Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1238results about "Textile disintegration and recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

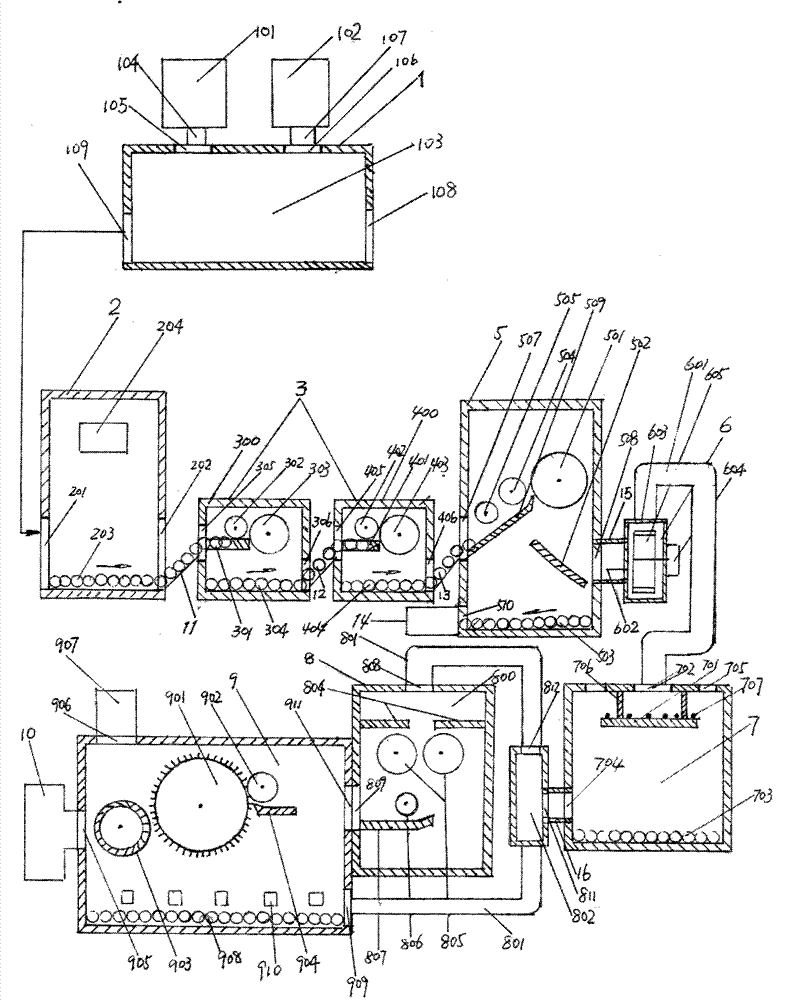

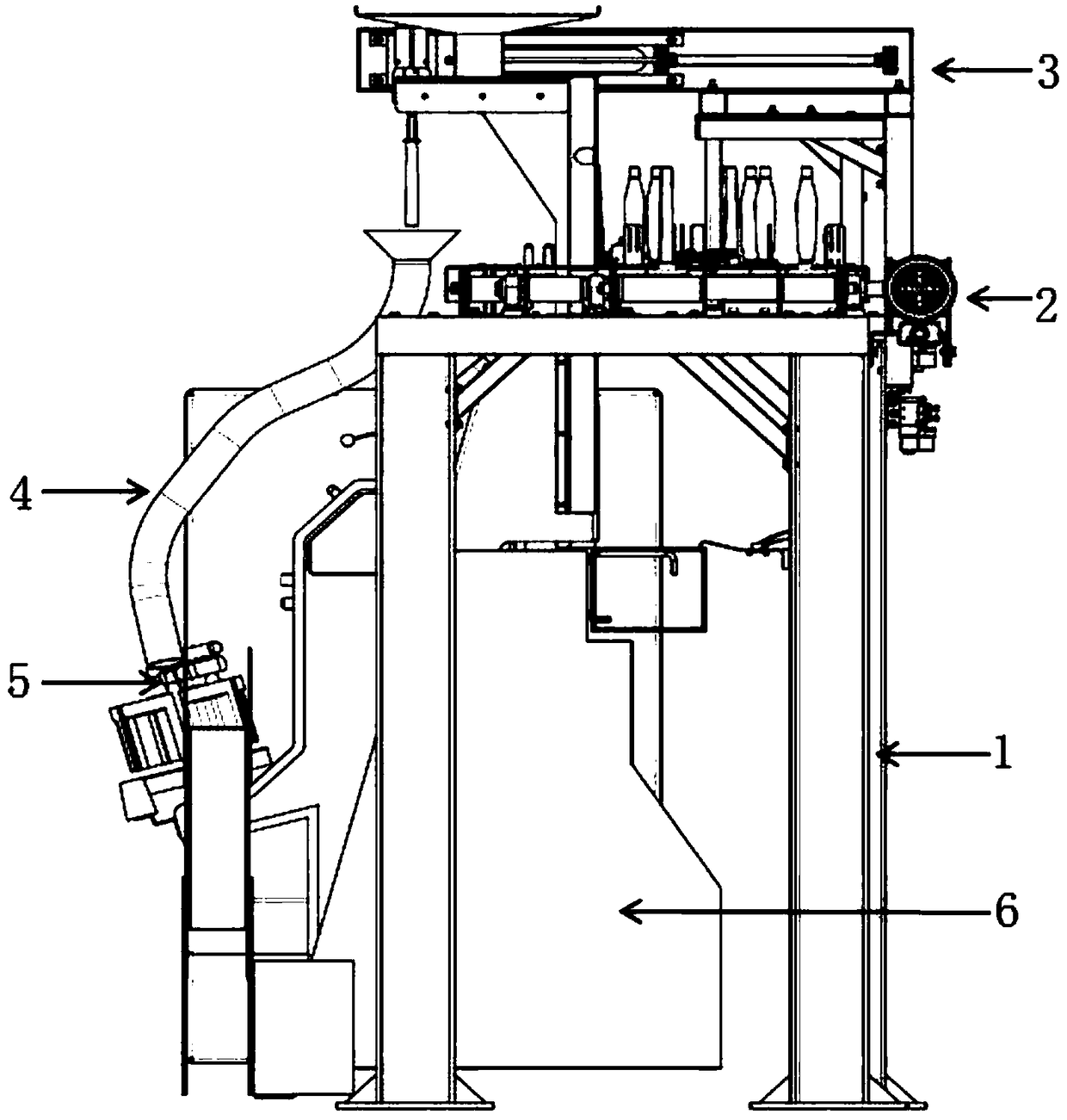

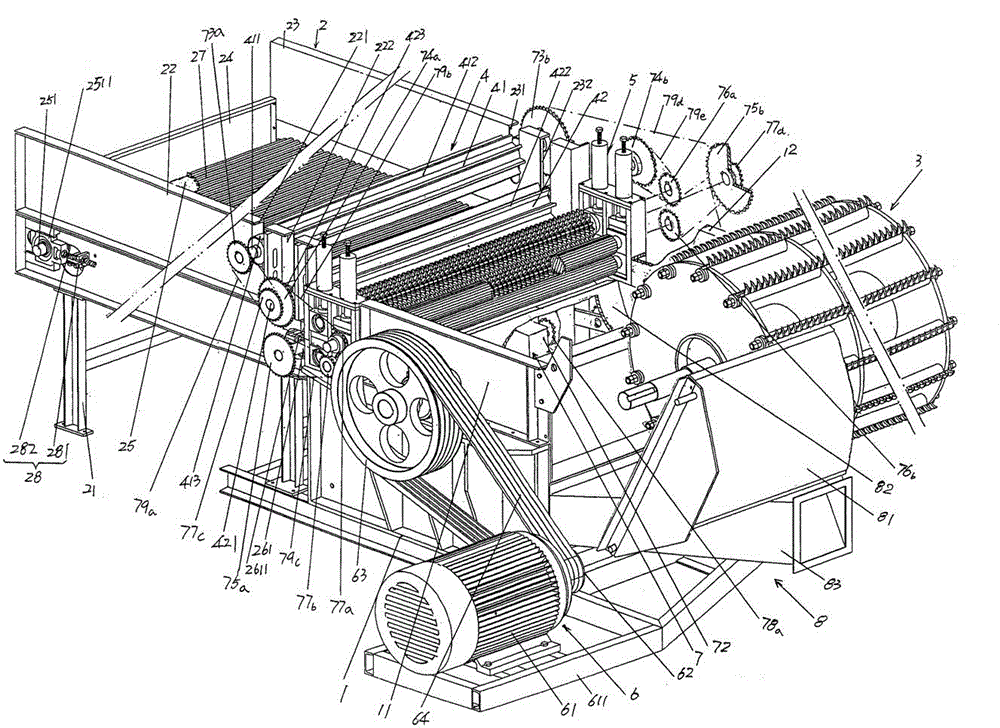

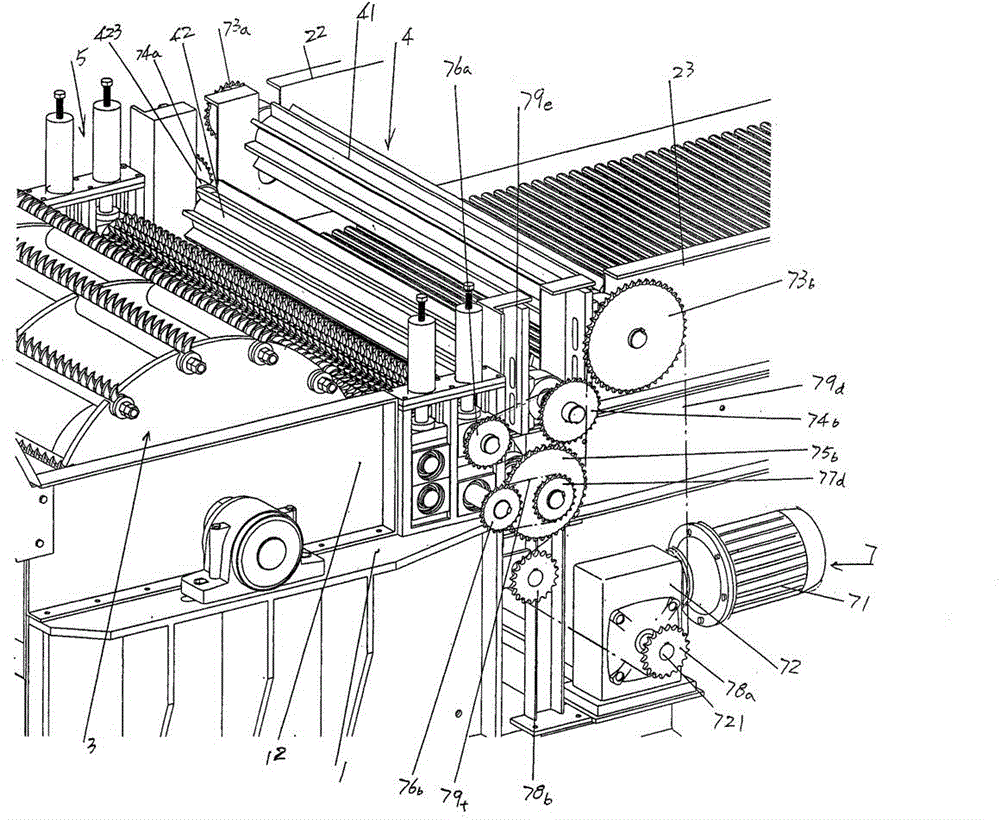

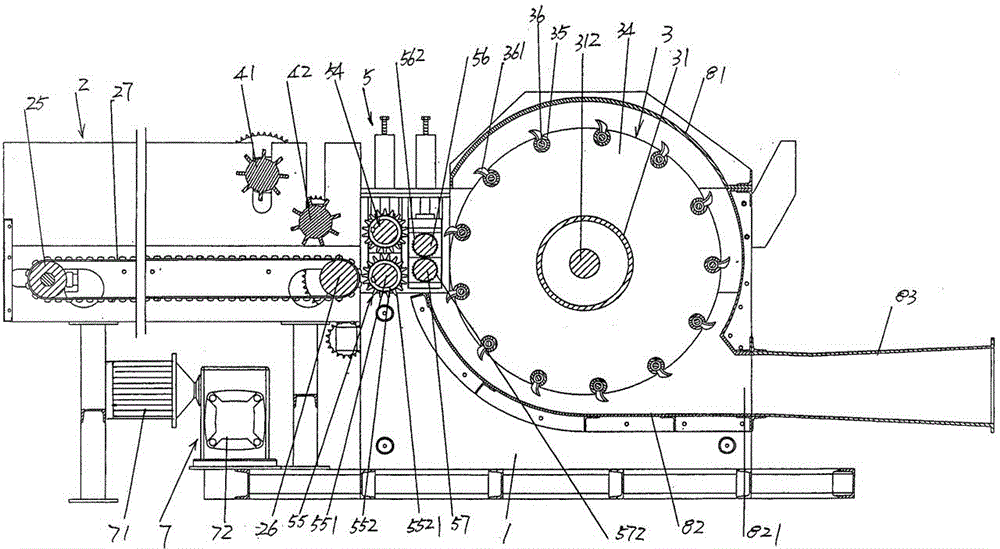

