Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Less fuzz" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Emulsion type carbon fiber sizing agent and preparation method and application thereof

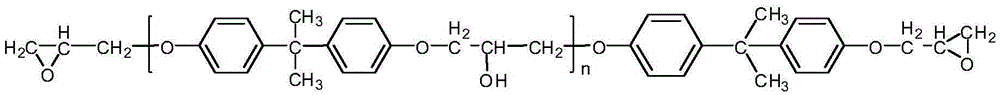

The invention discloses an emulsion type carbon fiber sizing agent, which comprises main size, an emulsifier, an aid and deionized water. The aid comprises a diluent and a penetrant, wherein the emulsifier is 5 to 15 mass percent of the main size, the diluent is 0 to 120 mass percent of the main size, the penetrant is 1 to 5 mass percent of the main size, and the mass ratio of the deionized water to the main size is 50-90:10-50. The invention also discloses a preparation method and application of the sizing agent. The sizing agent is suitable for unsaturated polyester resin and solves the problem of poor adhesion of the unsaturated polyester resin and the carbon fiber. After the sizing agent is used for sizing, the wear resistance of the carbon fiber is improved, and the broken filament amount is reduced, the post-processing performance of the fiber is improved, the interface adhesion of the carbon fiber and matrix resin is better, the shear strength between layers is improved, and the performance of composite materials is also improved.

Owner:UNIV OF JINAN

Carbon fiber emulsion sizing agent and preparation method and application thereof

The invention discloses a carbon fiber emulsion sizing agent. The sizing agent comprises a main sizing agent, an auxiliary agent, an organic solvent and de-ionized water, wherein the auxiliary agent accounts for 5 to 15 percent of the mass of the main sizing agent; the mass ratio of the organic solvent to the main sizing agent is 20-50 to 50-80; and the mass ratio of the de-ionized water to the main sizing agent is 50-90 to 10-50. The invention also discloses a preparation method and application of the sizing agent. The sizing agent has low cost and environment friendliness and can be applied to different types of resin matrixes by varying the ratio of the components in the sizing agent. The preparation method is simple to operate and easy to implement. The sizing agent can improve the processability of the carbon fiber and the mechanical property of carbon fiber-enhanced resin-based composite materials when used in carbon fiber.

Owner:UNIV OF JINAN

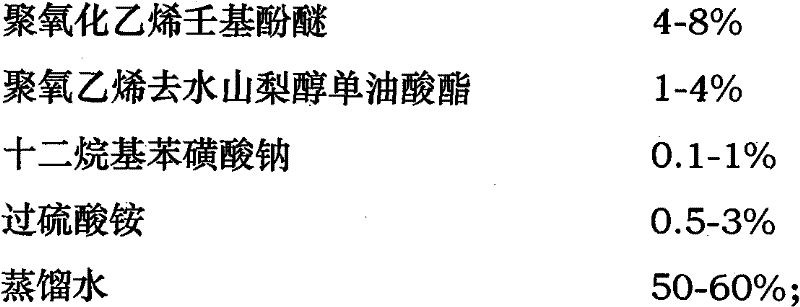

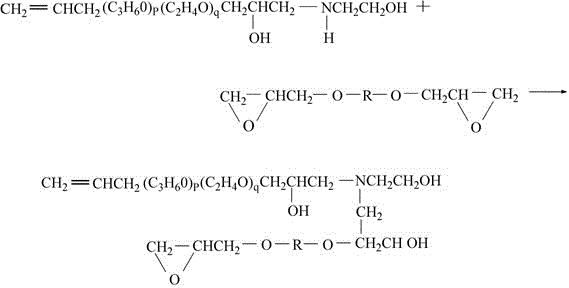

Method for preparing self-emulsifying carbon fiber sizing agent component

InactiveCN101880967AGood compatibilityGood static stabilityCarbon fibresCarbon fibersSelf emulsifying

The invention discloses a method for preparing a self-emulsifying carbon fiber sizing agent component, which comprises the following steps of: performing graft polymerization reaction on epoxy resin by adopting an emulsion polymerization method to prepare modified epoxy emulsion; and standing the modified epoxy emulsion at 80 DEG C for two hours, adding dropwise ammonia water into the solution after demulsification to make the solution alkaline, standing the solution at 95 DEG C in a sealing way, stirring and hydrolyzing the solution for 3 hours, taking the solution out, acidifying and neutralizing the redundant ammonia water, drying and rinsing the solution to produce modified bisphenol A epoxy resin, placing the synthesis product in the step and the bisphenol A epoxy resin into a container according to a certain weight ratio, and performing phase-inversion emulsification on the mixture at 70 DEG C to prepare a modified epoxy emulsion sizing agent component with certain solid content. The prepared carbon fiber sizing agent component has the characteristics of storage time longer than 12 months, high high-temperature stability, and high dilution stability, so that the method has huge breakthrough compared with the prior art. Carbon fibers sized by the sizing agent have high machining performance and improved inter-layer shear strength.

Owner:BEIHANG UNIV

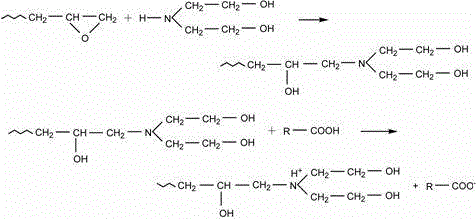

Carbon fiber water-soluble epoxy resin sizing agent

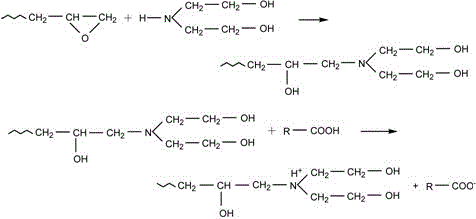

The invention discloses a carbon fiber water-soluble epoxy resin sizing agent and a preparation method thereof. The sizing agent comprises main slurry and deionized water as main components, wherein the mass ratio of the main slurry to the deionized water is (50-80):(20-50); and the main slurry consists of modified phenol-formaldehyde epoxy resin and allyl polyoxylethylene ether (AEPH), and the mass ratio of the modified phenol-formaldehyde epoxy resin to AEPH is (60-90):(10-40). The preparation method of the sizing agent comprises the following steps: firstly reacting phenol-formaldehyde epoxy resin with diethanolamine to obtain water-soluble phenol-formaldehyde epoxy resin; and then mixing the water-soluble resin with AEPH in proportion, and performing dilution to reach a certain concentration by using the deionized water to obtain the sizing agent. The sizing agent disclosed by the invention is good in stability and low in cost, cannot cause environmental pollution, and is simple in preparation method; good post-processing performance of carbon fibers can be provided by adding flexible molecular AEPH; experiments show that after the carbon fibers are coated with a proper amount of the sizing agent, the post-processing performance can be significantly improved; and the performance of a carbon fiber epoxy resin composite material can be improved.

Owner:UNIV OF JINAN

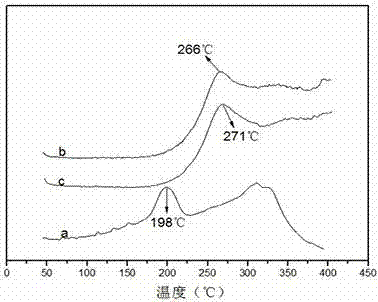

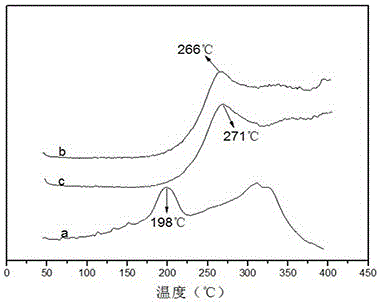

Temperature-resistant type emulsion sizing agent for carbon fiber, as well as preparation method and application of sizing agent

InactiveCN104294602AHigh glass transition temperatureImprove temperature resistanceCarbon fibresEmulsionMass ratio

The invention discloses a temperature-resistant type emulsion sizing agent for a carbon fiber. The temperature-resistant type emulsion sizing agent comprises the following materials: main size, an emulsifying agent, an additive and deionized water, wherein the main size is glycidyl amine type epoxy resin modified by dodecanamine, and in modification, the mass ratio of dodecanamine to the epoxy resin is (10-40) to (60-90); the mass of the emulsifying agent is 5-15% of the mass of the main size; the additive comprises a diluting agent and a penetrating agent, the mass of the diluting agent is 0-100% of the mass of the main size, and the mass of the penetrating agent is 1-5% of the mass of the main size; the mass ratio of the deionized water to the main size is (50-90) to (10-50). The invention also discloses a preparation method and application of the sizing agent. The sizing agent disclosed by the invention is high in stability and does not cause pollution to the environment, and the preparation method is simple; in the presence of a flexible molecule, namely dodecanamine, the carbon fiber has relatively high operability; proved by experiments, after the carbon fiber is treated by the sizing agent, the post processability is obviously improved; and the interface temperature resistance and the interlaminar shear strength (ILSS) of the carbon-fiber-enhanced epoxy resin composite material are also obviously improved.

Owner:UNIV OF JINAN

Carbon fiber emulsion sizing agent and preparation method and application thereof

Owner:UNIV OF JINAN

Thermoplastic emulsion sizing agent for carbon fiber and preparation method thereof and application thereof

The invention discloses a thermoplastic emulsion sizing agent for carbon fiber. The thermoplastic emulsion sizing agent comprises main pulp, an emulsifying agent, an organic solvent and deionized water. The main pulp is Acrylonitrile-Butadiene-Styrene (ABS) formed by modifying N-Phenylmaleimide-Styrene-Maleic anhydride (NSM). And the mass ratio of the ABS and the NSM is 50-100:0-50. The mass of the emulsifying agent accounts for 10-40% the mass of the main pulp, the mass of the main pulp accounts for 0.5-1.5% the mass of the organic solvent, and the mass of the main pulp accounts for 0.5-1% the mass of the deionized water. The invention further discloses the preparation method of the sizing agent and the application of the sizing agent. The sizing agent is good in stability, low in environmental pollution and simple in preparation method. The NSM can assist a carbon fiber rubber layer generated after sizing is conducted in keeping better completeness in the composite material hot press molding process. It is tested by experiment that the post-processability of the carbon fiber is obviously improved after the carbon fiber is processed through the sizing agent, and the inter-laminar shear strength (ILSS) of the carbon fiber reinforced ABS composite material is obviously improved as well.

