Highway marking machine

A technology for marking machines and roads, which is applied in the direction of roads, roads, road repairs, etc. It can solve the problems of reducing the use effect of marking machines, poor pigment grinding and dispersion, and high density of pigments and fillers, achieving low pressure and small tension , the effect of high transmission power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

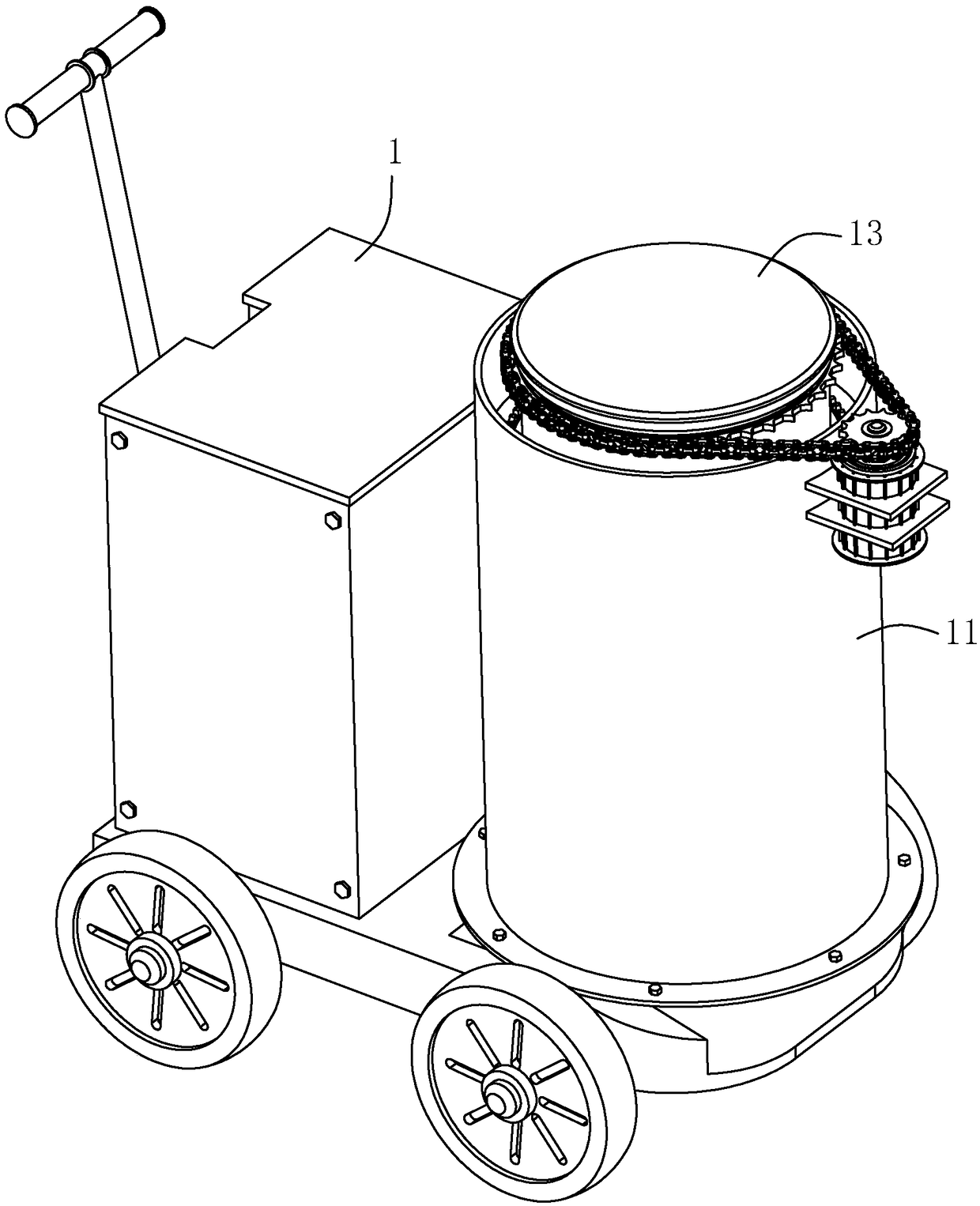

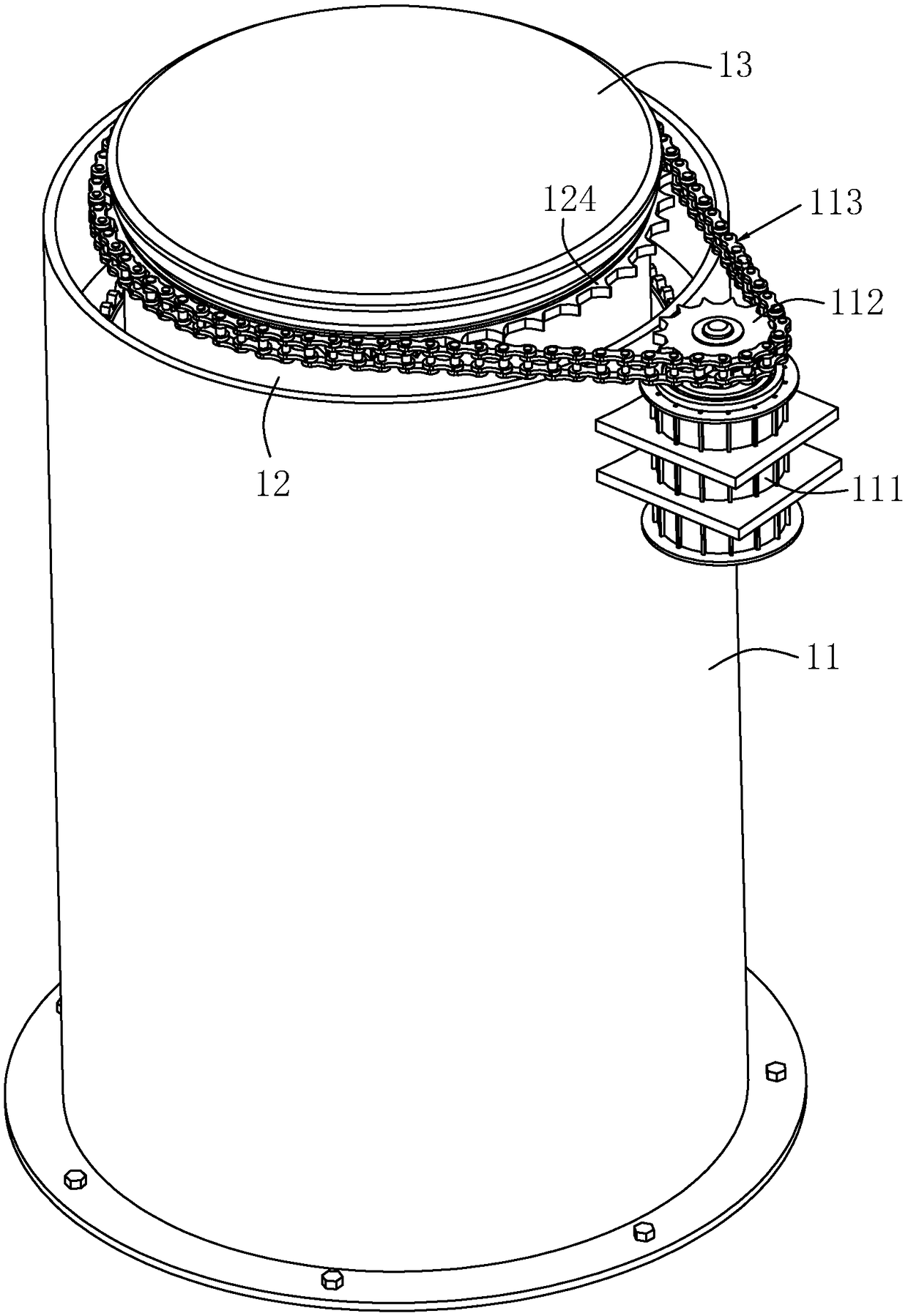

[0033] to combine figure 1 and figure 2 , is a road marking machine disclosed in the present invention, comprising a machine body 1 on which a hopper 11 is arranged.