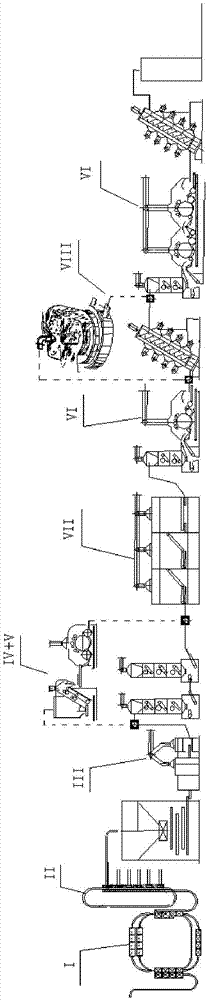

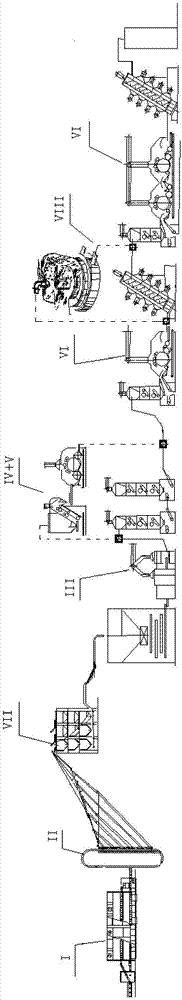

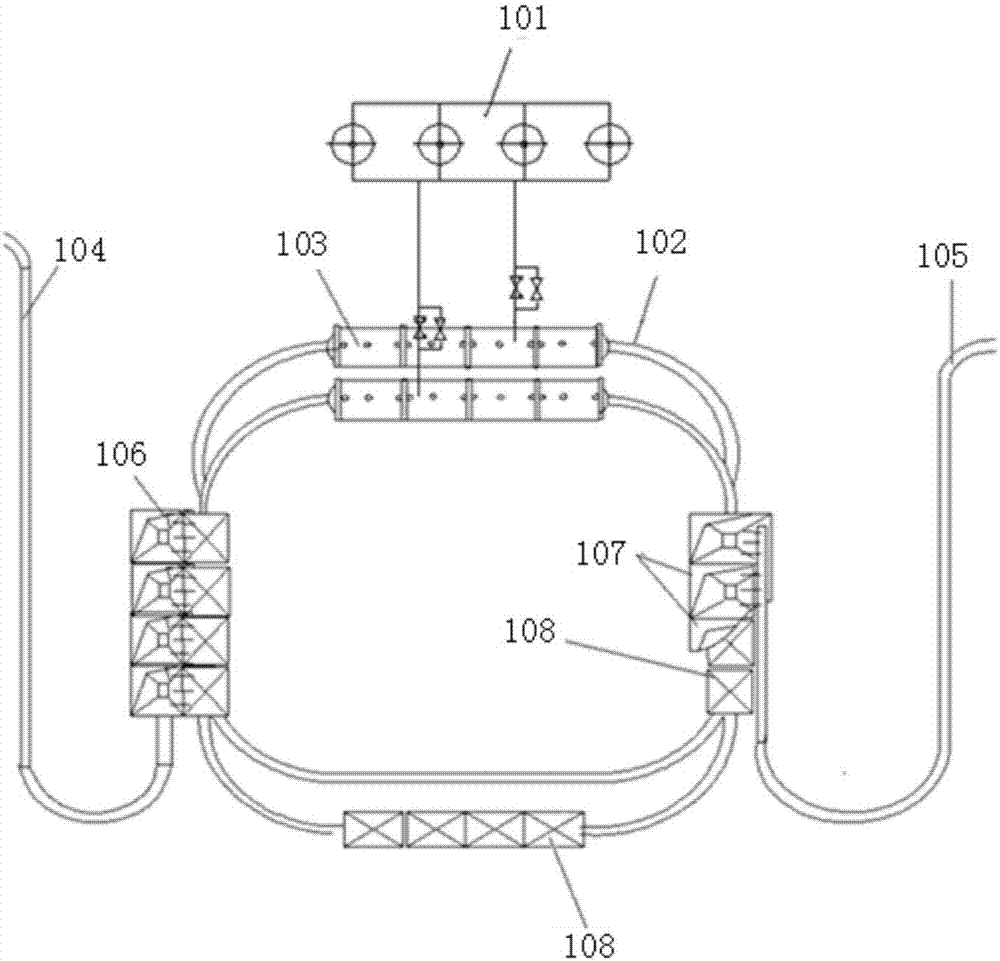

Production process and equipment for regenerating blend-material worn-out garments into spinnable fibers

ActiveCN103924325ANo pollution in the processHigh degree of automationTextile disintegration and recoveryFibre disintegrationForeign matterProduction line

