Continuous countercurrent extraction desolventizing system and process

An extraction and countercurrent technology, which is applied to the continuous countercurrent extraction and desolvation system and process field, can solve the problems of unsatisfactory solvent penetration effect and inability to guarantee extraction effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

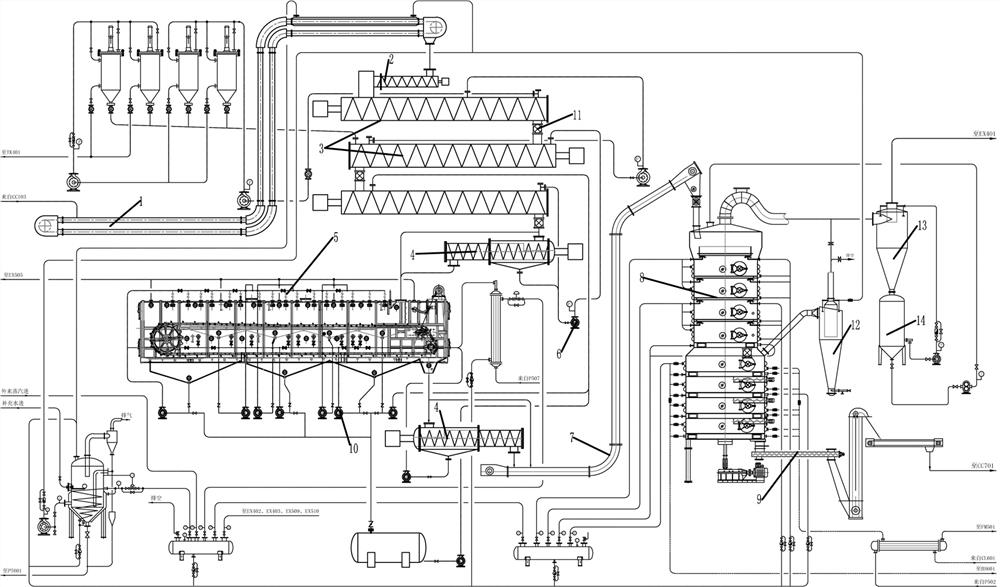

[0024] like figure 1 As shown, a continuous countercurrent extraction and desolvation system includes a raw material tank, a conveyor 1 connected to the raw material tank, a jacket is provided outside the conveyor 1, and a heat exchange medium is introduced into the jacket, and the conveyor 1 exits The feeder 2 connected to the feeder 2, the horizontal multistage countercurrent extractor 3 connected to the feeder 2, the horizontal multistage countercurrent extractor 3 is directly connected with the drag chain extractor 5 or through the extrusion separator 4. Divide the material into solid and liquid, the solid material is connected with the drag chain extractor 5, the liquid material is sent to the upper level horizontal extractor for cyclic extraction through the extraction liquid circulating pump 6, and the drag chain extractor 5 is provided with a solvent inlet, The solvent or the collected mixed liquid is set in the reverse direction of the material flow in the drag chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com