Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

352results about How to "Increased interlaminar shear strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Emulsion type carbon fiber sizing agent and preparation method and application thereof

The invention discloses an emulsion type carbon fiber sizing agent, which comprises main size, an emulsifier, an aid and deionized water. The aid comprises a diluent and a penetrant, wherein the emulsifier is 5 to 15 mass percent of the main size, the diluent is 0 to 120 mass percent of the main size, the penetrant is 1 to 5 mass percent of the main size, and the mass ratio of the deionized water to the main size is 50-90:10-50. The invention also discloses a preparation method and application of the sizing agent. The sizing agent is suitable for unsaturated polyester resin and solves the problem of poor adhesion of the unsaturated polyester resin and the carbon fiber. After the sizing agent is used for sizing, the wear resistance of the carbon fiber is improved, and the broken filament amount is reduced, the post-processing performance of the fiber is improved, the interface adhesion of the carbon fiber and matrix resin is better, the shear strength between layers is improved, and the performance of composite materials is also improved.

Owner:UNIV OF JINAN

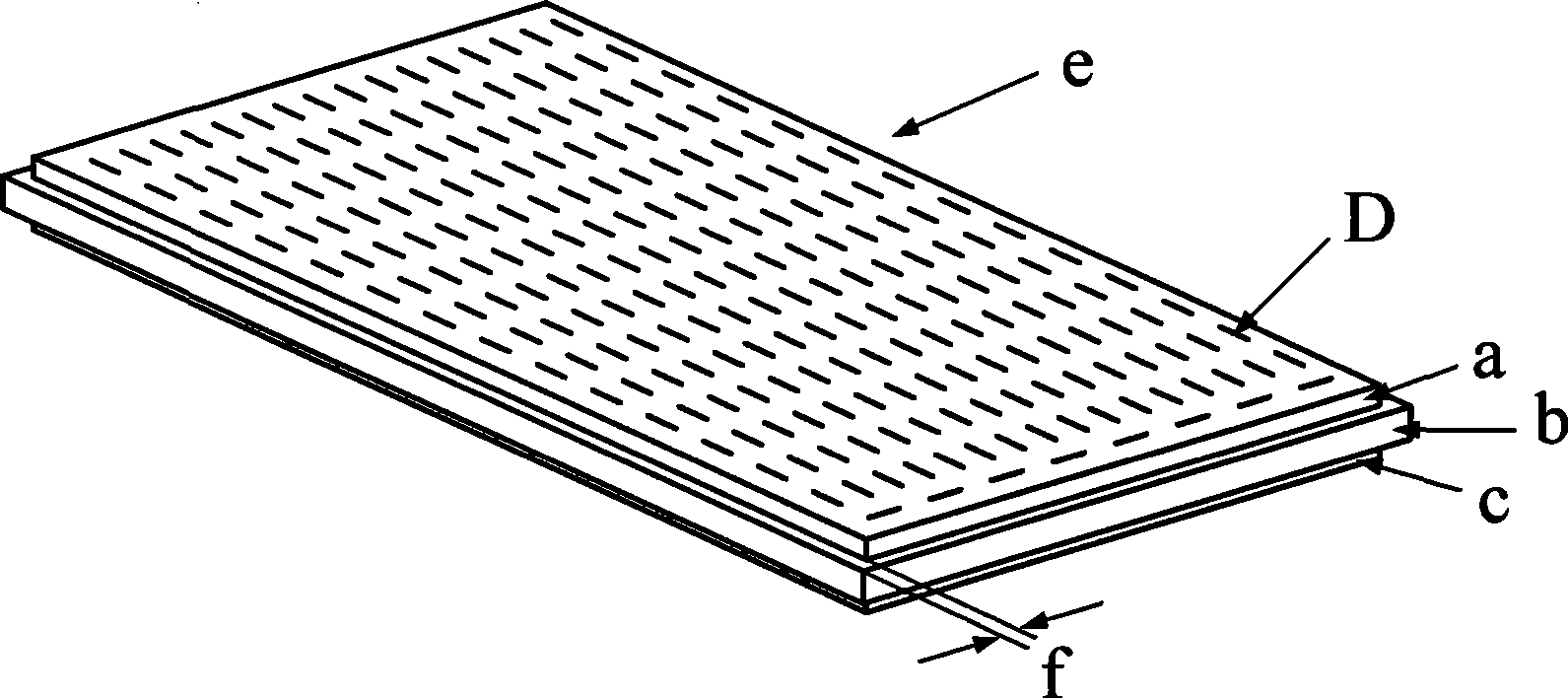

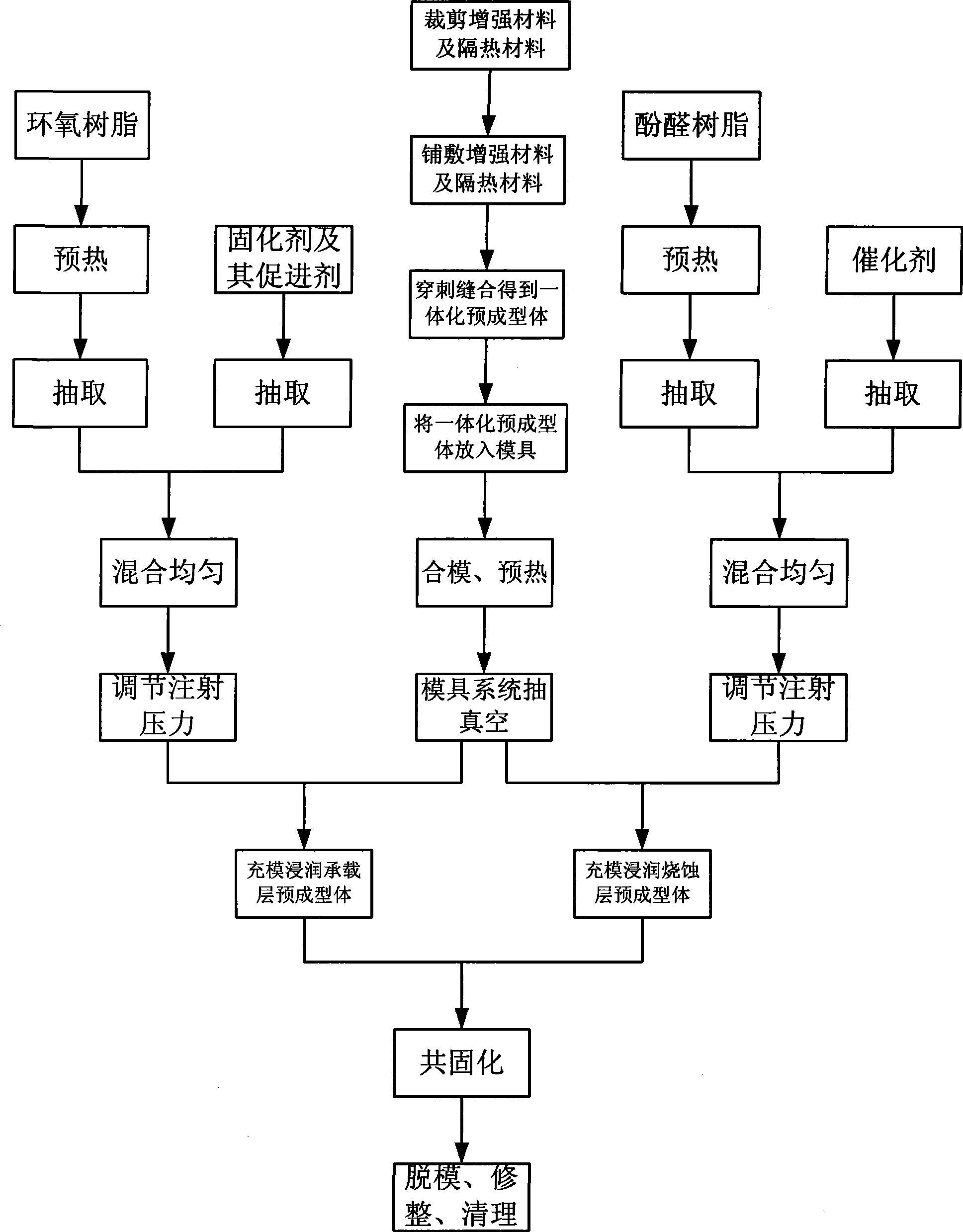

Bearing/insulating/ablating all-in-one sandwich structure composite material and preparation method thereof

InactiveCN101417516AImprove layer performanceIncreased interlaminar shear strengthLayered productsEpoxyInsulation layer

A composite material of sandwich structure integrating loading, heat insulation and ablation and the manufacturing method are characterized in that an integrated pre-forming body is acquired by puncture and suture of the reinforcing material of a bearing layer, the reinforcing material of an ablating cover, and a heating insulation layer positioned between the two layers; an epoxy resin system and a phenolic resin system are injected simultaneously into a vacuum-pumped mould, in which the integrated forming body is pre-placed, by two sets of RTM injection systems respectively, then, the reinforcing materials of the bearing layer and the ablating layer are soaked by epoxy resin and phenolic resin respectively; and the composite material of sandwich structure integrating loading, heat insulation and ablation can be obtained by solidified molding after mould filling. The invention has the advantages that the composite material of sandwich structure integrating loading, heat insulation and ablation is put forward and can be integrally formed by one-time operation, the function of the interlayer between every layer of the composite material is enhanced greatly, the integrality is good; the stratifying and peeling of the composite can be reduced effectively, and the products have good designable property and can be widely applied to the structural parts of aerospace which need heating insulation and thermal protection.

Owner:NAT UNIV OF DEFENSE TECH

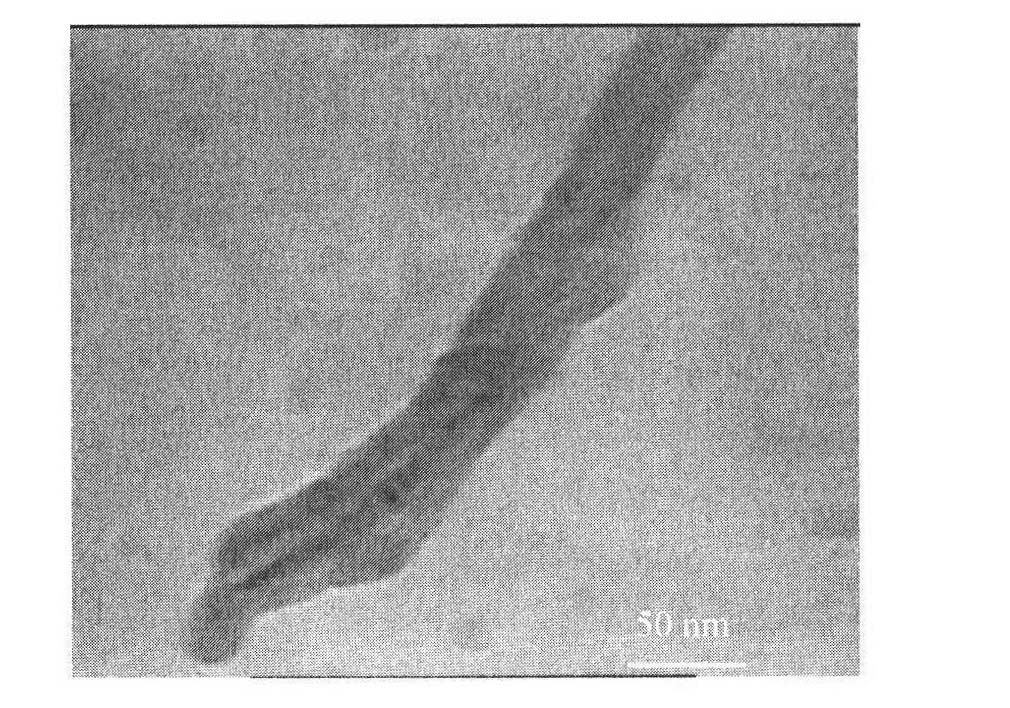

Method for preparing carbon nanofibers

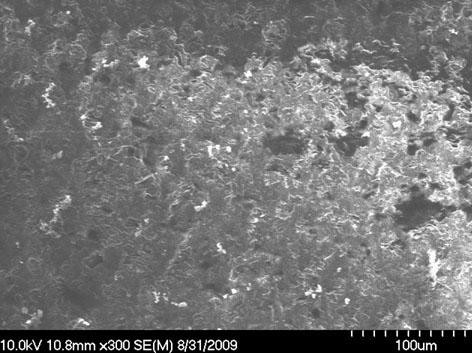

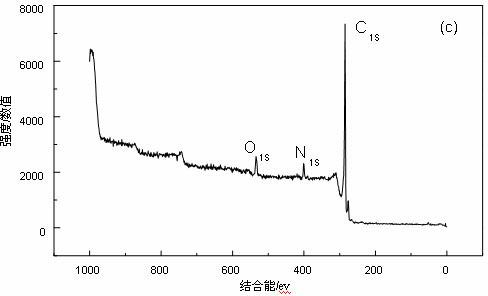

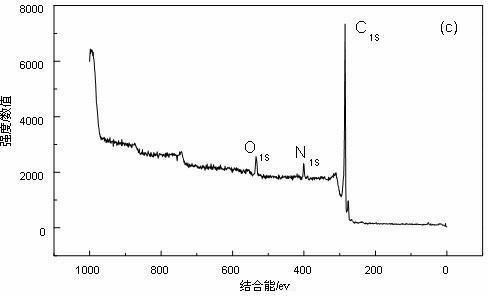

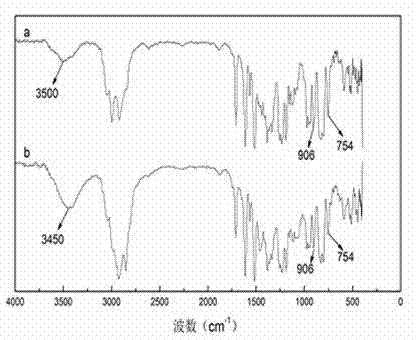

InactiveCN101718011AIncreased interlaminar shear strengthImprove efficiencyCarbon fibresFibre chemical featuresIonElectrospinning

The invention relates to a method for preparing carbon nanofibers. The method comprises the following steps: taking a polyacrylonitrile solution or an acrylonitrile copolymer solution or melt as materials, preparing nanofibers by the electrostatic spinning or the airflow spray method, and then preparing the nanofibers into carbon nanofibers. The method is characterized in that the carbon nanofibers are acidified or electrochemically treated into carbon nanofibers containing oxygen or nitrogen functional groups. The acidifying process comprises the following steps of: placing the carbon nanofibers in a nitric acid solution with the mass concentration of 30-68% and treating for 1-10 hours at 10-50 DEG C; rinsing with deionized water and drying; thus, obtaining the carbon nanofibers containing carboxyl functional groups. The electrochemical treating process comprises the steps of: placing the carbon nanofibers in a nitric acid or phosphoric acid solution with the mass percentage concentration of 1-20% at 10-50 DEG C, or in ammonium carbonate or ammonium hydrogen carbonate, and treating with the apparent current density of 10-100A / m2 for 1-120 minutes to obtain the carbon nanofibers containing carboxyl or amino functional groups.