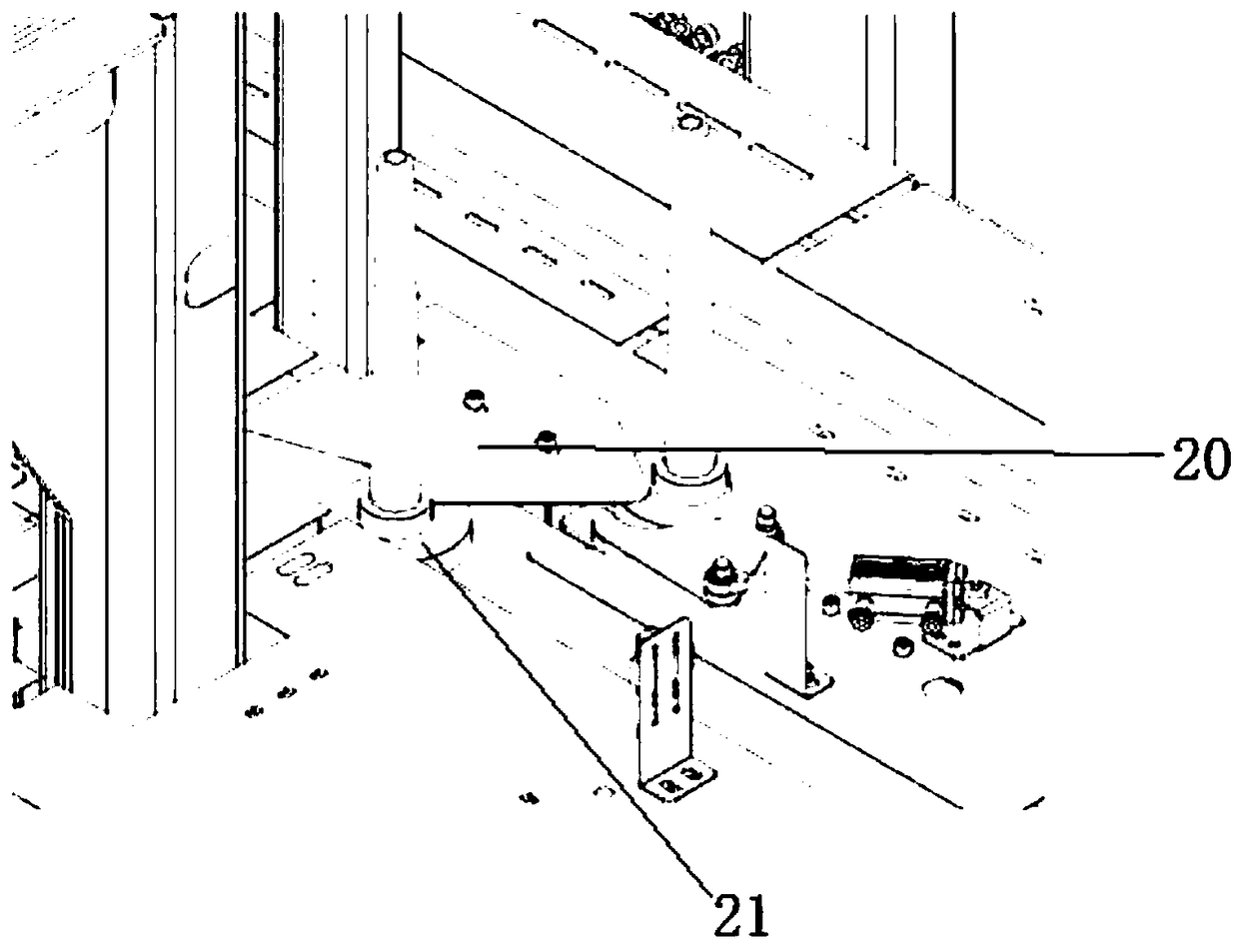

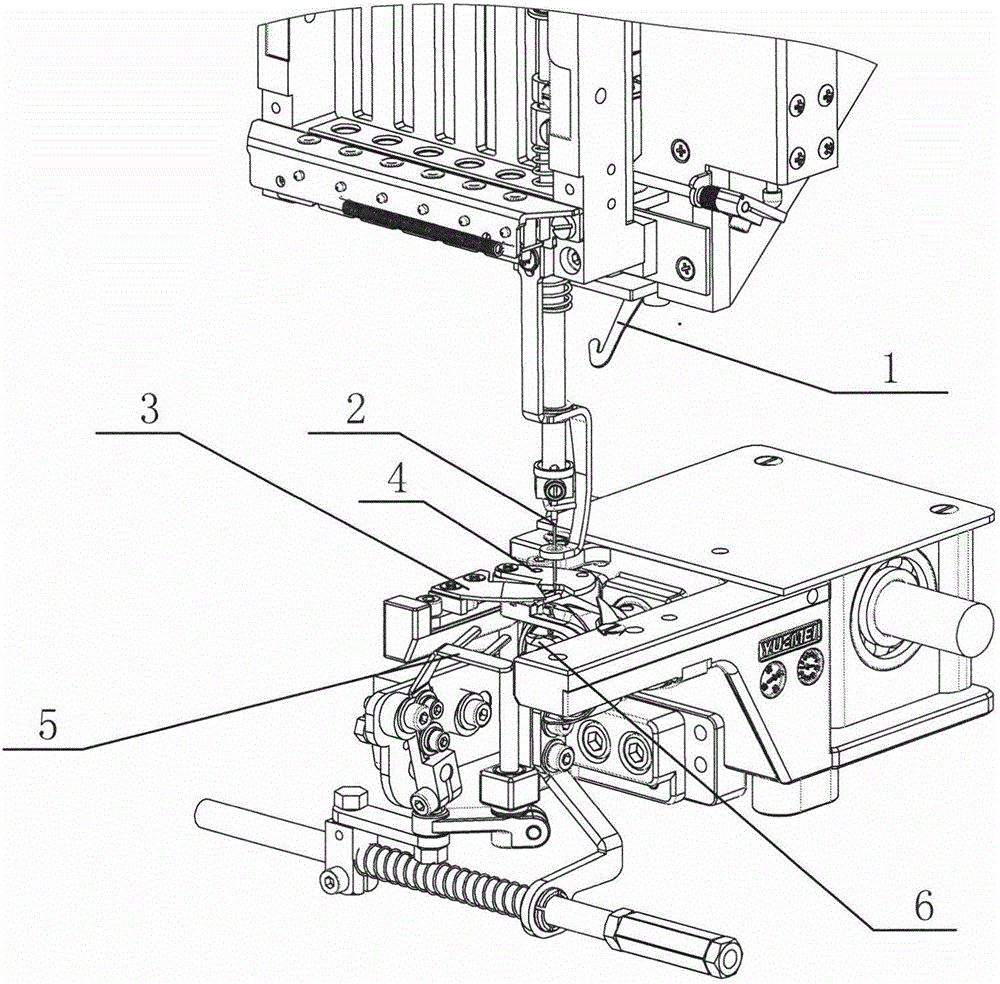

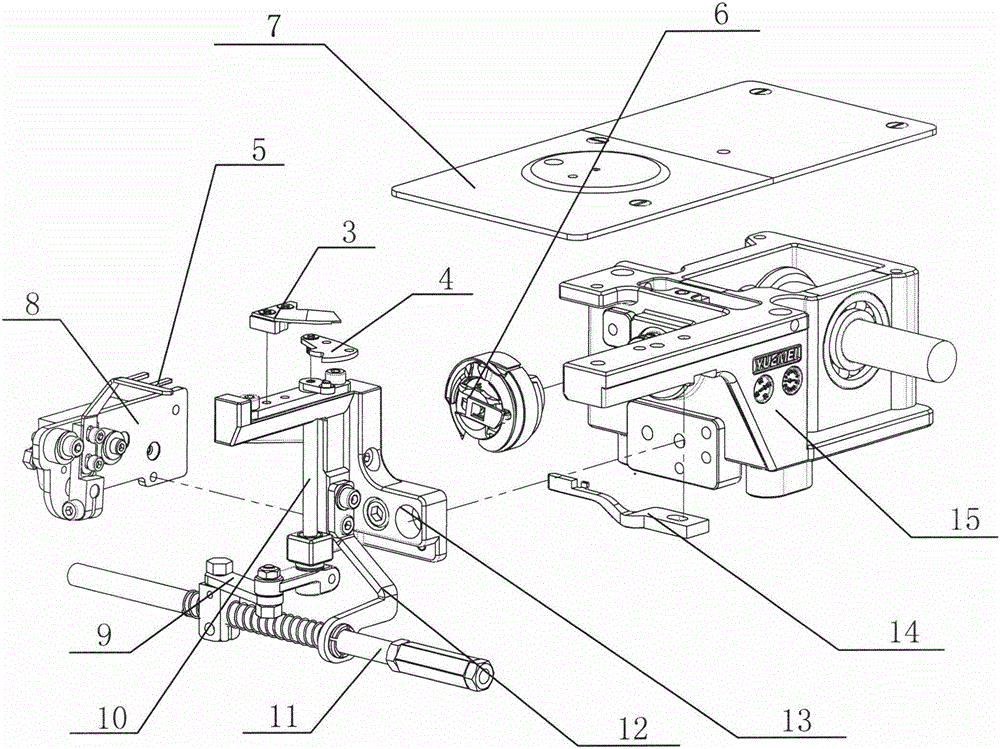

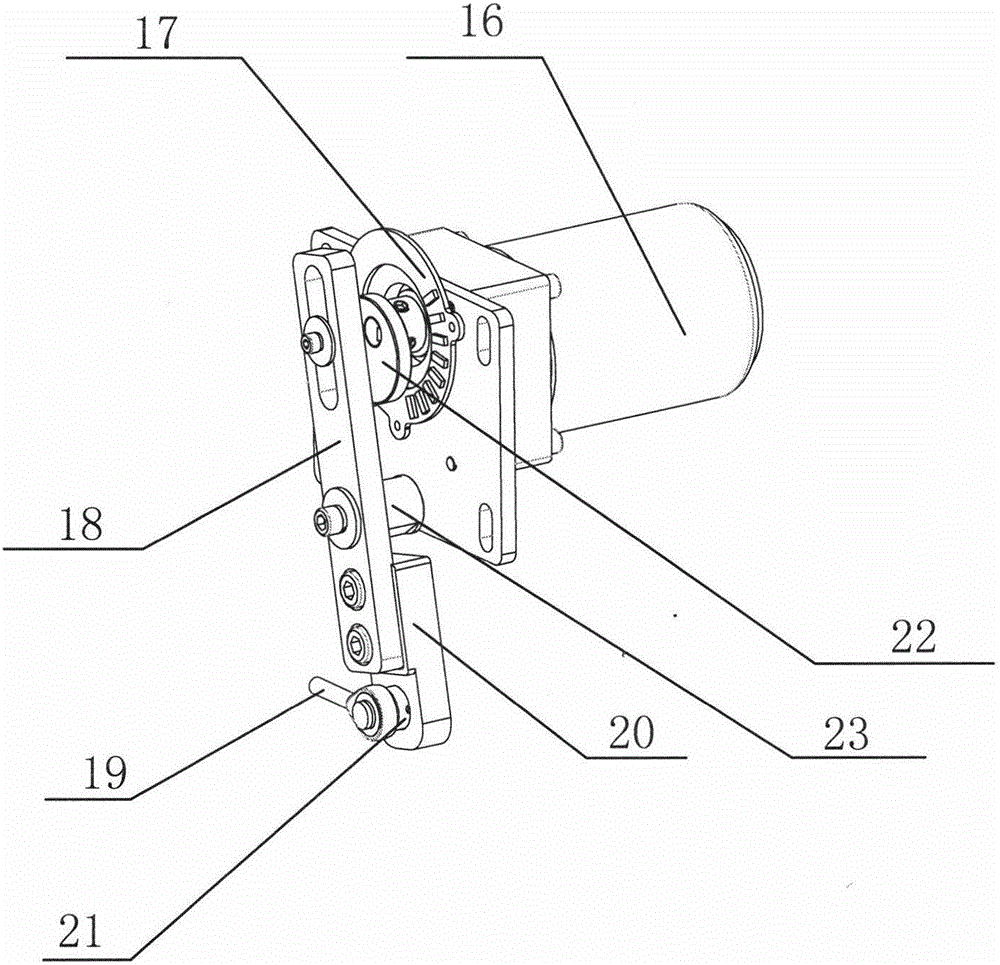

The invention provides a production process and equipment for regenerating blend-material worn-out garments into spinnable fibers. The production process is mainly characterized in that a whole production line adopts a non-woven solid foreign matter removing procedure, an even distribution and settlement procedure, a physical filter dust removing technology and a progressive pneumatic technology, so that a brand new pollution-free automatic production line which can regenerate various blend-material worn-out garments into spinnable fibers is formed. The invention further provides the production equipment for blend-material worn-out garments into spinnable fibers. The production equipment comprises a worn-out garment ozone negative pressure sterilizing machine, worn-out garment settling and conveying chamber, a bulk raw material cutting off unit, a non-woven solid foreign matter remover, a feed fan, a fiber bundle raw material automatic settling cabin, a flocculent fiber bundle extrusion feed device, a fiber processing unit and a spinnable fiber automatic packer.

