Unsaturated acid modified epoxy resin universal carbon fiber sizing agent, and preparation method and application thereof

An epoxy resin, unsaturated technology, applied in the direction of carbon fiber, fiber treatment, fiber type, etc., can solve the problem of only applying a single type of matrix resin, etc., to achieve improved interface binding ability, high reaction conversion rate, and excellent temperature resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] 1. Preparation of sizing agent

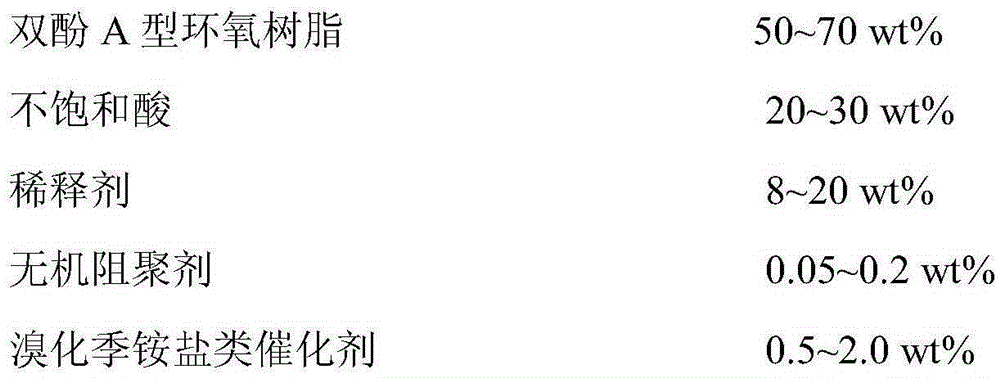

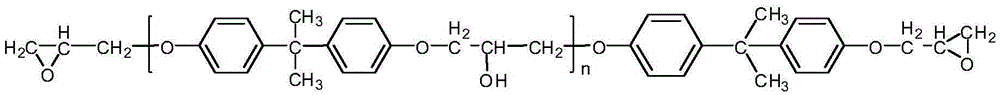

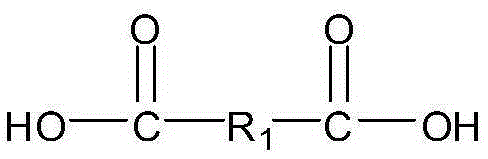

[0045] A quantitative amount of bisphenol A epoxy resin (Shell Company, USA) was placed in a four-necked flask with a mechanical stirring device, heated to 110°C, and dehydrated at a vacuum pressure of 10 to 0.5 mmHg for 2 hours until the system was completely free of bubbles. The temperature is lowered to 70°C, 99.999% high-purity nitrogen is introduced, and the vacuum device is removed. Add quantitative diluent, inorganic polymerization inhibitor, unsaturated acid, quaternary ammonium bromide catalyst (all from Sinopharm Chemical Reagent Co., Ltd.) into the four-neck flask, and control the material temperature to react at 70°C for 7 hours, then The temperature was raised to 120°C for 2.5 hours and the heating was stopped. When the system temperature drops to normal temperature, the stirring is stopped, and the unsaturated acid-modified epoxy resin sizing agent is prepared.

[0046] The varieties and dosages of the bisphenol A epoxy resin,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com