Owner:TIANJIN POLYTECHNIC UNIV

Continous sucker rod made of fiber reinforced composition and its making method

InactiveCN1461870AImprove the bonding force between layersImprove wear resistanceDrilling rodsLayered productsGlass fiberPolymer science

A continuous sucker rod made of fibre reinforced composition has a covered complex structure. Its covering layer uses the transversely arranged aramid fibres or ultrahigh-molecular polyethene fibres as weft and the glass fibres-aramid fibre or ultrahigh-molecular polyethene fibres band structure in longitudinal direction. Its preparing process includes such steps as dewinding fibres, surface treating, immersing in resin, covering solidifying, post-solidifying and twining. Its advantages are high strength and adhesion, and good antiwear nature.

Owner:胜利油田孚瑞特石油装备有限责任公司 +1

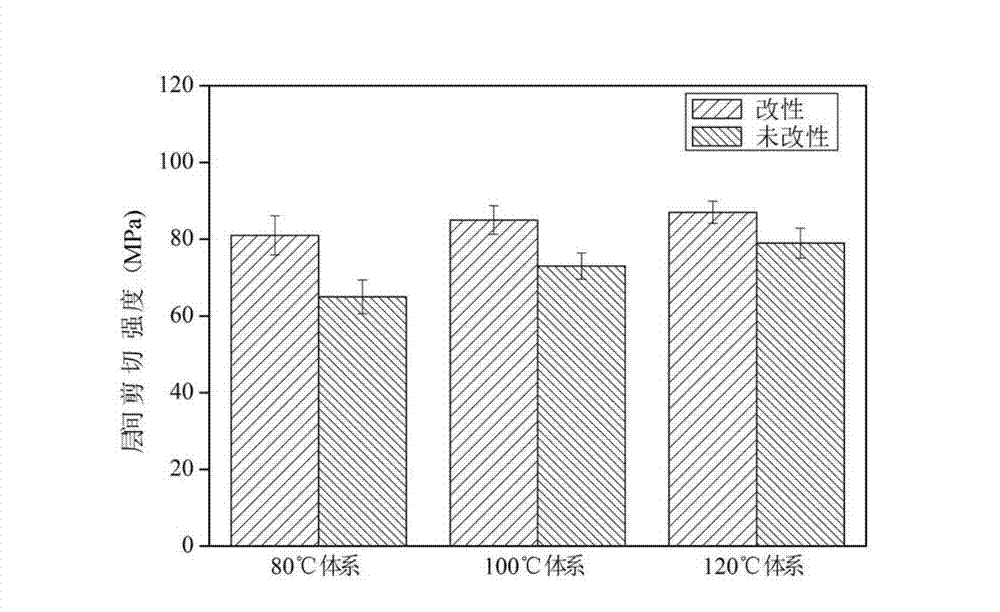

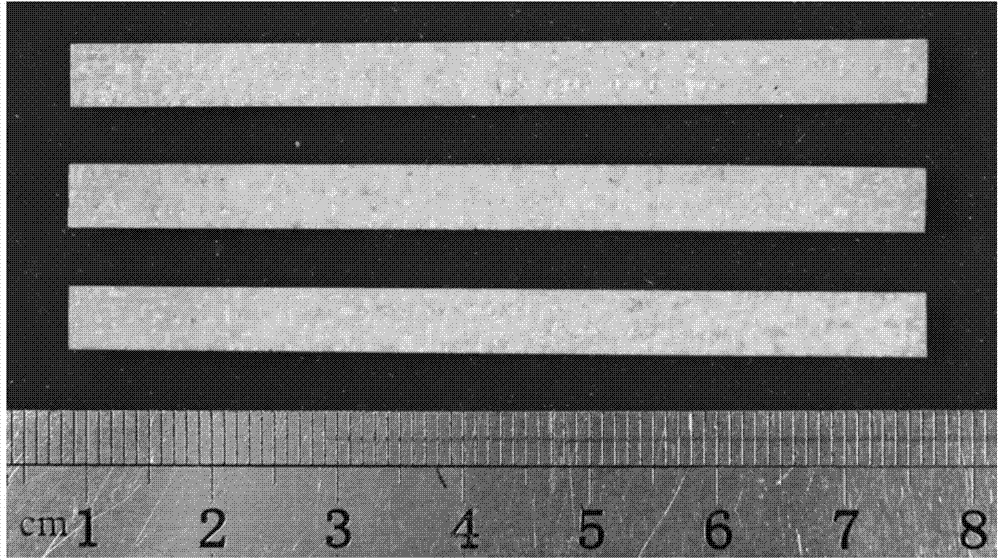

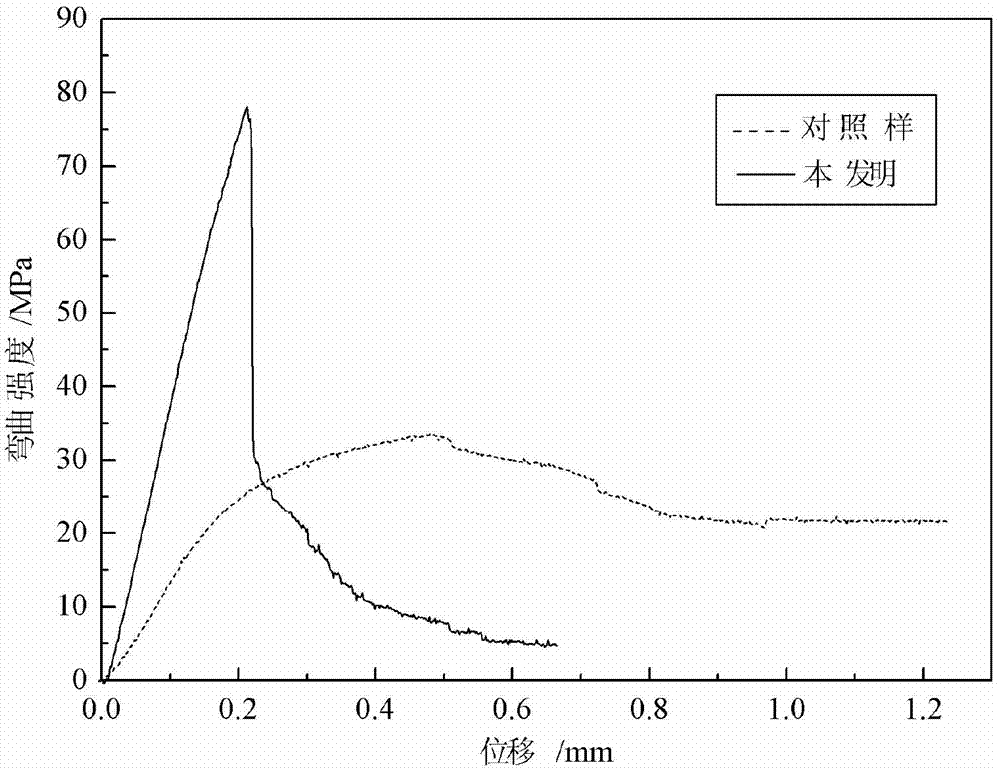

Method for improving interlaminar shear strength of medium/low-temperature cured prepreg by using polyurethane prepolymer

The invention provides a method for improving interlaminar shear strength of medium / low-temperature cured prepreg by using polyurethane prepolymer. The method comprises the following steps: firstly, reacting isocyanate with polyether polyol according to a controllable ratio to obtain a terminal isocyanate polyurethane prepolymer; grafting the terminal isocyanate polyurethane prepolymer to a bisphenol type epoxy resin, and adding a mixed epoxy resin to obtain a modified epoxy resin matrix; uniformly mixing the modified epoxy resin matrix with a curing agent and an accelerant to obtain a resin system for prepreg; and finally, preparing the resin system into a rubber film, compounding the rubber film with reinforced fibers or fabrics so as to prepare the medium / low-temperature cured prepreg with excellent adhesiveness. The prepreg preparation process is reasonable, the bonding strength of the resin system and fiber is high, the interlaminar shear strength of the composite material is obvious improved, and the method is particularly suitable for low-temperature cured prepreg.

Owner:中威北化科技有限公司

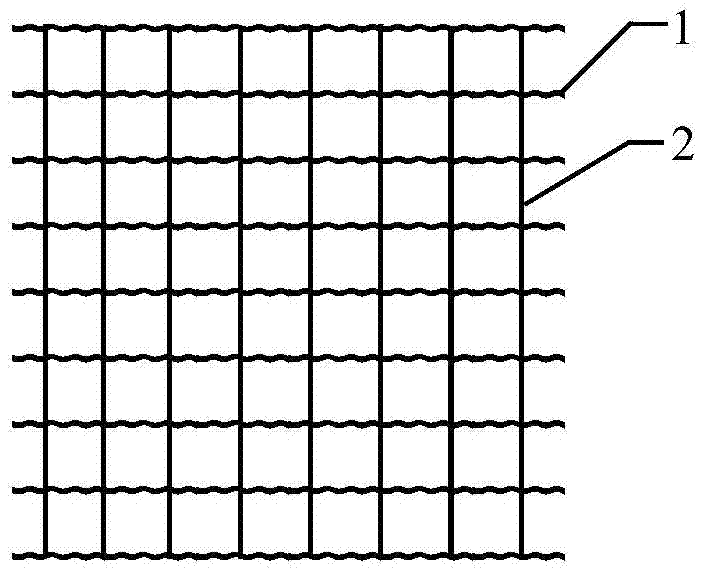

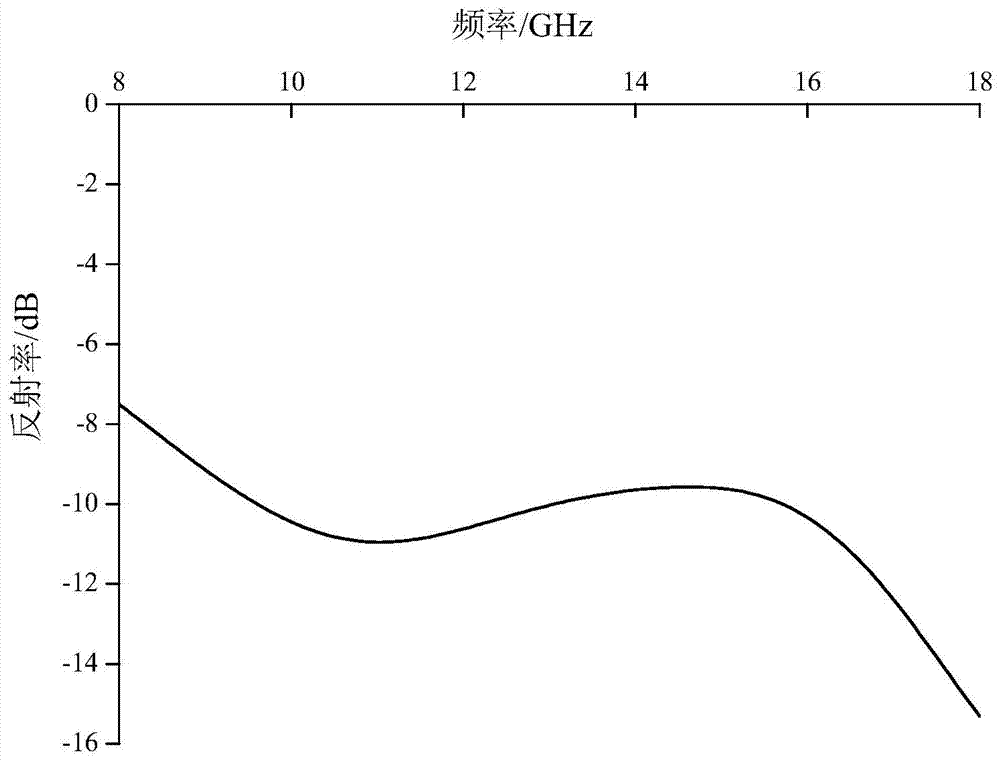

Silicon carbide fibre-reinforced silicon carbide composite microwave-absorbing ceramic and preparation method thereof

ActiveCN103922776AIncreased interlaminar shear strengthImprove mechanical propertiesCarbon fibersMicrowave

The invention discloses a silicon carbide fibre-reinforced silicon carbide composite microwave-absorbing ceramic. The microwave-absorbing ceramic consists of continuous silicon carbide fibre-reinforced silicon carbide composite material; wherein silicon carbide fibre cloth overlaid layer by layer is used as reinforcement; the silicon carbide fibre cloth is connected into a whole in a way of sewing with carbon fibres in Z direction; the band width, of which the reflectivity is lower than -8dB in frequency band of 8GHz to 18GHz, is 6.5 GHz to 10 GHz at normal temperature; and the density is lower than 2.1 / cm <3>. The method for preparing the microwave-absorbing ceramic comprises the following steps: weaving the continuous silicon carbide fibres into silicon carbide fibre plain cloth; sewing the plain cloth into a whole body in a Z direction by carbon fibres to prepare a preformed body; dipping, pyrolyzing and densifying the preformed body repeatedly by using precursor dipping and pyrolysis technology, thus obtaining the microwave-absorbing ceramic. The product provided by the invention has advantages of simple structure, wide absorbing frequency band, light weight, thin thickness, good mechanical property, etc.

