Preparation method of silicon-nitrogen-boron continuous ceramic fibers

A ceramic fiber, silicon nitrogen boron technology, applied in the chemical characteristics of fibers, chemical post-processing of rayon, rayon of inorganic raw materials, etc., can solve the problems of high cost, complex process equipment environment requirements, etc., to achieve low equipment requirements, manufacturing The effect of low cost and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment includes the following steps:

[0038] (1) Nitriding decarburization: place the obtained infusible PCS fiber in a high-temperature atmosphere furnace, vacuumize and introduce nitrogen into it and repeat it three times. ℃, keep warm for 1h;

[0039] (2) Boronation treatment: evacuate to a furnace pressure of 30Pa, and then introduce a mixture of boron trichloride gas and nitrogen gas, in which BCl is added. 3 The gas volume concentration is 10%, the mixed gas flow rate is 30L / min, and after 3h, the pressure in the furnace is evacuated to 30Pa, then ammonia gas is introduced at 2L / min to quench the excess B-Cl bond, and the reaction is carried out for 1h;

[0040] (3) High temperature sintering: Stop feeding ammonia gas, feed nitrogen gas at a flow rate of 20L / min, continue to heat up to 1300°C at a heating rate of 100°C / hour, and keep heat for 2 hours to obtain silicon-nitrogen-boron continuous ceramic fibers.

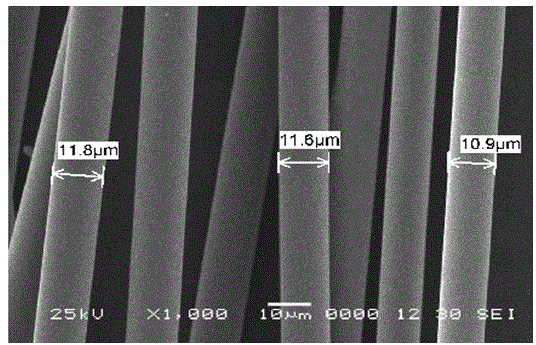

[0041] The diameter of the silicon nit...

Embodiment 2

[0043] This embodiment includes the following steps:

[0044] (1) Nitriding decarburization: place the obtained infusible PCS fiber in a high-temperature atmosphere furnace, and after vacuuming, introduce nitrogen and repeat three times, in a mixed gas atmosphere of ammonia and nitrogen, press 100 ℃ / The temperature was raised to 900 °C at a rate of 1 hour, and the nitriding decarburization was carried out, and the temperature was kept for 1 h;

[0045] In the mixture of ammonia and nitrogen, the ammonia volume concentration is 50%;

[0046] (2) Boronation treatment: vacuum until the pressure in the furnace is 28 Pa , and then pass into the mixture of boron trichloride and nitrogen, in the mixture, BCl 3 The gas volume concentration is 25%, the mixed gas flow is 20L / min, after 0.5h, vacuum again The pressure in the furnace is 30Pa , and then pass ammonia gas at 2L / min to quench the excess B-Cl bond, and react for 2h;

[0047] (3) High temperature sintering: stop feeding...

Embodiment 3

[0050] This embodiment includes the following steps:

[0051] (1) Nitriding decarburization: place the obtained infusible PCS fiber in a high-temperature atmosphere furnace, and after vacuuming, feeding nitrogen and repeating it three times, in a mixed atmosphere of ammonia and nitrogen, the temperature is 150℃ / hour. The rate of heating to 800 ℃, nitriding decarburization, holding for 2h;

[0052] In the mixture of ammonia and nitrogen, the ammonia volume concentration is 70%;

[0053] (2) Boronation treatment: vacuuming to The furnace pressure is 28Pa , and then pass into the mixture of boron trichloride and nitrogen, in the mixture, BCl 3 The gas volume concentration is 60%, the flow rate is 10L / min, and the vacuum is evacuated after 1h to furnace pressure 28Pa , then pass high-purity ammonia gas at 5L / min to quench the excess B-Cl bond, and react for 1h;

[0054] (3) High temperature sintering: stop feeding ammonia gas, feed nitrogen gas at a flow rate of 25L / min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com