Owner:UNIV OF JINAN

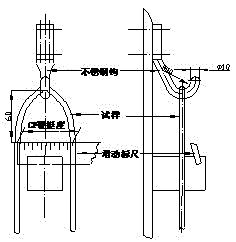

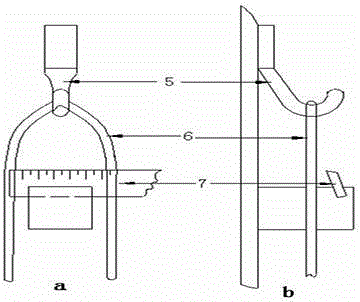

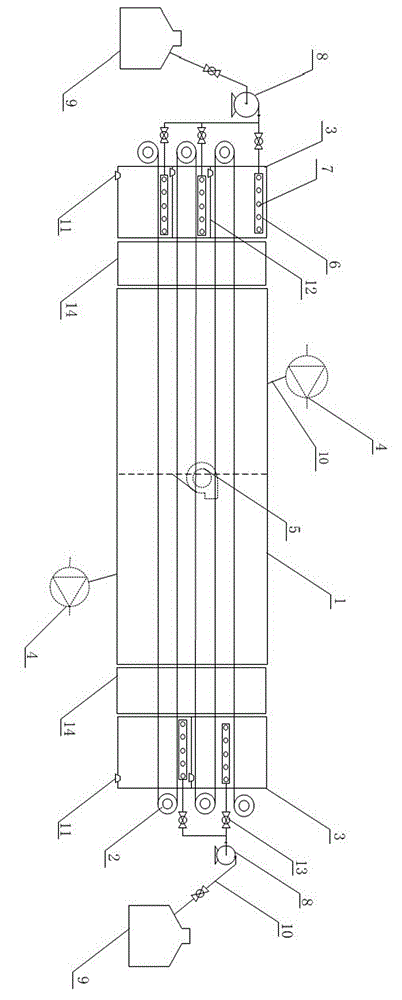

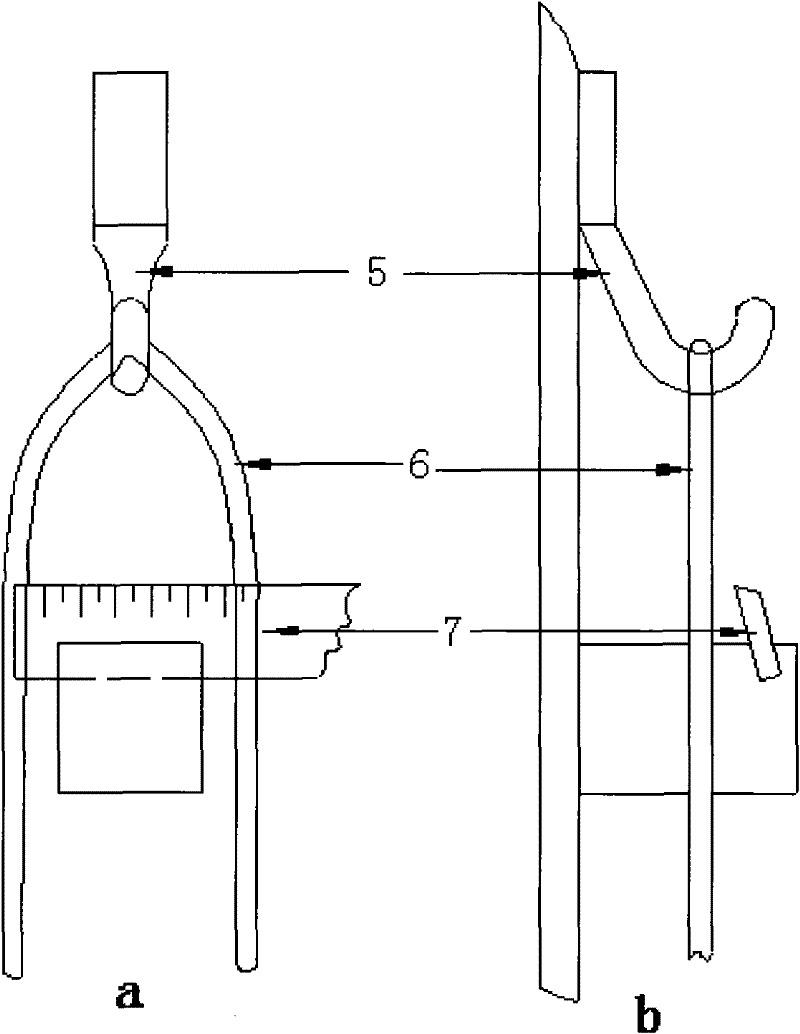

Pre-oxidation furnace

ActiveCN104674380AReduce mechanical friction damageLess fuzzFibre chemical featuresEngineeringLiquid storage tank

The invention discloses a pre-oxidation furnace. The pre-oxidation furnace comprises a furnace body shell, a roller, a circulating fan and an exhaust fan, wherein the circulating fan and the exhaust fan are connected with the furnace body shell by virtue of connecting pipelines, two ends of the furnace body shell are provided with furnace end humidifying devices, a humidifying pipe is arranged inside each furnace end humidifying device, a humidifying hole is formed in the humidifying pipe, and each humidifying pipe is connected with a humidifying liquid storage tank by virtue of a connecting pipeline. Two ends of the pre-oxidation furnace are provided with the furnace end humidifying devices, so that in the pre-oxidation production process, the mechanical abrasion and damage of carbon fibers can be greatly reduced, the quantity of broken filaments on the surface of the carbon fibers can be greatly reduced, a pre-oxidized filament obtained by pre-oxidizing carbon fiber crude filaments by virtue of the pre-oxidation furnace basically has no skin-core structure or has a slightly skin-core structure, the tensile strength and the tensile elastic modulus of the carbon fibers prepared by carbonizing the pre-oxidized filament are greatly improved, and the carbon fibers are not prone to break.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV

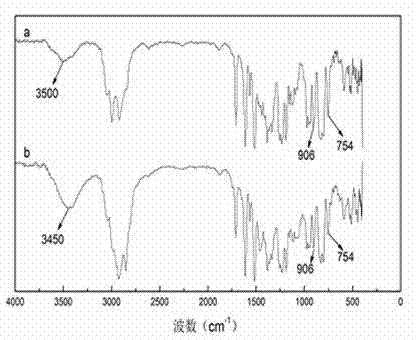

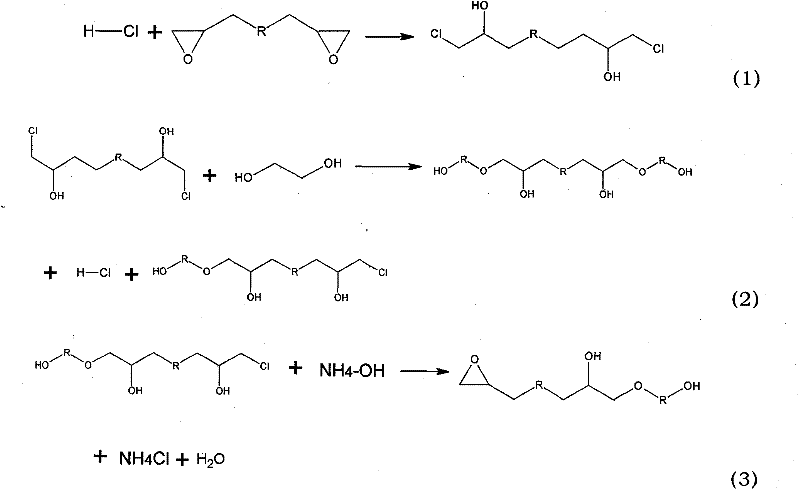

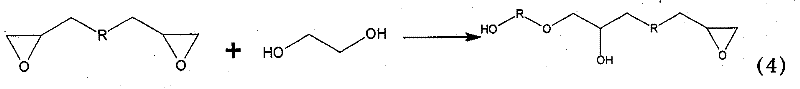

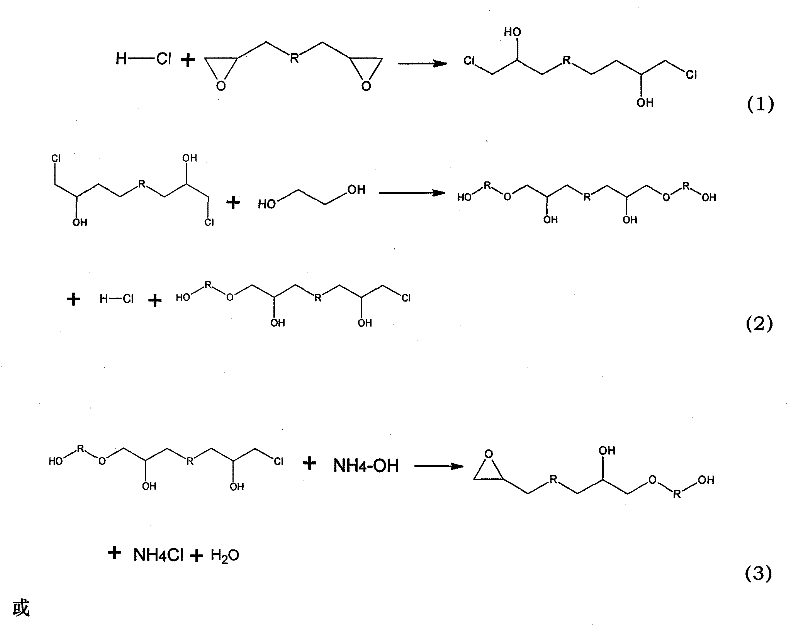

Preparation method of sizing agent for self-emulsifying waterborne epoxy resin carbon fiber

The invention relates to a preparation method of a sizing agent for self-emulsifying waterborne epoxy resin carbon fiber and solves the technical problems that products prepared by existing methods have room for improvement in mechanical performance, are low in mechanical tensile strength, cause environment pollution and are ideal in resistance to dampness and heat. The preparation method includes following steps: synthesizing a surfactant containing epoxy functional group; synthesizing self-emulsifying waterborne epoxy resin polymer containing surfactant functional group; emulsifying the self-emulsifying waterborne epoxy resin polymer containing the surfactant functional group. The preparation method is widely used in the field of preparing the sizing agent for carbon fiber.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing self-emulsifying carbon fiber sizing agent component

InactiveCN101880967BGood compatibilityGood static stabilityCarbon fibresCarbon fibersSelf emulsifying

The invention discloses a method for preparing a self-emulsifying carbon fiber sizing agent component, which comprises the following steps of: performing graft polymerization reaction on epoxy resin by adopting an emulsion polymerization method to prepare modified epoxy emulsion; and standing the modified epoxy emulsion at 80 DEG C for two hours, adding dropwise ammonia water into the solution after demulsification to make the solution alkaline, standing the solution at 95 DEG C in a sealing way, stirring and hydrolyzing the solution for 3 hours, taking the solution out, acidifying and neutralizing the redundant ammonia water, drying and rinsing the solution to produce modified bisphenol A epoxy resin, placing the synthesis product in the step and the bisphenol A epoxy resin into a container according to a certain weight ratio, and performing phase-inversion emulsification on the mixture at 70 DEG C to prepare a modified epoxy emulsion sizing agent component with certain solid content. The prepared carbon fiber sizing agent component has the characteristics of storage time longer than 12 months, high high-temperature stability, and high dilution stability, so that the method has huge breakthrough compared with the prior art. Carbon fibers sized by the sizing agent have high machining performance and improved inter-layer shear strength.

