Chemical barrel cleaning device for multistage driving type line body operation

A technology for cleaning devices and chemical barrels, applied in the chemical industry, can solve the problems of not necessarily having a drainage outlet, low operation efficiency, inconvenient sewage discharge, etc., and achieve the effect of convenient and effective overall operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

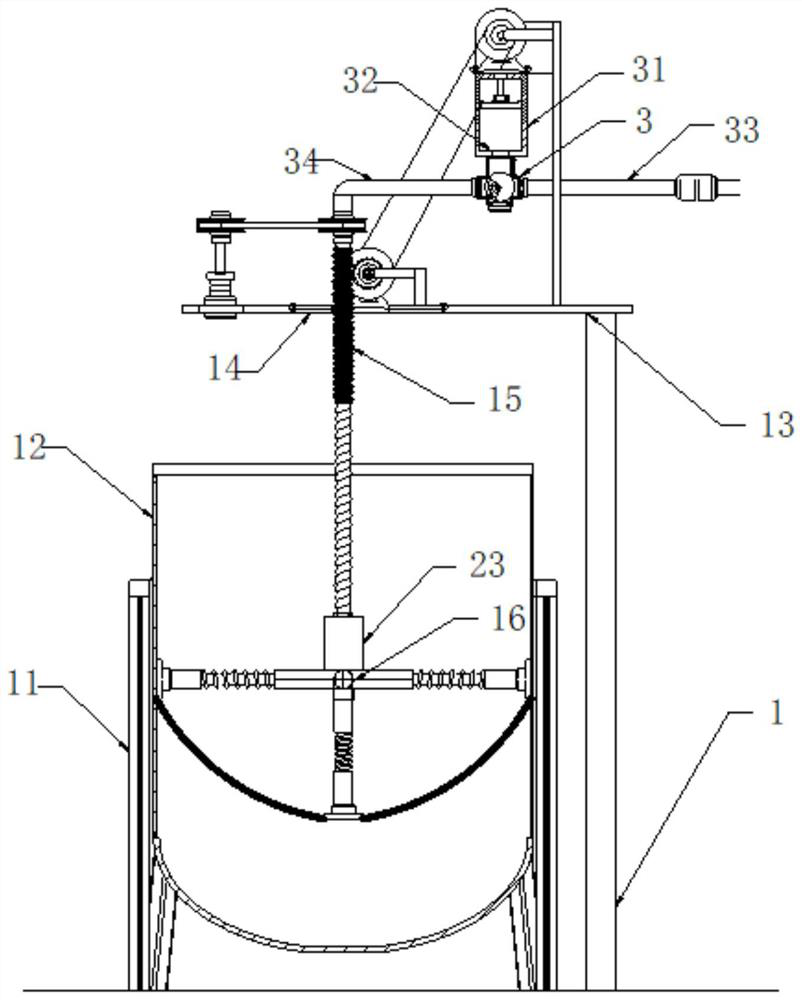

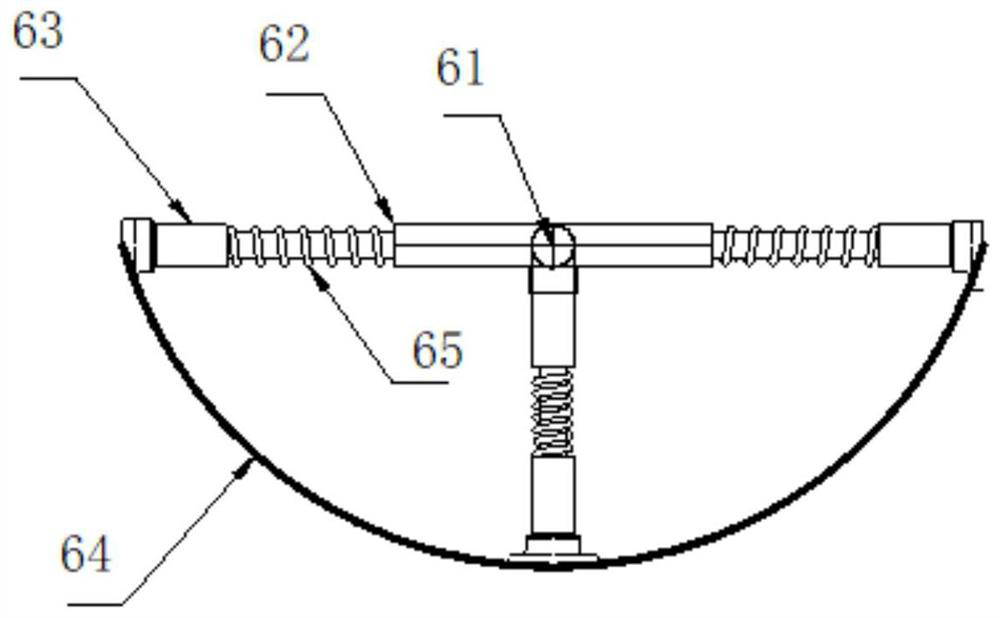

[0031] see figure 1 and figure 2 , a multi-stage drive-type linear operation chemical tank cleaning device, comprising an equipment frame 1, the equipment frame 1 is provided with a support frame 11, a chemical tank 12 is erected on the support frame 11, and the chemical tank 12 The top is provided with a driving frame 13, and the top of the driving frame 13 is provided with a mounting seat 14, and a cleaning rod 15 is installed in the mounting seat 14, and a cleaning frame 16 is provided at the bottom of the cleaning rod 15. The middle position of cleaning frame 16 is provided with trilateral support 61, and the trilateral branch of described trilateral support 61 is provided with branch rod 62, and the outer end of described branch rod 62 is all provided with cleaning head 63, and