Owner:NAT UNIV OF DEFENSE TECH

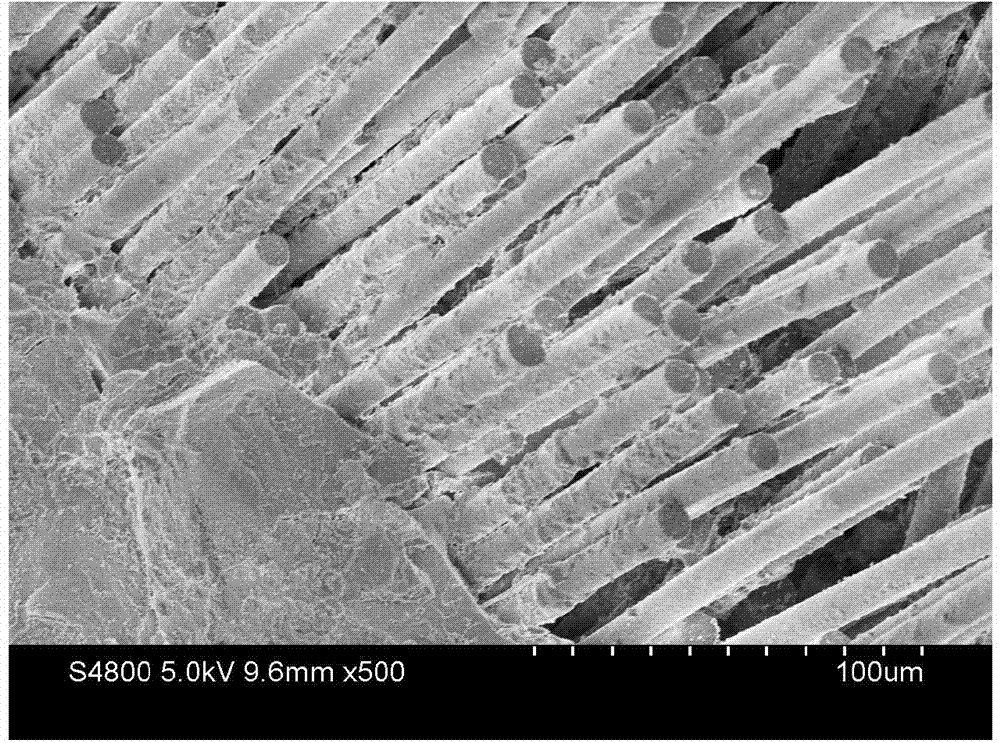

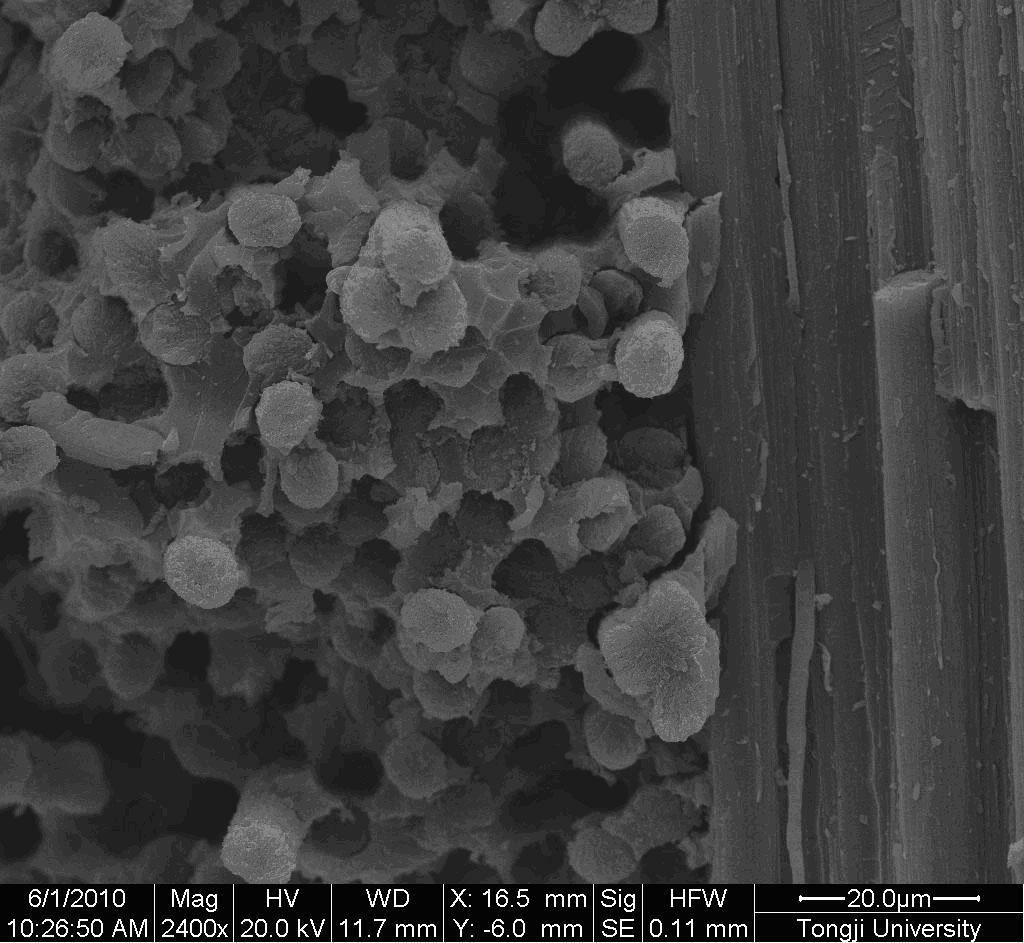

Preparation method of carbon nano tube/carbon fiber multi-dimension mixing composite material

InactiveCN101284423AIncreased interlaminar shear strengthImprove impact resistanceFiberCarbon fibers

The invention relates to a method for preparing a carbon nanometer tube / carbon fiber multi-scale mixed composite material. The invention is technically characterized in that the method adopts the ultrasonic assistant electrochemical deposition manner to prepare a nanometer composite fiber prefabricated part; and then under the double-action of ultrasonic and direct current field, molding is carried out according to the composite material liquid molding process (LCM), such as resin transfer molding (RTM) and resin film infusion (RFI), and the carbon nanometer tubes are dispersed and oriented along the electric field direction, thereby obtaining the multi-scale mixed composite material. The power of the ultrasonic is 100-400W and the frequency is 20-80KHz; the electric field is a direct current field with the voltage of 20-1200V. The method combines the high performance of the carbon nanometer tube with the characteristics of low cost and high performance of the traditional composite material liquid molding process, thereby realizing the complementary and reinforced advantages; the obtained composite material effectively utilizes the characteristics of the carbon nanometer tube, and can be used as the structural and functional material.

Owner:SHENYANG INST OF AERONAUTICAL ENG +1

Carbon fiber emulsion sizing agent and preparation method and application thereof

The invention discloses a carbon fiber emulsion sizing agent. The sizing agent comprises a main sizing agent, an auxiliary agent, an organic solvent and de-ionized water, wherein the auxiliary agent accounts for 5 to 15 percent of the mass of the main sizing agent; the mass ratio of the organic solvent to the main sizing agent is 20-50 to 50-80; and the mass ratio of the de-ionized water to the main sizing agent is 50-90 to 10-50. The invention also discloses a preparation method and application of the sizing agent. The sizing agent has low cost and environment friendliness and can be applied to different types of resin matrixes by varying the ratio of the components in the sizing agent. The preparation method is simple to operate and easy to implement. The sizing agent can improve the processability of the carbon fiber and the mechanical property of carbon fiber-enhanced resin-based composite materials when used in carbon fiber.

Owner:UNIV OF JINAN

Super hybrid carbon nano material modified carbon fiber/epoxy matrix composite material and preparation method thereof

InactiveCN103552325AImproved interlaminar shear performanceThe interface is firmly bondedSynthetic resin layered productsModified carbonResin matrix

The invention relates to a super hybrid carbon nano material modified carbon fiber / epoxy matrix composite material and a preparation method thereof. The composite material an epoxy resin matrix material and an inorganic nano filler which is uniformly dispersed in the epoxy resin matrix material, wherein the composite nano inorganic filler is composed of graphene and carbon nanotubes. The excellent mechanical properties of the graphene and carbon nanotubes and the active functional groups on the surface are utilized to effectively enhance the mechanical properties of the epoxy resin matrix and the interface bonding strength between the matrix and the carbon fibers. The prepared composite material has excellent interlaminar shear property, and the interlaminar shear strength is enhanced from 50 MPa to 68 MPa.

Owner:JIAXING UNIV

Method for preparing hybrid composite material of carbon fibers/carbon nanotubes/bismaleimide resin

InactiveCN101787128AIncreased interlaminar shear strengthImprove interface strengthFiberCarbon fibers

The invention belongs to the technical field of nano materials, and in particular relates to a method for preparing a hybrid composite material of carbon fibers / carbon nanotubes / bismaleimide resin. The method comprises the following steps: after carboxylating, acylating and chlorinating the surfaces of purified carbon nanotubes and dried carbon fibers, introducing diamine or polyamine with a feature structure thereon, wherein a large amount of the diamine or the polyamine are jointed on the surfaces of the carbon nanotubes and the carbon fibers; performing an addition reaction on the carbon nanotubes jointed with the amidogen and the bismaleimide resin to obtain a carbon nanotubes-containing bismaleimide resin linear block polymer serving as a substrate; and compositing the substrate and the carbon fibers in a certain mode to form a multi-dimensional hybrid composite material structure linked by covalent bonds finally. The method has the advantages of strengthening and toughening bismaleimide by using the strength and the toughness of the carbon nanotubes, improving the bonding strength between the bismaleimide and the carbon fiber substrate surface, improving overall performance of the multi-dimensional hybrid composite material of the carbon fibers / the carbon nanotubes / the bismaleimide resin, and widening the application of the carbon fibers, the carbon nanotubes and the bismaleimide resin.

Owner:TONGJI UNIV

Preparation method of chopped carbon fiber reinforced phenolic resin base composite material

The invention provides a preparation method of a chopped carbon fiber reinforced phenolic resin base composite material, which comprises the following steps: dissolving chopped carbon fibers after dispersion, which are used as the reinforcing material, in anhydrous alcohol; meanwhile, adding phenolic resin, and evenly mixing; and carrying out die pressing to obtain the chopped carbon fiber reinforced phenolic resin base composite material. The chopped carbon fibers in the material have a three-dimensional network structure, the three-dimensional network structure converts the combination of fibers and resin matrix from two-dimensional connection to three-dimensional connection with spatial effect; when being subjected to shear action, work needs to be applied to overcome the binding force between the matrix and the fibers, so that the expansion of the cracks consumes more energy, thereby enhancing the interlaminar shear strength, avoiding the generation of aggregation and requiring low cost.

Owner:SHAANXI UNIV OF SCI & TECH

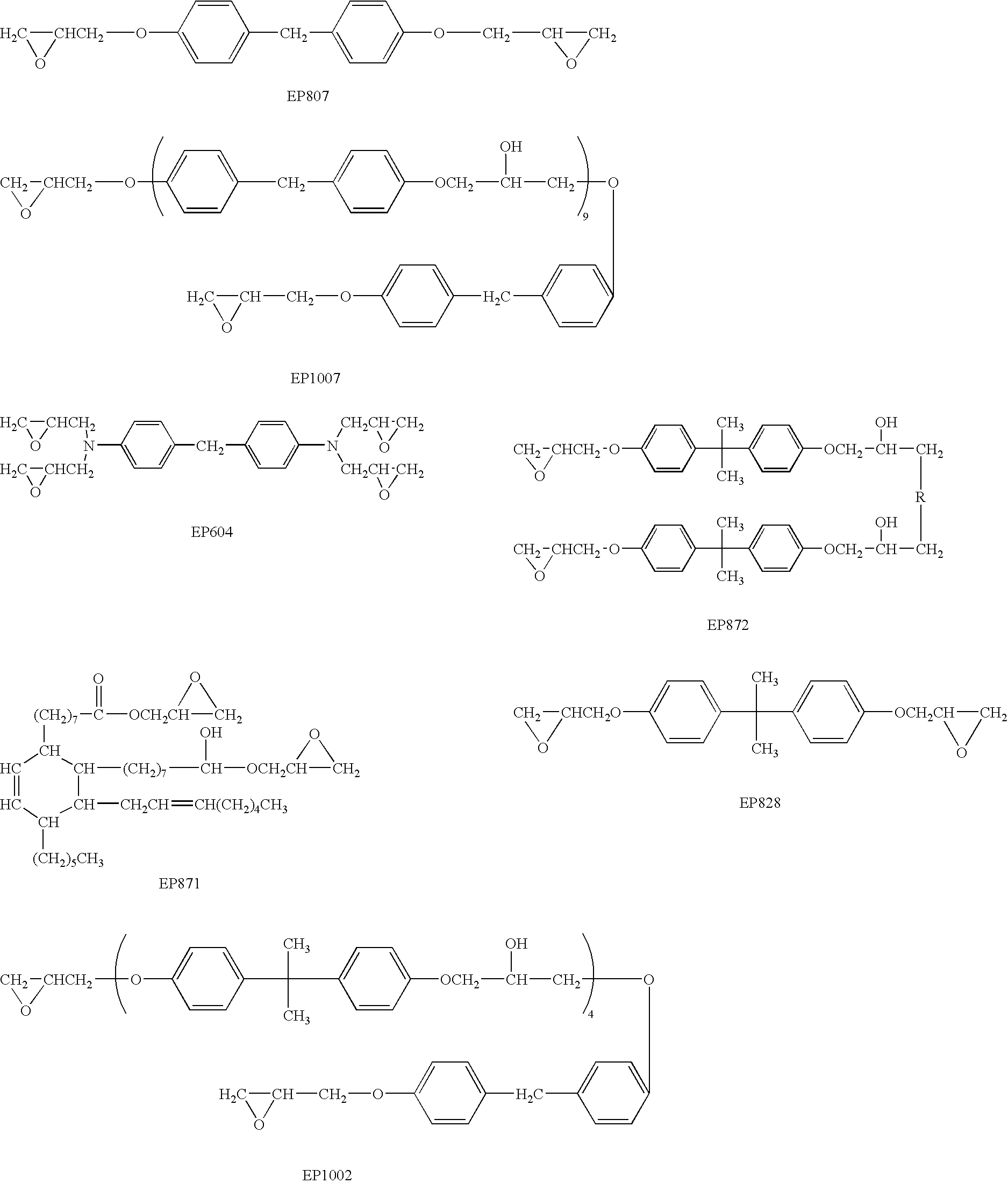

Carbon fiber strand

InactiveUS20050271874A1Increased interlaminar shear strengthCarbon fibresGrip property fibresFiberAlcohol

A sizing agent for carbon fiber consisting of a reaction products containing an unsaturated urethane compound as the principal component obtained by reacting an unsaturated alcohol with an isocyanate compound is disclosed in claim 1.