Owner:BEIHANG UNIV

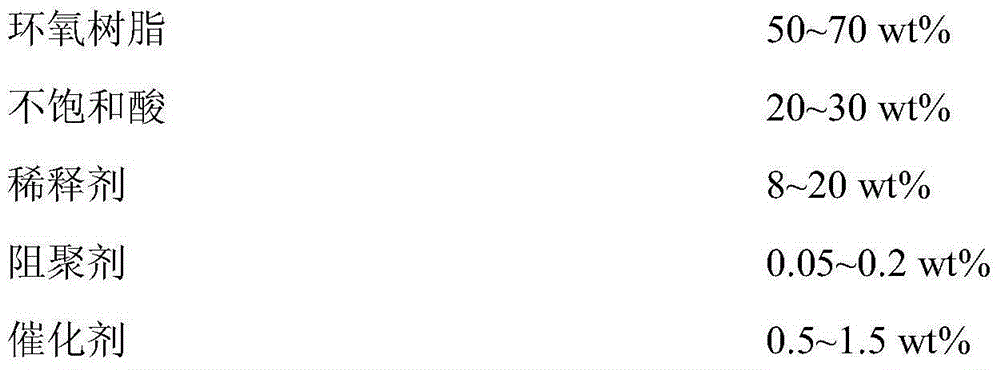

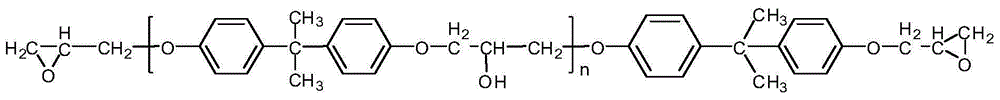

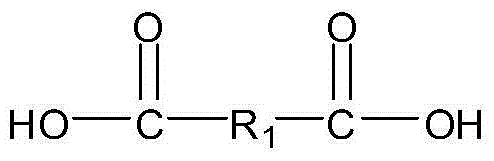

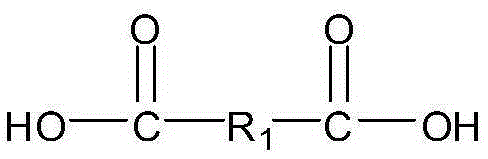

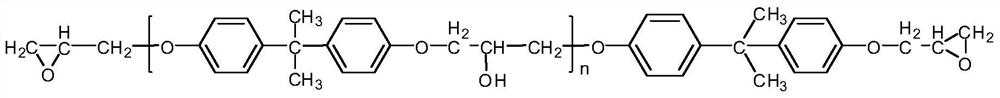

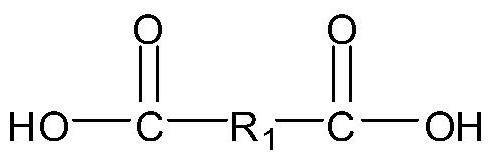

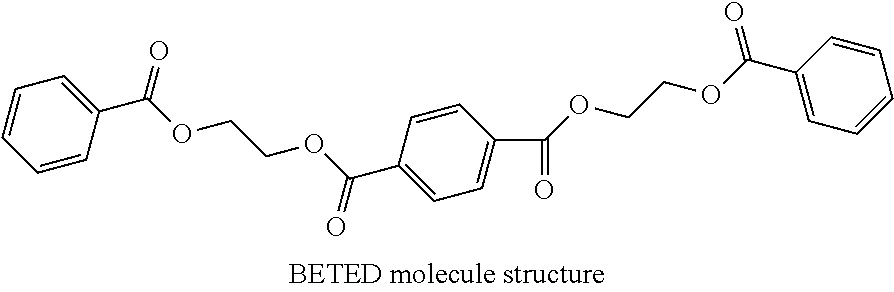

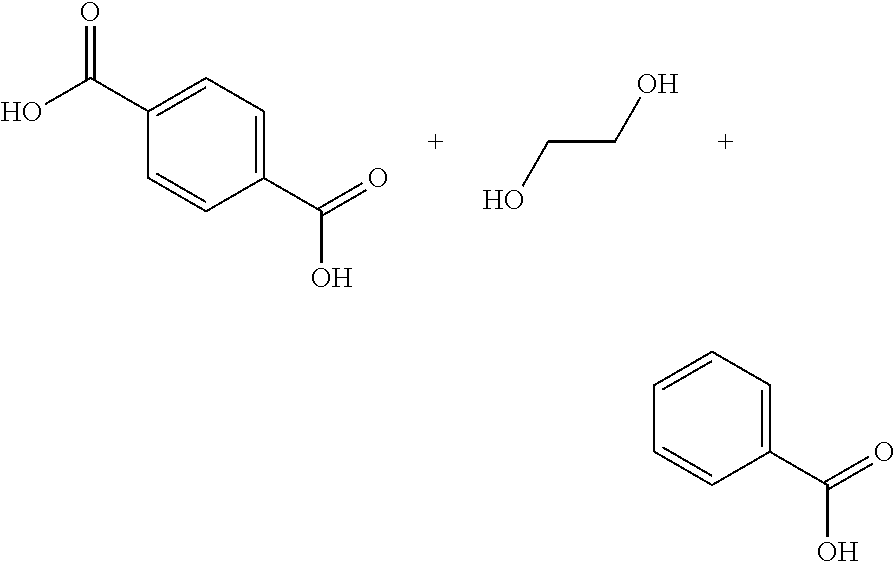

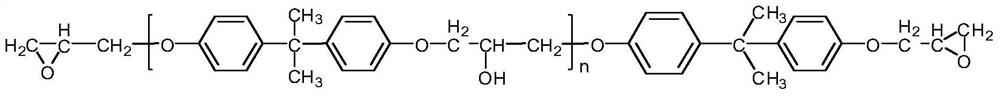

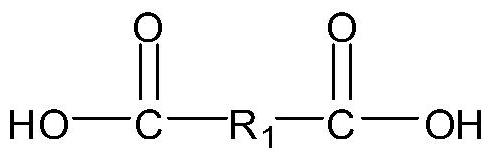

Small silk bundle universal carbon fiber sizing agent as well as preparation method and application of small silk bundle universal carbon fiber sizing agent

ActiveCN106592236AIncrease intermolecular forcesImprove interface strengthCarbon fibresCarbon fibersPolymer science

The invention discloses a small silk bundle universal carbon fiber sizing agent as well as a preparation method and application of the small silk bundle universal carbon fiber sizing agent. The small silk bundle universal carbon fiber sizing agent comprises the following components: bisphenol A epoxy resin, aliphatic binary monounsaturated acid of which both end groups are carboxyl, an aliphatic reactive diluent of which a molecule comprises one epoxy group, a hydroquinone polymerization inhibitor and a quaternary ammonium bromide catalyst. The small silk bundle universal carbon fiber sizing agent disclosed by the invention is applicable to sizing of industrial 1K-12K small silk bundle carbon fiber, the number-average molecular weight of a reaction product is 2500-2700, sized carbon fiber has good interface bonding strength with thermosetting resin matrixes such as epoxy resin, phenolic resin and bismaleimide resin, is good in universality, and is particularly remarkably improved in interface bonding strength with the epoxy resin and the phenolic resin.

