Drying device for chemical raw materials and medicine

A chemical raw material and drying device technology, applied in the direction of drying gas arrangement, drying solid material, drying room/container, etc., can solve the problems of easy accumulation of materials, short service life, insufficient drying, etc., achieve long service life, avoid Good effect of high temperature and accumulation, drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

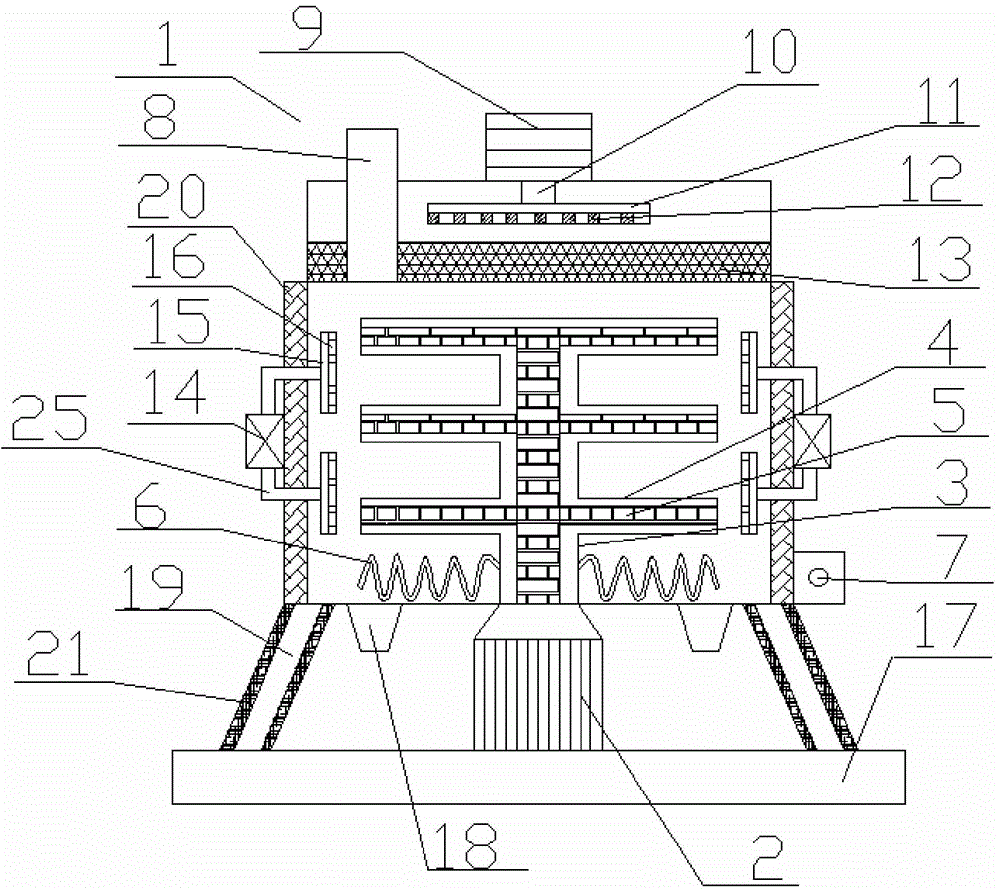

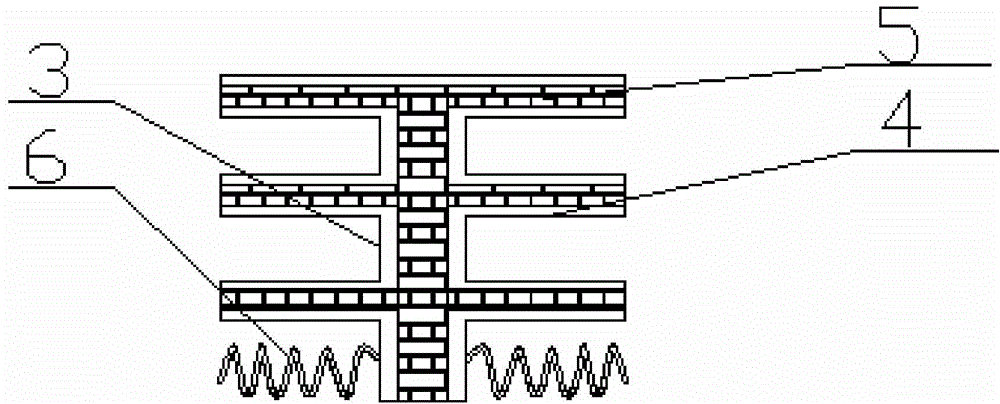

[0024] Such as Figure 1 to Figure 2 As shown, a drying device for chemical raw materials and medicine, it includes a body 1, the body 1 includes a frequency conversion motor 2, a base 17, a feed port 8 and a discharge port 18, the base 17 is set below the body 1 The frequency conversion motor 2 is arranged between the body 1 and the base 17; the output part of the frequency conversion motor 2 is connected to the stirring shaft 3; and the stirring shaft 3 extends into the body 1; Stirring wheel 4; the stirring shaft 3 and the horizontal stirring wheel 4 are both hollow structures; and electric heating tubes are arranged inside the horizontal stirring wheel 4 and the stirring shaft 3; a plurality of spiral scrapers are arranged on the upper surface of the circumference of the stirring shaft 3 plate 6; the feed inlet 8 is arranged on the top of the body 1; a hot air blower 9 is arranged above the body 1; the hot air blower 9 is connected to the air duct 11 provided in the body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com