Owner:中民社会捐助发展中心

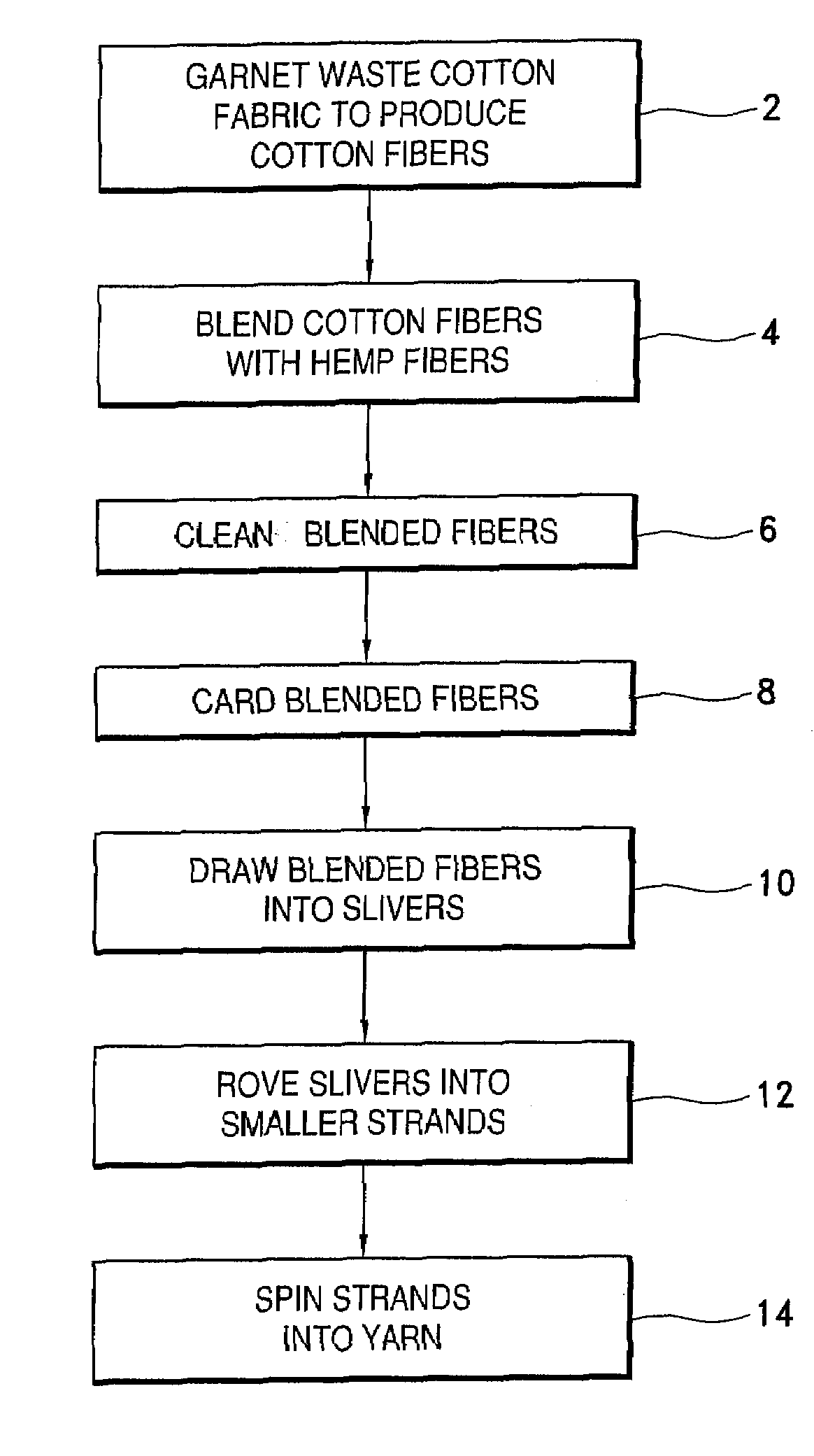

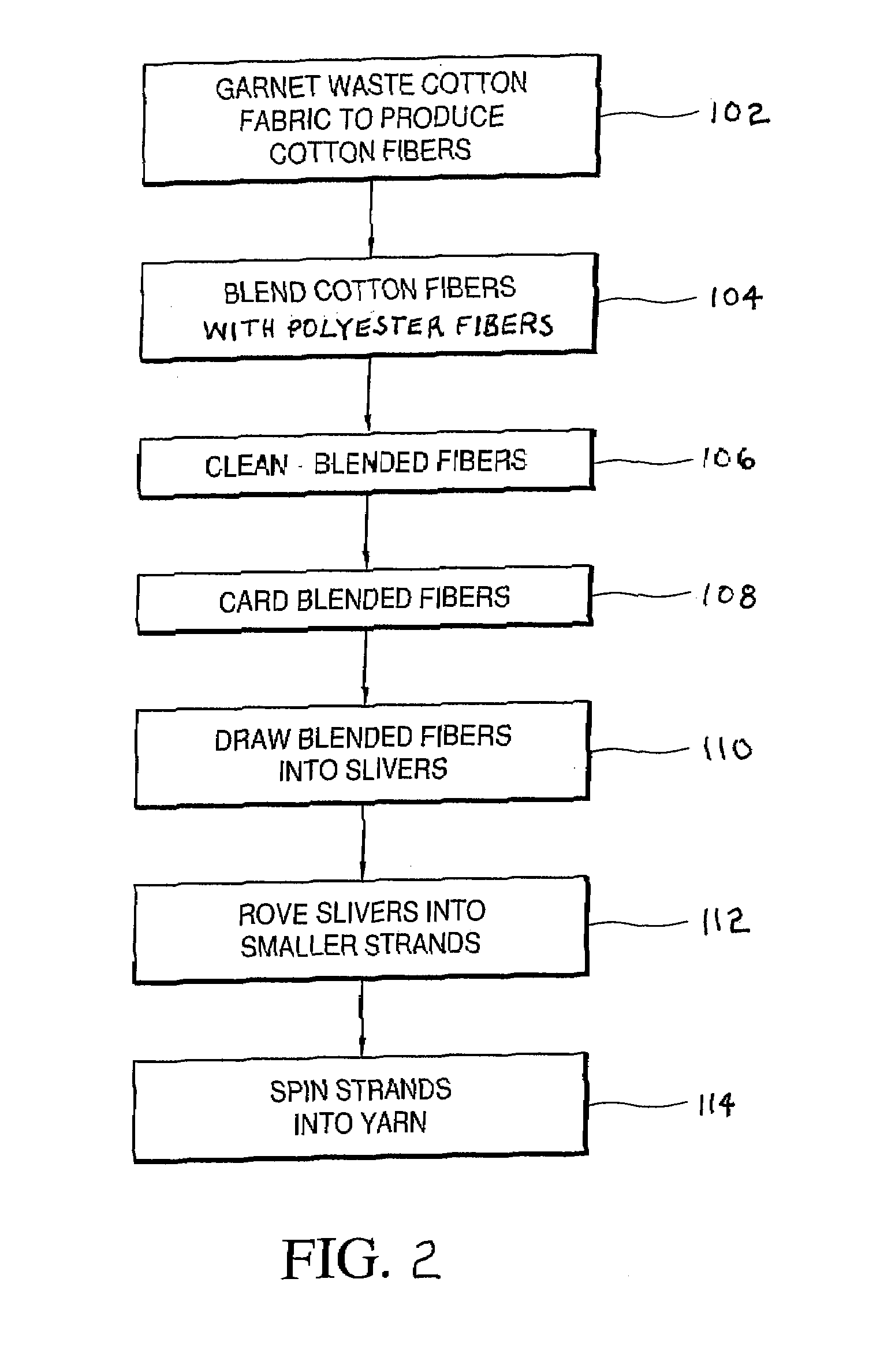

Composite cotton and polyester yarn and method for making same

InactiveUS20090173055A1Reduce impurityFibre mixingTextile disintegration and recoveryCotton fibrePolyester

A composite polyester and cotton yarn is formed by blending polyester fibers with cotton fibers which have been regenerated from waste cotton material such as trimmings and cuttings from the apparel manufacturing industry. The fibers are cleaned and blended, then carded to align the fibers into strands. Depending on the size and texture of the desired yarn, the fibers are stretched and drawn into slivers prior to spinning to join the fibers together. The polyester fibers are preferably recycled polyethylene terephthalate fibers which are up to three time longer than the regenerated cotton fibers, so that the polyethylene terephthalate fibers overlap and braid onto the regenerated cotton fibers during spinning. The resultant yarn is stronger and more absorbent than yarns made solely out of regenerated cotton fibers. The yarn is suitable for producing woven or knit fabric for the production of colorful and functional clothing and home textiles without the need for further bleaching or dyeing.

Owner:SILVER SCOTT

Preparation method of regenerated cotton

InactiveCN104593910AReduce pollutionReduce defective rateMechanical cleaningPressure cleaningYarnFiber

The invention discloses a preparation method of regenerated cotton. The method comprises the following steps: a, sorting: firstly performing vibratory screening treatment on leftover, scrap, waste silk and yarn ends to obtain various cotton textile scraps; b, pretreating: performing alkaline cleaning, primary washing, hydrogen peroxide bleaching and secondary washing treatment on the obtained various cotton textile scraps respectively to obtain a pure white fabric stock with moisture content of being smaller than 1 percent; c, reprocessing: cutting the pure white fabric stock into fabrics with a physical character of being smaller than 1,200 mm, then reducing the fabrics into wool cotton, next loosening the wool cotton, and finally fluffing the wool cotton to form the regenerated cotton; d, packing: collecting fibers with length of 26-28 mm in the regenerated cotton, and packing the collected fibers to obtain the qualified regenerated cotton. According to the method, the waste textiles such as the leftover, the cloth scrap, the waste silk and the yarn ends are recovered and recycled.

Owner:YIBIN WEILUO TEXTILE

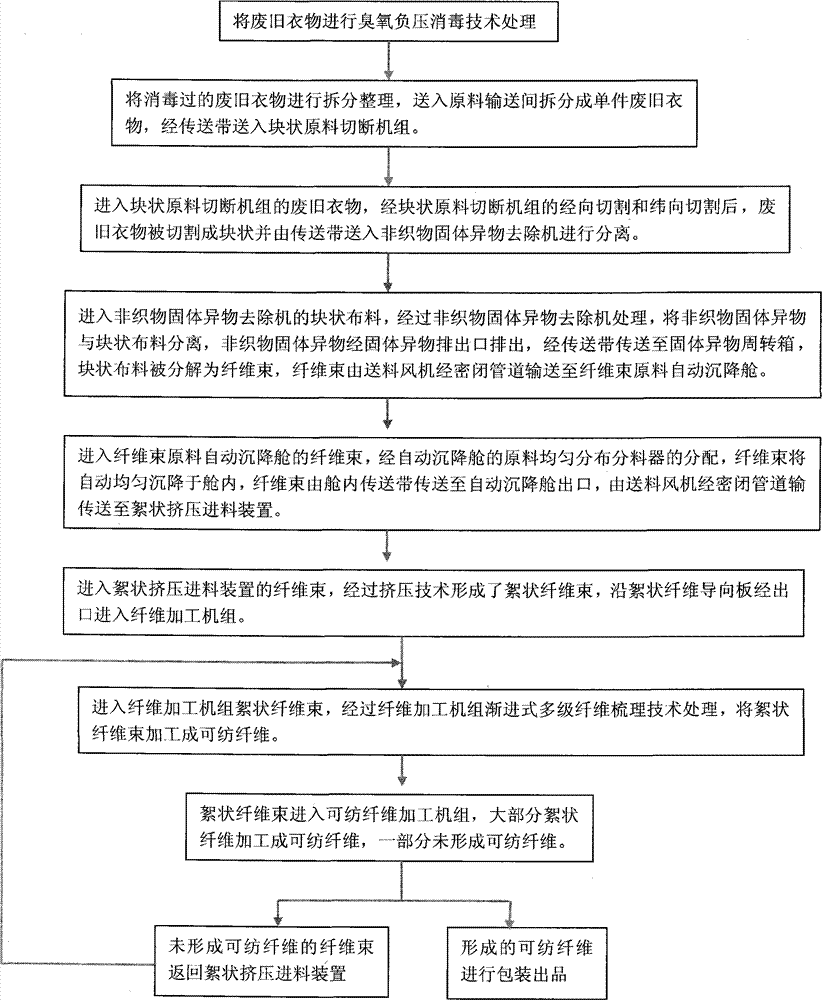

Method for regenerating spinnable fibers from blended worn-out garments

InactiveCN103924326ASolve pollutionSolve environmental problemsTextile disintegration and recoveryFibre disintegrationFiberSquare Millimeter

The invention relates a method for regenerating spinnable fibers from blended worn-out garments. The method includes: sterilizing the worn-out garments, removing buttons, cutting the garment into cut cloth 50-100 square millimeters, using a feeding roller and an opening licker-in to continuously perform opening twice so as to allow the large tangled fibers of the cut cloth to be opened into small or bunchy fibers, using the feeding roller and a carding licker-in to continuously perform disintegration and carding for four times so as to allow the fibers of the cut cloth to be further disintegrated and carded, and obtaining the reusable spinnable fibers. The method has the advantages that the problem that manual operation is high in cost is solved, production efficiency is increased by dozens of times, high automation level is achieved, intelligent production is preliminarily achieved, the problem of impurity pollution is solved, environmental protection is achieved, the whole process is clean and environmentally friendly, and the obtained spinnable fibers are longer and fewer in nep as compared with the fibers processed by traditional processing processes.