Owner:CHINA PETROLEUM & CHEM CORP +1

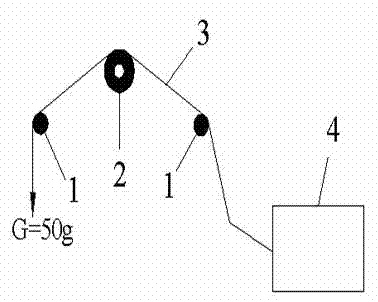

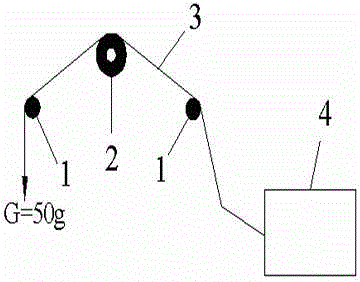

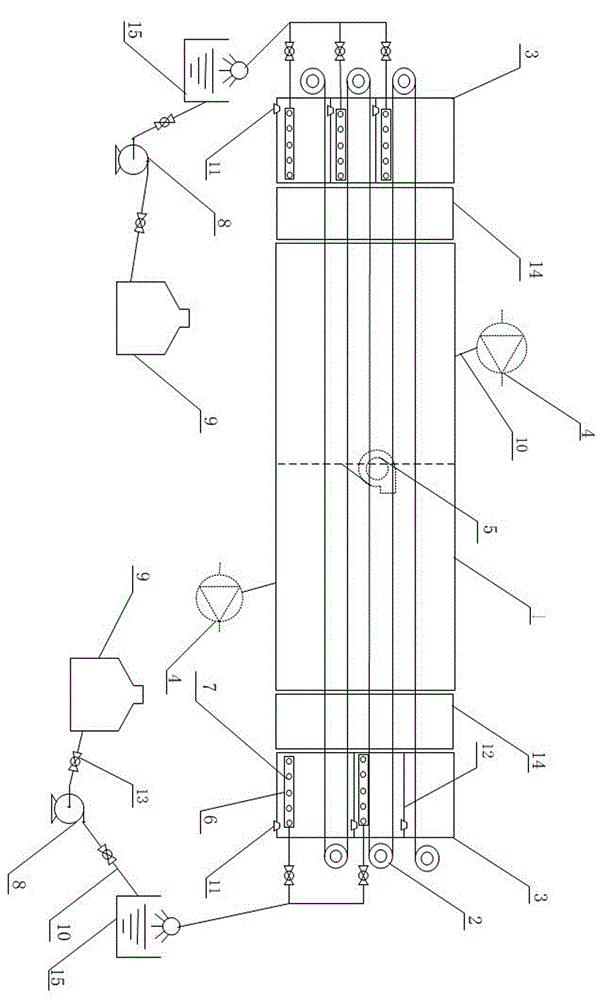

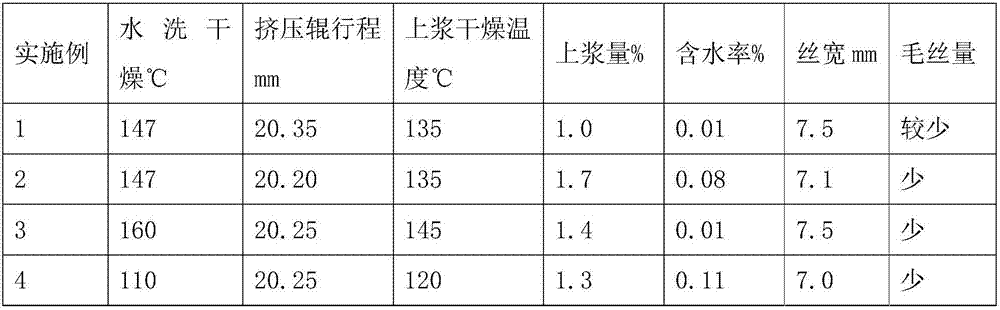

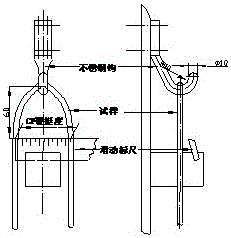

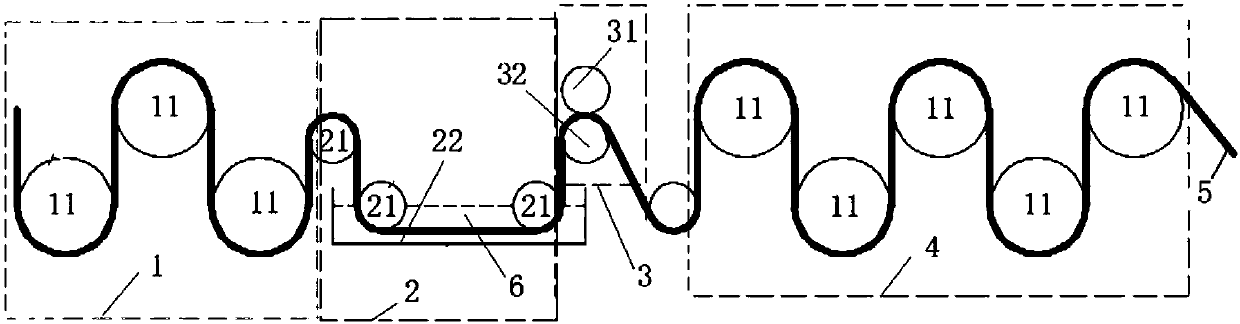

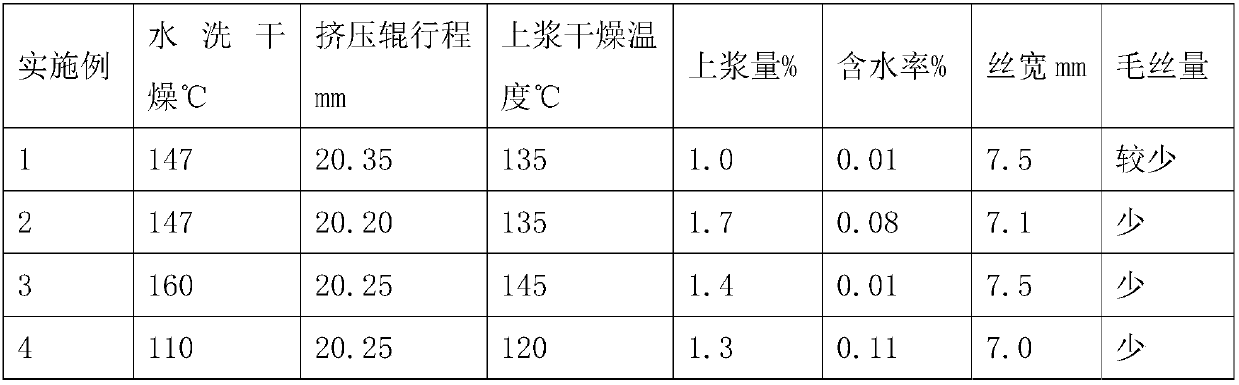

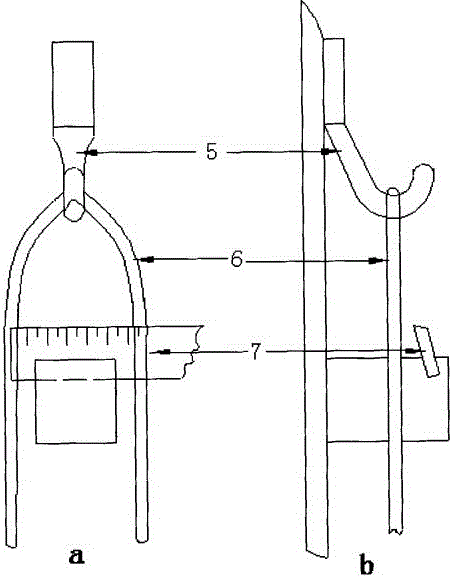

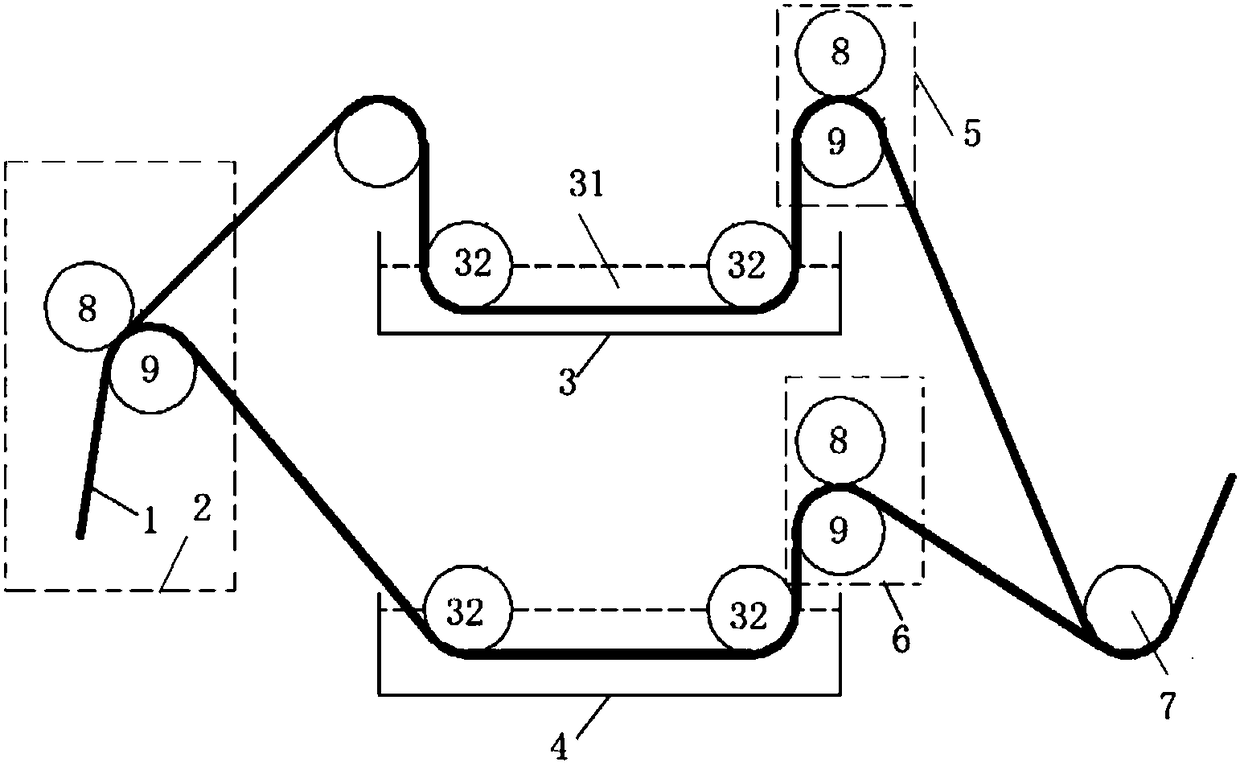

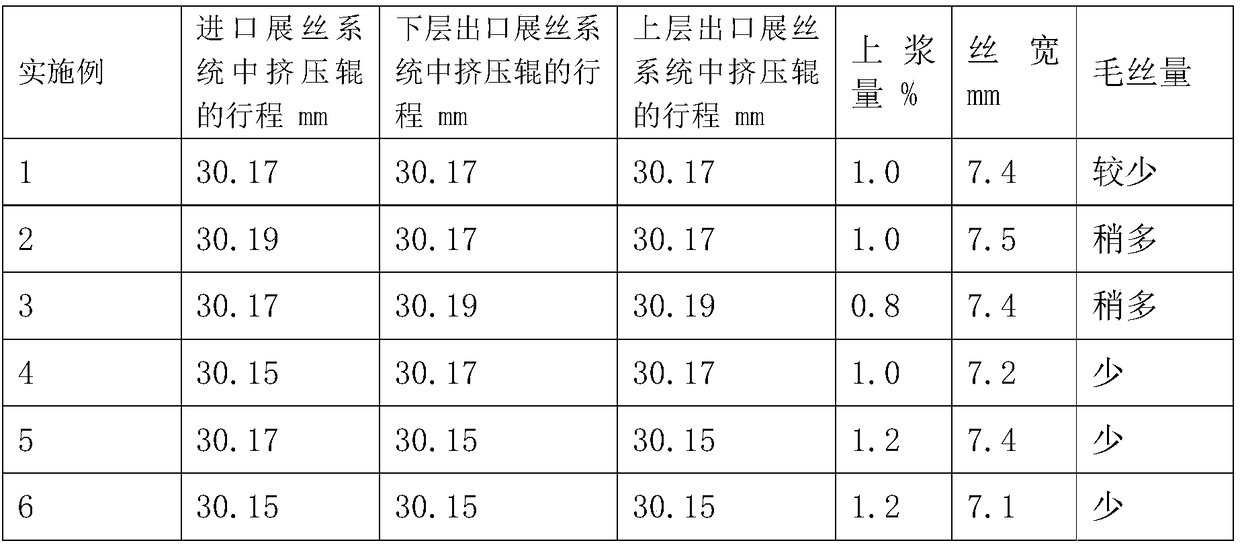

System for water-washing drying, sizing and drying setting of carbon fiber

ActiveCN107385735ASmall footprintLess fuzzSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersFiberCarbon fibers

The invention discloses a system for water-washing drying, sizing and drying setting of carbon fiber. The system comprises a water-washing drying hot roller unit, a sizing system, an extruding rubber roller set and a sizing drying hot roller setting unit, the water-washing drying hot roller unit is used for drying moisture of the carbon fiber in a water-washing section and comprises a first hot roller unit and a first heating system, the sizing system is connected to the water-washing drying hot roller unit, the extruding rubber roller set is connected to the sizing system and used for extruding spare sizing agent in tows of the carbon fiber and comprises a first extruding roller and a second extruding roller in parallel arrangement, and the sizing drying hot roller setting unit is connected to the extruding rubber roller set and used for drying moisture in the sizing process and expanding silk width of the carbon fiber and comprises a second hot roller unit and a second heating system. The system saves space and can remarkably reduce broken filament amount of the carbon fiber and increase the silk width.

