Preparation method of carbon nano tube and functionalized carbon fiber reinforced bismaleimide resin matrix composite

A technology of bismaleimide resin and maleimide resin, which is applied in the field of nanomaterials, can solve the problems of difficult uniform dispersion, easy agglomeration, and high surface energy of carbon nanotubes, and achieve good interlayer shear strength , The preparation method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

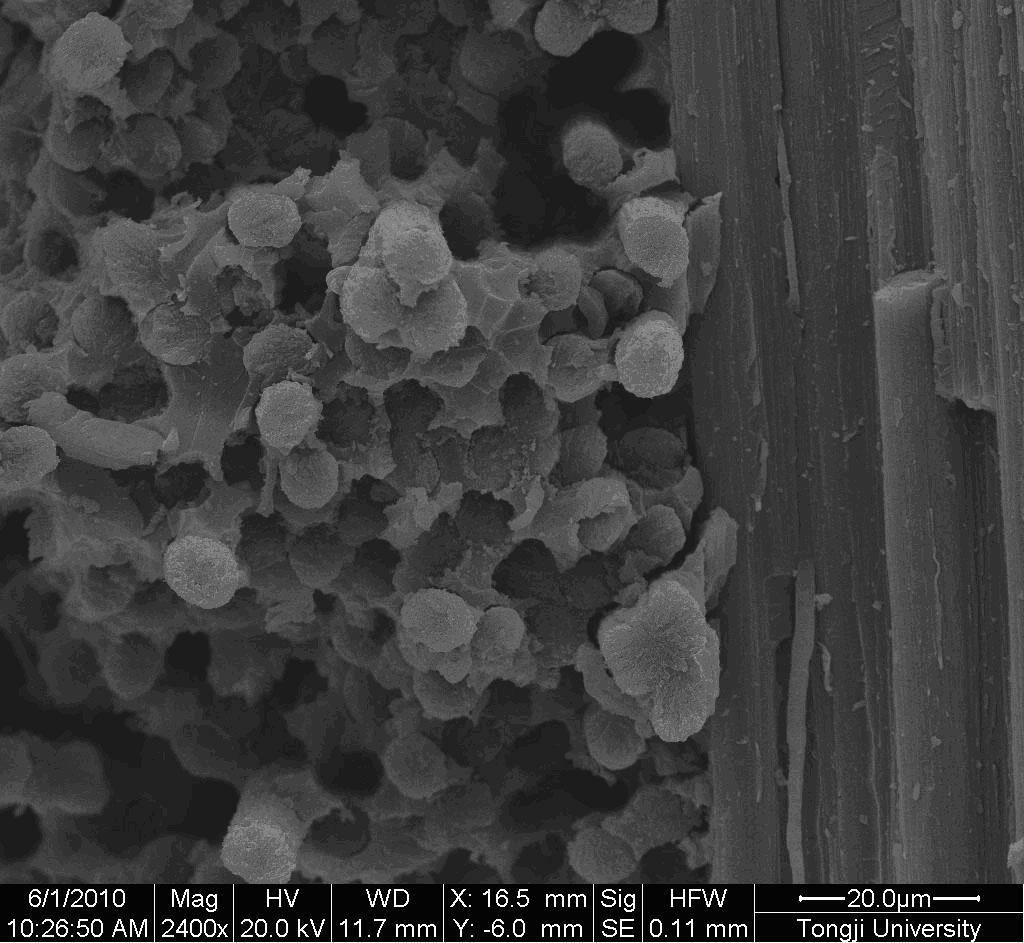

[0034] Example 1: Multi-walled carbon nanotubes (OD<8nm) and carbon fibers prepared by the arc discharge method are used as initial raw materials. After purification, acidification and amination, the multi-walled carbon nanotubes react with acidified carbon fibers. After a certain period of reaction , and then add decyl diamine to the system to fully aminate the carboxyl groups that have not completely reacted with the aminated carbon nanotubes on the surface of the carbon fiber, and the surface of the obtained carbon fiber is grafted with carbon nanotubes and decyl diamine, and then the carbon fiber and 4,4′-bismaleimidodiphenylmethane (BDM) prepolymerization reaction to obtain functionalized carbon fiber surface grafted with 4,4′-bismaleimidodiphenylmethane (BDM) Reinforcement; react aminated carbon nanotubes with 4,4'-bismaleimidodiphenylmethane (BDM) resin to obtain carbon nanotube-strengthened 4,4'-bismaleyl The matrix of imidodiphenylmethane (BDM) resin; finally, the sur...

Embodiment 2

[0044] Example 2: Single-walled carbon nanotubes (OD<8nm) prepared by chemical vapor deposition are used as the initial raw material. After purification, acidification and amination, the single-walled carbon nanotubes react with acidified carbon fibers. After a certain period of time, Then add hexamethylenediamine to the system to fully aminate the carboxyl groups that have not completely reacted with the aminated carbon nanotubes on the surface of the carbon fiber, and the surface of the obtained carbon fiber is grafted with carbon nanotubes and hexamethylenediamine, and then the carbon fiber and N- Methyl phthalimide prepolymerization reaction, the functionalized carbon fiber surface is grafted with N-methyl phthalimide reinforcement; aminated carbon nanotubes and N-methyl Phthalimide resin reacts to obtain the matrix of N-methylphthalimide resin reinforced by carbon nanotubes; finally, the functionalized carbon fiber surface obtained above is grafted with N-methyl-phthalimid...

Embodiment 3

[0054] Example 3: Single-walled carbon nanotubes (OD<8nm) prepared by laser evaporation method were used as the initial raw material. After purification, acidification and amination, the single-walled carbon nanotubes reacted with acidified carbon fibers. Add ethylenediamine to the system to fully aminate the carboxyl groups that have not completely reacted with the aminated carbon nanotubes on the surface of the carbon fiber, and the surface of the obtained carbon fiber is grafted with carbon nanotubes and ethylenediamine, and then the carbon fiber is mixed with 4, 4'-bismaleimido-diphenylmethane (BDM) resin prepolymerization reaction to obtain functionalized carbon fiber surface grafted with 4,4'-bismaleimido-diphenylmethane (BDM) resin Reinforcement; react aminated carbon nanotubes with 4,4'-bismaleimidodiphenylmethane (BDM) resin to obtain carbon nanotube-strengthened 4,4'-bismaleyl The matrix of imidodiphenylmethane (BDM) resin; finally, the surface of the functionalized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com