between described cleaning head 63 An arc-shaped soft cleaning cloth 64 is connected between them, and a spring telescopic rod 65 is arranged between the branch rod 62 and the cleaning head 63 . ...

Embodiment 2

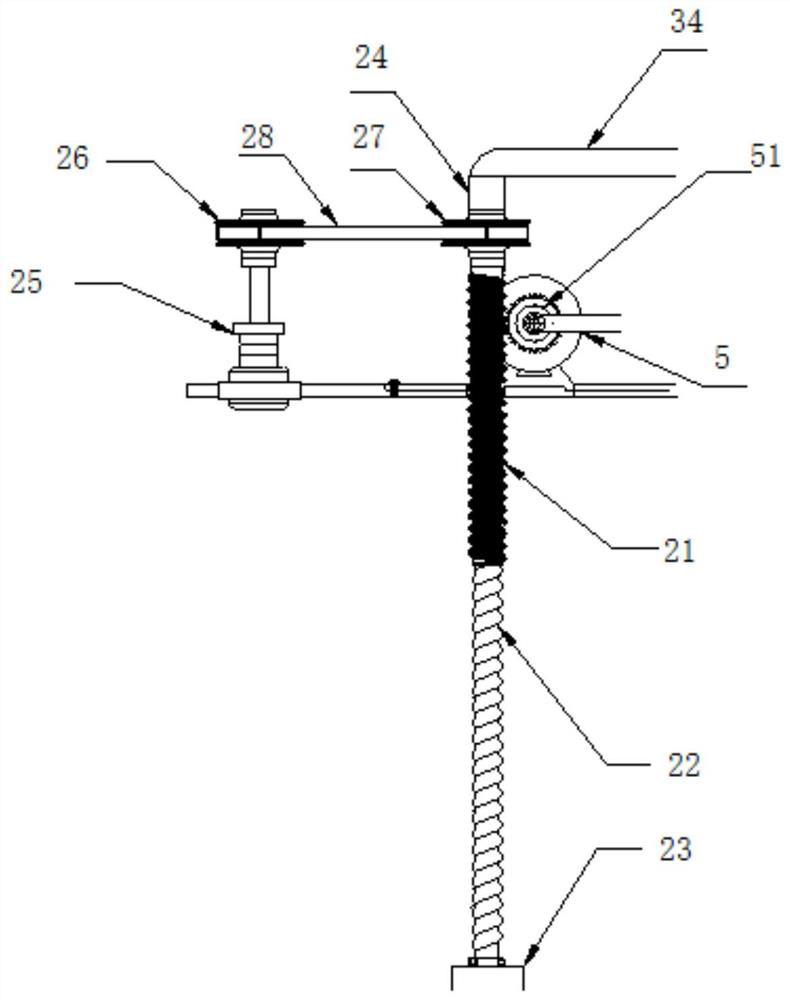

[0039] see figure 1 , image 3 and Figure 5 , in embodiment one, the working procedure of its pumping tube 31 and the working procedure of cleaning bar 15 are independent of each other, but in the present application, pumping tube 31 maintains the consistency of operation, can reach best working requirement; Therefore this implementation Example As a further optimization of the first embodiment, on the basis of it, the support frame 11 is provided with a transmission medium frame 5, and the transmission medium frame 5 is provided with a driven turbine 51, a medium turntable 52 and a secondary driven wheel 53 ; The driven turbine 51 is engaged with the external thread of the external drive rod 21 for transmission, the driven turbine 51 and the medium turntable 52 are coaxially driven, and the medium turntable 52 and the secondary driven wheel 53 The media synchronous rollers 54 are connected by unloadable media synchronous rollers. The media synchronous rollers 54 are driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com