Preparation method of polyurethane solid-solid phase-change material with high enthalpy of phase change

A technology of phase change materials and polyurethane, which is applied in the field of phase change energy storage materials and its preparation, can solve the problems of long preparation process, difficulty in obtaining raw materials, and restrictions on the promotion and application of polyurethane solid-solid phase change materials, and achieves a simple and convenient preparation method Easy-to-control, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The one-step preparation method of the polyurethane solid-solid phase change material of high phase change enthalpy of the present invention, comprises the steps of following order successively:

[0044] (1) Vacuumize polyol I and polyol II at a temperature of 120°C to 140°C for 2h to 4h, so that the moisture content in the raw material is lower than 0.02%, and cool the raw material to 60°C to 100°C;

[0045] (2) Mix polyol Ⅰ and polyol Ⅱ evenly in proportion to remove air bubbles;

[0046] (3) Add diisocyanate to the mixture of polyol I and polyol II obtained in step (2), and stir for 1min~5min at a stirring speed of 500rpm~2500rpm;

[0047] (4) Add a catalyst to the material obtained in step (3), and stir for 10s~300s at a stirring speed of 500rpm~2500rpm;

[0048] (5) removing air bubbles in the material obtained in step (4);

[0049] (6) Pour the material obtained in step (5) into a mold at a temperature of 40°C~80°C, then place the mold in an oven at 80°C~120°C f...

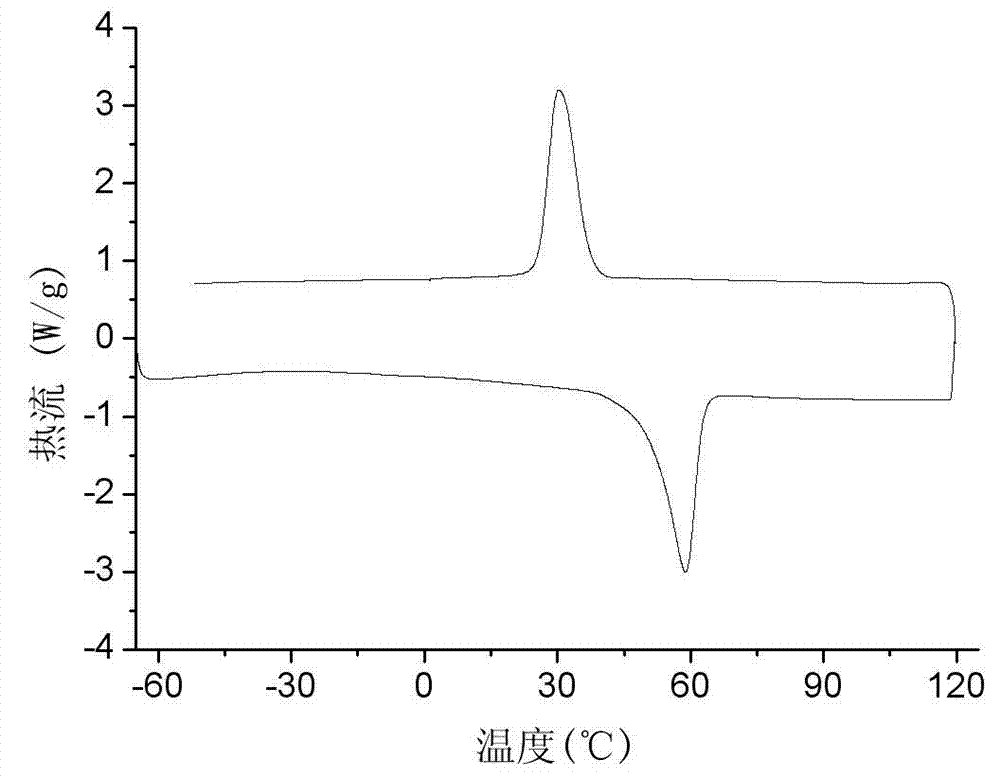

Embodiment 1

[0058] The polyol I used in the formula is polyethylene glycol with a relative molecular mass of 6000, the polyol II is polyhexamethylene adipate polyol with a relative molecular mass of 3000, and the diisocyanate used is polyol-modified diphenyl methyl methane diisocyanate. When preparing the material, polyethylene glycol with a relative molecular mass of 6000 and polyhexamethylene adipate polyol with a relative molecular mass of 3000 were heated and melted, and then placed in a vacuum oven at 140°C for 4 hours of vacuum treatment. Cool to 80°C and set aside. Add 82.8 parts of polyethylene glycol and 11.2 parts of polyhexamethylene adipate polyol into the reaction kettle and mix evenly, remove air bubbles, and control the temperature of the reactant at 80°C; add 5.9 parts of polyol to the above mixture to modify Diphenylmethane diisocyanate, stirred at a stirring rate of 1500rpm for 5min, then added 0.1 part of dibutyltin dilaurate, stirred for 15s, removed the air bubbles i...

Embodiment 2

[0063] Others of this embodiment are the same as Example 1, except that the consumption of polyethylene glycol is 74.9 parts, the consumption of polyhexamethylene adipate polyol is 18.7 parts, polyol modified diphenylmethane diisocyanate The dosage is 6.3 parts.

[0064] The melting peak temperature of the prepared material is 56.9 ℃, the melting enthalpy is 96.2 J / g, the crystallization peak temperature is 35.0 ℃, and the crystallization enthalpy is 84.2 J / g. The phase transition process of the material is solid-solid phase transition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com