Iron ore crushing device

A pulverizing device, iron ore technology, applied in mixers with rotary stirring devices, transportation and packaging, dissolving and other directions, can solve the problems of short service life, parts wear, poor pulverization effect, etc., to extend the residence time, prolong the Long service life and good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

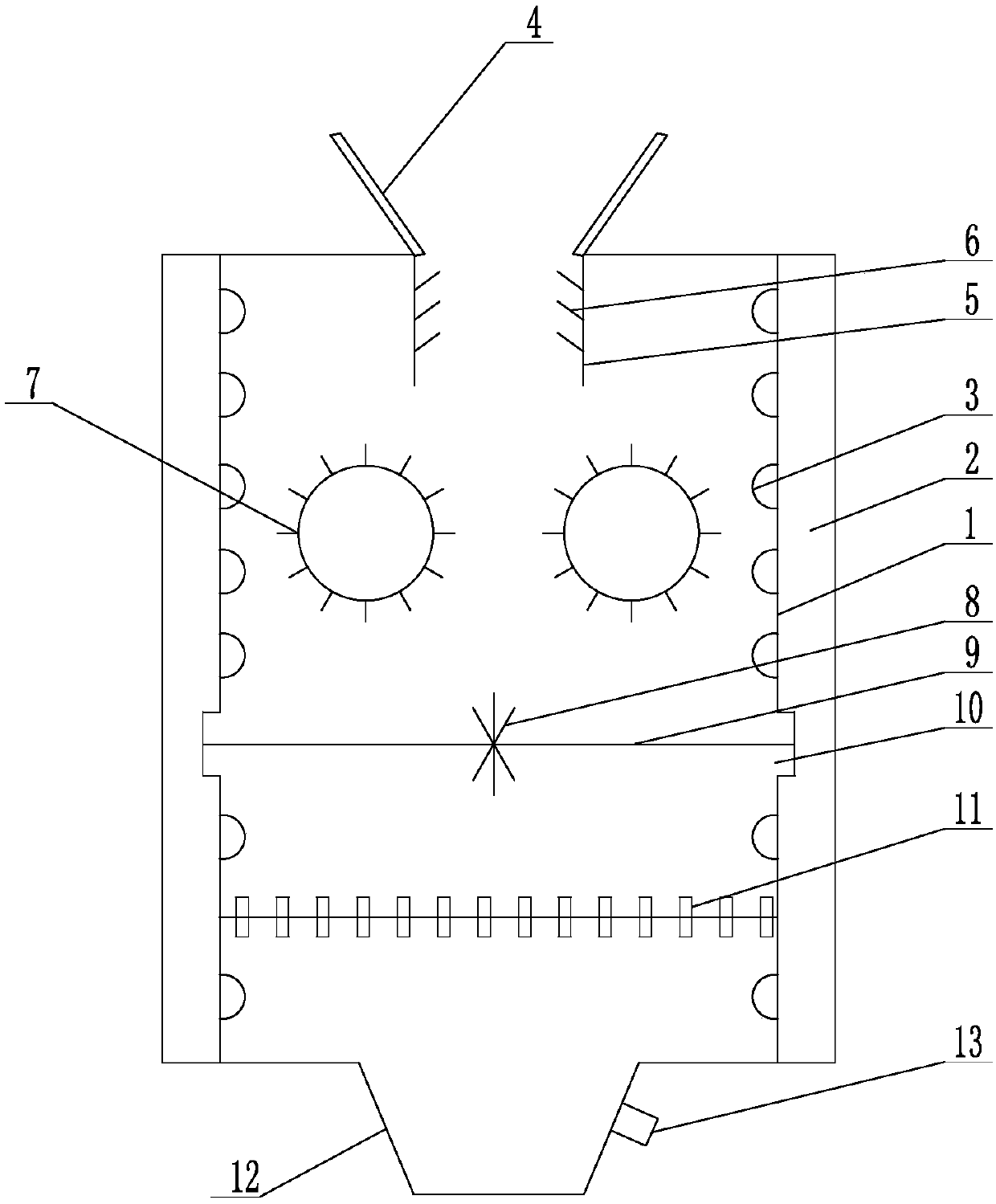

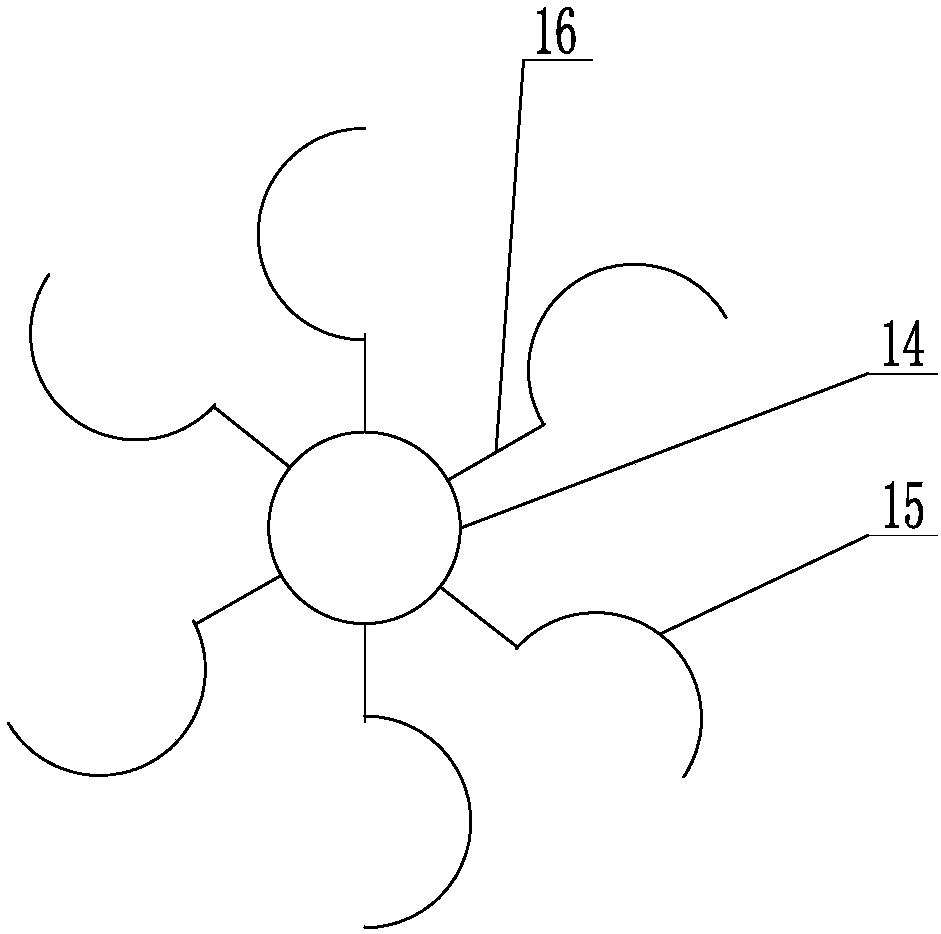

[0028] Such as Figure 1-2 As shown, the described iron ore crushing device includes a crushing box 1, a water jacket 2 is arranged on the outside of the crushing box 1, a protrusion 3 is provided on the inner wall of the crushing box 1, and a feed hopper 4 is fixed on the top of the crushing box 1, and the feeding The outlet of the bucket 4 is connected to the feeding chute 5, which is fixed on the inner surface of the upper plate of the crushing box 1, the inner cavity of the feeding chute 5 is provided with a baffle 6, and two rollers are symmetrically arranged inside the crushing box 1. Press the crushing wheel 7, the outlet of the feed chute 5 is located in the middle of the two crushing and crushing wheels 7, a stirring device 8 is arranged below the crushing and crushing wheel 7, and the stirring device 8 is connected to the rotating shaft 9 in rotation, and the rotating shaft 9 is fixed on the crushing wheel 7. In the groove 10 of the inner wall of the box 1, crushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com