Anti-crack concrete and preparation method thereof

A concrete and uniform mixing technology, which is applied in the field of concrete, can solve the problems of crack-resistant concrete limitations, achieve the effects of improving crack resistance, alkali resistance, and prolonging the time of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

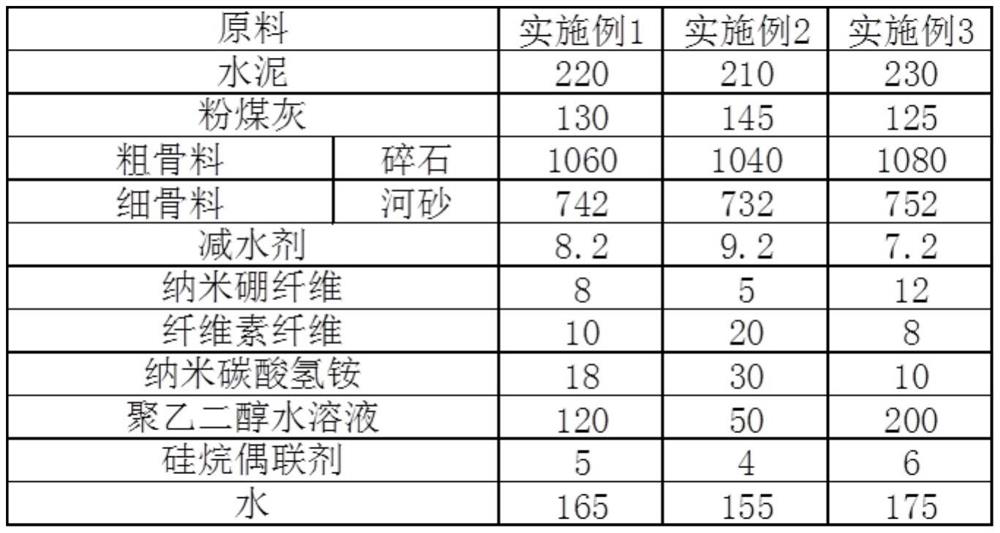

[0074] A kind of anti-crack concrete, its preparation method is as follows:

[0075] Add the silane coupling agent KH550 into the 15wt% polyethylene glycol aqueous solution according to the ratio in Table 1, stir evenly to obtain the soaking solution, then add the cellulose fiber into the soaking solution, soak for 1.5h, take it out, and dry it to obtain the pre-modified Sexual cellulose fibers;

[0076] Uniformly mixing pre-modified cellulose fibers, nano-boron fibers and nano-ammonium bicarbonate to obtain a mixture, and performing ball milling modification on the mixture, the ball milling speed is 450rad / min, and the ball milling time is 45min, to obtain modified fibers;

[0077] Mix cement and fly ash evenly to obtain cementitious material;

[0078] Coarse aggregate, fine aggregate and modified fiber are uniformly mixed to obtain aggregate; in this embodiment;

[0079] Mix the water reducer and water evenly to obtain the water reducer solution;

[0080] The cementitious...

Embodiment 2

[0085] A kind of anti-crack concrete, its preparation method is as follows:

[0086] Add the silane coupling agent KH560 into the 5wt% polyethylene glycol aqueous solution according to the ratio in Table 1, stir evenly to obtain the soaking solution, then add the cellulose fiber into the soaking solution, soak for 2 hours, take it out, and dry it to obtain the pre-modification Cellulose fibers;

[0087] Uniformly mixing pre-modified cellulose fibers, nano-boron fibers and nano-ammonium bicarbonate to obtain a mixture, and performing ball milling modification on the mixture, the ball milling speed is 320rad / min, and the ball milling time is 60min, to obtain modified fibers;

[0088] Mix cement and fly ash evenly to obtain cementitious material;

[0089] Coarse aggregate, fine aggregate and modified fiber are uniformly mixed to obtain aggregate; in this embodiment;

[0090] Mix the water reducer and water evenly to obtain the water reducer solution;

[0091] The cementitious ...

Embodiment 3

[0096] A kind of anti-crack concrete, its preparation method is as follows:

[0097] Add the silane coupling agent KH570 into the 25wt% polyethylene glycol aqueous solution according to the ratio in Table 1, stir evenly to obtain the soaking solution, then add the cellulose fiber into the soaking solution, soak for 1 hour, take it out, and dry it to obtain the pre-modification Cellulose fibers;

[0098] Uniformly mixing pre-modified cellulose fibers, nano-boron fibers and nano-ammonium bicarbonate to obtain a mixture, and performing ball milling modification on the mixture, the ball milling speed is 560rad / min, and the ball milling time is 30min, to obtain modified fibers;

[0099] Mix cement and fly ash evenly to obtain cementitious material;

[0100] Coarse aggregate, fine aggregate and modified fiber are uniformly mixed to obtain aggregate; in this embodiment;

[0101] Mix the water reducer and water evenly to obtain the water reducer solution;

[0102] The cementitious ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com