Segregation-prevention vertical sand silo

A technology of vertical sand silo and silo body is applied in the field of sand silo, which can solve the problems of affecting the quality of dry-mixed mortar, large drop between upper and lower, secondary separation, etc., and achieves the effects of simple structure, high reliability and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

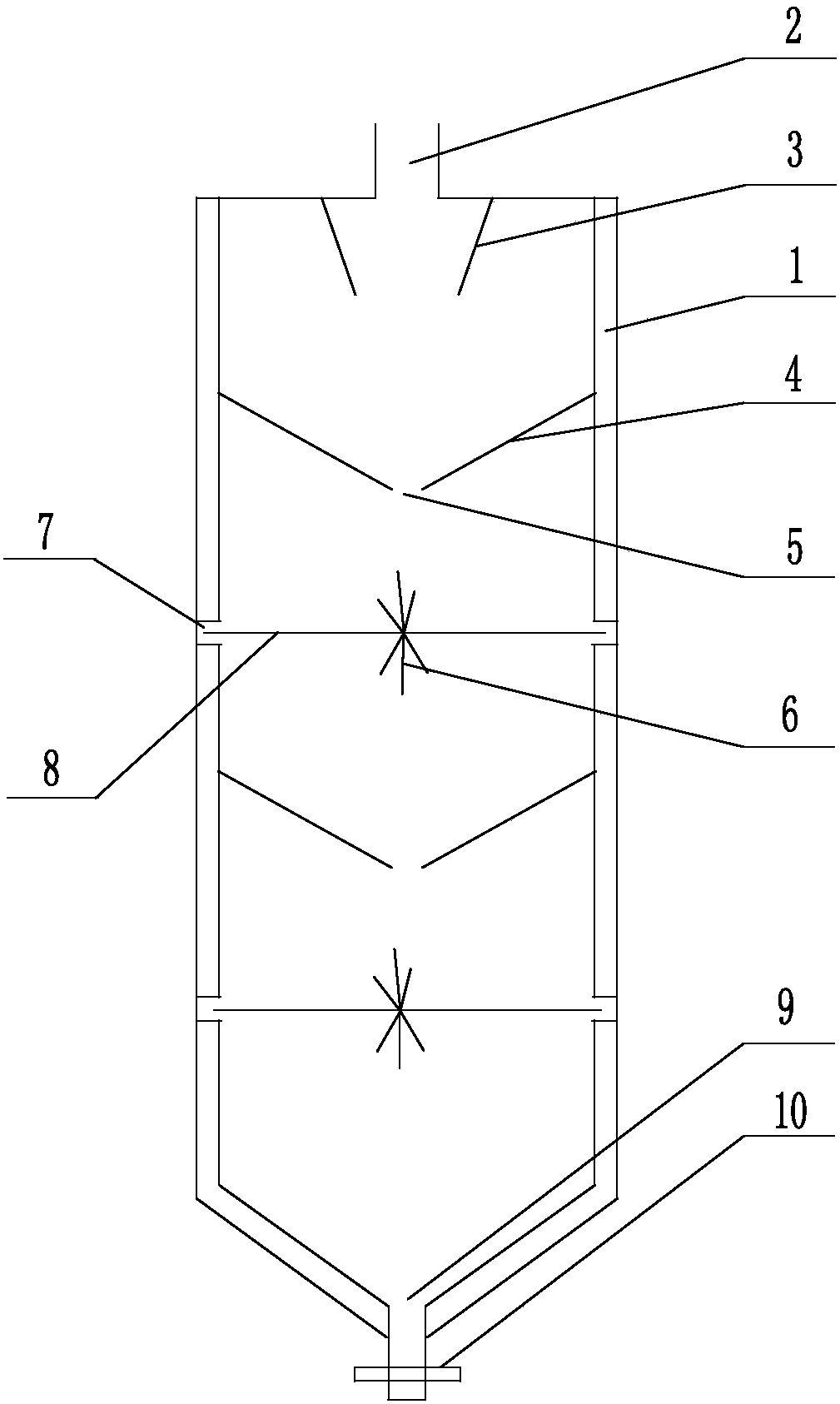

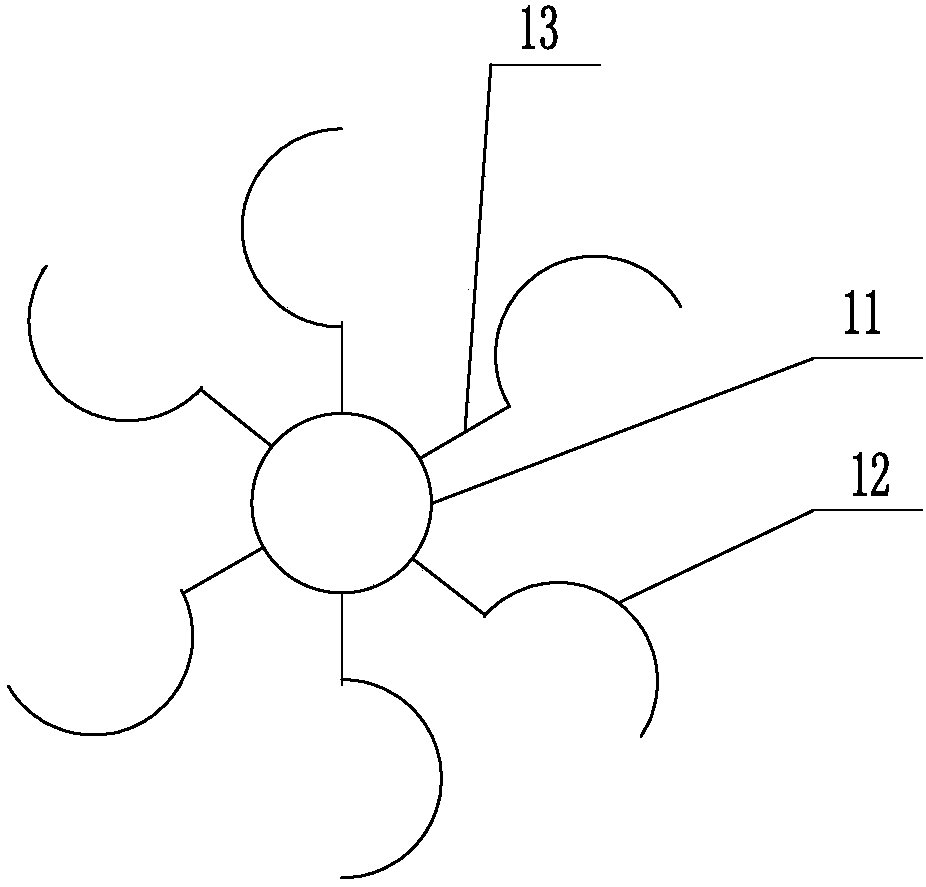

[0024] Such as Figure 1-2 As shown, the vertical sand bin for preventing segregation includes a bin body 1, and the bin body 1 mainly includes an upper cylinder body and a lower cone body, and the lower end of the cone body is provided with a sand outlet 9 for placing The lower part of the sand port 9 is provided with a sand release valve 10, and the center of the upper cover plate of the bin body 1 is fixed with a feed chute 2, and the outlet of the feed chute 2 is connected to the feed hopper 3, and the feed hopper 3 is fixed on the bin body 1 On the inner surface of the cover plate, a drain plate 4 is fixed on the inner side wall of the bin body 1, an opening 5 is arranged at the center of the drain plate 4, and a stirring device 6 is arranged at the lower end of the opening 5, and the stirring device 6 is rotatably connected to a rotating shaft 8, and the rotating shaft 8 It is fixed in the groove 7 of the inner side wall of the warehouse body 1.

[0025] The diversion p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com