Owner:TOHO TAYON CO LTD

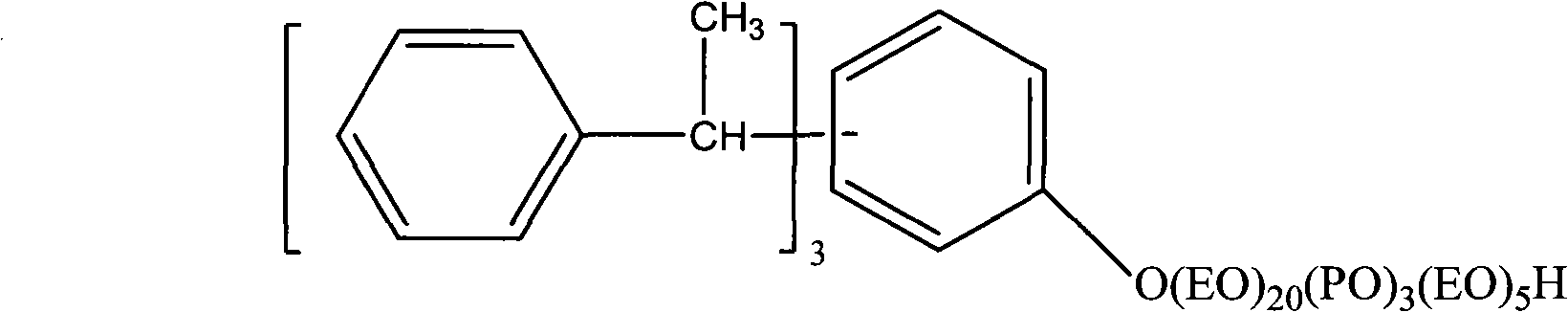

Method for preparing self-emulsifying carbon fiber sizing agent component

InactiveCN101880967AGood compatibilityGood static stabilityCarbon fibresCarbon fibersSelf emulsifying

The invention discloses a method for preparing a self-emulsifying carbon fiber sizing agent component, which comprises the following steps of: performing graft polymerization reaction on epoxy resin by adopting an emulsion polymerization method to prepare modified epoxy emulsion; and standing the modified epoxy emulsion at 80 DEG C for two hours, adding dropwise ammonia water into the solution after demulsification to make the solution alkaline, standing the solution at 95 DEG C in a sealing way, stirring and hydrolyzing the solution for 3 hours, taking the solution out, acidifying and neutralizing the redundant ammonia water, drying and rinsing the solution to produce modified bisphenol A epoxy resin, placing the synthesis product in the step and the bisphenol A epoxy resin into a container according to a certain weight ratio, and performing phase-inversion emulsification on the mixture at 70 DEG C to prepare a modified epoxy emulsion sizing agent component with certain solid content. The prepared carbon fiber sizing agent component has the characteristics of storage time longer than 12 months, high high-temperature stability, and high dilution stability, so that the method has huge breakthrough compared with the prior art. Carbon fibers sized by the sizing agent have high machining performance and improved inter-layer shear strength.

Owner:BEIHANG UNIV

Three-dimensional alumina fiber fabric reinforced oxide ceramic and preparation method thereof

The invention discloses three-dimensional alumina fiber fabric reinforced oxide ceramic. Al2O3, SiO2 and SiOC ceramics are used as a substrate, a three-dimensional alumina fiber fabric is used as a reinforcing body, alumina and silicon dioxide in the substrate are introduced by a sol-gel process, and the SiOC ceramic is obtained by high-temperature cracking of polysiloxane. The preparation method of the three-dimensional alumina fiber fabric reinforced oxide ceramic comprises the following steps: performing vacuum soaking, gelating and high-temperature ceramic treatment on oxide sol serving as a precursor, and repeating for multiple times to obtain an alumina fiber reinforced oxide blank body; soaking the blank body in vacuum by using a polysiloxane-ethanol solution as a precursor, and performing crosslinking and high-temperature ceramic treatment to complete a densifying process; and repeating the steps for multiple times to obtain the oxide ceramic blank body, and oxidizing to prepare the three-dimensional alumina fiber fabric reinforced oxide ceramic. The three-dimensional alumina fiber fabric reinforced oxide ceramic has the advantages of high bending strength, high modulus, good interlaminar shear strength and the like.

Owner:NAT UNIV OF DEFENSE TECH

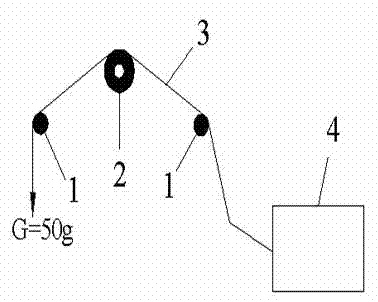

Method for manufacturing needle-punched carbon fiber pseudo-three-dimensional preform

InactiveCN101575766AImprove wear resistanceExtended service lifeNeedling machinesCarbon compositesCarbon fibers

The invention relates to a method for manufacturing a needle-punched carbon fiber pseudo-three-dimensional preform, which comprises the following steps: adopting alternating laminations of continuous carbon fibers and short carbon fiber mesh carcasses, wherein the laminations of the continuous carbon fibers are paved alternately with included angles between 0 and 30 degrees; and introducing longitudinal fortifying fibers through a needle-punching process in the axial direction of the short carbon fiber mesh carcasses and the continuous carbon fiber laminations, and controlling the needling density to between 36 to 44 needles / cm so as to manufacture a full carbon fiber pseudo-three-dimensional structural preform with the volume density of between 0.55 and 0.82g / cm. The preform manufactured by the method has the most important characteristics of high volume content of the carbon fibers, evener continuous carbon fiber laminations, high needling density, high mechanical property of a manufactured carbon / carbon composite material and good wear resistance, and is applicable to manufacturing aircraft carbon brake disc materials with high torque characteristics.

Owner:XIAN CHAOMA SCI TECH

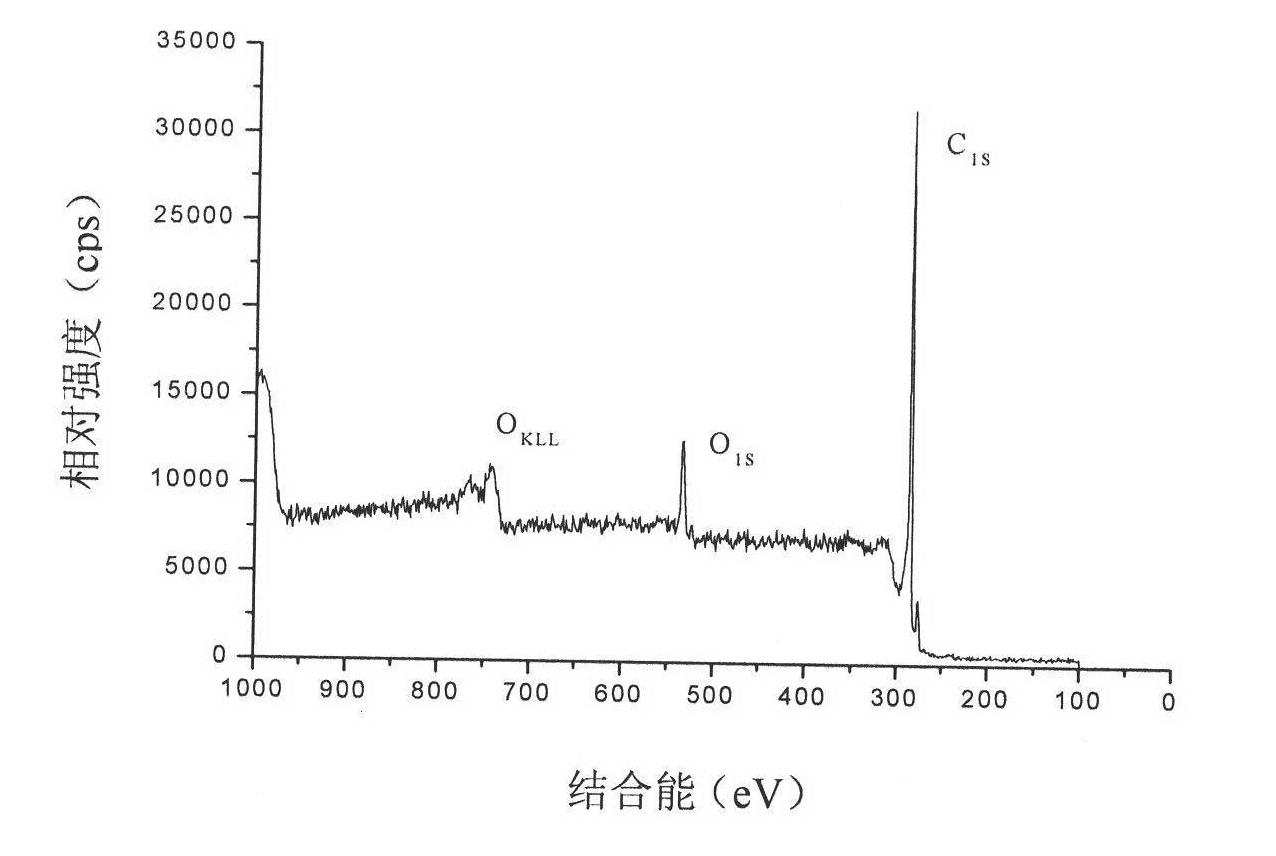

Carbon fiber surface treatment method

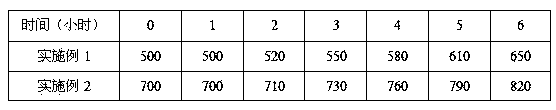

ActiveCN102345228AIncreased content of active polar functional groupsGroove deepeningPhysical treatmentAmbient humidityInterlaminar shear

The invention relates to a carbon fiber surface treatment method. The method comprises that under an atmosphere environment, air is adopted as a carbon fiber surface treatment medium, electroneutral low temperature plasma is emitted by a plasma emitting device for low temperature plasma bombardment to the surface of a moving carbon fiber tow at a speed of 60-150m / h; the ambient temperature of carbon fiber treatment ranges from -10DEG C to 50DEG C; the gap between the carbon fiber and the plasma emitting device is 5-30mm; the ambient humidity of carbon fiber surface treatment is 30-90%; the power of carbon fiber surface treatment ranges from 500 to 800W / tow; and the temperature of carbon fiber surface treatment by low temperature plasma is 30DEG C-100DEG C. The method of the invention can enhance the content of active and polar functional groups on the carbon fiber surface, deepen grooves on the carbon fiber surface, increase the specific surface area, improve the interlaminar shear strength of carbon fiber composite materials, save energy and reduce energy consumption, and is clean and free of pollution.