Owner:北京中民慈善项目发展中心 +1

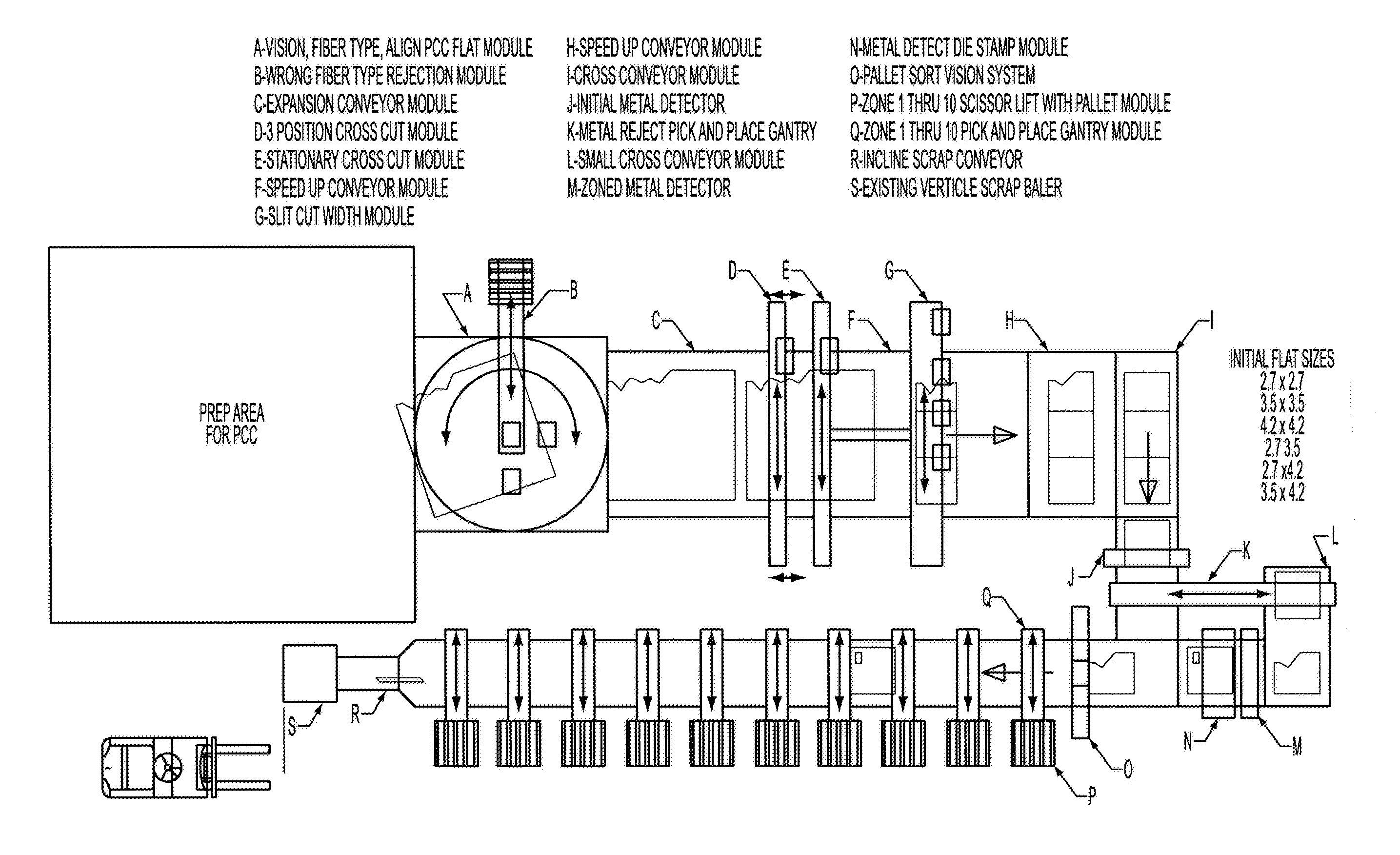

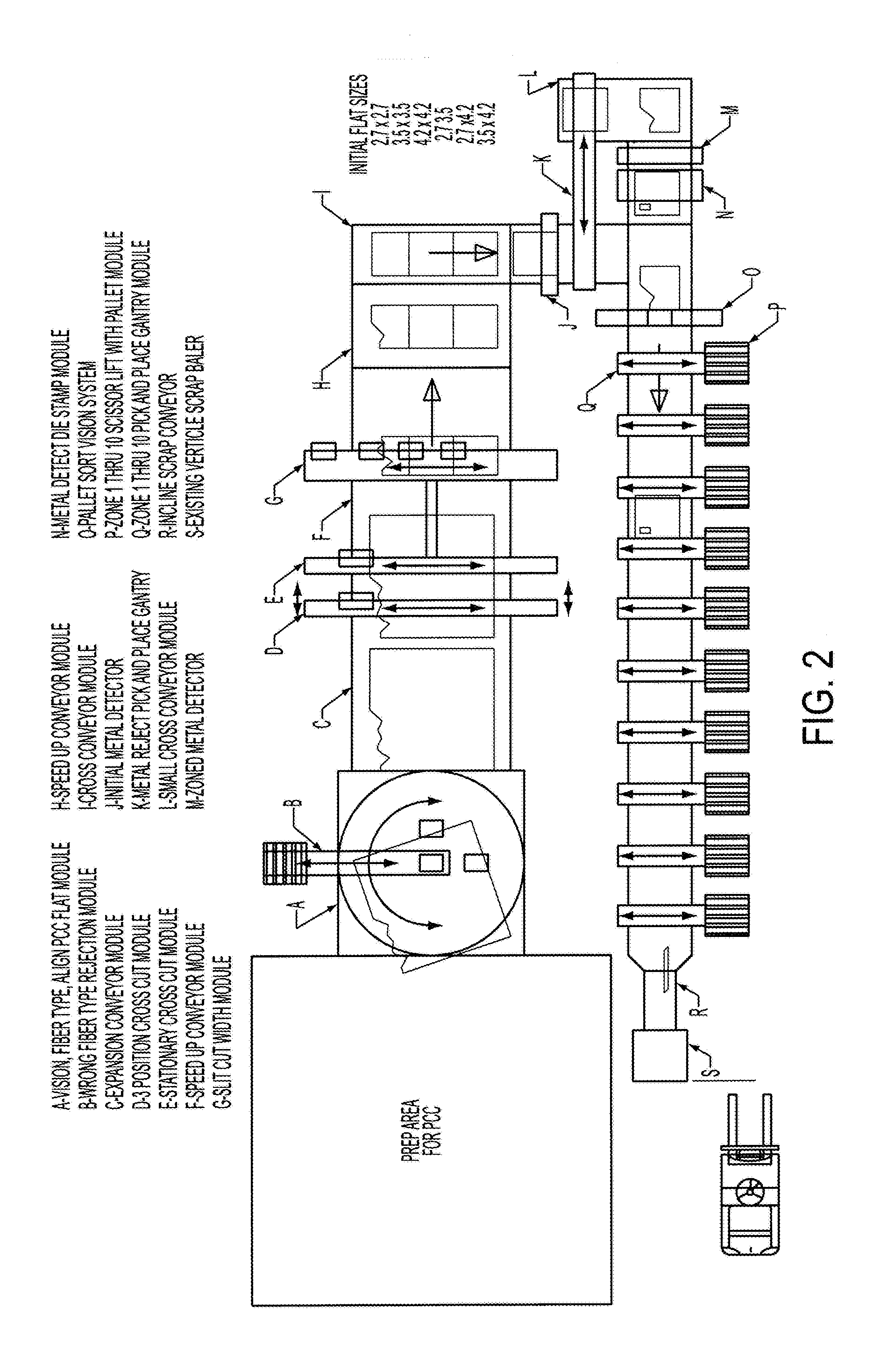

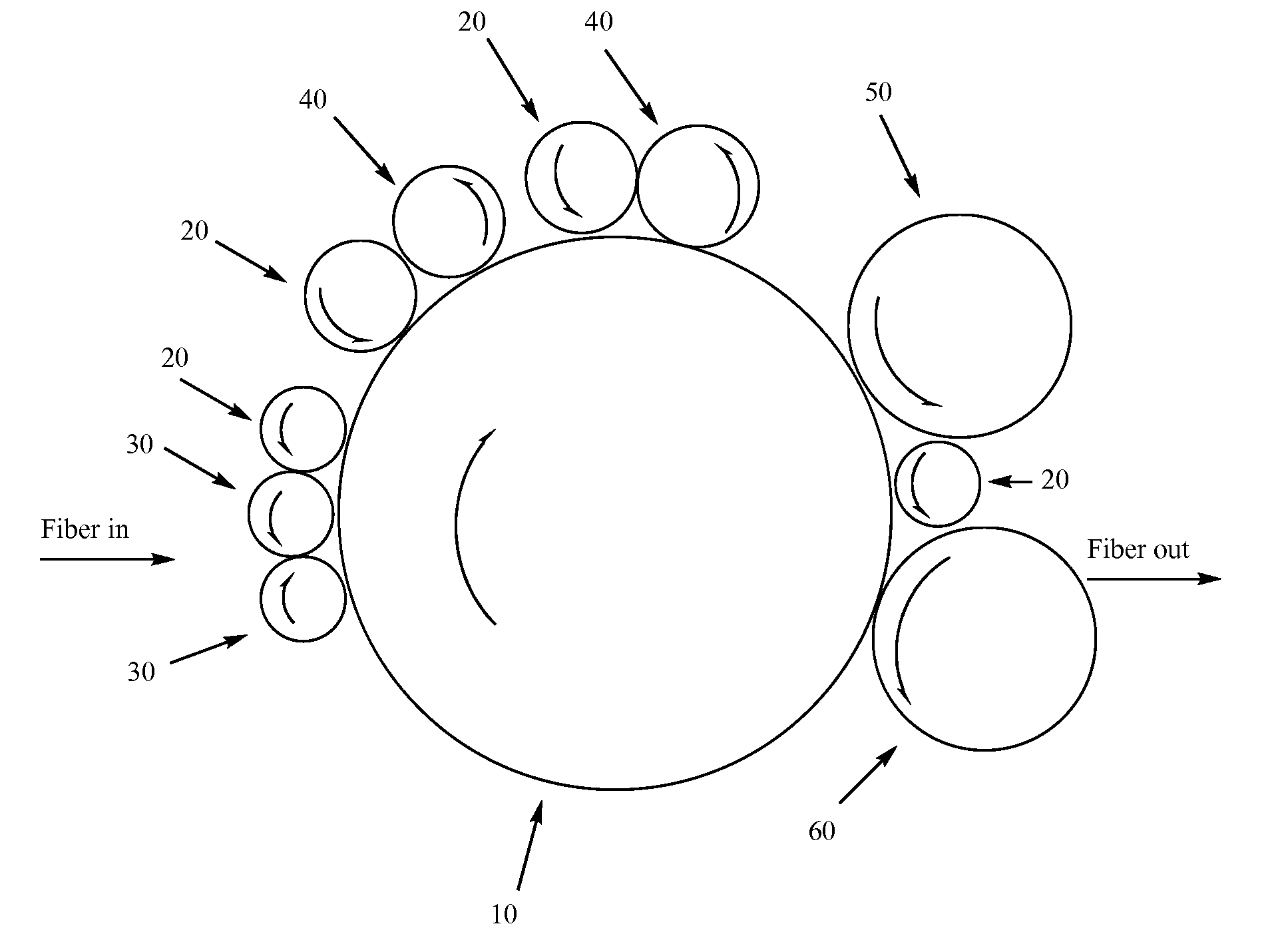

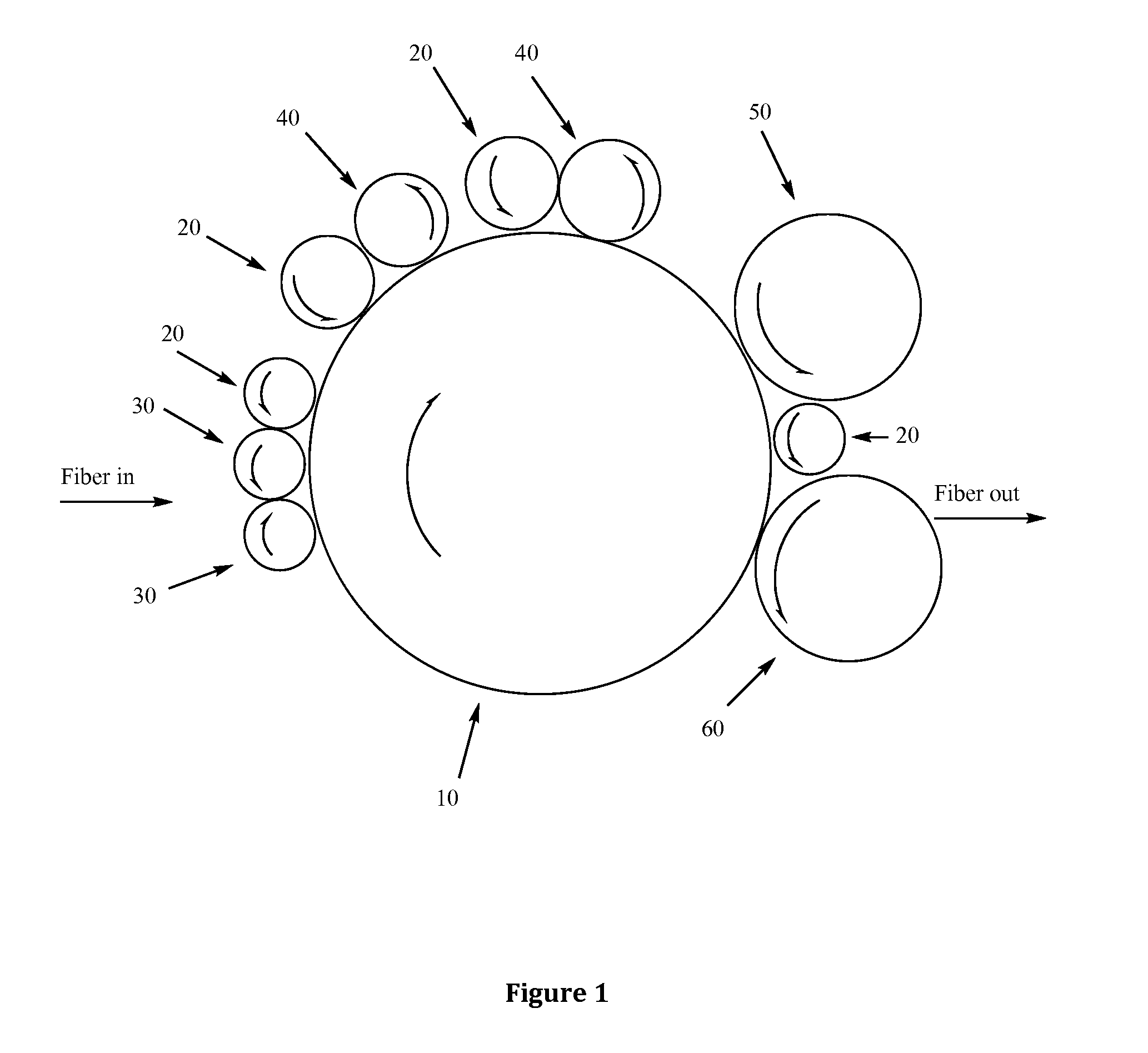

Component recovery process

A component recovery process to recover one or more of the constituent components of a feed material. In one embodiment, the process is a carpet recycling process, the feed material being carpet, and the constituent components being fiber, filler and adhesive. The process can refine the polypropylene backing polymer and face fibers of post industrial edge trim selvage, whole carpet construction post industrial scraps and pieces, as well as whole carpet post consumer scraps and pieces and in particular mixtures there of. The process beneficially uses land filled edge trim and pre land filled selvage, whole carpet construction scraps and whole carpet post consumer scraps and mixtures there of for component purification.

Owner:ALADDIN MFG CORP

Method for producing cowhide fiber base fabric

InactiveCN102660844AReduce pollutionReduce manufacturing costLiquid/gas/vapor removalTextile disintegration and recoveryNatural fiberFlame resistance

The invention belongs to the field of cowhide materials, and particularly relates to a method for producing a cowhide fiber base fabric. The cowhide fiber base fabric is made of cowhide fibers by means of nonwoven technology and by performing fine combing lapping, airflow lapping, spunlace pre-needling, needling reinforcement, pressing, dyeing, drying, trimming and packaging after uncoiling leftover cowhide. The cowhide fiber base fabric is breathable, moisture-absorbent and comfortable, has all properties of natural fibers including fluffiness, resilience, flame resistance, softness, no abnormal odor and the like, can be made into genuine leather products including garments, cases, sofas, shoes and the like, and is an effective substitute product for genuine leather. Raw materials of the cowhide fiber base fabric are the leftover cowhide and discarded cowhide, production cost is saved, and environmental pollution is reduced.

