Compound phase-change cold accumulation material and preparation method thereof

A cold storage material and composite phase change technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve problems such as sudden drop in cold storage effect, damage to electronic devices, etc., achieve excellent cold preservation effect, convenient application, and good thawing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

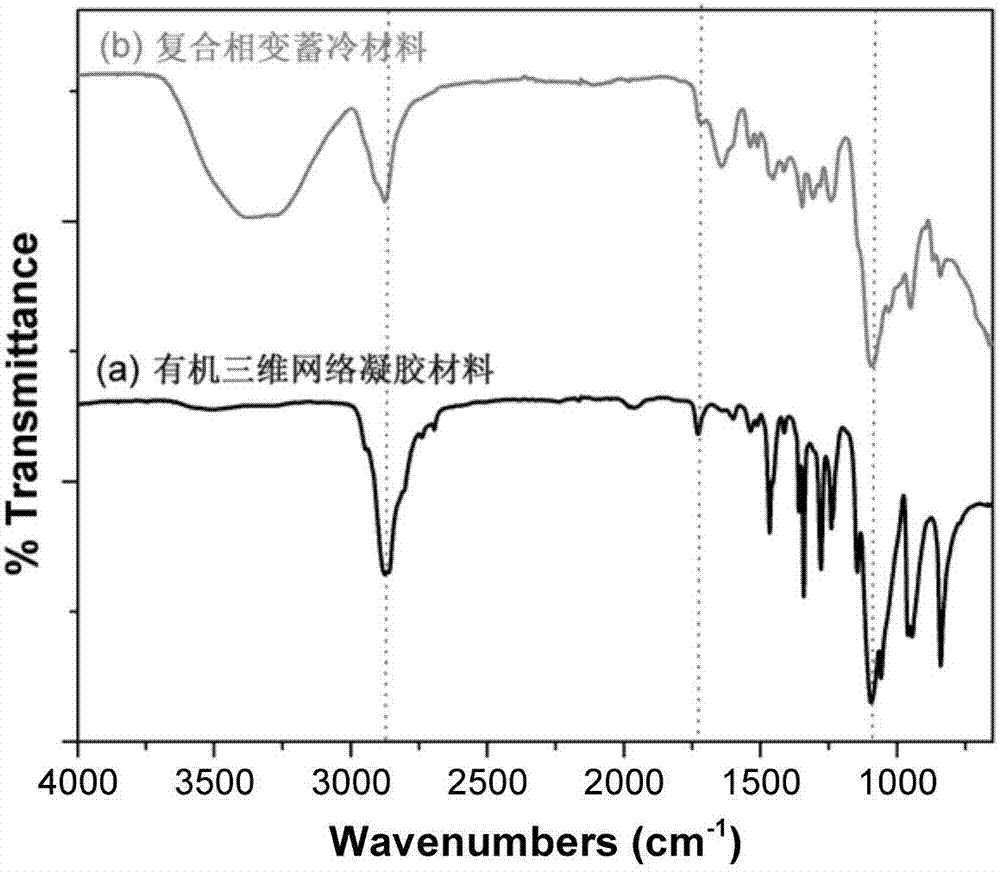

Image

Examples

Embodiment 1

[0031] (1) Take polyethylene glycol (Mn=10000) and toluene with a mass ratio of 1:10 and heat them in a constant temperature water bath at 80°C until the polyethylene glycol is completely dissolved;

[0032] (2) Add triphenylmethane triisocyanate and 3 drops of dibutyltin dilaurate catalyst to the above solution in a molar ratio of 2:3 to polyethylene glycol, stir magnetically for 6 hours, and cross-link at 90°C. Pour it into a tetrafluoroethylene mold when it is viscous, and continue to cross-link at 90°C to form an organic three-dimensional network gel material containing toluene;

[0033] (3) Place the organic three-dimensional network gel material containing toluene in a sufficient amount of ethanol, sonicate for 2 hours, replace fresh ethanol and continue to sonicate twice, each time for 2 hours; then place the material in a sufficient amount of water, sonicate for 2 hours, After replacing fresh water, continue to sonicate twice, each time for 2 hours, to make the water a...

Embodiment 2-4

[0038] Change the mass ratio of polyethylene glycol (Mn=10000) to toluene to 1:5, 1:7, and 1:9 respectively to obtain the corresponding phase change cold storage gel material, and other conditions are consistent with Example 1. The measurement results show that the phase change enthalpy of the prepared phase change cold storage gel material reaches 250J / g.

Embodiment 5-6

[0040] N,N-dimethyl sulfoxide and ethylene glycol were used as low-temperature phase change materials to obtain corresponding phase change cold storage gel materials, and other conditions were consistent with those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com