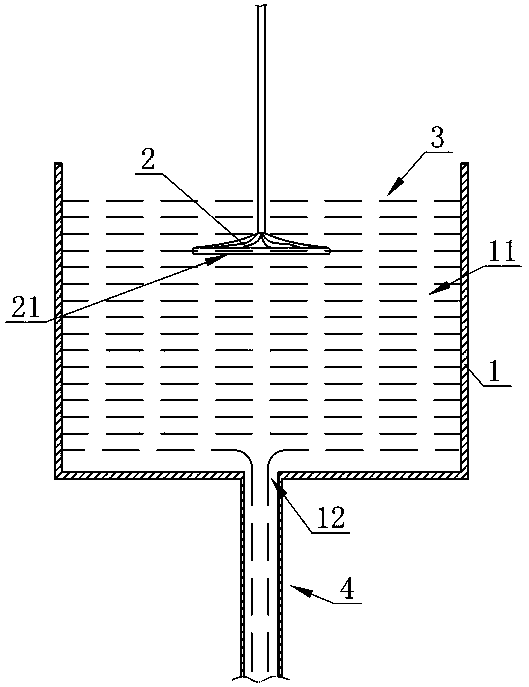

Simple unpowered stirring device

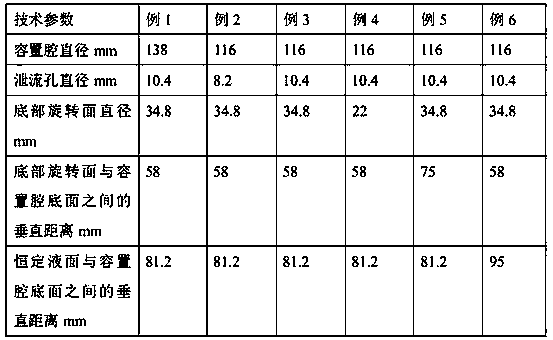

ActiveCN108786542APlay a stirring effectLow cost to manufacture and useTransportation and packagingRotary stirring mixersBiochemical engineeringVertical distance

The invention relates to the technical field of unpowered stirring devices, in particular to a simple unpowered stirring device. the bottom part of a bottling tank body is provided with a drainage hole which is communicated with a containing cavity; when the diameter of the containing cavity is L mm, the diameter of the drainage hole is 0.06L to 0.15L mm; a stirrer is provided with a bottom rotating surface; the diameter of the bottom rotating surface is 0.15L to 0.4L mm; the vertical distance between the bottom rotating surface and the bottom surface of the containing cavity is 0.25L to 0.6Lmm; vortex flow generated by the simple unpowered stirring device which is prepared according to a proportional value is just enough to propel the stirrer to rotate, and the rotating speed of the stirrer is inconsistent with that of the vortex flow, so that a stirring effect is realized. According to the simple unpowered stirring device disclosed by the invention, the proportional value and a related range value are obtained through long-term accumulated experience and experiments, a whole structure is realized, an unpowered stirring effect is simply completed, and the manufacturing and usingcost is reduced.

Owner:自驱力智能精密科技(广东)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com