Owner:朱晓华 +1

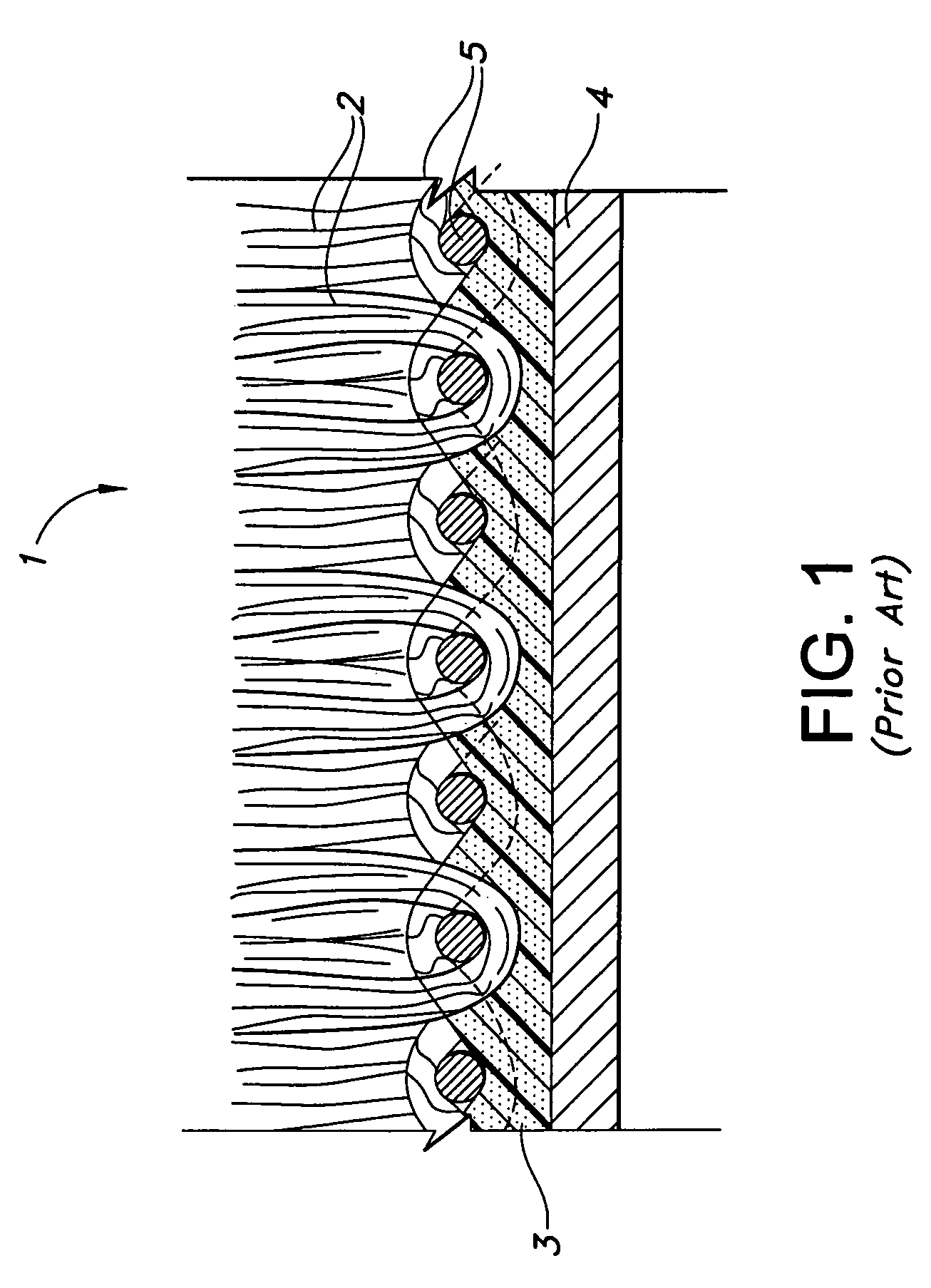

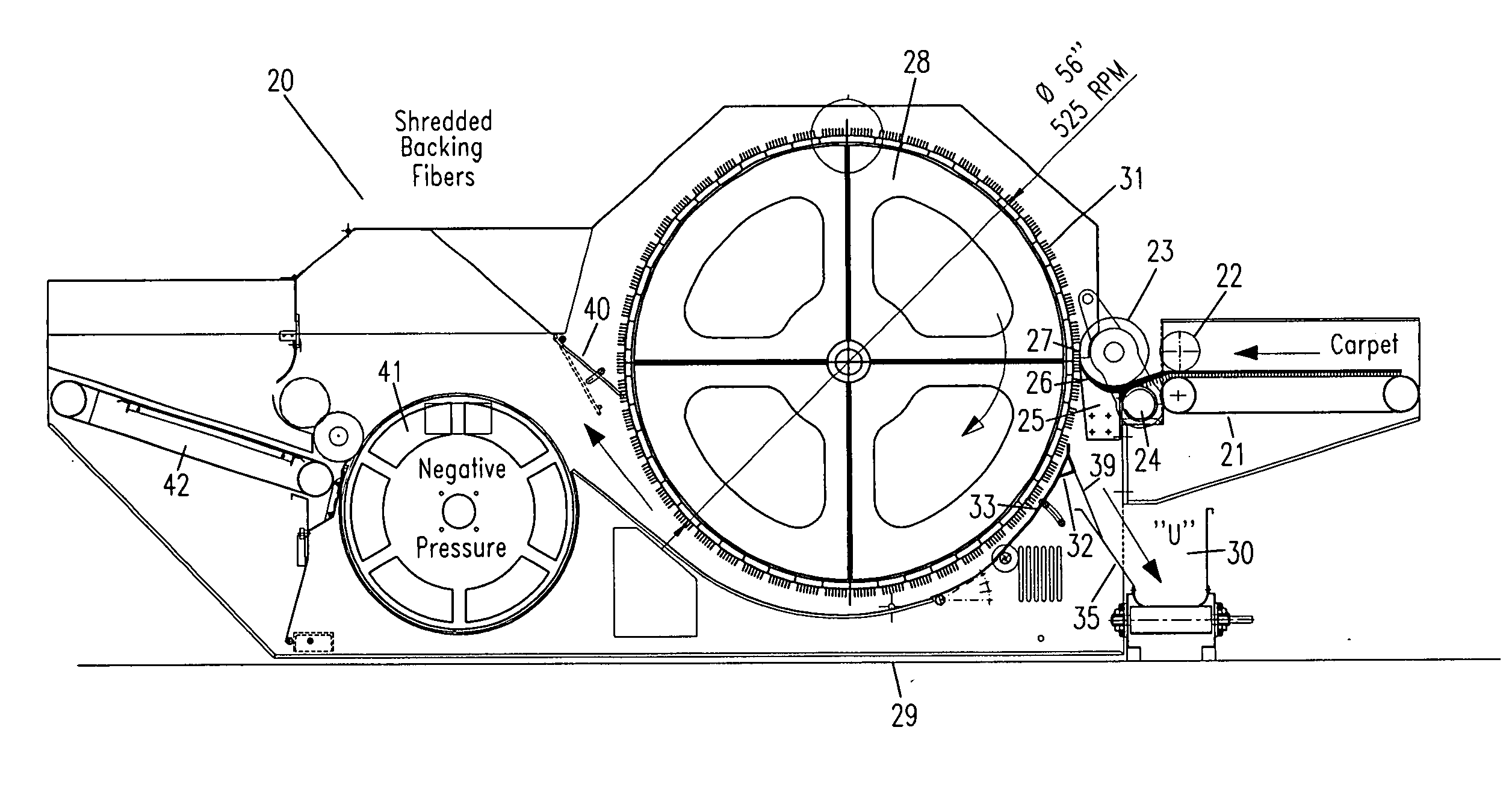

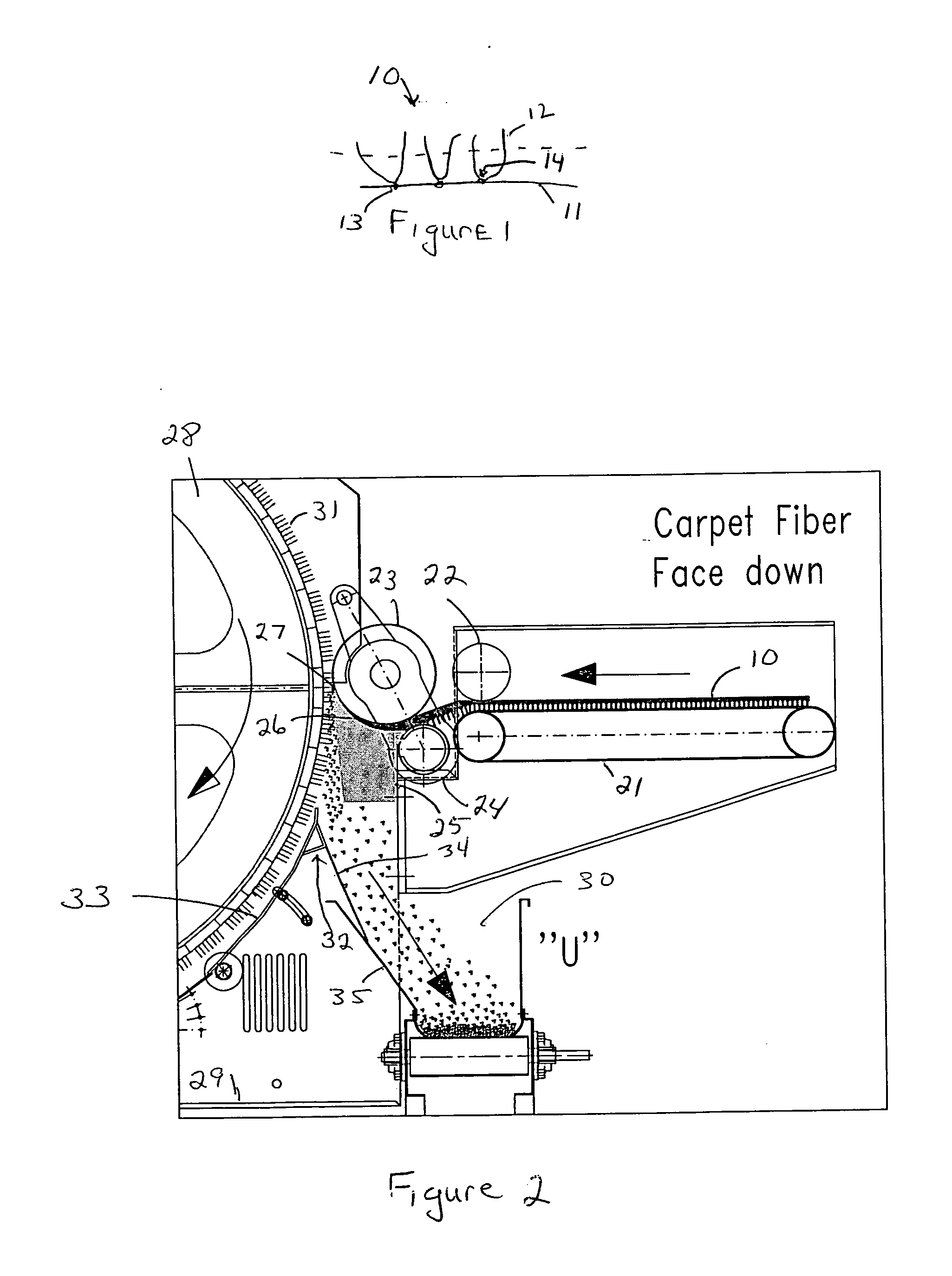

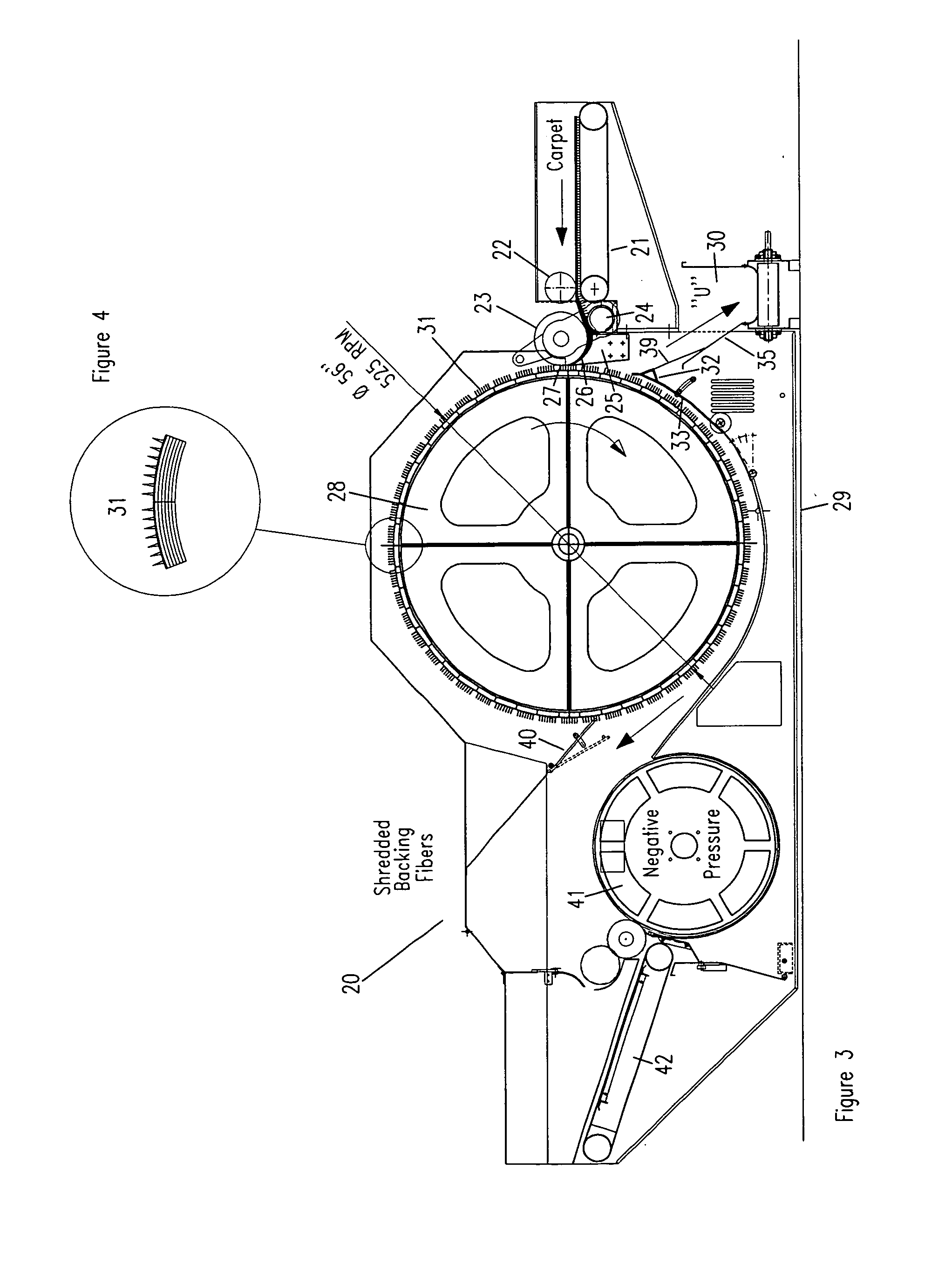

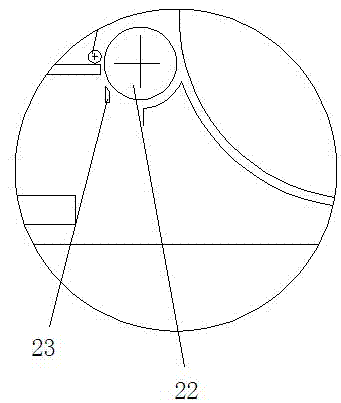

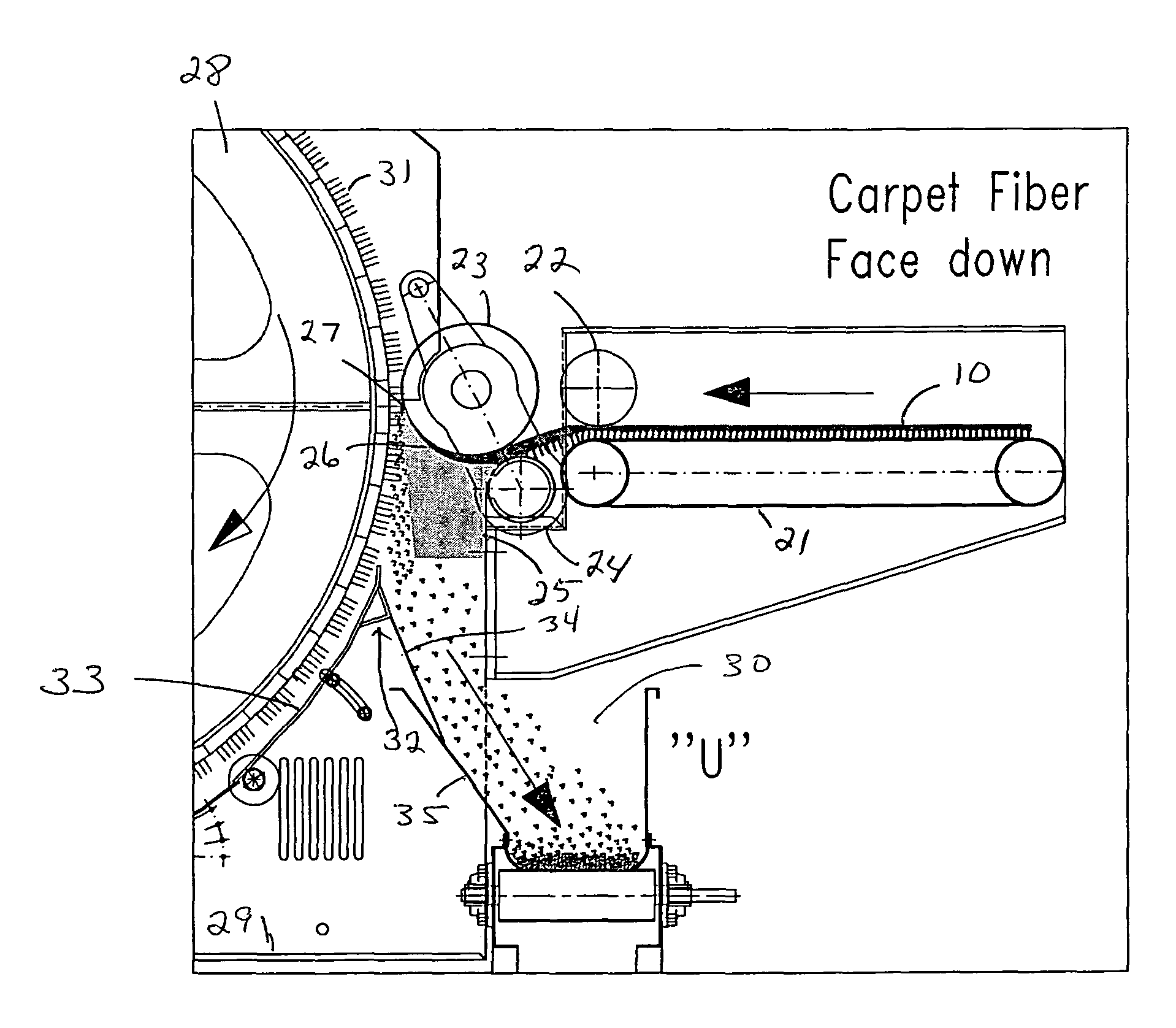

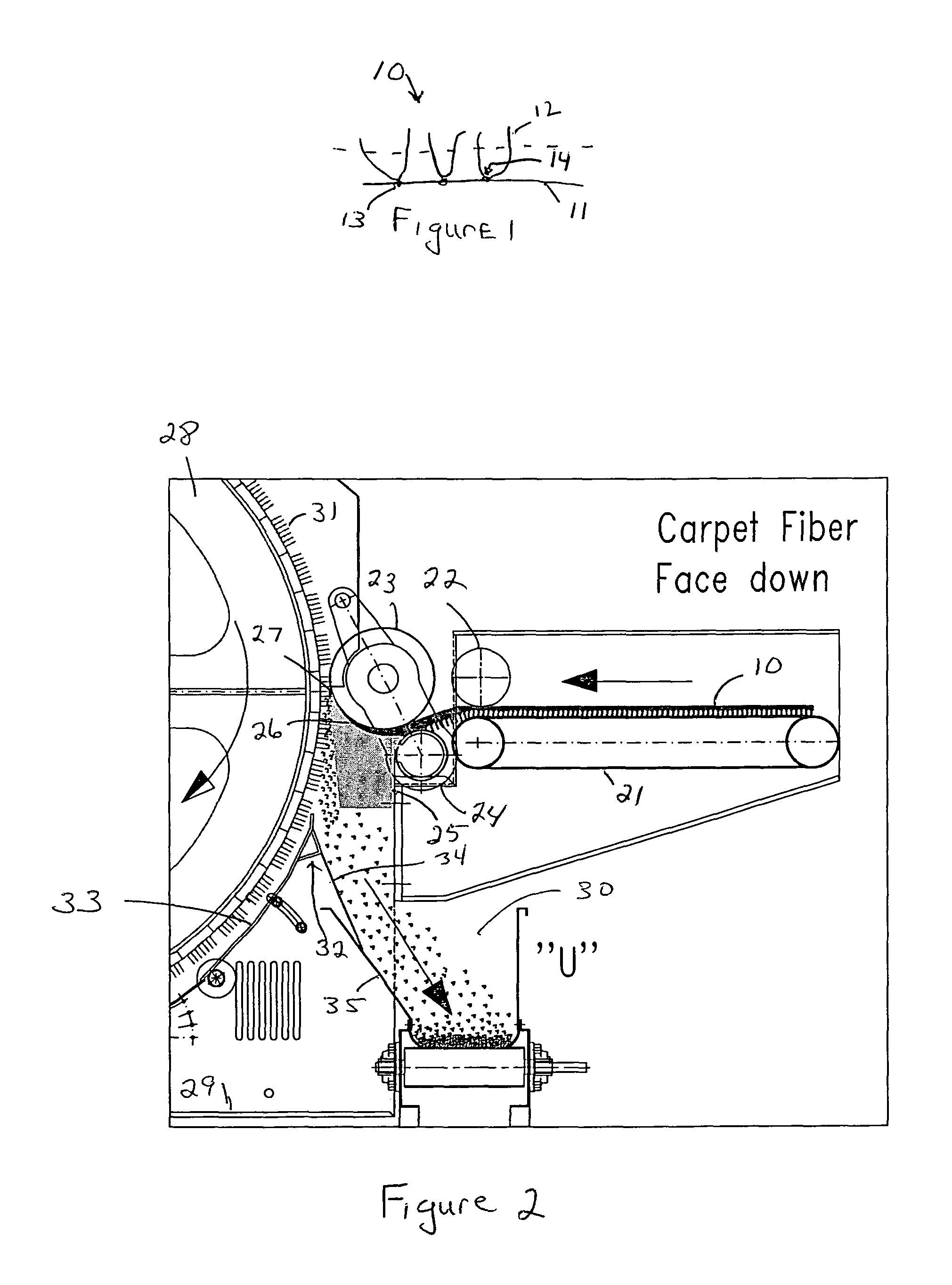

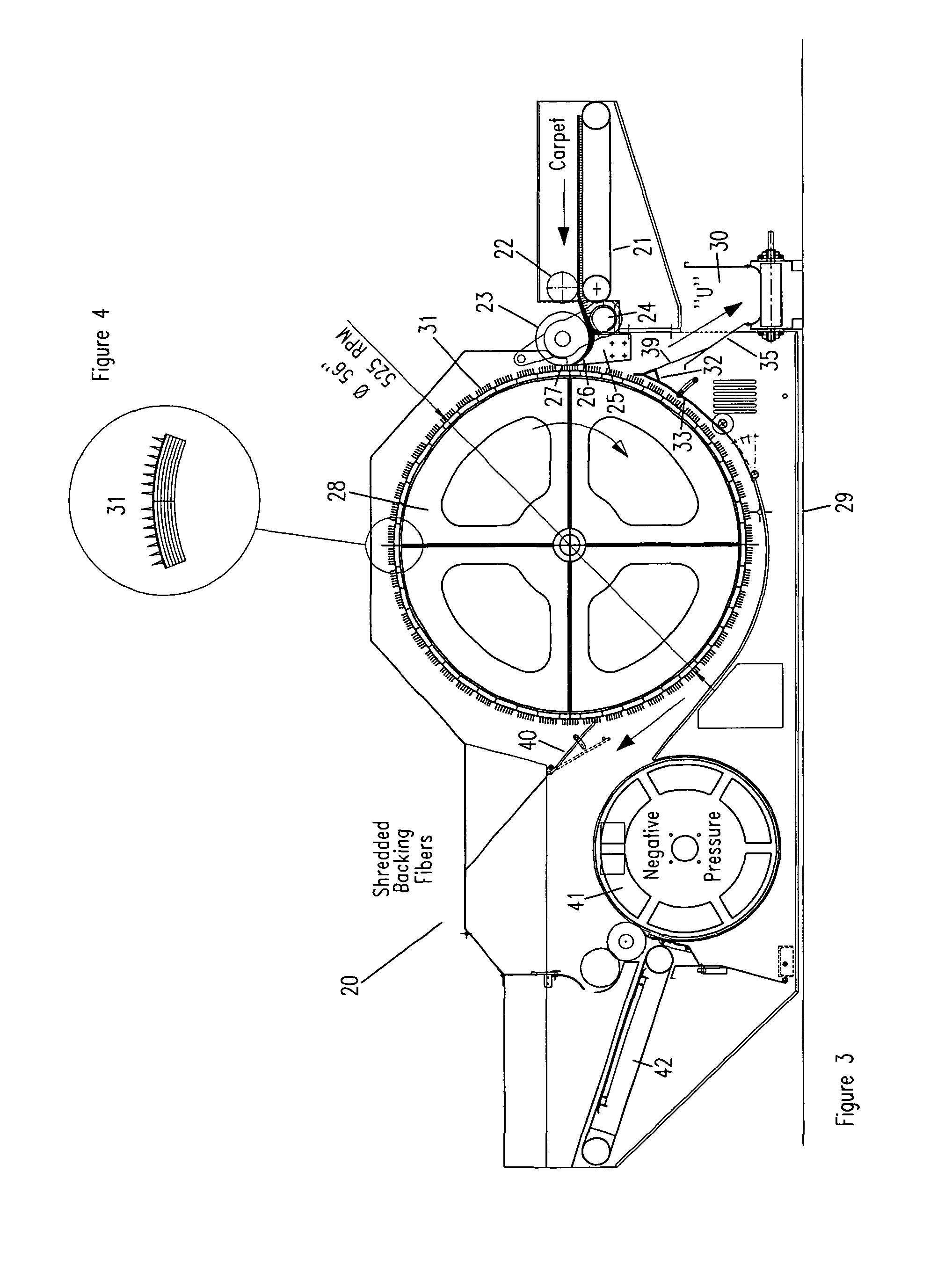

Method and apparatus for recycling carpet

The present invention is directed to an apparatus and method for separating carpet fibers from a backing material to which said fibers are secured. The apparatus includes a belt for driving a carpet strip having