Owner:ZHONG AN XIN TECH CO LTD

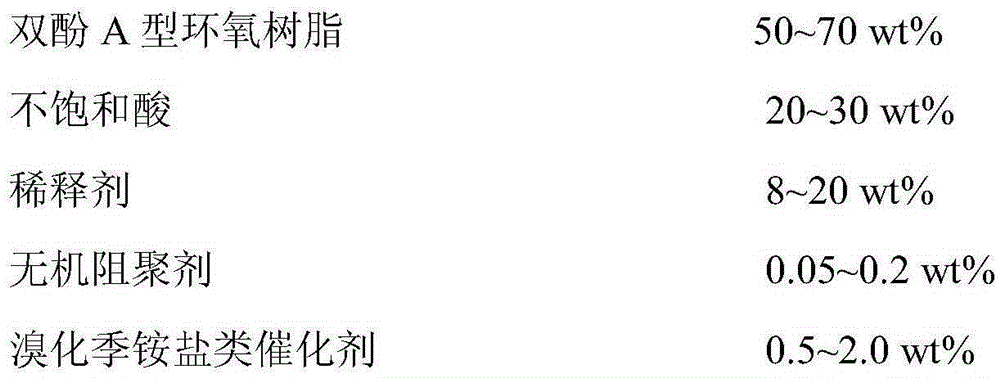

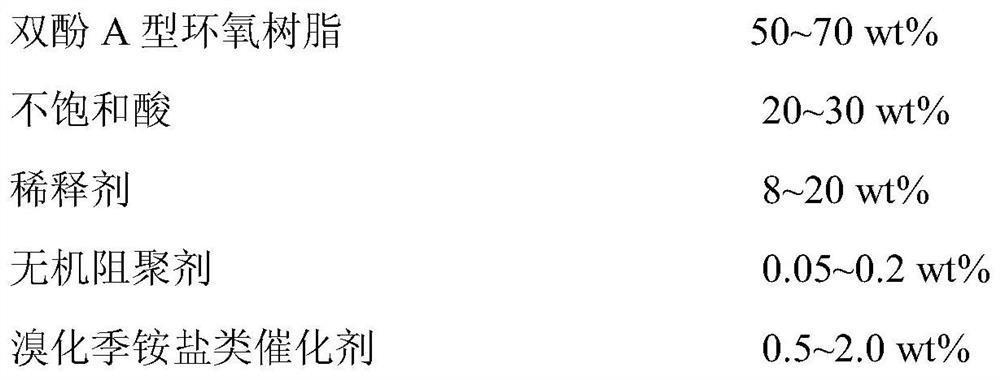

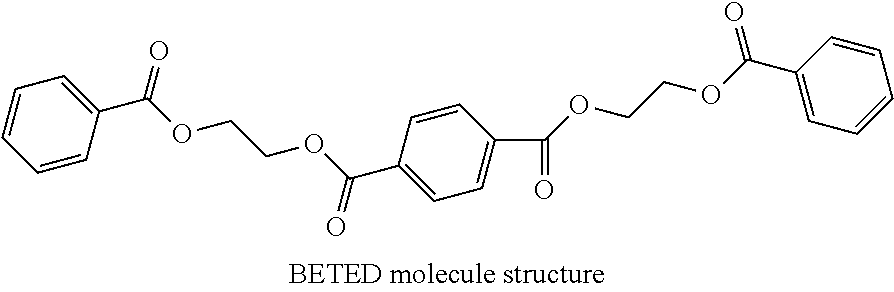

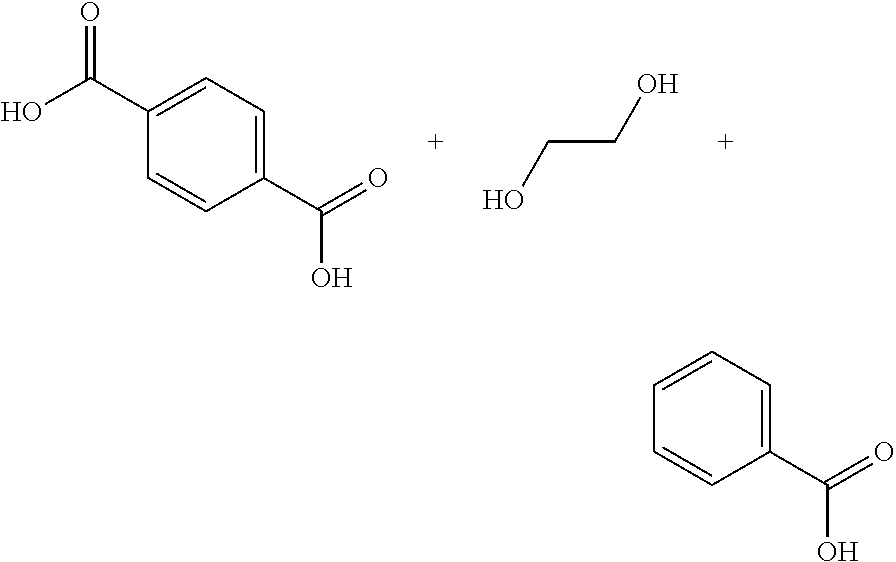

Unsaturated acid modified epoxy resin universal carbon fiber sizing agent, and preparation method and application thereof

ActiveCN106589313AIncrease intermolecular forcesImprove interface strengthCarbon fibresCarbon fibersEnd-group

The invention discloses an unsaturated acid modified epoxy resin universal carbon fiber sizing agent, and a preparation method and an application thereof. The universal carbon fiber sizing agent comprises the following components: bisphenol A based epoxy resin, aliphatic binary monounsaturated acid with double end groups which are carboxyl, an aromatic active diluent containing one epoxide group in molecule, an inorganic polymerization inhibitor, and a quaternary ammonium bromide catalyst. The sizing agent is suitable for sizing 1K-12K small filament bundle carbon fiber for aerospace, the maximum decomposition peak temperature of reaction products is higher than 325 DEG C, sized carbon fiber and epoxy resin, phenolic resin, bismaleimide resin and other thermosetting resin substrates have good interface bonding strength with good versatility, and especially interface bonding strength of phenolic resin is substantially improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Emulsion type carbon fiber sizing agent and preparation method and application thereof

The invention discloses an emulsion type carbon fiber sizing agent, which comprises main size, an emulsifier, an aid and deionized water. The aid comprises a diluent and a penetrant, wherein the emulsifier is 5 to 15 mass percent of the main size, the diluent is 0 to 120 mass percent of the main size, the penetrant is 1 to 5 mass percent of the main size, and the mass ratio of the deionized waterto the main size is 50-90:10-50. The invention also discloses a preparation method and application of the sizing agent. The sizing agent is suitable for unsaturated polyester resin and solves the problem of poor adhesion of the unsaturated polyester resin and the carbon fiber. After the sizing agent is used for sizing, the wear resistance of the carbon fiber is improved, and the broken filament amount is reduced, the post-processing performance of the fiber is improved, the interface adhesion of the carbon fiber and matrix resin is better, the shear strength between layers is improved, and the performance of composite materials is also improved.

Owner:UNIV OF JINAN

A temperature-resistant emulsion sizing agent for carbon fiber and its preparation method and application

InactiveCN104294602BHigh glass transition temperatureImprove temperature resistanceCarbon fibresEmulsionMass ratio

The invention discloses a temperature-resistant type emulsion sizing agent for a carbon fiber. The temperature-resistant type emulsion sizing agent comprises the following materials: main size, an emulsifying agent, an additive and deionized water, wherein the main size is glycidyl amine type epoxy resin modified by dodecanamine, and in modification, the mass ratio of dodecanamine to the epoxy resin is (10-40) to (60-90); the mass of the emulsifying agent is 5-15% of the mass of the main size; the additive comprises a diluting agent and a penetrating agent, the mass of the diluting agent is 0-100% of the mass of the main size, and the mass of the penetrating agent is 1-5% of the mass of the main size; the mass ratio of the deionized water to the main size is (50-90) to (10-50). The invention also discloses a preparation method and application of the sizing agent. The sizing agent disclosed by the invention is high in stability and does not cause pollution to the environment, and the preparation method is simple; in the presence of a flexible molecule, namely dodecanamine, the carbon fiber has relatively high operability; proved by experiments, after the carbon fiber is treated by the sizing agent, the post processability is obviously improved; and the interface temperature resistance and the interlaminar shear strength (ILSS) of the carbon-fiber-enhanced epoxy resin composite material are also obviously improved.

Owner:UNIV OF JINAN

A kind of carbon fiber water-soluble epoxy resin sizing agent

The invention discloses a carbon fiber water-soluble epoxy resin sizing agent and a preparation method thereof. The main components of the sizing agent are main size and deionized water, and the mass ratio of main size to deionized water is 50~80:20~50. The main slurry is composed of modified novolac epoxy resin and allyl polyoxyethylene ether (AEPH), and the mass ratio of the two is 60~90:10~40. To prepare the sizing agent, first react the novolac epoxy resin with diethanolamine to obtain a water-soluble novolac epoxy resin; then mix the water-soluble resin and AEPH in proportion, and dilute it to a certain concentration with deionized water to obtain the sizing agent. The sizing agent has good stability, low cost, no environmental pollution and simple preparation method. The addition of flexible molecule AEPH endows carbon fibers with good post-processing properties. Experiments show that after the carbon fiber is coated with the appropriate sizing agent, the post-processing performance is obviously improved; the performance of the carbon fiber epoxy resin composite material is improved.

Owner:UNIV OF JINAN

Polyalcohol modified epoxy resin carbon fiber emulsion sizing agent component and preparation method thereof

The invention discloses a polyalcohol modified epoxy resin carbon fiber emulsion sizing agent component and a preparation method thereof. The method comprises the steps of ring-opening the preparing modified epoxy. The modified epoxy resin has hydropathy, can be dissolved in water, and can be prepared into a modified epoxy emulsion under certain conditions. The modified epoxy emulsion is the polyalcohol modified epoxy resin carbon fiber emulsion sizing agent component. A foreign emulsifying agent is added in the preparation process, and the modified epoxy emulsion belongs to a self-emulsifying system without breaking the emulsion and demixing and has controllable and proper viscosity, good standing stability, excellent pH value stability and high-temperature stability. The foreign emulsifying agent does not remain on the fiber after the sizing; and compared with the carbon fiber without being sized, the carbon fiber coated with the sizing agent component has less broken filament amount and good bundling performance, and can ensure that the interface performance is improved because of a structure that one end of the modified epoxy resin is a polyether bond and the other end is an epoxy group.

Owner:BEIHANG UNIV

Systems for washing-drying, sizing and dry-setting of carbon fibers

ActiveCN107385735BSmall footprintLess fuzzSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersFiberCarbon fibers

The invention discloses a system for water-washing drying, sizing and drying setting of carbon fiber. The system comprises a water-washing drying hot roller unit, a sizing system, an extruding rubber roller set and a sizing drying hot roller setting unit, the water-washing drying hot roller unit is used for drying moisture of the carbon fiber in a water-washing section and comprises a first hot roller unit and a first heating system, the sizing system is connected to the water-washing drying hot roller unit, the extruding rubber roller set is connected to the sizing system and used for extruding spare sizing agent in tows of the carbon fiber and comprises a first extruding roller and a second extruding roller in parallel arrangement, and the sizing drying hot roller setting unit is connected to the extruding rubber roller set and used for drying moisture in the sizing process and expanding silk width of the carbon fiber and comprises a second hot roller unit and a second heating system. The system saves space and can remarkably reduce broken filament amount of the carbon fiber and increase the silk width.

