Rapid installation spacing school bag

A school bag and limit technology, applied in the field of school bags, to achieve the effects of simple use, increased auxiliary handles, and clear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

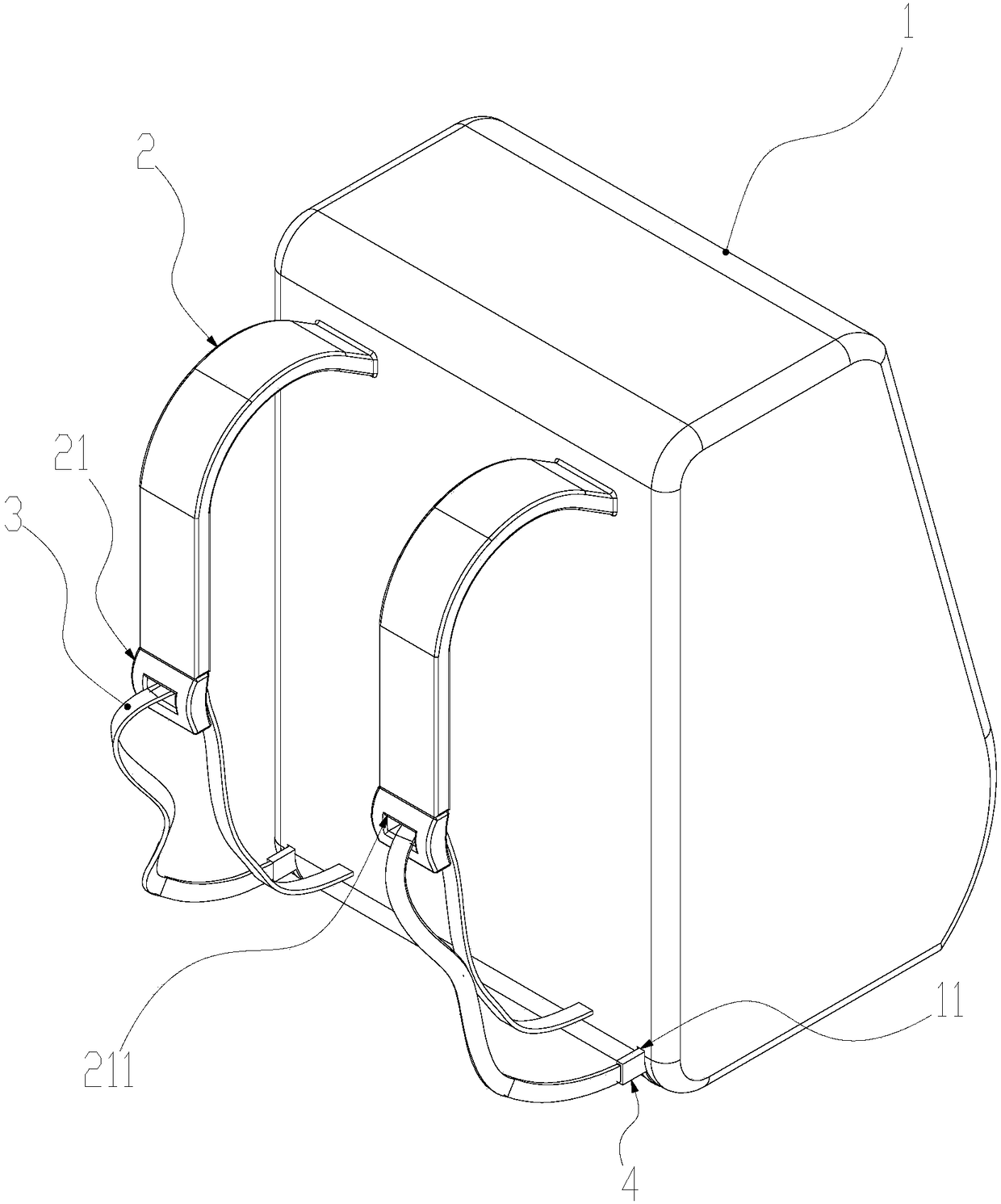

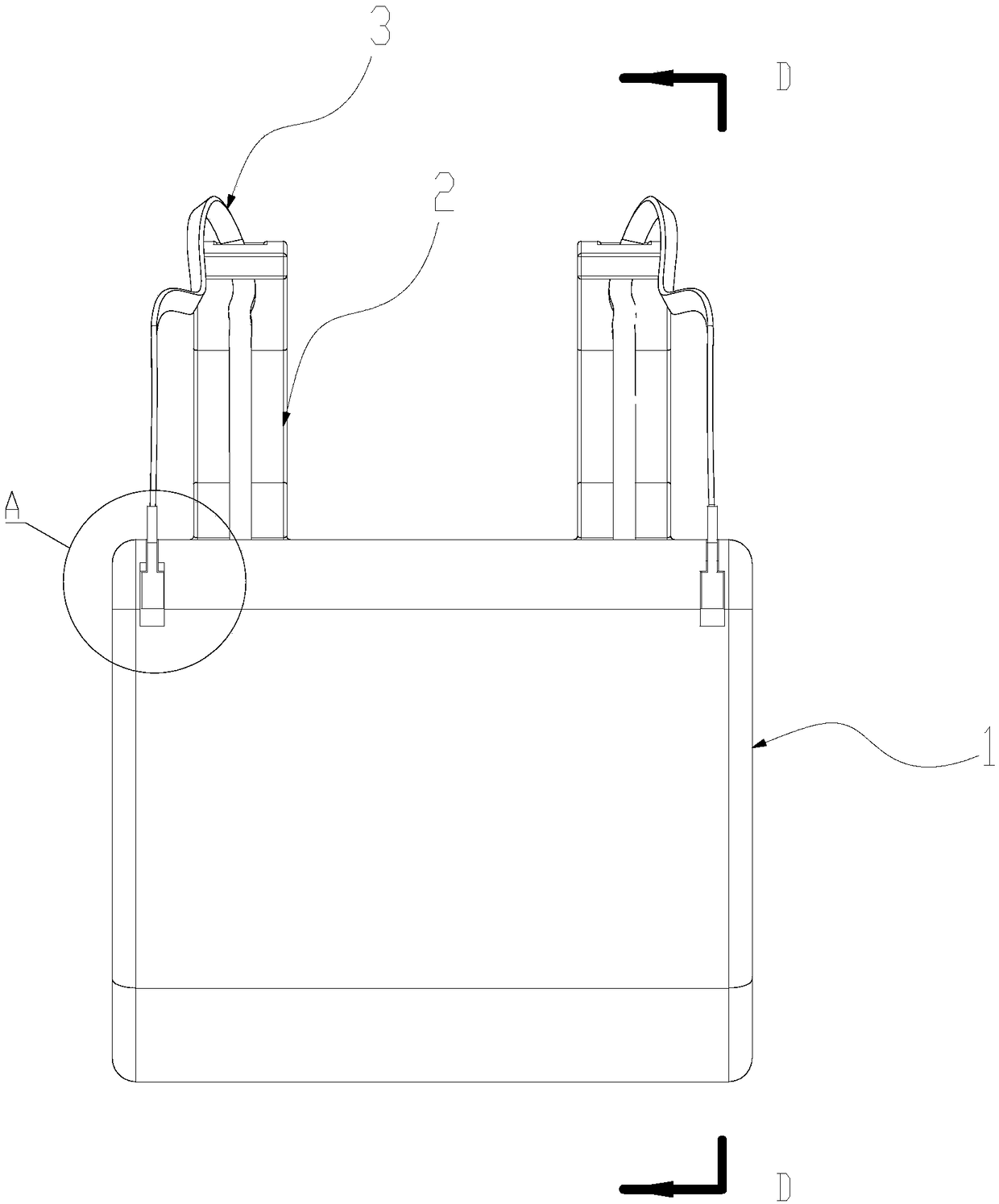

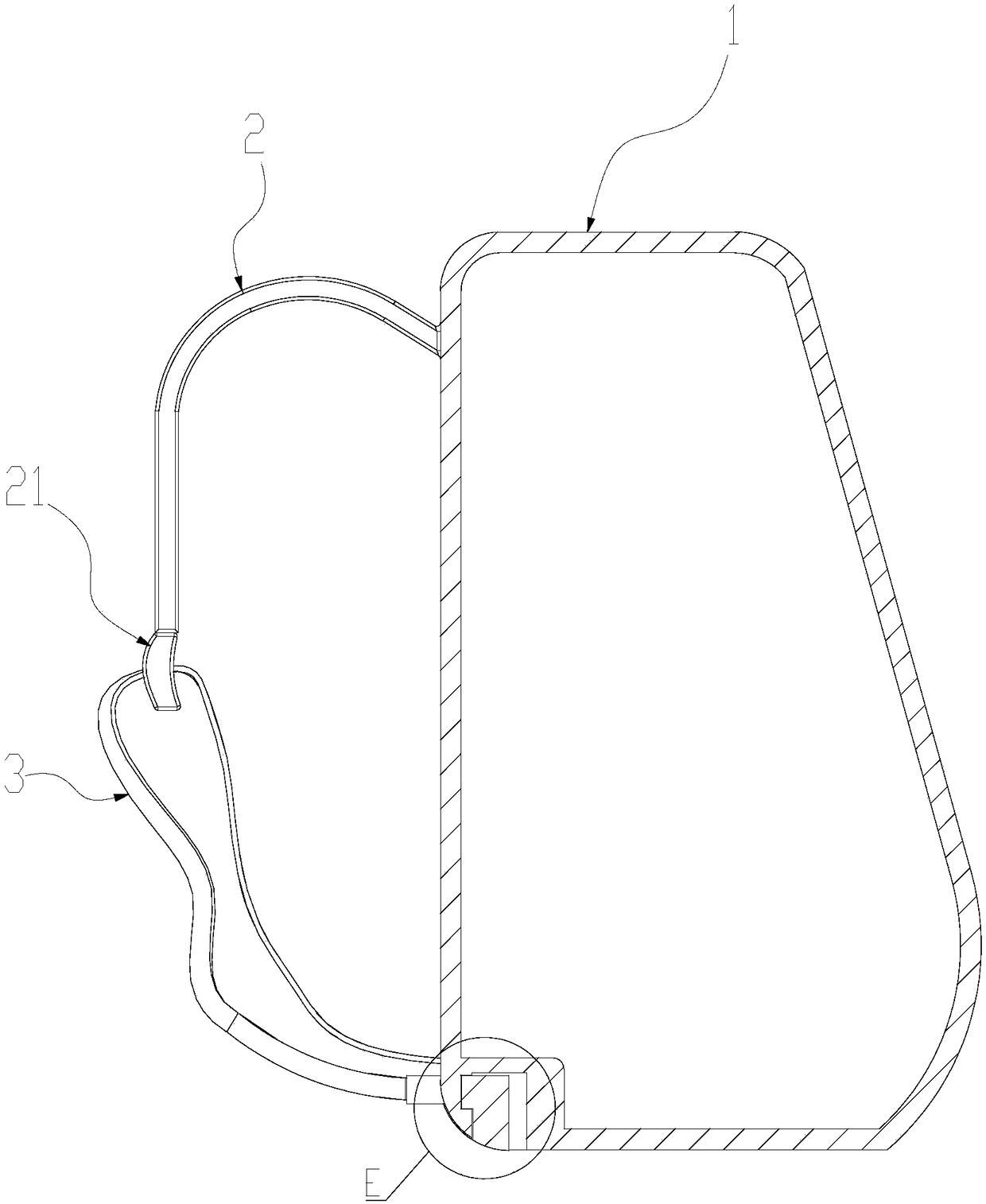

[0043] Such as Figures 1 to 5 The shown one kind of fast installation limit schoolbag includes schoolbag body 1 , upper strap 2 , lower strap 3 and fixing clip 4 , and the above-mentioned schoolbag body 1 is provided with installation groove 11 . One end of the upper strap 2 and the lower strap 3 is fixedly mounted on the schoolbag body 1 , and the other end of the upper strap 2 is provided with a connecting ring 21 , and the connecting ring 21 is provided with a sliding through hole 211 . The other end of the above-mentioned lower strap passes through the sliding through hole 211 and is connected with the fixing clip 4. The above-mentioned fixing clip 4 is stuck in the installation groove 11, and can be fixed by structures such as a limiting platform, a buckle, and a self-locking device. .

