Rubber shock pad for motor, and preparation method of rubber shock pad

A technology for generators and shock-absorbing pads, applied in the rubber field, can solve the problems of large compression deformation and poor elasticity of shock-absorbing pads, and achieve the effects of excellent resilience, improved elasticity, and excellent oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

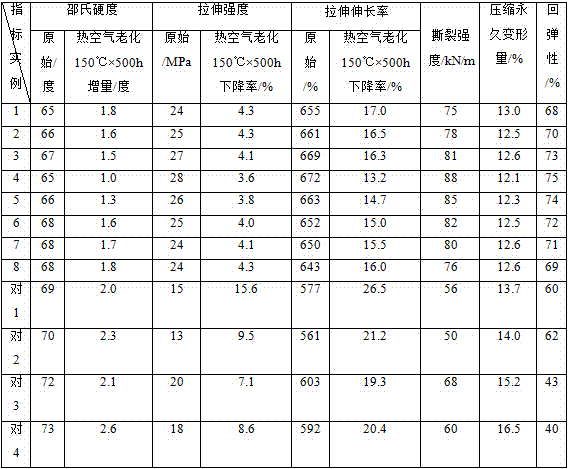

Examples

Embodiment 1

[0026] A generator rubber shock absorber, made of the following raw materials in parts by weight: 60 parts of natural rubber, 30 parts of EPDM rubber, 10 parts of tetrafluoroethylene-hexafluoropropylene copolymer, 5 parts of boron fiber, oxidized 5 parts of zinc, 1 part of stearic acid, 1 part of anti-aging agent RD, 1 part of anti-aging agent 4010NA, 10 parts of white carbon black, 10 parts of attapulgite, 30 parts of light calcium carbonate, 3 parts of chlorinated paraffin, liquid ancient horse 20 parts of Long, 1 part of bis-pentasulfurizing agent, 2 parts of silane coupling agent K550, 0.1 part of accelerator TBTD and 0.2 parts of accelerator M.

[0027] The preparation method of above-mentioned generator rubber damping pad, comprises the following steps:

[0028] (1) Evenly disperse boron fiber, white carbon black, attapulgite and light calcium carbonate in silane coupling agent K550 to form a mixed solution;

[0029] (2) Add natural rubber, EPDM rubber and tetrafluoroet...

Embodiment 2

[0033] A generator rubber shock absorber, made of the following raw materials in parts by weight: 62 parts of natural rubber, 28 parts of EPDM rubber, 12 parts of tetrafluoroethylene-hexafluoropropylene copolymer, 6 parts of boron fiber, oxidized 6 parts of zinc, 1.2 parts of stearic acid, 1.5 parts of anti-aging agent RD, 1.5 parts of anti-aging agent 4010NA, 11 parts of white carbon black, 11 parts of attapulgite, 35 parts of light calcium carbonate, 4 parts of chlorinated paraffin, liquid ancient horse 22 parts of Long, 1.5 parts of double pentasulfurizing agent, 3 parts of silane coupling agent K560, 0.3 parts of accelerator TBTD and 0.3 parts of accelerator M.

[0034]The preparation method of above-mentioned generator rubber damping pad, comprises the following steps:

[0035] (1) Evenly disperse boron fiber, white carbon black, attapulgite and light calcium carbonate in silane coupling agent K560 to form a mixed solution;

[0036] (2) Add natural rubber, EPDM rubber an...

Embodiment 3

[0040] A generator rubber shock absorber, made of the following raw materials in parts by weight: 63 parts of natural rubber, 20 parts of EPDM rubber, 10 parts of tetrafluoroethylene-hexafluoropropylene copolymer, 7 parts of boron fiber, oxidized 7 parts of zinc, 1.5 parts of stearic acid, 2 parts of anti-aging agent RD, 1.5 parts of anti-aging agent 4010NA, 12 parts of white carbon black, 12 parts of attapulgite, 36 parts of light calcium carbonate, 4 parts of chlorinated paraffin, liquid ancient horse 23 parts of Long, 1.5 parts of bis-pentasulfurizing agent, 4 parts of silane coupling agent Si69, 0.5 parts of accelerator TBTD and 0.3 parts of accelerator M.

[0041] The preparation method of above-mentioned generator rubber damping pad, comprises the following steps:

[0042] (1) Evenly disperse boron fiber, white carbon black, attapulgite, and light calcium carbonate in silane coupling agent Si69 to form a mixed solution;

[0043] (2) Add natural rubber, EPDM rubber and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com