Owner:ZHONG AN XIN TECH CO LTD

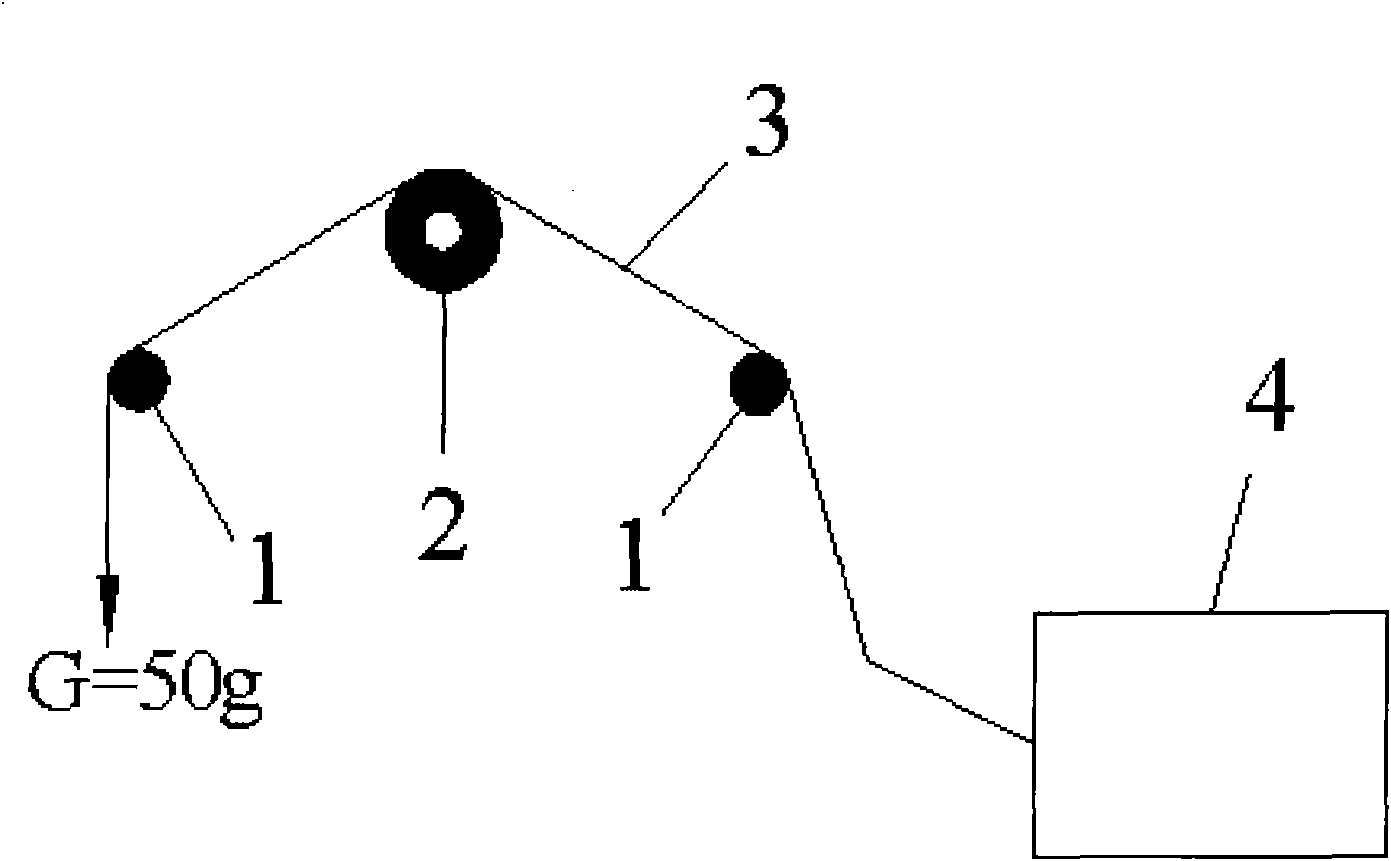

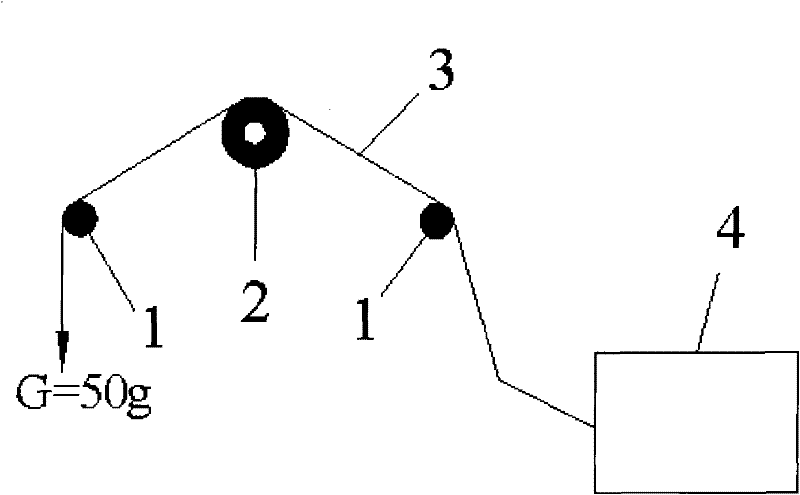

Production device and technological method of twisted yarn for ground retreating

ActiveCN114481394ARaw silk is goodReduce the probability of trippingTextile disintegration and recoveryYarnYarnIndustrial engineering

The invention relates to the technical field of plied yarn processes, in particular to a production device and process method of plied yarn for ground retreating. The production process method of the plied yarn for external retreating on the ground comprises the following steps: rotating a raw yarn cake to a creel, firstly passing through a probe yarn guide eye on the creel, then passing through a yarn guide bar on a suspension yarn regulator, continuously passing through a stand column yarn guide eye, then passing through a yarn guide eye beam splitting wheel on the ground, and finally passing through a yarn guide eye of a winder and a V-shaped guide wheel in the horizontal direction to enter the winder; plied yarns are obtained; and the yarn enters the winder at an angle of 42 degrees through the V-shaped guide wheel. According to the production process method for the ground twisted yarn for external retreating, the use efficiency of the twisted yarn product for external retreating is improved, and the quality requirement of customers for the product is guaranteed. The invention also provides a production device.

Owner:TAISHAN FIBERGLASS ZOUCHENG

Universal carbon fiber sizing agent for unsaturated acid-modified epoxy resin, preparation method and application thereof

ActiveCN106589313BRelieve high viscosityHigh reaction conversion rateCarbon fibresFiberPolymer science

