Preparation method of paraffin-SEBS thermoplastic elastomer composite phase change material

A composite phase change material, thermoplastic elastomer technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of complicated preparation process, complicated preparation method, low amount of paraffin incorporation, etc. The method is simple, the application value is broad, and the effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 20g of SEBS 6150, 20g of SEBS 6152, and 20g of SEBS 6154, and add them to 100g of melted RT10 phase-change paraffin respectively. After drying under conditions until the material has no paraffin leakage and reaches constant weight, it is cooled to room temperature to obtain RT10-SEBS6150 composite phase change material, RT10-SEBS6152 composite phase change material, and RT10-SEBS6154 composite phase change material.

Embodiment 2

[0025] Referring to Example 1, the difference is that the stirring temperature is 50°C, and the drying temperature is 60°C. Prepare RT28-SEBS6150, RT28-SEBS6152, RT28-SEBS6154 composite phase change materials, RT44-SEBS6150, RT44-SEBS6152, RT44-SEBS6154 composite phase change materials, No. 48 paraffin-SEBS6150, No. 48 paraffin-SEBS6152, No. 48 paraffin- SEBS6154 composite phase change material, others are identical with embodiment 1.

Embodiment 3

[0027] Referring to Example 1, the difference is that the stirring temperature is 70°C, and the drying temperature is 80°C. Prepare RT55-SEBS6150, RT55-SEBS6152, RT55-SEBS6154 composite phase change materials, RT58-SEBS6150, RT58-SEBS6152, RT58-SEBS6154 composite phase change materials, No. 52 paraffin-SEBS6150, No. 52 paraffin-SEBS6152, No. 52 paraffin- SEBS6154 composite phase change material, No. 58 paraffin-SEBS6150, No. 58 paraffin-SEBS6152, No. 58 paraffin-SEBS6154 composite phase change material.

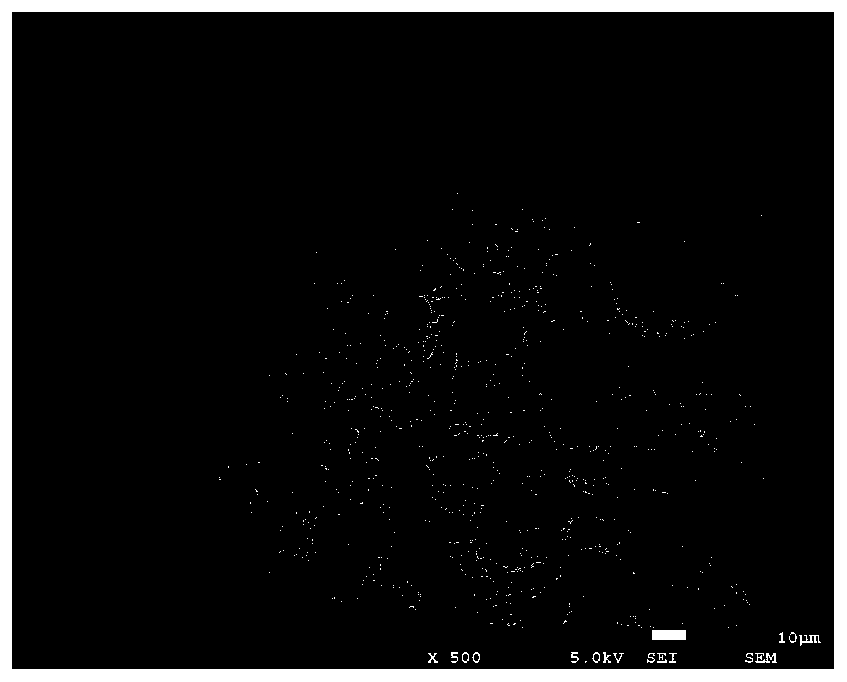

[0028] figure 1 Example 1 SEM images of SEBS6152 and RT10-SEBS6152 composite phase change materials of the composite phase change material.

[0029] figure 2 Performance data of the composite phase change materials of Examples 1-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com