Owner:PETROCHINA CO LTD

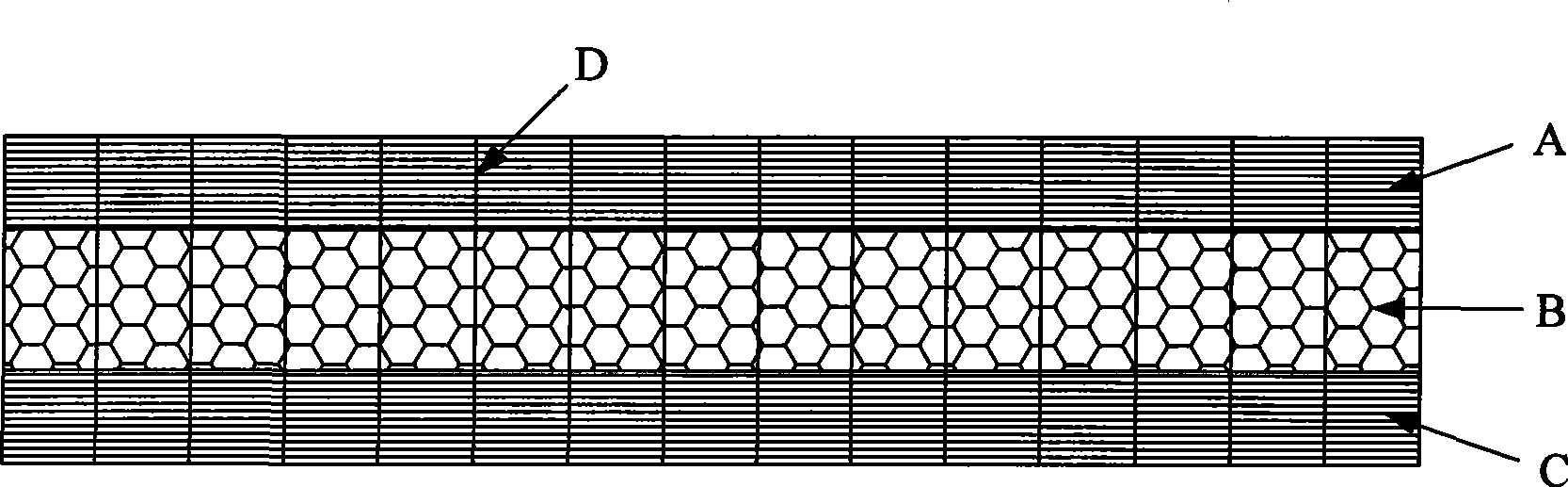

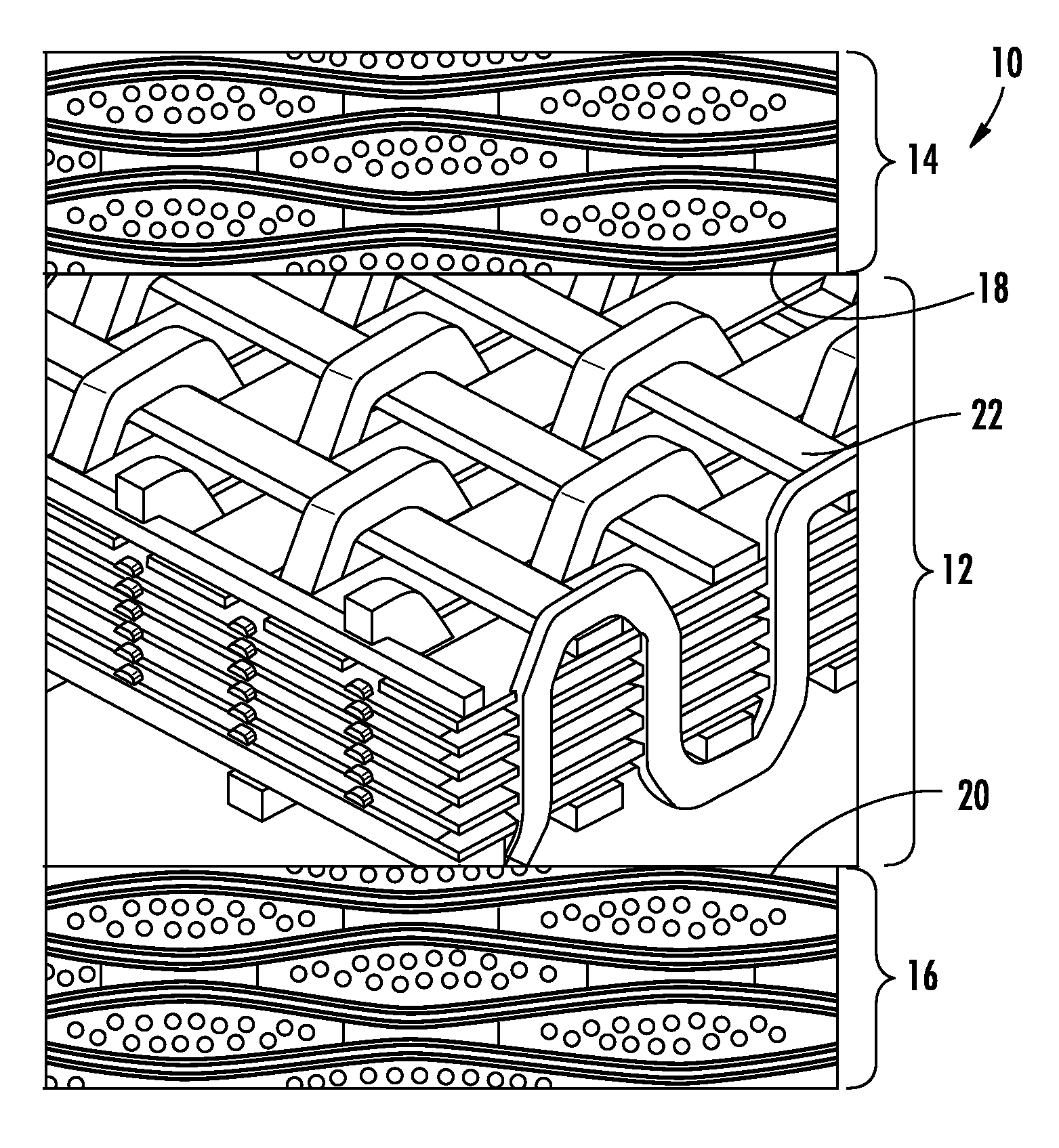

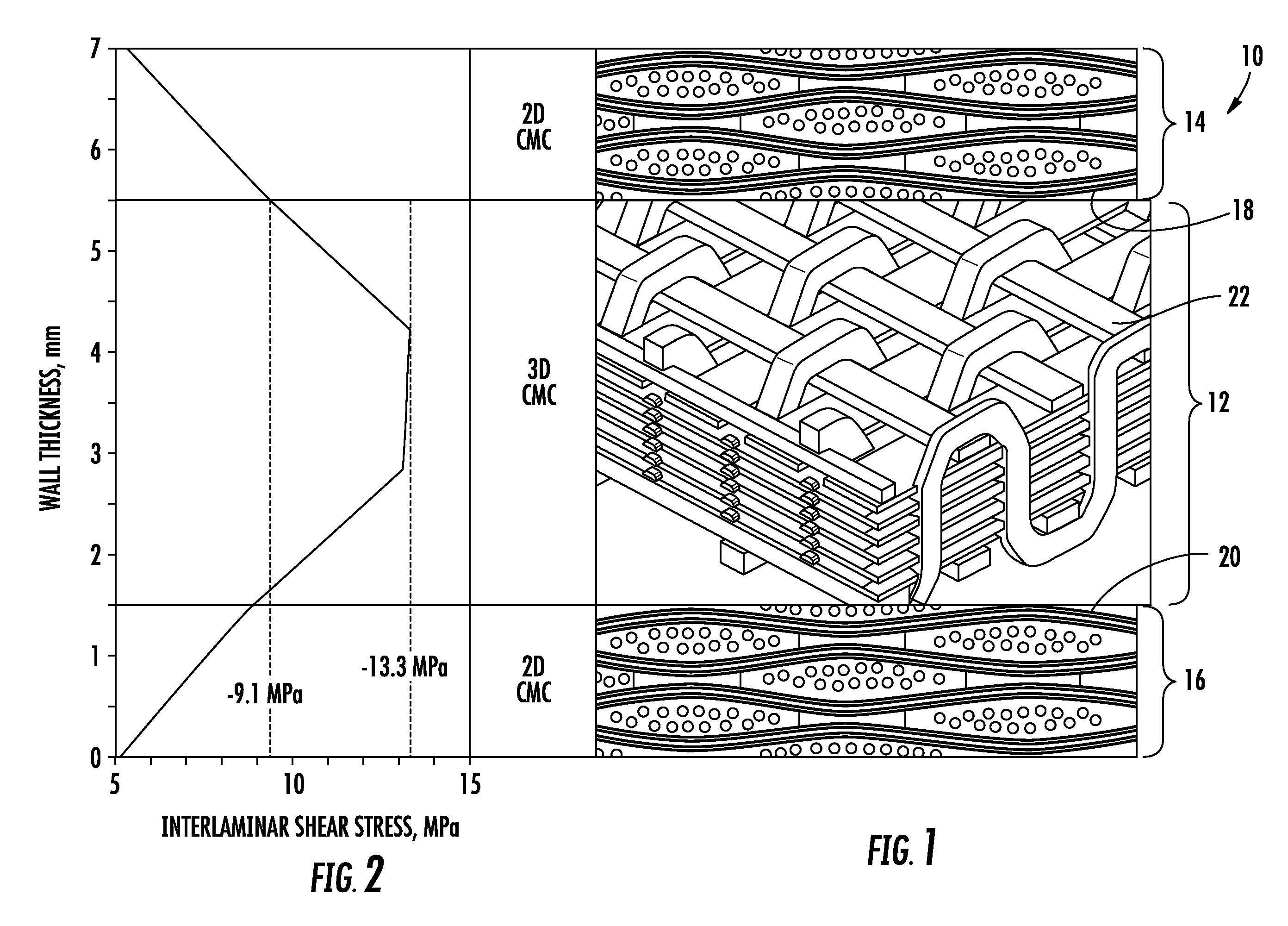

Multilayered ceramic matrix composite structure having increased structural strength

ActiveUS20100056006A1Improve strength propertiesImprove bending strengthSynthetic resin layered productsLaminationMetallurgyInterlaminar shear

A multilayer ceramic matrix composite structure is disclosed. The ceramic matrix composite structure may include a three-dimensional weave fabric forming a core layer. The ceramic matrix composite structure may also include a two-dimensional weave fabric attached to an outer top surface of the three-dimensional weave fabric such that the two-dimensional weave fabric forms a top layer, and a two-dimensional weave fabric attached to an outer bottom surface of the three-dimensional weave fabric generally opposite to the outer top surface such that the two-dimensional weave fabric forms a bottom layer. The structure may include increased interlaminar shear strength.

Owner:SIEMENS ENERGY INC

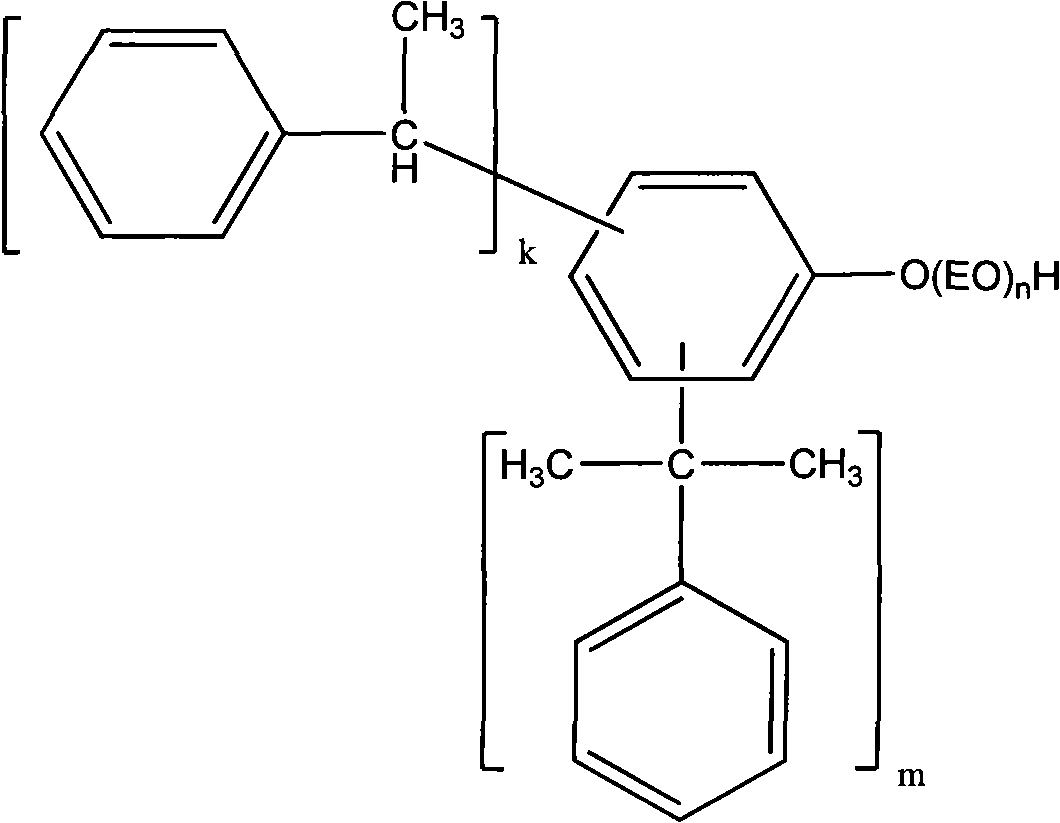

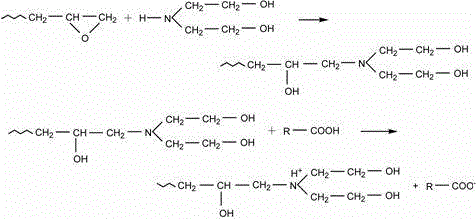

Carbon fiber water-soluble epoxy resin sizing agent

The invention discloses a carbon fiber water-soluble epoxy resin sizing agent and a preparation method thereof. The sizing agent comprises main slurry and deionized water as main components, wherein the mass ratio of the main slurry to the deionized water is (50-80):(20-50); and the main slurry consists of modified phenol-formaldehyde epoxy resin and allyl polyoxylethylene ether (AEPH), and the mass ratio of the modified phenol-formaldehyde epoxy resin to AEPH is (60-90):(10-40). The preparation method of the sizing agent comprises the following steps: firstly reacting phenol-formaldehyde epoxy resin with diethanolamine to obtain water-soluble phenol-formaldehyde epoxy resin; and then mixing the water-soluble resin with AEPH in proportion, and performing dilution to reach a certain concentration by using the deionized water to obtain the sizing agent. The sizing agent disclosed by the invention is good in stability and low in cost, cannot cause environmental pollution, and is simple in preparation method; good post-processing performance of carbon fibers can be provided by adding flexible molecular AEPH; experiments show that after the carbon fibers are coated with a proper amount of the sizing agent, the post-processing performance can be significantly improved; and the performance of a carbon fiber epoxy resin composite material can be improved.

Owner:UNIV OF JINAN

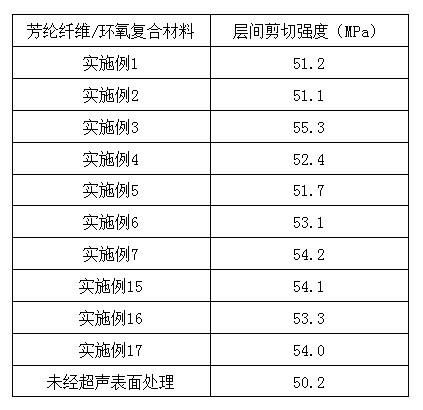

Ultrasonic surface modification treatment method for aramid fibers

InactiveCN102605606AImprove surface conditionQuality improvementFibre typesUltrasonic/sonic fibre treatmentPolymer scienceOrganic solvent

The invention provides an ultrasonic surface modification treatment method for aramid fibers. One or more amidic organic solvents in any proportion are selected as an ultrasonic treatment medium; under an ultrasonic action, fiber surfaces can be etched effectively by the amidic solvents; simultaneously, the sticking points among aramid fiber filaments can be reduced, and the state of the surfaces can be improved, so that the bonding strength between a resin and a fiber is increased; and meanwhile, the online treatment of the fibers is easy to realize by the ultrasonic treatment, and the time for modifying the fiber surfaces is shortened.

Owner:中蓝晨光化工有限公司

Preparation method of carbon nano tube and functionalized carbon fiber reinforced bismaleimide resin matrix composite

The invention relates to a preparation method of a carbon nano tube and functionalized carbon fiber reinforced bismaleimide resin matrix composite, which comprises the steps of: after a carbon nano tube is subjected to carboxylation, introducing diamine or polyamine on the carbon nano tube to obtain a surface aminated carbon nano tube; making the aminated carbon nano tube react with a carbon fiber subjected to surface carboxylation to obtain an aminated carbon fiber with the surface grafted with the carbon nano tube, introducing diamine or polyamine on the surface of the carbon fiber to ensure that carboxyl on the surface of the carbon fiber, which incompletely reacts with the aminated carbon nano tube, is fully aminated, carrying out polymerization on the carbon fiber and bismaleimide to obtain an reinforcement of the functionalized carbon fiber with the surface grafted with the toughened bismaleimide resin; making the aminated carbon nano tube react with the bismaleimide resin to obtain a matrix of the bismaleimide resin roughened by the carbon nano tube; and compounding the reinforcement of the obtained functionalized carbon fiber with the surface grafted with the bismaleimide resin with the matrix of bismaleimide resin roughened by the carbon nano tube to obtain a required product. The carbon fiber and the matrix resin are roughened by using the strength and flexibility of the carbon nano tube, the binding performance of the carbon fiber and the resin matrix is improved, the interface binding strength of the composite is increased, and therefore, the integral performance of the composite is enhanced.

Owner:TONGJI UNIV

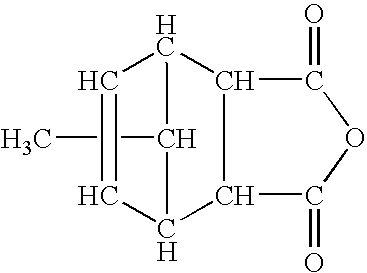

Preparation method of glass fiber/carbon nanotube/epoxy resin multi-dimensional hybrid composite material

InactiveCN102276795AIncreased interlaminar shear strengthImprove interface strengthResin matrixCarbon nanotube

The invention relates to a preparation method of a glass fiber / carbon nanotube / epoxy resin multi-dimensional hybrid composite material. The preparation method provided by the invention comprises the following steps of: treating glass fiber with a silane coupling agent; carrying out surface carboxylation and chlorination on carbon nanotubes, then introducing diamine or polyamine to the carbon nanotubes, and modifying the carbon nanotubes connected with an amino group by a polybasic anhydride compound to prepare the carbon nanotubes carrying an anhydride group; dispersing the treated carbon nanotubes in an epoxy resin matrix by ultrasonic oscillation and high-speed stirring, and curing with an organic anhydride curing agent; and compounding the obtained carbon-nanotube-containing epoxy resin polymer used as a matrix with the coupling-agent-treated glass fiber to form a multi-dimensional hybrid composite material structure linked through covalent bonds. The preparation method provided by the invention has the advantages that: the composite material is convenient to prepare, the dispersion of the carbon nanotubes in epoxy resin is improved, and the strength and toughness of the carbon nanotubes are utilized to toughen epoxy resin and to improve the bonding strength with the base surface of the glass fiber, thereby enhancing the overall performance of the glass fiber / carbon nanotube / epoxy resin multi-dimensional hybrid composite material and broadening the applications of the glass fiber, carbon nanotubes and epoxy resin.

