Ceramic CBN arc grinding wheel with embedded transition layer and preparation method of ceramic CBN arc grinding wheel

A transition layer, embedded technology, applied in the direction of bonded grinding wheels, manufacturing tools, metal processing equipment, etc., can solve the problems of grinding wheel cracking, abrasive waste, etc., achieve low abrasive cost, improve overall stability, and avoid grinding wheel expansion crack problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

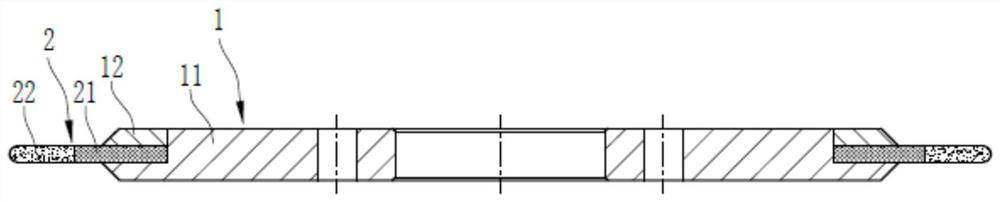

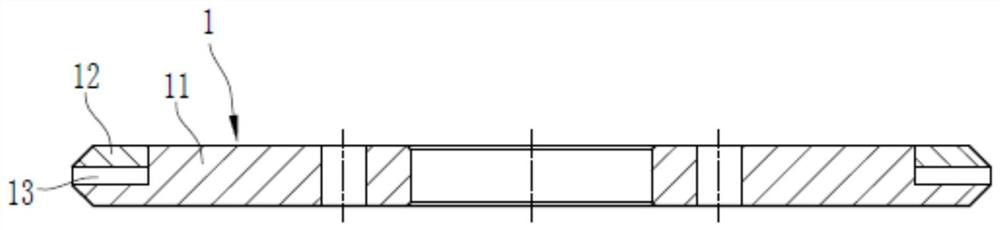

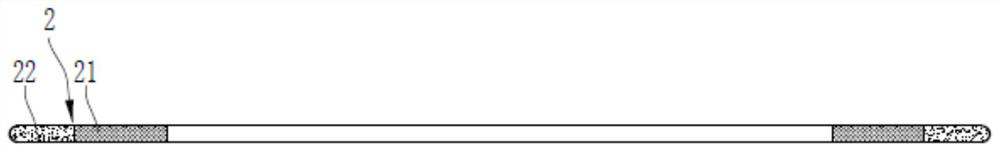

[0032] Such as Figure 1 to Figure 3 As shown, the embedded transition layer ceramic CBN arc grinding wheel includes an original disc-shaped steel substrate 1 and a double-layer abrasive ring 2 .

[0033] Wherein: the steel substrate 1 is 45# steel, which is formed by splicing the first substrate 11 and the second substrate 12, and the first substrate 11 and the second substrate 12 are spliced to form an embedding groove 13;

[0034] The double-layer abrasive ring 2 is embedded in the embedding groove 13, the double-layer abrasive ring 2 includes a transition layer 21 on the inner periphery and an abrasive layer 22 on the outer periphery, the transition layer 21 and the abrasive layer 22 are integrated molding structure. The transition layer 21 is a ceramic green silicon carbide layer, the abrasive layer 22 is a ceramic CBN layer, the thickness of the transition layer 21 is the same as that of the abrasive layer 22 (ceramic CBN layer), and the width of the transition layer ...

Embodiment 2

[0046] The preparation method of this embodiment is the same as that of Embodiment 1, the difference is that the ratio of raw materials in the vitrified bond, the transition layer, and the abrasive layer is different; wherein:

[0047] Raw material ratio of vitrified bond: The mass ratio of zirconia, calcium carbonate, lithium carbonate, sodium carbonate, boric acid and silicon dioxide is 5:7:4:16:31:45.

[0048] The raw material ratio of the transition layer mixture: the mass ratio of green silicon carbide abrasive, vitrified bond, and resin liquid is 45:28:7.

[0049] The raw material ratio of the abrasive layer mixture: the mass ratio of CBN abrasive, vitrified bond, and resin liquid is 52:25:6.

Embodiment 3

[0051] The preparation method of this embodiment is the same as that of Embodiment 1, the difference is that the ratio of raw materials in the vitrified bond, the transition layer, and the abrasive layer is different; wherein:

[0052] Raw material ratio of ceramic bond: the mass ratio of zirconium dioxide, calcium carbonate, lithium carbonate, sodium carbonate, boric acid and silicon dioxide is 8:7:6:16:34:50.

[0053] The raw material ratio of the transition layer mixture: the mass ratio of green silicon carbide abrasive, vitrified bond, and resin liquid is 62:33:9.

[0054] Raw material ratio of abrasive layer mixture: the mass ratio of CBN abrasive, vitrified bond and resin liquid is 62:32:8.

[0055] The conventional ceramic CBN broach grinding wheel on the market and the embedded transition layer ceramic CBN arc grinding wheel prepared in Example 1, Example 2, and Example 3 were used as a comparison.

[0056] When domestic customers process W18Cr4V material broaches, perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com