Multi-rotation-direction type building material processing system

A technology for processing systems and building materials, applied in clay preparation devices, chemical instruments and methods, cement mixing devices, etc., can solve the problems of easily existing mixing dead angles, reducing the mixing effect of the device, and low mixing speed, and reducing the mixing dead angle. Probability, increased flow rate and effect of flow, effect of increased mixing and stirring rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the examples.

[0036] The following examples are used to illustrate the present invention, but cannot be used to limit the protection scope of the present invention. The conditions in the embodiment can be further adjusted according to the specific conditions, and the simple improvement of the method of the present invention under the premise of the concept of the present invention belongs to the protection scope of the present invention.

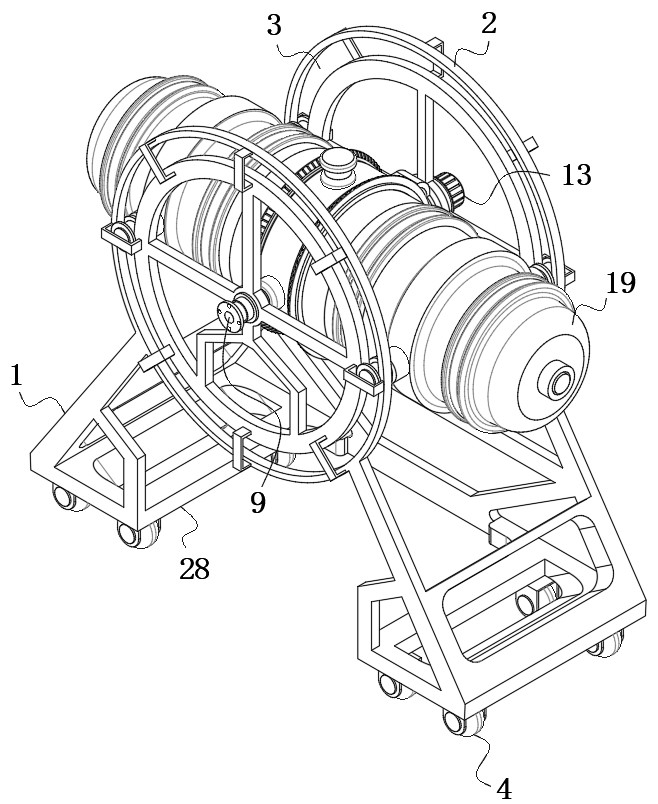

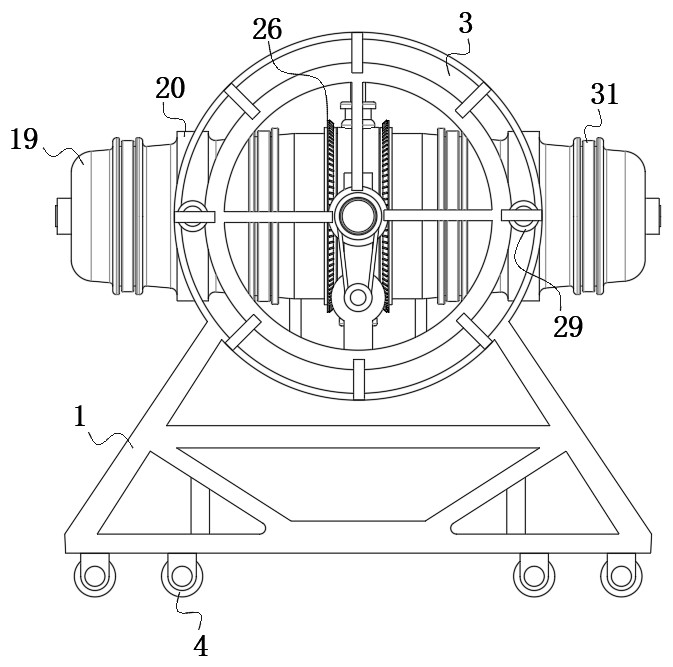

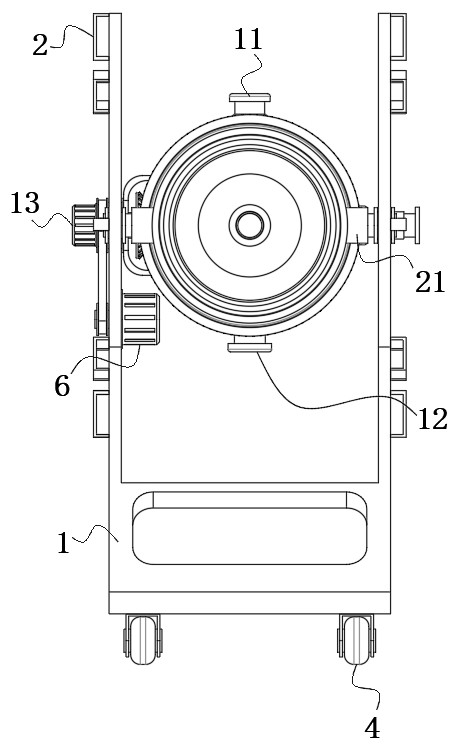

[0037] see Figure 1-8 , the present invention provides a multi-rotation building material processing system, comprising a base frame 1; the top surface of the base frame 1 is fixedly connected with two symmetrically arranged guide frames 2; the surfaces of the two guide frames 2 are provided with guide ring grooves 3; The opposite surfaces of the guide frame 2 are connected with a rotating mechanism 5 through bearing rotation; during work, the rotating mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com