Owner:TONGJI UNIV

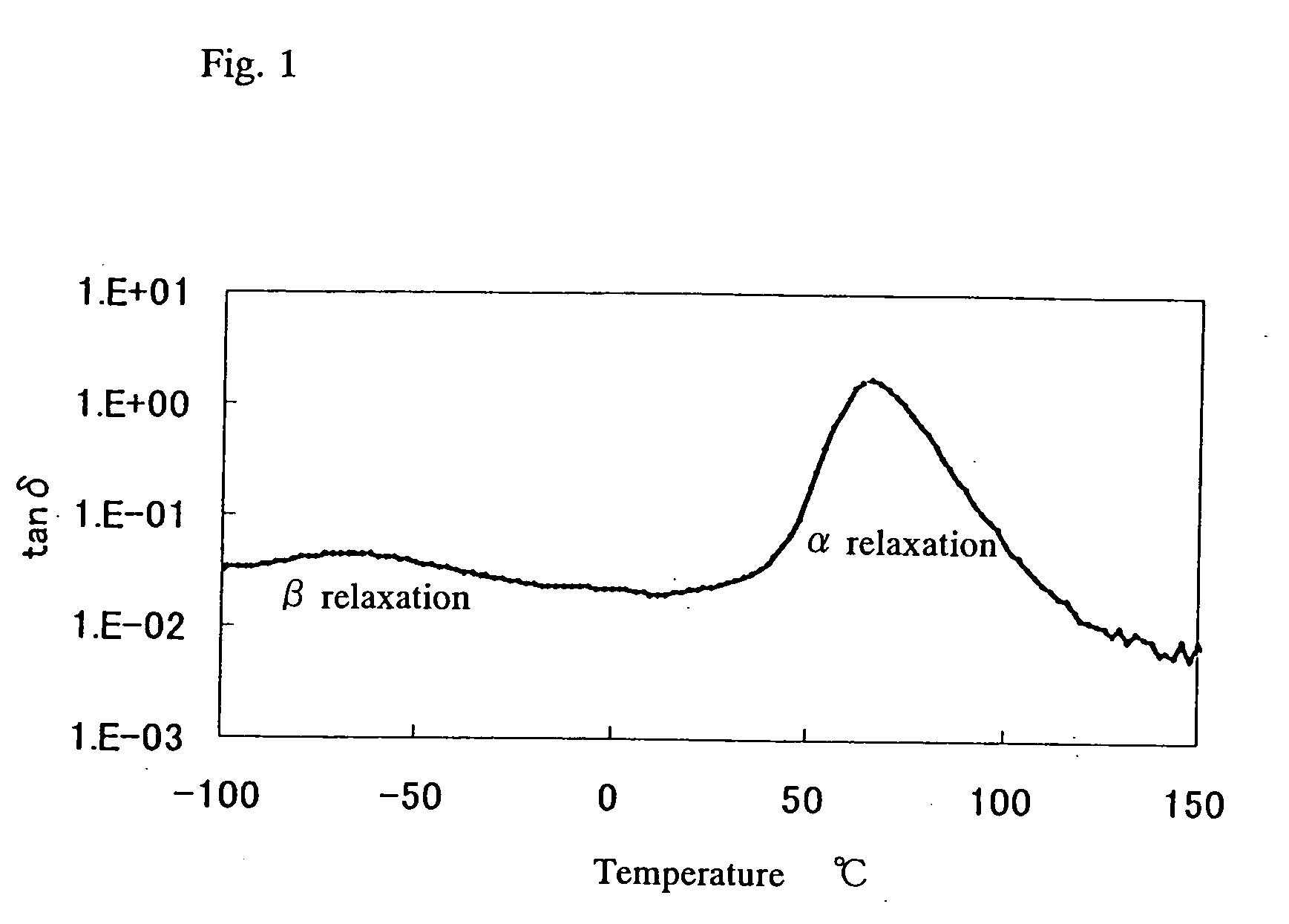

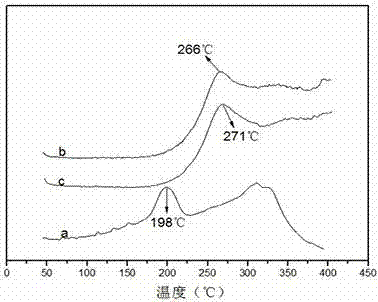

Temperature-resistant type emulsion sizing agent for carbon fiber, as well as preparation method and application of sizing agent

InactiveCN104294602AHigh glass transition temperatureImprove temperature resistanceCarbon fibresEmulsionMass ratio

The invention discloses a temperature-resistant type emulsion sizing agent for a carbon fiber. The temperature-resistant type emulsion sizing agent comprises the following materials: main size, an emulsifying agent, an additive and deionized water, wherein the main size is glycidyl amine type epoxy resin modified by dodecanamine, and in modification, the mass ratio of dodecanamine to the epoxy resin is (10-40) to (60-90); the mass of the emulsifying agent is 5-15% of the mass of the main size; the additive comprises a diluting agent and a penetrating agent, the mass of the diluting agent is 0-100% of the mass of the main size, and the mass of the penetrating agent is 1-5% of the mass of the main size; the mass ratio of the deionized water to the main size is (50-90) to (10-50). The invention also discloses a preparation method and application of the sizing agent. The sizing agent disclosed by the invention is high in stability and does not cause pollution to the environment, and the preparation method is simple; in the presence of a flexible molecule, namely dodecanamine, the carbon fiber has relatively high operability; proved by experiments, after the carbon fiber is treated by the sizing agent, the post processability is obviously improved; and the interface temperature resistance and the interlaminar shear strength (ILSS) of the carbon-fiber-enhanced epoxy resin composite material are also obviously improved.