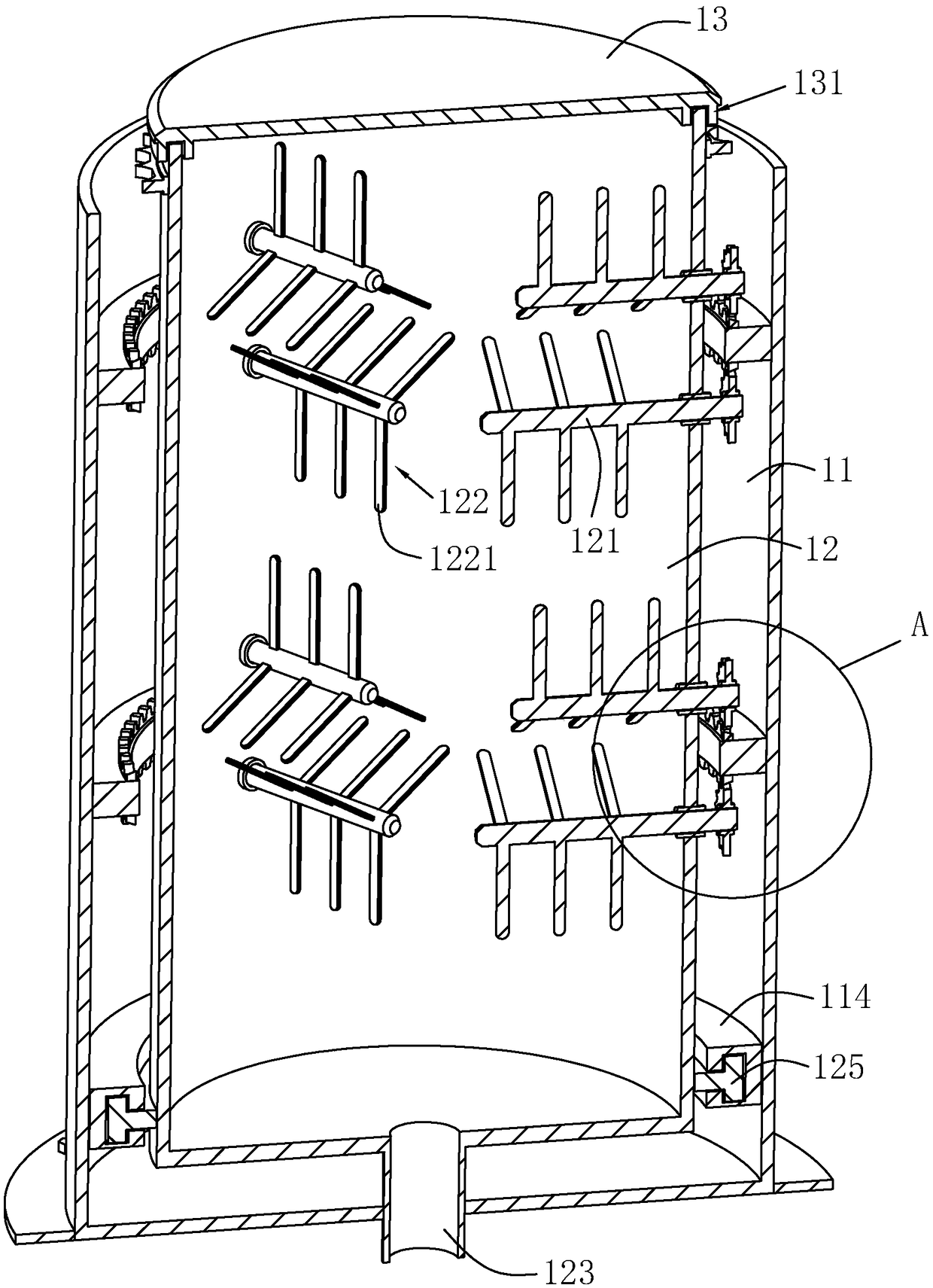

[0034] to combine figure 2 and image 3 A mixing bucket 12 is arranged coaxially with the hopper 11 in the hopper 11, a chute 114 is arranged on the inner wall of the hopper 11 along the inner wall of the hopper 11, and the chute 114 is located on the hopper 11 near the bottom wall of the hopper 11. A slider 125 slidably connected in the sliding groove 114 is provided on the top.

[0035] Such as image 3 As shown, in this embodiment, the cross section of the chute 114 is set in a "T" shape, and the slider 125 is arranged in cooperation with the "T"-shaped chute 114, and the "T"-shaped chute 114 and the slider 125 are paired The rotation of the mixing bucket 12 in the hopper 11 has a be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com