Energy-accumulating temp-controlled thermoplastic cross-link high-molecular composite material with solid-solid phase change and its preparing process

A composite material and phase change energy storage technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve problems such as difficulty in making various complex shapes, large investment in equipment, pollution, etc., and achieve good thermal stability, The effect of high energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020]With 1000 grams of high-density polyethylene (HDPE, 2200J, melt index: 7), 15 grams of vinyltrimethoxysilane (A171, U.S. Oskar product), 0.08 gram of dicumyl peroxide (DCP, industrial product) , and 4 grams of antioxidant 1010 were uniformly mixed and melt-grafted in a screw extruder, and the extrusion temperature was 220°C. The melt index of the grafted product was 1.8 and the gel content was zero. The grafted product was cut into pellets, soaked in an aqueous emulsion (80° C.) containing 0.05% dibutyltin dilaurate for 6 hours to obtain a cross-linked polyethylene with a gel content of 58.6%.

[0021] Vinyltrimethoxysilane (A171) in the above example was replaced by vinyltrimethoxyethoxysilane (A172), the melt index of the grafted product obtained was 0.6, and the gel content was 3.8%. The grafted product was cut into granules, soaked in an aqueous emulsion (80° C.) containing 0.05% dibutyltin dilaurate for 6 hours to obtain a cross-linked polyethylene with a gel conte...

Embodiment 2

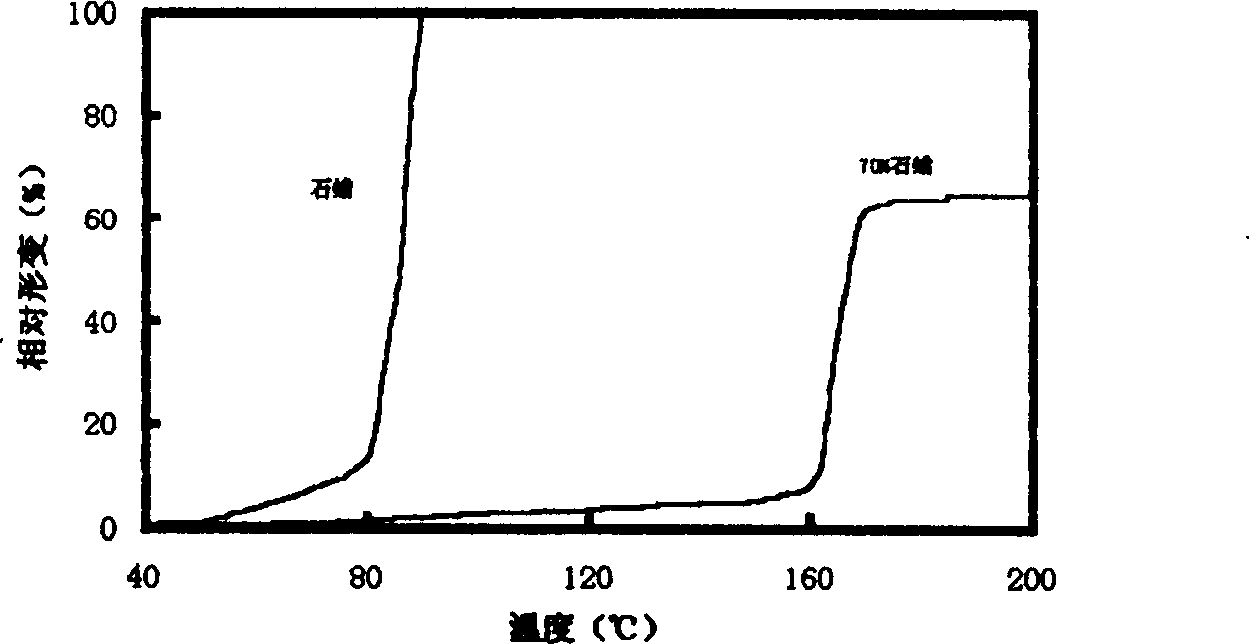

[0023] Add paraffin wax with a crystallization melting point of 80°C into a container with heating and stirring, and heat to 160°C. The grafted polyethylene (melt index 1.8) obtained in Example 1 was added into the container according to the ratio of 30:70 to the paraffin wax, and stirring was applied to completely dissolve the grafted silane polyethylene in the paraffin wax. After the viscous melt is cooled, it is hot-pressed into a 2.5 mm thick sheet, and soaked in a hot water emulsion (80°C) containing 0.05% dibutyltin dilaurate for 4 hours to obtain a cross-linked polyethylene / paraffin polymer Solid-solid phase transition materials. The phase transition temperature of the material is 80° C. (the melting temperature measured by differential scanning calorimeter is 81.5° C., and the crystallization temperature is 79.6° C.), and the phase transition enthalpy is 137 joules / g.

[0024] The cross-linked polyethylene / paraffin wax macromolecular solid-solid phase transition mater...

Embodiment 3

[0029] The grafted polyethylene obtained in Example 1 (melt index 1.8) was cut into pellets, soaked in an aqueous emulsion (80° C.) containing 0.1% dibutyltin dilaurate for 6 hours, and obtained a gel content of 58.6%. Cross-linked polyethylene pellets. Soak the cross-linked polyethylene pellets in paraffin wax at 160°C and a crystal melting point of 60°C for swelling. After swelling for 4 hours, separate the swollen particles from the hot paraffin with a filter, and then put the swollen body into a hot water washing and separating device Remove paraffin adsorbed on the surface. After drying, the cross-linked polyethylene / paraffin wax polymer solid-solid phase transition material is obtained. The material contains 80% paraffin and has a phase transition enthalpy of 141 Joules / gram. The phase transition temperature is 60°C (the melting temperature measured by a differential scanning calorimeter is 61.7°C, and the crystallization temperature is 59.3°C).

[0030] Another cross...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com