Preparation method of carbon nanotube-carbon fiber mixed enhanced epoxy resin composite material

A carbon nanotube and epoxy resin technology, which is applied in the field of preparation of carbon nanotube-carbon fiber hybrid reinforced epoxy resin composite materials, can solve problems such as the reduction of fiber mechanical properties, achieve performance improvement, increase shear strength, and improve infiltration. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

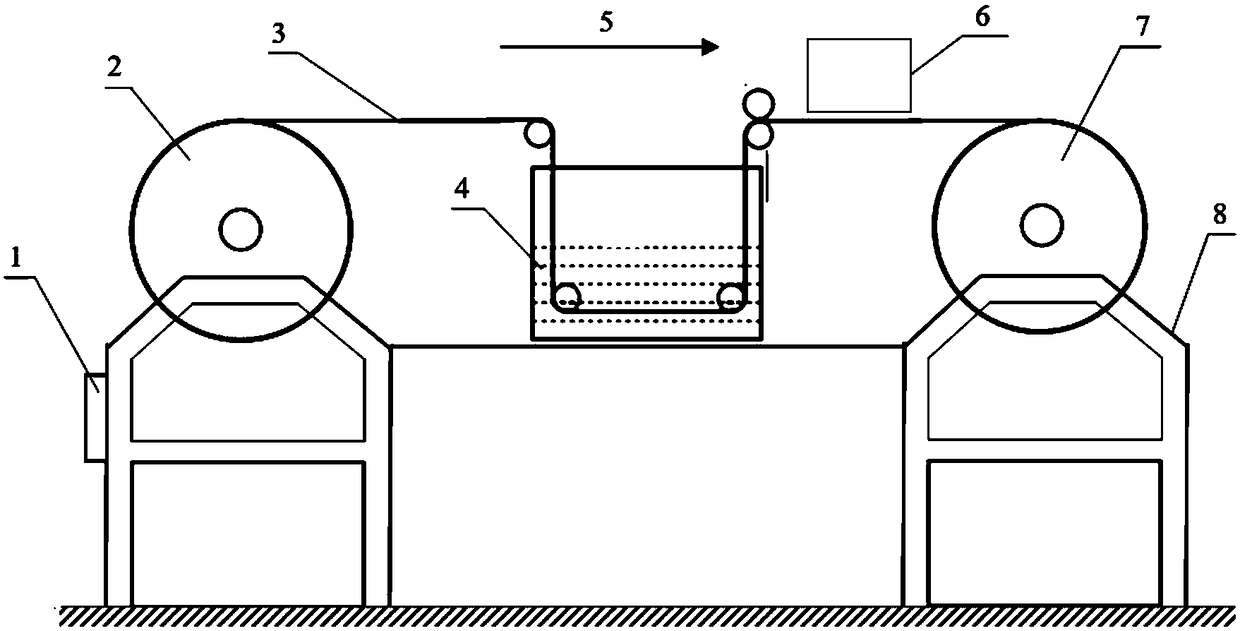

Image

Examples

Embodiment 1

[0028] The preparation method of the carbon nanotube-carbon fiber hybrid reinforced epoxy resin composite material provided in this embodiment includes the following steps in order:

[0029] (1) Modification of carbon fiber surface:

[0030] The commercially available industrial grade JT300A carbon fiber was immersed in analytically pure ammonia water, etched at 25°C for 12 hours, and then the carbon fiber was washed with deionized water several times to remove residual ammonia water on the surface; the carbon fiber treated with ammonia water Immerse in concentrated nitric acid of analytical grade, oxidize at 115°C for 5 minutes at a constant temperature, and then wash the carbon fiber with deionized water several times to remove residual nitric acid on the surface; finally put it in a vacuum drying oven and dry it at a drying temperature of 100°C Vacuum dried for 3 hours for later use.

[0031] (2) prepare the sizing agent containing carbon nanotubes:

[0032] Add 20g of TG...

Embodiment 2

[0040] The preparation method of the carbon nanotube-carbon fiber hybrid reinforced epoxy resin composite material provided in this embodiment includes the following steps in order:

[0041] (1) Modification of carbon fiber surface:

[0042] Commercially available industrial grade JT300A carbon fibers were immersed in analytically pure ammonia water, etched at 25°C for 24 hours, and then the carbon fibers were washed with deionized water for several times to remove residual ammonia water on the surface; the carbon fibers treated with ammonia water Immerse in concentrated nitric acid of analytical grade, oxidize at a constant temperature of 115°C for 10 minutes, then wash the carbon fiber with deionized water several times to remove residual nitric acid on the surface; Vacuum dried for 3h for later use.

[0043] (2) prepare the sizing agent containing carbon nanotubes:

[0044] Add 20g of TGDDM resin, 1.0g of carboxylated multi-walled carbon nanotubes with a diameter of 40-60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com