Production device and technological method of twisted yarn for ground retreating

A production process and production device technology, which is applied in the field of the production device of the plied yarn for withdrawing from the ground, can solve the problems of inconsistent monofilament tension, reduced strength of pultrusion materials, broken filaments, etc. The effect of reducing yarn breaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

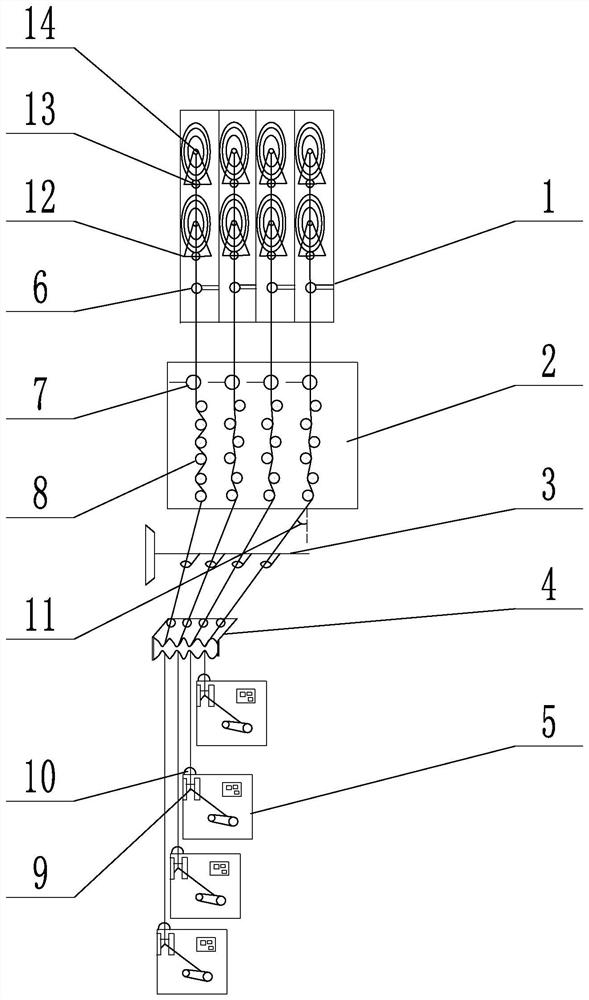

[0026] In the production process of plied yarn for ground retreat in this embodiment, the original silk cake is transferred to the creel, first passes through the probe yarn guide eye on the creel, then passes through the yarn guide rod on the hanging yarn adjuster, and continues to pass through the column The yarn guide eye, then through the yarn guide eye splitting wheel on the ground, and finally through the yarn guide eye and V-shaped guide wheel of the winder in the horizontal direction, enters the winder to obtain plied yarn; the yarn enters through the V-shaped guide wheel The angle of the winder is 42°.

[0027] The position of the raw silk cake is parallel to the direction of the probe on the creel. The yarn guide eye of the probe is located in the center of the silk cake and penetrates 1-2cm into the silk cake.

[0028] The inner diameter of the small guide eye of the probe on the creel is 6mm, the inner diameter of the middle guide eye is 9mm, and the inner diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com