Owner:UNIV OF JINAN

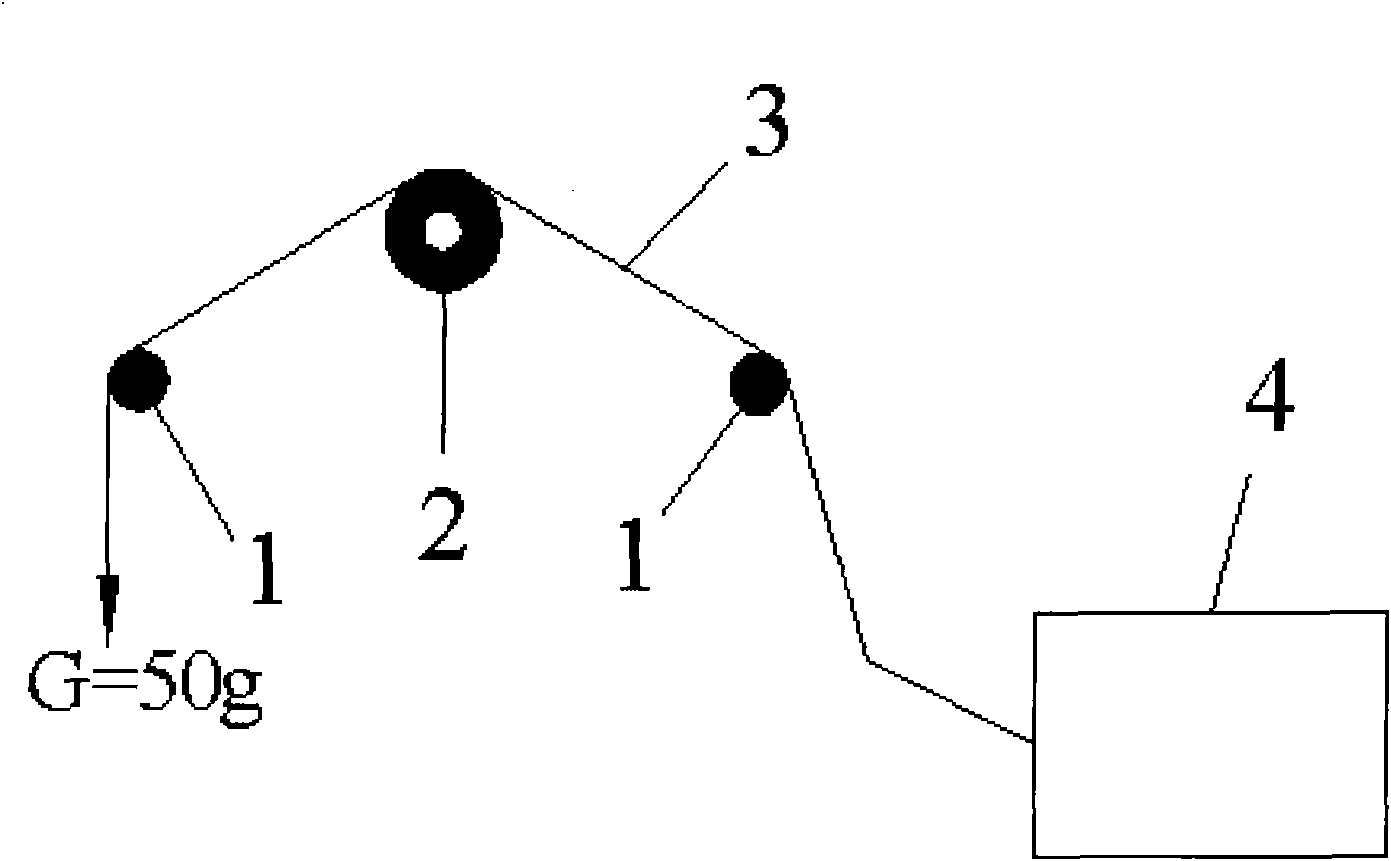

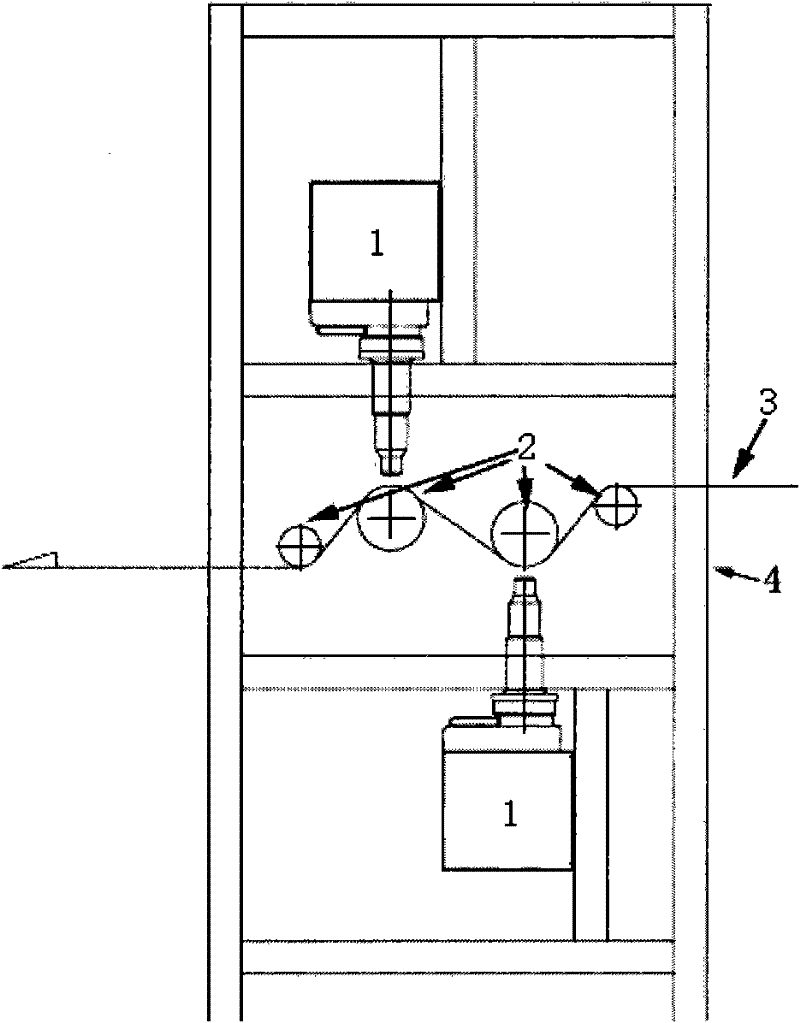

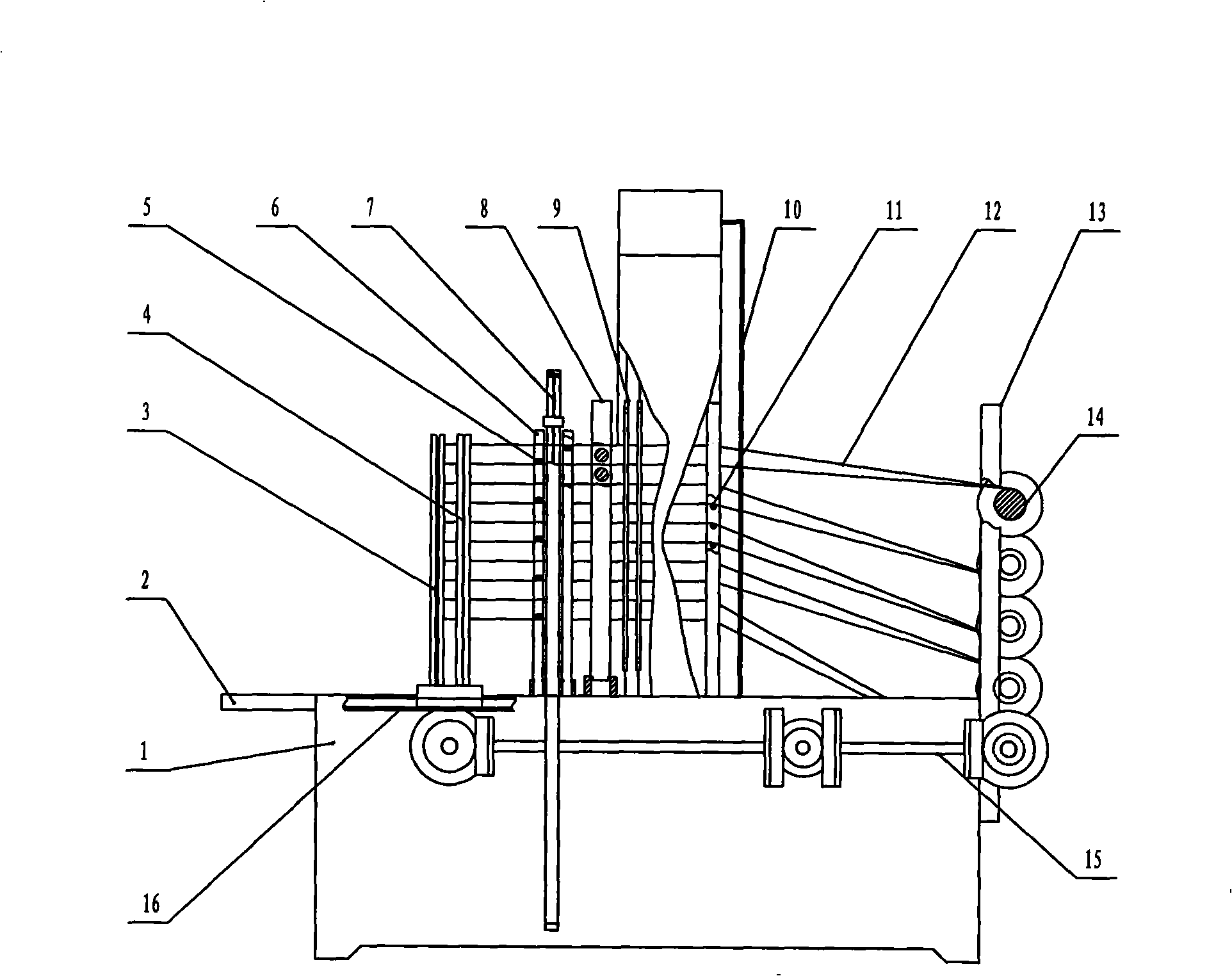

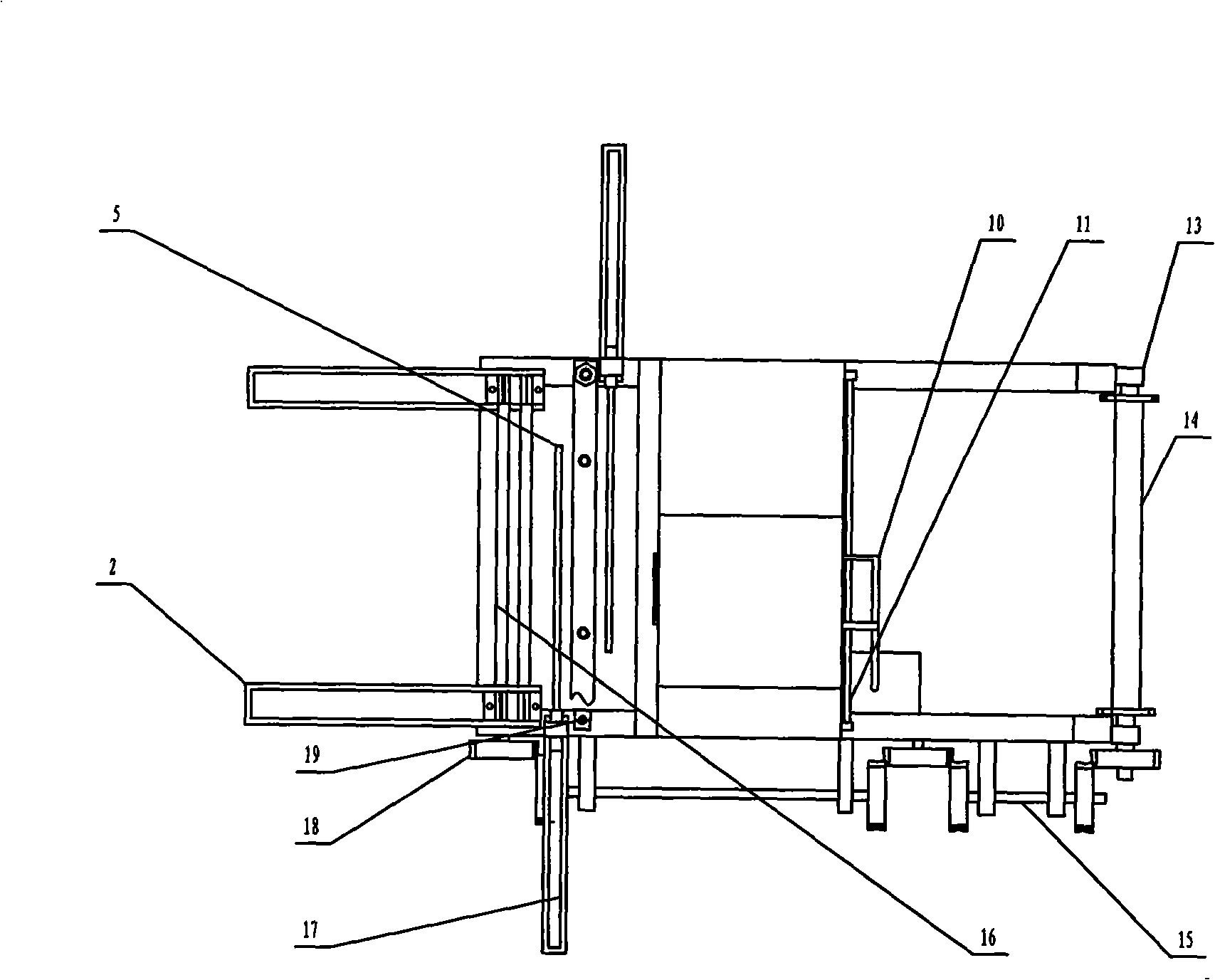

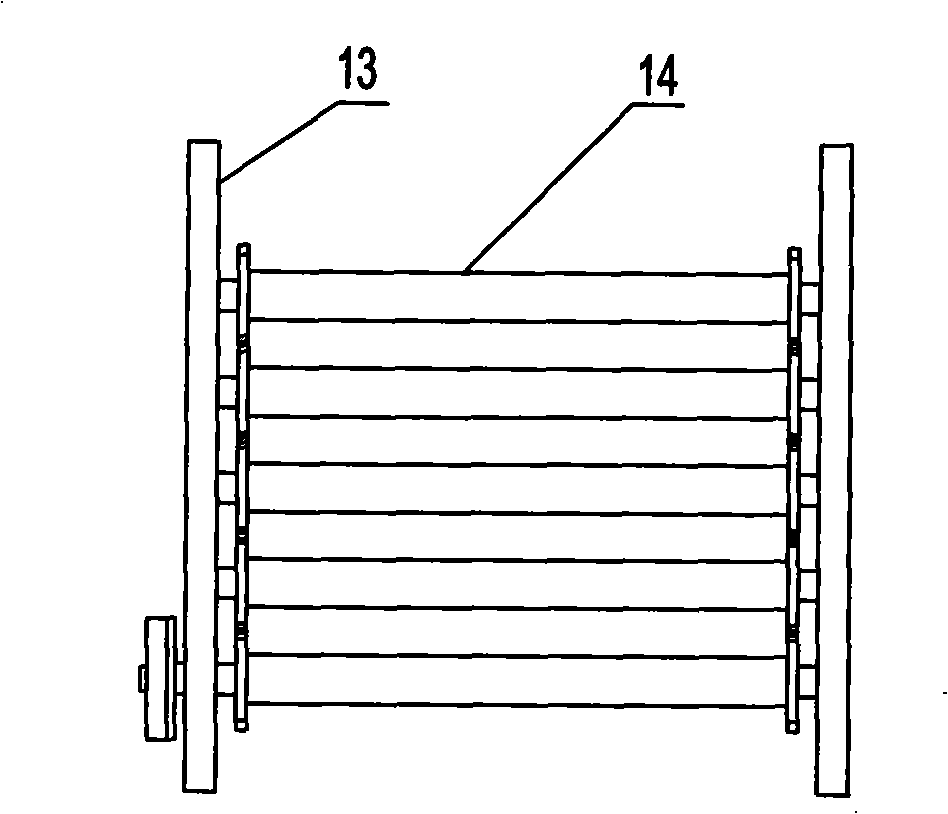

Novel three-dimensional weaving machine

InactiveCN101294327AGood interlaminar shear strengthGood resistance to impact damageLoomsKnittingWoven fabricYarn

The invention belongs to the field of textile machinery, in particular to a novel 3D loom capable of producing 3D textile composite material skeleton. The novel 3D loom comprises a frame and a transmission portion, and is characterized in that the loom also includes a 3D woven fabric winding mechanism arranged on the front end of the frame, a multilayer warp let-off mechanism arranged on the tailend of the frame, and a Y-direction opening, a Z-direction weft inserting mechanism, a Z-direction opening and a Y-direction weft inserting mechanism, which are sequentially arranged between the winding mechanism and the let-off mechanism. The 3D loom has the advantages that (1) the loom can weave completely and has good stability, the woven fabrics have various structures, and the produced textile composite material has excellent performance; (2) four different fabrics can be woven; (3) the integrity of the fabric can be ensured; (4) the pitch between yarns can be better controlled to combine with the looseness of the 3D woven fabrics, and the loom obviates the need of a beating up mechanism; and (5) the loom has simple structure and operation and convenient maintenance by fully utilizing electromechanical integration technology.