Owner:CHINA PETROLEUM & CHEM CORP +1

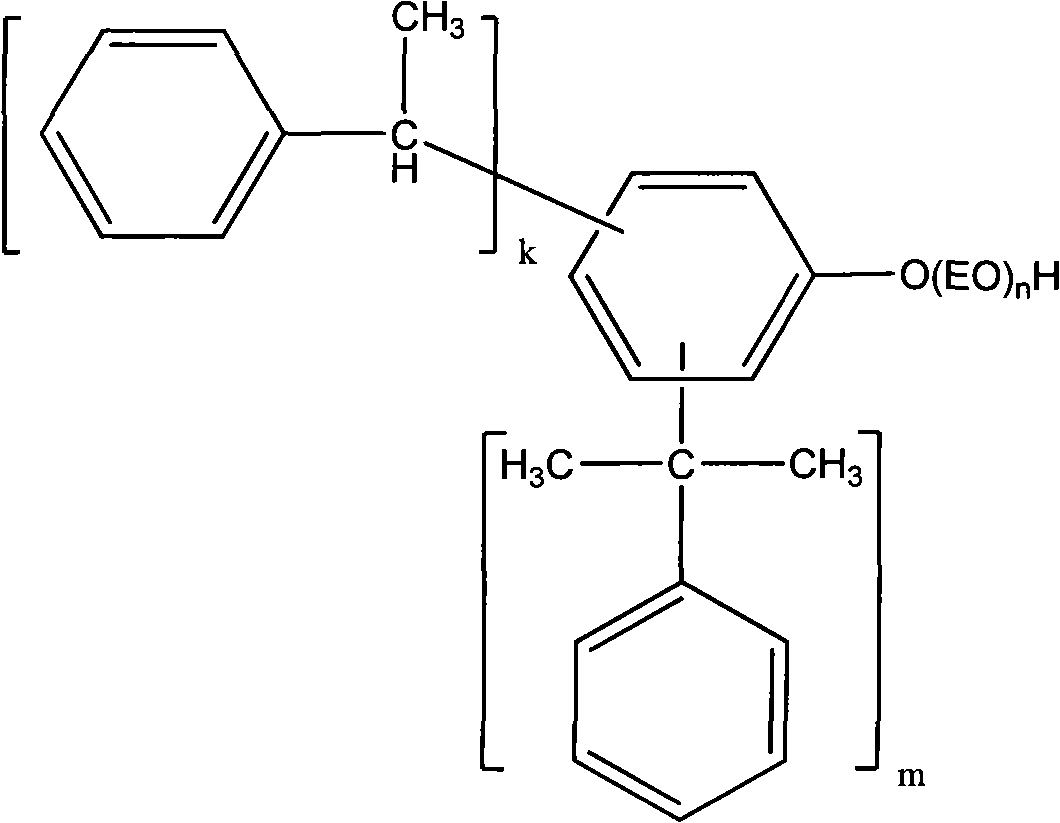

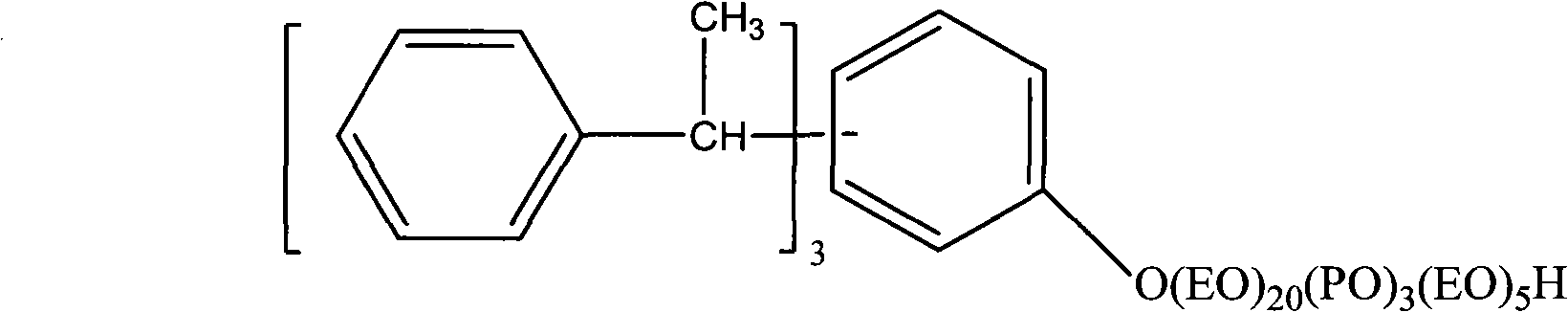

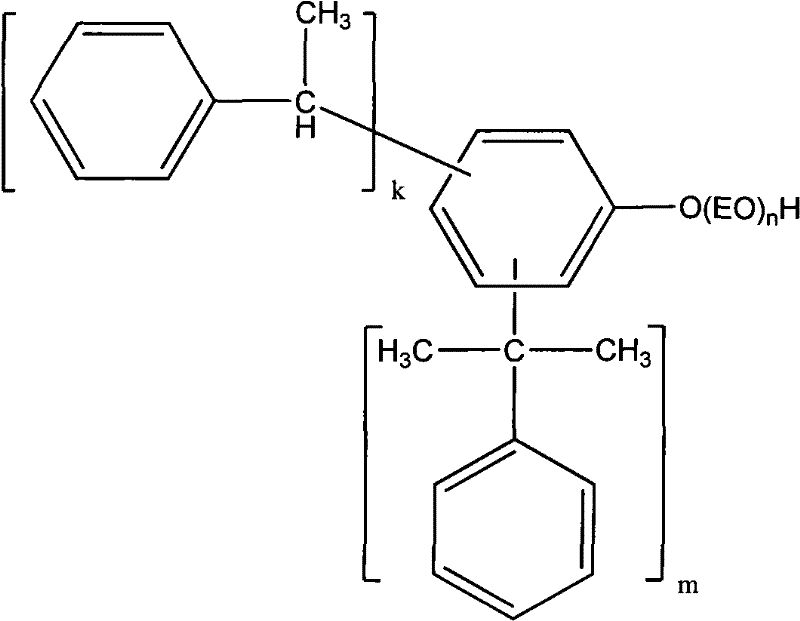

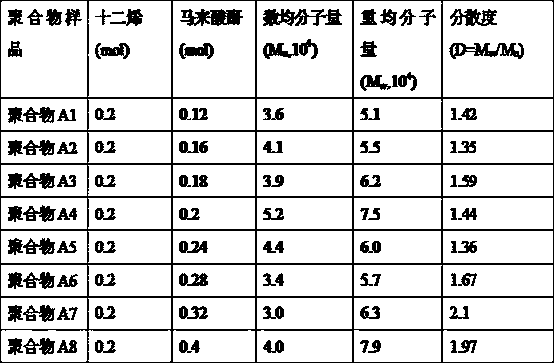

A kind of water-based self-emulsifying carbon fiber sizing agent suitable for thermoplastic resin and preparation method thereof

The invention relates to a waterborne self-emulsifying carbon fiber sizing agent applicable to thermoplastic resin and a preparation method thereof and belongs to the technical field of production of carbon fibers. The waterborne self-emulsifying carbon fiber sizing agent is prepared from an amphiphilic polymer A and / or an amphiphilic polymer B and de-ionized water. The preparation method comprises the following steps: dissolving the amphiphilic polymer A and / or the amphiphilic polymer B into a small amount of a proper organic solvent at a room temperature or a heating condition, and stirring by using a high-speed shearing and dispersion emulsifying machine to stir, wherein the stirring speed is 1000-25000; adding the de-ionized water until phase transferring occurs, and further stirring for 0.5-2 hours; and then carrying out rotary evaporation on the solution to remove the organic solvent to obtain the waterborne self-emulsifying carbon fiber sizing agent. The sizing agent prepared by the invention is the waterborne self-emulsifying sizing agent, has low cost and stable performances, is convenient to use, does not pollute the environment and belongs to a green environment-friendly product.

Owner:GUANGDONG UNIV OF TECH

Method of treating polyester textile

InactiveUS10202723B2Feel goodImprove fabric qualityWeft knittingBiochemical treatment with enzymes/microorganismsCellulosePolyester

Owner:NOVOZYMES AS

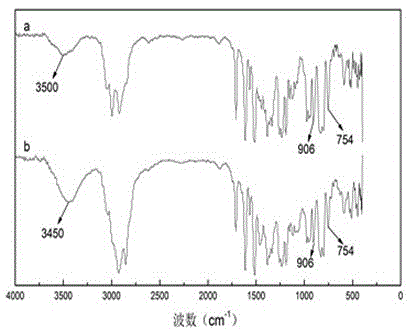

A self-emulsifying epoxy resin sizing agent with a macromolecular emulsifier for carbon fibers

The invention discloses a macromolecular emulsifier self-emulsifying epoxy resin sizing agent for carbon fibers. The components include main slurry, macromolecular emulsifier, diluent and deionized water. The mass ratio of macromolecular emulsifier to main slurry is 10~40:60~90, the mass ratio of diluent to main slurry is 10~30:70~90, and the mass ratio of deionized water to main slurry is 50 ~90:10~50. The main slurry is a glycidyl ether type epoxy resin, and the macromolecular emulsifier is obtained by hydrophilically modifying the glycidyl ether type epoxy resin with ethanolamine, allyl polyoxyethylene polyoxypropylene epoxy ether and glacial acetic acid. The invention also discloses a preparation method and an application method of the sizing agent. The preparation method of the sizing agent is simple and easy to implement, and the flexible macromolecular emulsifier can improve the brittleness of the composite material interface. The sizing agent is used for carbon fiber and can improve the processing performance of the fiber and the mechanical properties of the carbon fiber reinforced resin matrix composite material.

Owner:UNIV OF JINAN

Method for producing thermoplastic chopped strands after modification of glass fiber filaments

ActiveCN113060946BImprove bindingExcellent performance such as bending resistance and impact resistanceGlass making apparatusThermoplasticGlass fiber

The invention relates to the technical field of production technology of thermoplastic chopped strands, in particular to a method for producing thermoplastic chopped strands after modification of glass fiber filaments. The process waste produced in the glass fiber production process of the present invention is short-cut by a Humen guillotine, granulated by a granulator, then sprayed with a self-developed infiltration agent, then dedusted by a dust removal device, and finally enters a vibration fluidization The bed is dried to produce thermoplastic-reinforced chopped strands. The sizing agent is composed of the following raw materials in weight percentage: coupling agent 0.3‑1%, film forming agent A1‑15%, film forming agent B1‑16%, lubricant 0.6‑2%, crosslinking agent 0.050.01‑0.3% , 0.05‑0.2% of antistatic agent and the balance of deionized water, and optimize the preparation method of wetting agent. The treatment process of the invention is simple and reasonable, and the final product is clean and of good quality.

Owner:山东墨匠新材料科技有限公司 +1

Method of Treating Polyester Textile

InactiveUS20170342656A1Achieve effectFeel goodWeft knittingBiochemical treatment with enzymes/microorganismsCellulosePolyester

Owner:NOVOZYMES AS

Impregnating compound for thermoplastic chopped yarn production, preparation method of impregnating compound and method for producing thermoplastic chopped yarn after modification of glass fiber filaments

ActiveCN113060946AImprove bindingExcellent performance such as bending resistance and impact resistanceGlass making apparatusYarnThermoplastic

The invention relates to the technical field of thermoplastic chopped yarn production processes, and in particular, relates to an impregnating compound for thermoplastic chopped yarn production, a preparation method of the impregnating compound and a method for producing the thermoplastic chopped yarn after modification of the glass fiber filaments. Process waste generated in the glass fiber production process is chopped by a tiger's guillotine, granulated by a granulator, sprayed with the independently developed impregnating compound, dedusted by a dedusting device, finally enters a vibrated fluidized bed and is dried to finally produce the reinforced thermoplastic chopped yarn. The impregnating compound is prepared from the following raw materials in percentage by weight: 0.3-1% of a coupling agent, 1-15% of a film-forming agent A, 1-16% of a film-forming agent B, 0.6-2% of a lubricating agent, 0.05-0.3% of a cross-linking agent, 0.05-0.2% of an antistatic agent and the balance being deionized water. The preparation method of the impregnating compound is optimized. The treatment process is simple and reasonable, and the final product is clean and good in quality.

