Nano thermal conductivity enhanced microcapsule composite phase change material and preparation method thereof

A technology of enhanced thermal conductivity and energy storage materials, applied in the direction of microcapsule preparations, heat exchange materials, microsphere preparation, etc., can solve the problems of low thermal conductivity, achieve broad application prospects, excellent thermal conductivity and stability, and improve energy The effect of using efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

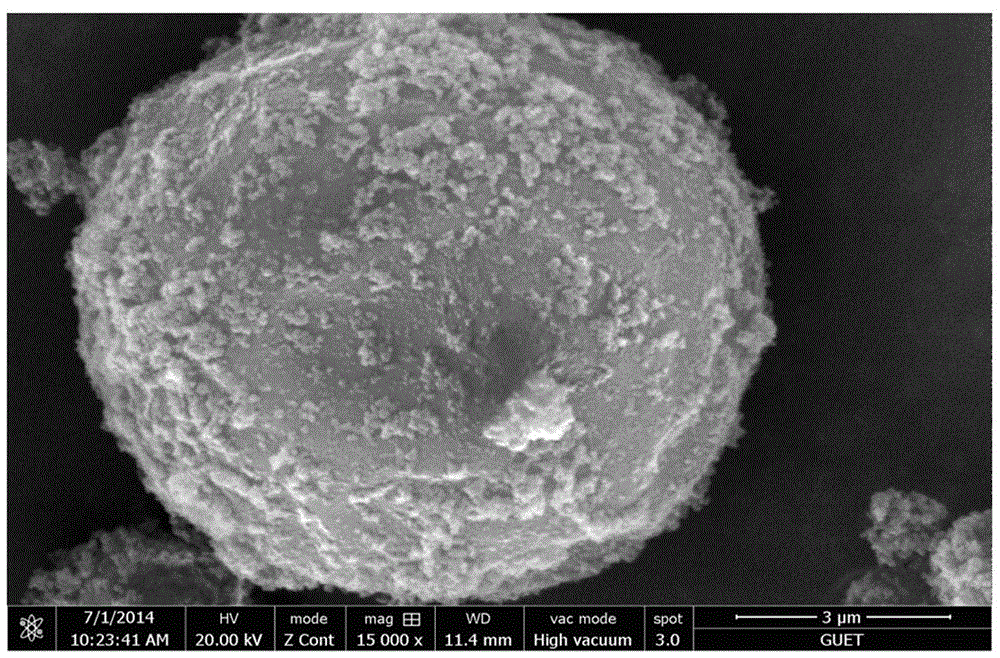

Image

Examples

Embodiment 1

[0038] Step 1, modification of BN

[0039] Weigh 3 g BN and add 50% sodium hydroxide solution, 70 o C, heated in a water bath for 2 h, and filtered with suction at 80 o C dry for 24 h.

[0040] Step 2, the emulsification process of organic phase change materials

[0041] Firstly, the BN nano thermal conductivity enhanced particles were mixed with the organic phase change material and ultrasonically dispersed for 30 min to form a uniform dispersion. Then this dispersion liquid is mixed with emulsifier, solvent, after 50 o C, stirring and emulsifying at 1200 rpm for 2 h to form a stable and uniform emulsion.

[0042] Step 3, adding BN nanometer heat conduction to enhance the preparation of particle wall material prepolymer

[0043] The modified BN nano heat conduction enhancing particles are ultrasonically dispersed and evenly mixed with the microcapsule wall material raw materials, and copolymerized under certain conditions to form a prepolymer.

[0044] Step 4, preparation...