[0044] In order to facilitate installation and to facilitate the exertion of the lower back strap, the above-mentioned installation groove 11 is provided with openings towards the back ...

Embodiment 2

[0049] Such as Figure 6~7 The shown one kind of fast installation limit schoolbag includes schoolbag body 1 , upper strap 2 , lower strap 3 and fixing clip 4 , and the above-mentioned schoolbag body 1 is provided with installation groove 11 . One end of the upper strap 2 and the lower strap 3 is fixedly mounted on the schoolbag body 1 , and the other end of the upper strap 2 is provided with a connecting ring 21 , and the connecting ring 21 is provided with a sliding through hole 211 . The other end of the above-mentioned lower strap passes through the sliding through hole 211 and is connected with the fixing clip 4. The above-mentioned fixing clip 4 is stuck in the installation groove 11, and can be fixed by structures such as a limiting platform, a buckle, and a self-locking device. .

[0050] As a preference of the present invention, the above-mentioned installation groove 11 is provided with openings towards the back and side of the schoolbag body, wherein the two ends o...

Embodiment 3

[0053] Such as Figure 8~11 The shown one kind of fast installation limit schoolbag includes schoolbag body 1 , upper strap 2 , lower strap 3 and fixing clip 4 , and the above-mentioned schoolbag body 1 is provided with installation groove 11 . One end of the upper strap 2 and the lower strap 3 is fixedly mounted on the schoolbag body 1 , and the other end of the upper strap 2 is provided with a connecting ring 21 , and the connecting ring 21 is provided with a sliding through hole 211 . The other end of the above-mentioned lower strap passes through the sliding through hole 211 and is connected with the fixing clip 4. The above-mentioned fixing clip 4 is stuck in the installation groove 11, and can be fixed by structures such as a limiting platform, a buckle, and a self-locking device. .

[0054] In order to combine the advantages and disadvantages of the above-mentioned embodiment 1 and embodiment 2, the 0-degree installation adopted in embodiment 1, that is, the plane inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com