Owner:山东墨匠新材料科技有限公司 +1

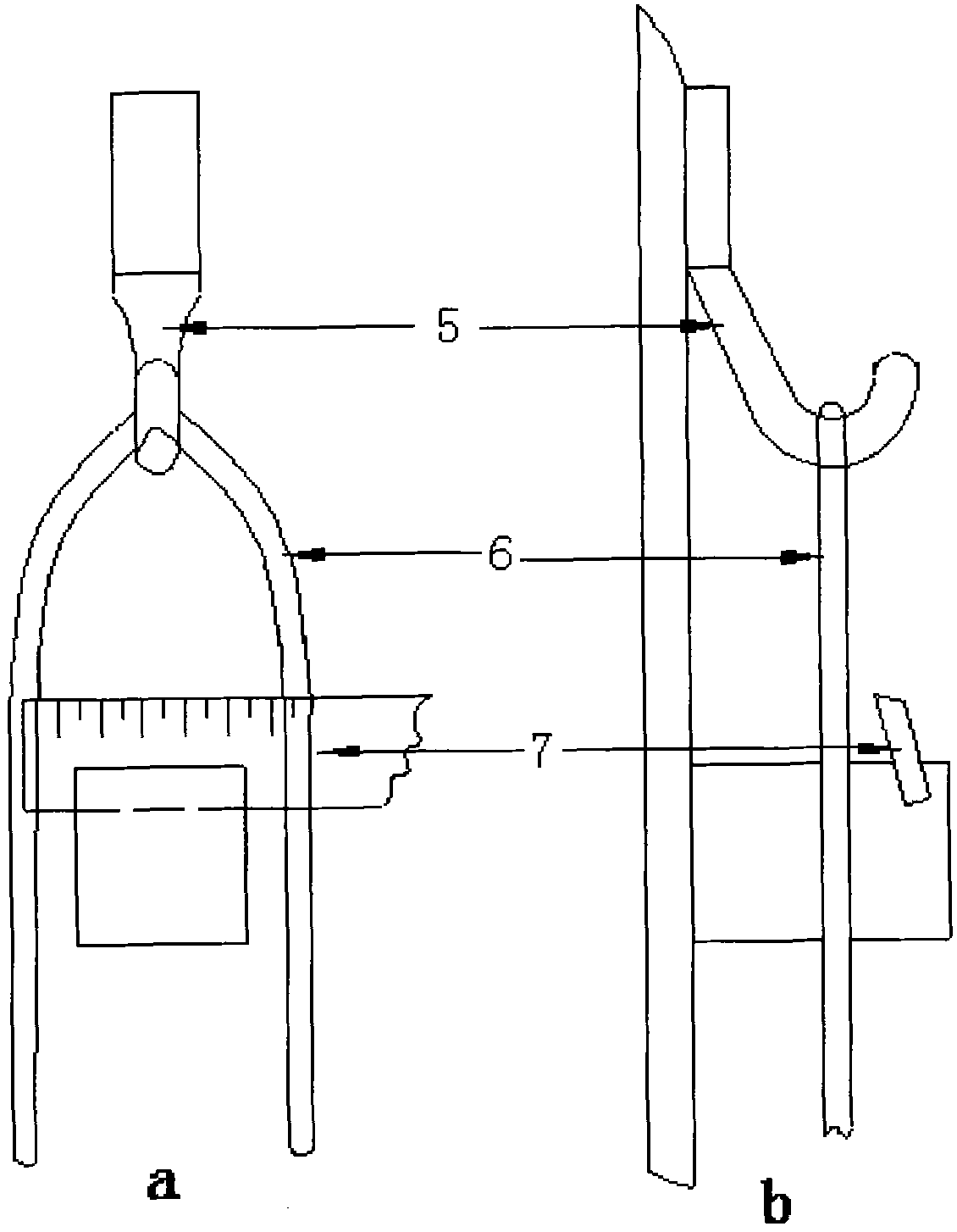

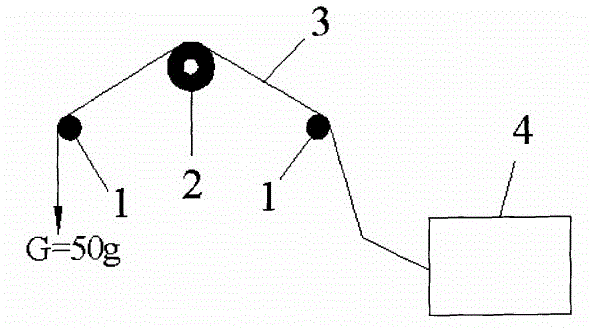

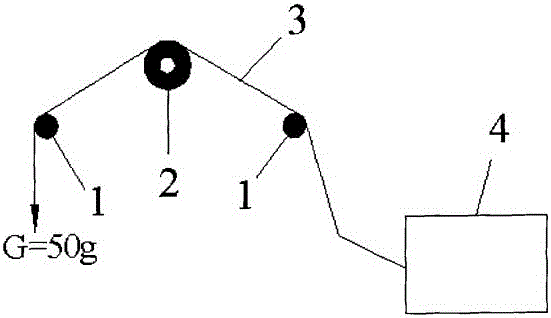

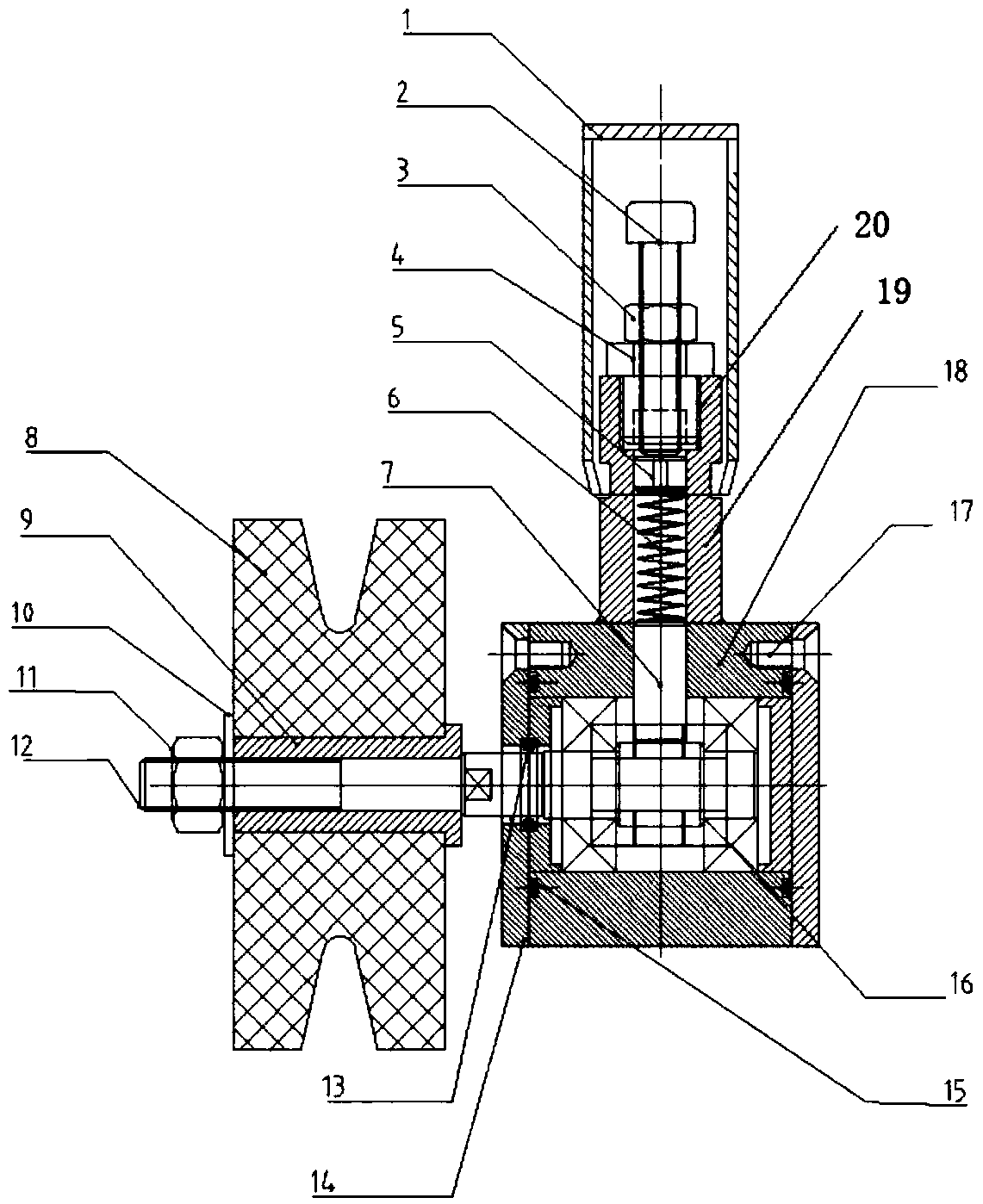

Speed adjustable rotating device for bunding wheel

ActiveCN109056088AExtend your lifeLess fuzzNew-spun product collectionRolling resistance optimizationYarnGlass fiber

The invention relates to a speed adjustable rotating device for a bunding wheel, which comprises a bunding wheel shaft, a shell, end covers, a deep groove ball bearing and a speed adjusting mechanism,wherein one end cover is respectively arranged on the left side and right side of the shell through sunk screws, one end of the bunding wheel shaft penetrates through one of the end covers and extends into the shell, and the bunding wheel shaft is rotatably arranged in the shell through the deep groove ball bearing. The device has the advantages that the bundling wheel rotates along with the movement of the filament bundle during the wire drawing operation, so as to achieve the purposes of reducing the wool yarn quantity of the glass fiber filament bundle and improving the service life of thebunding wheel.

Owner:TAISHAN FIBERGLASS INC

A kind of modified epoxy resin universal carbon fiber sizing agent, preparation method and application

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of sizing agent for self-emulsifying waterborne epoxy resin carbon fiber

Owner:BEIJING UNIV OF CHEM TECH

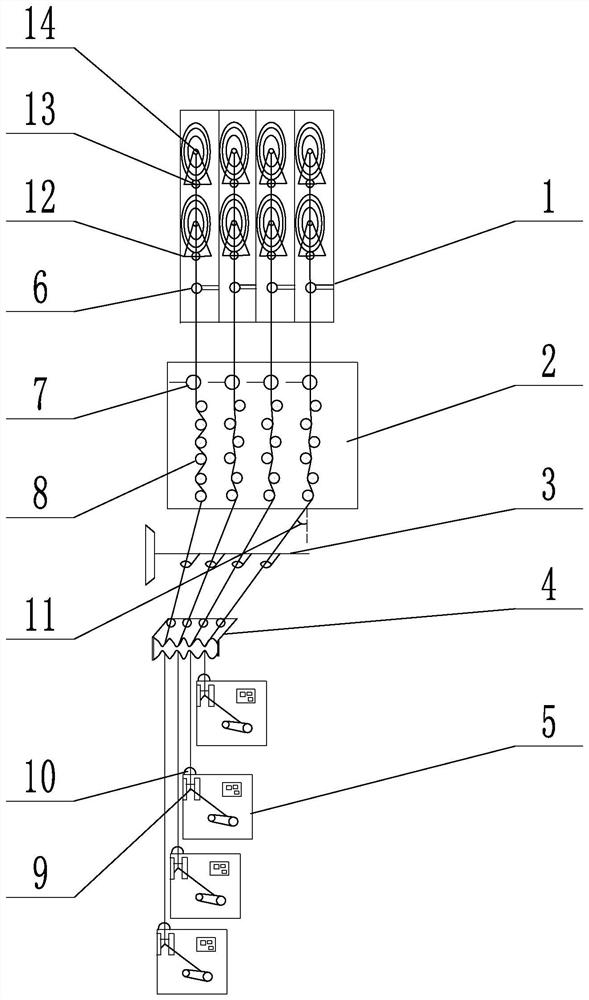

Sizing and sizing systems and sizing processes for carbon fibers

ActiveCN107475945BReasonable structural designSave spaceLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsTemperature controlFiber

The invention discloses a novel sizing and shaping system for carbon fibers and a sizing technology. The sizing and shaping system comprises an upper layer sizing tank, a lower layer sizing tank, an inlet filament stretching system, an upper layer outlet filament stretching system and a lower outlet filament stretching system, wherein the upper layer sizing tank comprises a first temperature control system with a jacket, and two stainless steel polished rollers; the lower layer sizing tank is distributed in the vertical direction of the upper layer sizing tank, and the lower layer sizing tank comprises a second temperature control system with a jacket, and two stainless steel polished rollers; an inlet of the upper layer sizing tank and an inlet of the lower layer sizing tank are jointly connected with the inlet filament stretching system; the upper layer outlet filament stretching system is connected with an outlet of the upper layer sizing tank; the lower layer outlet filament stretching system is connected with an outlet of the lower layer sizing tank; the inlet filament stretching system, the upper layer outlet filament stretching system and the lower layer outlet filament stretching system each comprise two parallel supporting rollers, and bearings at the two ends of every two supporting rollers are arranged in same slide ways respectively. According to the sizing and sizing system and the sizing technology, adhesion of adjacent carbon filaments is avoided, so that the consistency of the width and sizing amount of the carbon fiber filaments is greatly improved.

Owner:ZHONG AN XIN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com