Owner:FOSHAN CIHUI TONGDA SCI & TECH

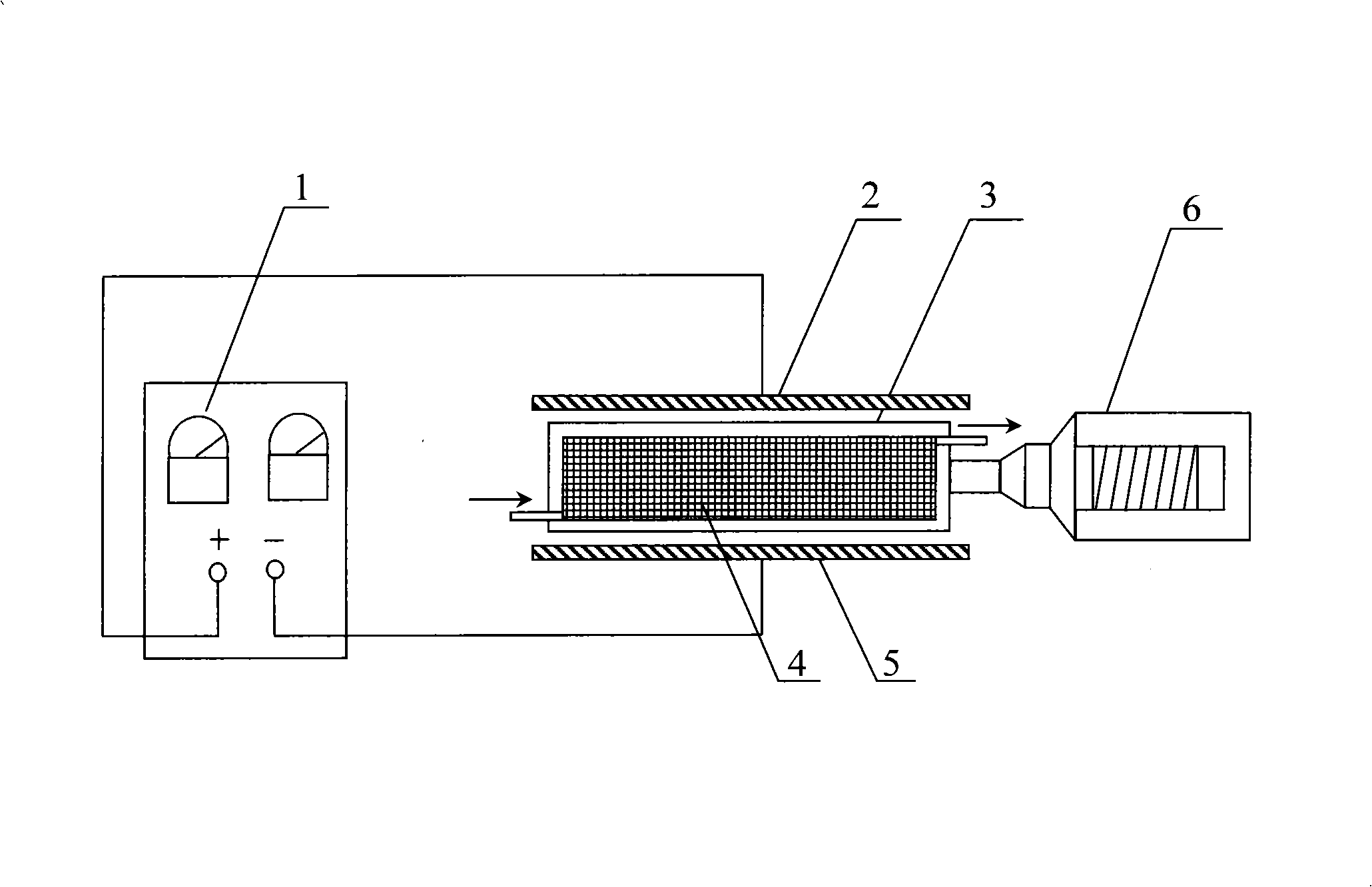

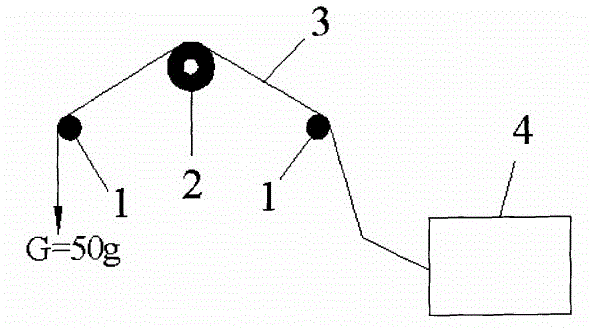

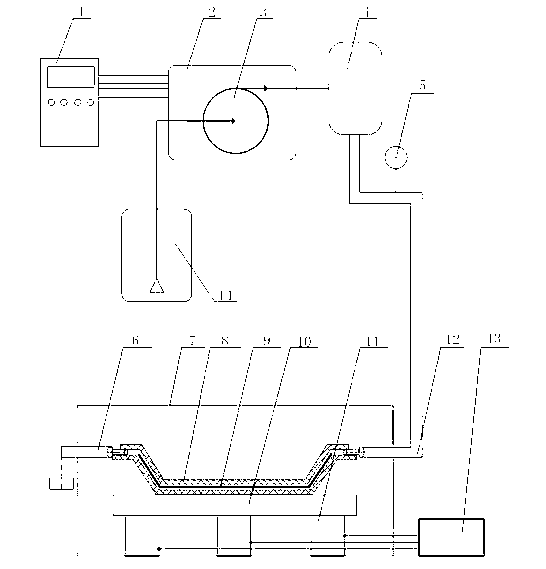

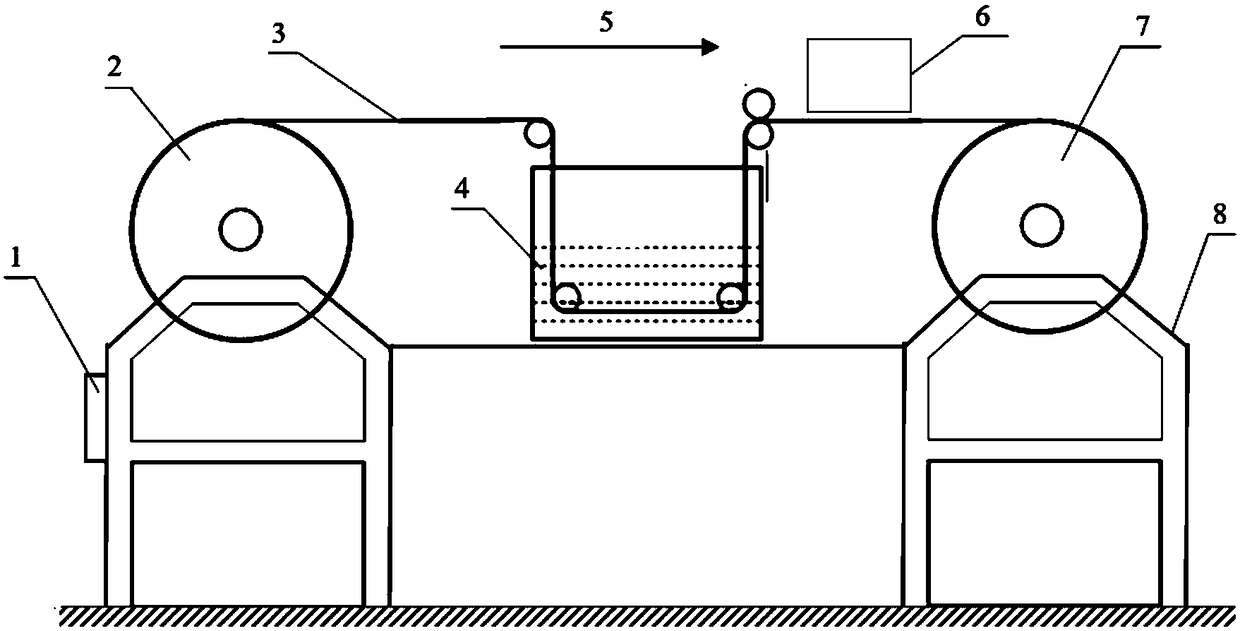

Method for adopting microwave ultrasound solidification fibre reinforced composite component and special device thereof

ActiveCN102990946ASmall internal stressSmall overall deformationMicrowave cavityFiber-reinforced composite

The invention discloses a method for adopting a microwave ultrasound solidification fibre reinforced composite component and a special device thereof. The method comprises the following steps of: firstly placing a prefabricated part in a filling module, wherein the filling module simultaneously uses ultrasonic wave to accelerate a resin to permeate and increase the wettability; and using a microwave heating module after finishing until resin is full solidified. The special device is used for installing a mould in a microwave cavity, the microwave cavity is externally connected with a microwave generator, and the microwave cavity is internally provided with an ultrasonic transducer and is externally connected with an ultrasonic generator. The method and the special device provided by the invention solve the problems that when a fibre reinforced composite material is manufactured by using the traditional composite material forming method, the manufacturing time is long, the energy consumption is high, the fiber soakage is not full and a local region is not filled by a module, and the quality and performance of composite material parts are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

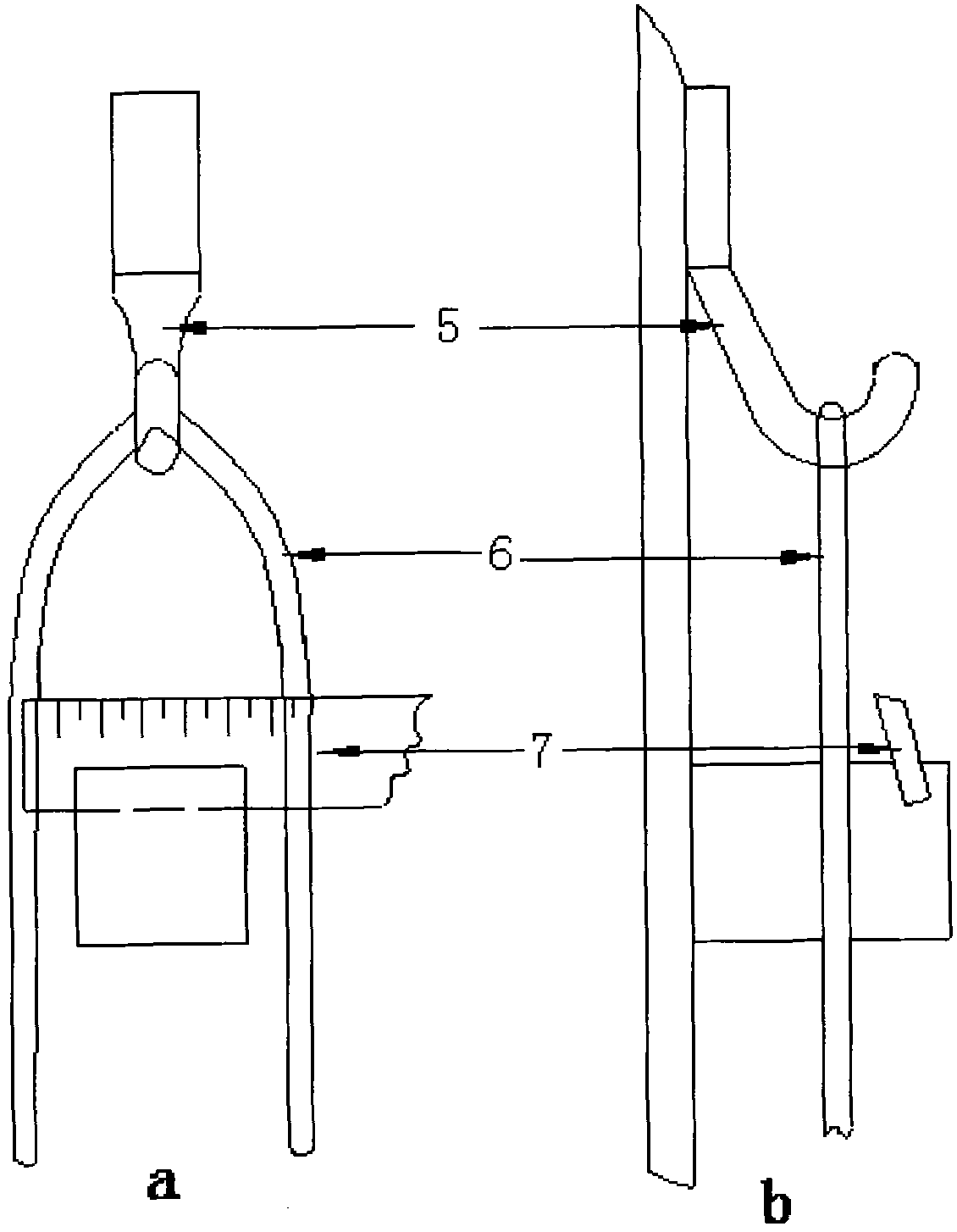

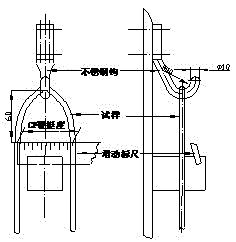

Carbon fiber surface treatment method and treatment device

The invention relates to a carbon fiber surface treatment method and treatment device. The method uses an anode electrolytic oxidation process. The electrolyte used by the method is easy to clean, and has fewer residues after being dried; the method has the advantages of short treatment time and small electric quantity; and after the carbon fiber is treated, the ILSS value can be enhanced by 25%, and no tensile strength is lost. The method adopts a half-contact electrolysis bath, and the anode material can not generate the corrosion phenomenon, thereby reducing the contact between the filament bundle and the guide roller and reducing the damage of the filament bundle. The method adopts a two-stage water washing device with a sprayer to perform water washing, and has the characteristics of low water consumption and fewer electrolyte residues. The drying adopts a contact-type drier which has the characteristics of short time and small space.

Owner:ZHONGFU SHENYING CARBON FIBER +1

Method for producing carbon/carbon skid of magnetic suspension train

The production of carbon / carbon skid for magnetic suspension train includes needle punching process of preparing quasi-3D prefabricated body of carbon cloth and carbon fiber and isothermal CVI densifying process of the prefabricated body inside negative pressure directional flow vapor carbon depositing furnace to form pyrolytic carbon base body; soaking with furfural acetone resin or phenolic resin with superfine SiC, Al2O3 or ZrO2 powder added inside a vacuum-pressure soaking tank; curing, carbonizing and high temperature processing to form the modified binary carbon base skid material. The present invention has high interlayer shearing strength and heat conducting coefficient, excellent wear resistance and low production cost and is suitable for industrial production.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

Preparation method of acrylic polymer grafted carbon fiber multi-scale reinforcement

InactiveCN103275282AThe surface is inertSmall specific surface areaPhysical treatmentInterlaminar shearResin matrix

The invention discloses a preparation method of an acrylic polymer grafted carbon fiber multi-scale reinforcement, relating to a carbon fiber reinforcement and a preparation method thereof. The preparation method comprises the following steps of: 1) performing oxidation treatment on a carbon fiber surface; 2) grafting a silane coupling agent to the carbon fiber surface after the oxidation treatment; 3) obtaining chain transfer agent grafted carbon fiber through a reaction between the carbon fiber surface grafted silane coupling agent and a chain transfer agent; and 4) initiating acrylic monomer grafting polymerization on the surface of the chain transfer agent grafted carbon fiber to finally obtain an acrylic polymer grafted carbon fiber multi-scale reinforcement. The method disclosed by the invention has the advantages that the roughness of the carbon fiber surface can be greatly improved, a great quantity of active functional groups can be introduced, the reaction activity of the carbon fiber surface is improved, the wettability and cohesiveness between the carbon fiber and a resin matrix are improved, and the interlaminar shear strength of an epoxy composite material is enhanced by 40-50%.

Owner:NANCHANG HANGKONG UNIVERSITY

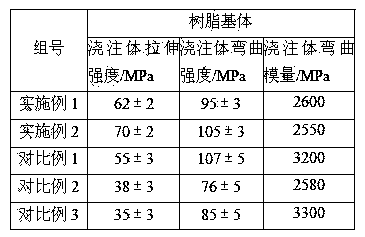

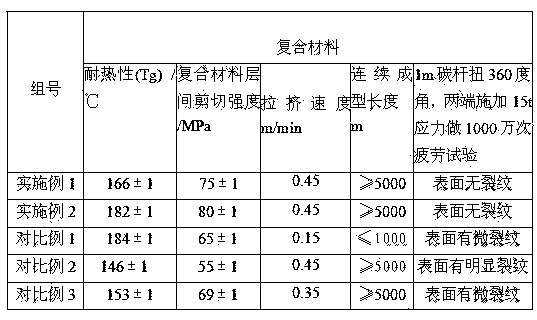

Carbon nano dual-cured resin matrix for pultrusion process and composite of carbon nano dual-cured resin matrix

The invention relates to a carbon nano dual-cured resin matrix for a pultrusion process and a composite of the carbon nano dual-cured resin matrix. The resin matrix is made from the following raw materials in parts by weight: 50-90 parts of epoxy resin and a curing agent thereof, 10-50 parts of vinyl ester resin and an initiator thereof, 1-2 parts of carbon nanotubes, and an appropriate amount of optional additives; the resin matrix is a dual-cured homogeneous system formed by the epoxy resin and the curing agent thereof, the vinyl ester resin and the initiator thereof, and the carbon nanotubes uniformly dispersed in the resin matrix. The resin system has the characteristics of low viscosity, high invasion with fibers, high curing speed and uniform heat and mass transfer; the resin matrix is high in stability and continuity in the pultrusion process. The composite prepared through pultrusion is high in flexibility, higher in interlaminar shear strength, high in heat resistance, and excellent in surface smoothness and rigidity.

Owner:SHANDONG YANGXIN FENGYUAN SCI & TECH

Preparation method of carbon nanotube-carbon fiber mixed enhanced epoxy resin composite material

The invention provides a preparation method of a carbon nanotube-carbon fiber mixed enhanced epoxy resin composite material. The preparation method comprises the following steps: carrying out modification treatment on surfaces of carbon fibers; preparing a sizing agent of carbon-containing nanotubes; preparing a carbon nanotube-carbon fiber enhanced body; preparing a carbon-containing nanotube enhanced epoxy resin matrix; and preparing the carbon nanotube-carbon fiber mixed enhanced epoxy resin composite material and the like. Compared with a traditional carbon fiber enhanced epoxy resin composite material, the carbon nanotube-carbon fiber mixed enhanced epoxy resin composite material has the advantages that the mechanical properties are obviously improved; and the interfacial shear strength is improved by 34 to 42 percent and the inter-laminar shear strength of the composite material is improved by 31 to 34 percent. The preparation method of the composite material, provided by the invention, has the advantages of simple molding technology, excellent mechanical properties and the like.

Owner:CIVIL AVIATION UNIV OF CHINA

Composite water based carbon fiber sizing agent and preparation method and use method thereof

ActiveCN107022901ASolve the problem of sizing carbon fibers that cannot be used for high temperature resistant thermoplastic resin matrix compositesGood sizing effectCarbon fibresEpoxyWater based

The invention relates to a composite water-based carbon fiber sizing agent and a preparation method and a use method thereof, and belongs to the field of carbon fiber manufacturing. Waterborne polyamide imide / epoxy resin is adopted for compounding; the obtained water-based carbon fiber sizing agent is applied to both conventional thermosetting resin and a thermoplastic matrix, and is specially suitable for high temperature-resistant engineering plastics such as polyether-ether-ketone (PEEK), polyimide (PI) and polyphenylene sulfide (PPS).

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com