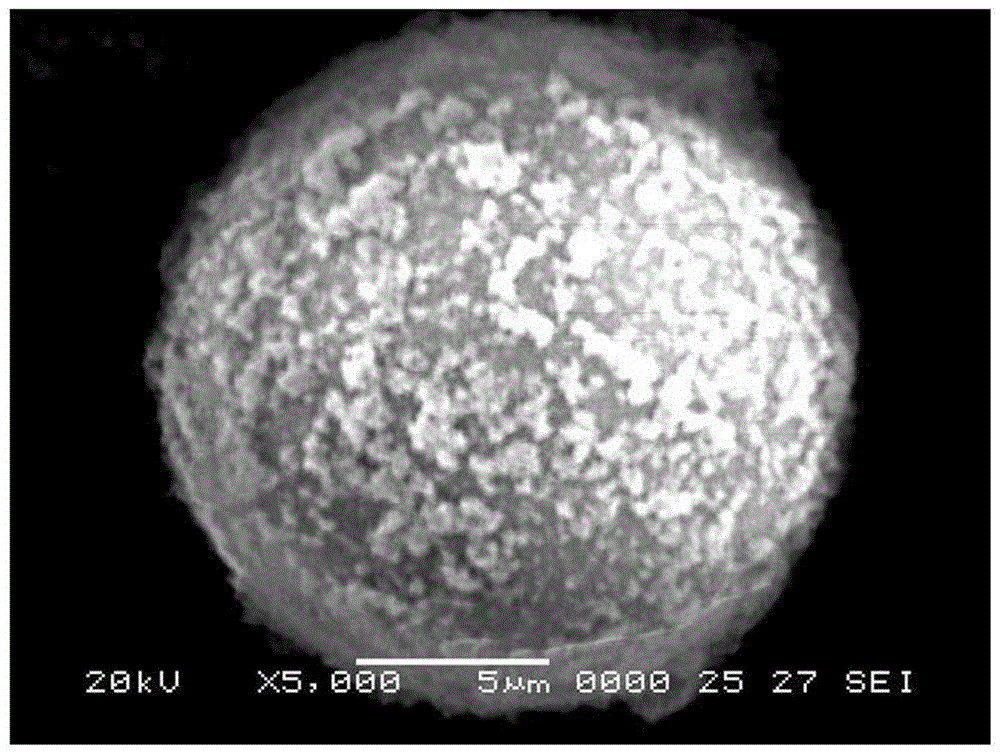

Embodiment 2

[0047] Step 1, modification of CNT

[0048] Weigh 1.2 g CNT, add 50 ml concentrated sulfuric acid, stir magnetically for 15 min, ultrasonicate for 1 h, then add 50 ml concentrated nitric acid, stir magnetically for 15 min, place at 140 o Reflux reaction in the oil bath of C for 2 h, after cooling, diluting, filtering, drying, grinding, ultrasonication for later use.

[0049] Step 2, the emulsification process of organic phase change materials

[0050] Firstly, the CNT nano thermal conductivity enhanced particles were mixed with the organic phase change material and ultrasonically dispersed for 30 min to form a uniform dispersion. Then this dispersion liquid is mixed with emulsifier, solvent, after 50 o C, stirring and emulsifying at 1200 rpm for 2 h to form a stable and uniform emulsion.

[0051] Step 3, adding CNT nano thermal conductivity to enhance the preparation of particle wall material prepolymer

[0052] The modified CNT nano heat conduction enhancing particles are...

Embodiment 3

[0056] Step 1, Preparation of GO

[0057] Weigh 3 g of graphite and 18 g of potassium permanganate and mix, add 360ml / 40ml of concentrated sulfuric acid / concentrated phosphoric acid mixed solution, stir at 50°C for 12 hours, then cool to room temperature. Add 400 ml of ice and 3 ml of 30% hydrogen peroxide solution, the color of the solution turns bright yellow. Wash with 5% hydrochloric acid and deionized water three times until the solution is neutral. The resulting solution was dried at 80°C, ground, and ultrasonicated for 1 hour to finally obtain graphene oxide.

[0058] Step 2, the emulsification process of organic phase change materials

[0059] First, the GR nano thermal conductivity enhanced particles were mixed with the organic phase change material and ultrasonically dispersed for 30 min to form a uniform dispersion. Then this dispersion liquid is mixed with emulsifier, solvent, after 50 o C, stirring and emulsifying at 1200 rpm for 2 h to form a stable and unifo...

PUM

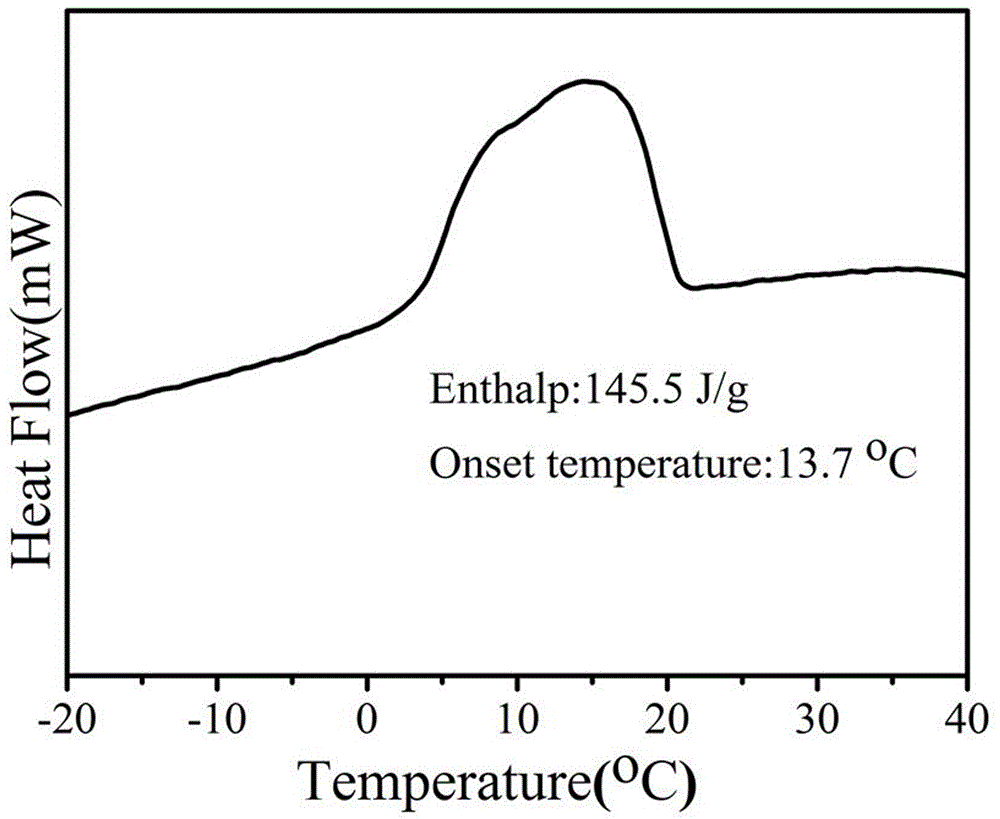

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com