Casting method for producing copper strip without oxygen or with low oxygen content

A technology of oxygen content and copper plate, which is applied in foundry workshops, casting equipment, manufacturing tools, etc., can solve the problems of copper liquid heat loss, oxygen absorption, serious surface slagging, and high oxygen content of products, so as to improve the yield and production The effect of cost reduction and shortening process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the invention:

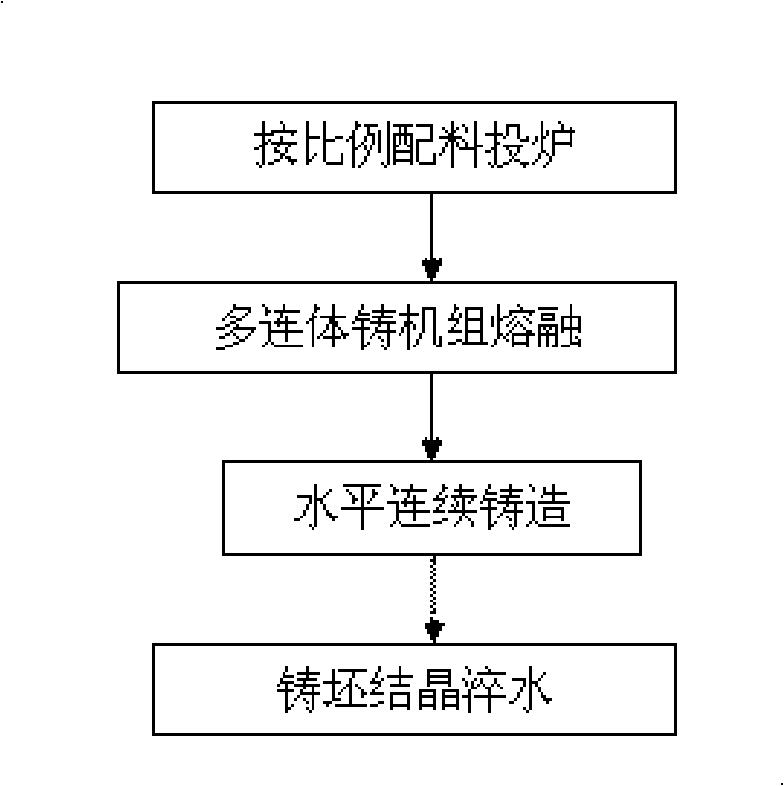

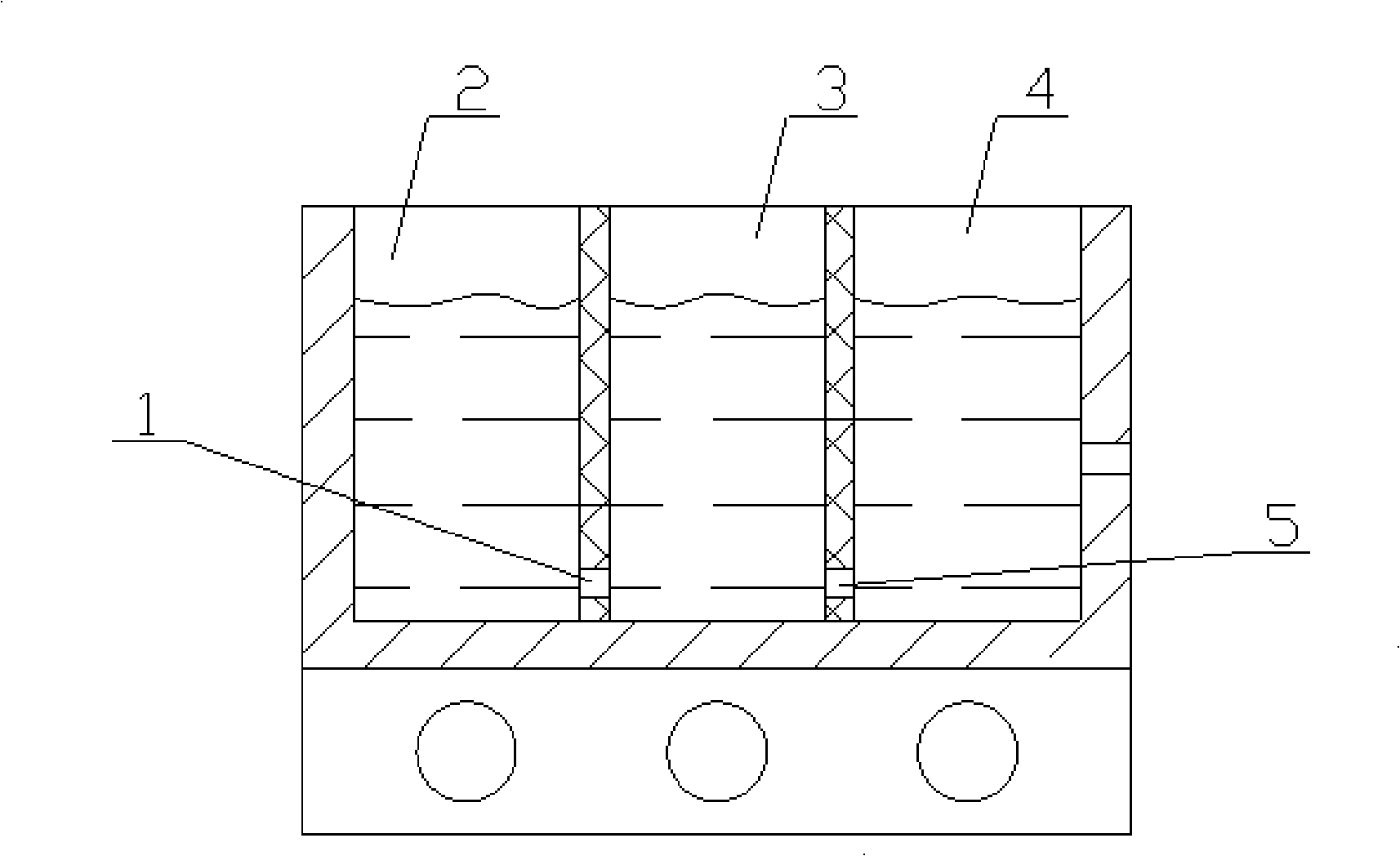

[0017] First of all, the ingredients are proportioned, and the raw materials are put into the melting furnace 2 of the multi-unit casting unit, and melted in a non-vacuum state. The temperature of the melting furnace 2 is controlled at 1200-1250 ° C, so that the copper liquid in the homogeneous furnace 3 is kept in a boiling state. , the holding furnace 4 temperature is controlled at 1160~1180 ℃. The homogeneous furnace 3 temperature is controlled at 1160~1190 ℃. Phosphorus needs to be supplemented in the holding furnace 4 during the production process so that the composition of the copper liquid meets the requirements. The melted copper flows to the homogenizing furnace 3 through the channel 1. Because the copper liquid in the homogenizing furnace 3 is in a boiling state, the copper liquid continues to churn, which has the effect of stirring, so the copper liquid stays in the homogenizing furnace 3 During this period of time, it is uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com