one or more backings and one or more fibers secured on a face of said backing into the operative part of the device. There are a pair of rollers that are adapted to receive the carpet strip from said belt, and pass the carpet strip to a dish plate. The dish plate has an edge extending upwardly from the dish plate. The face of the carpet having the fibers contacts the edge after the carpet passes through the rollers. The edge of the blade holds the carpet presenting it to the main drum. The main drum rotates downwards and has a plurality of pins that shred the carpet backing and tear apart and free the face carpet fibers from the backing fibers. The face fibers pass to a receptacle for recycling. The torn backing fibers, being usually longer and lighter than the face fibers, remain within the pins of the drum and are transported towards the back end of the machine and fall in a different receptacle for recycling.

Owner:LEVY FRANK +1

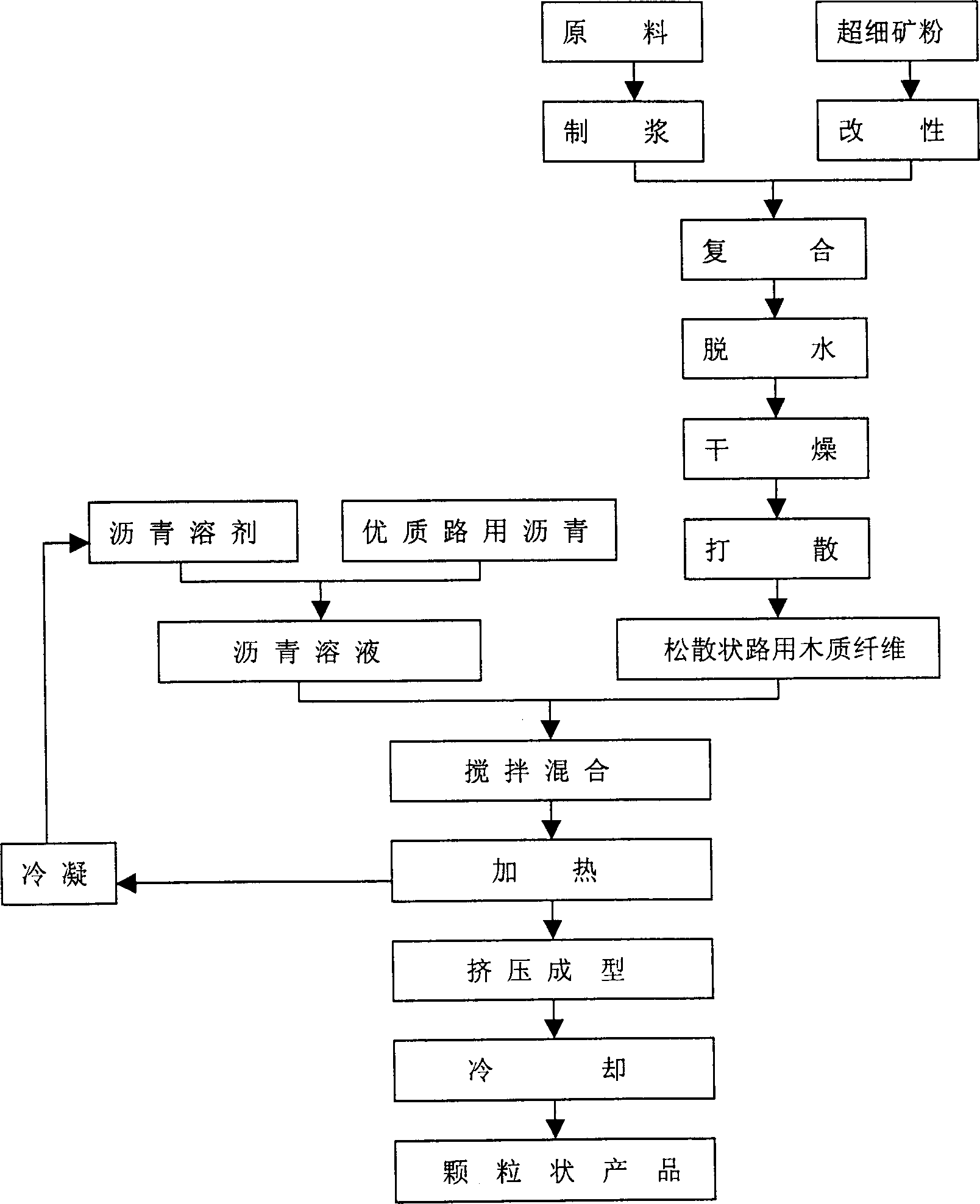

Method for preparing lignocellulose for road

InactiveCN1405372AHigh oil absorption valueLarge specific surface areaTextile disintegration and recoveryFibre disintegrationFiberRoad surface

Owner:NORTHEASTERN UNIV

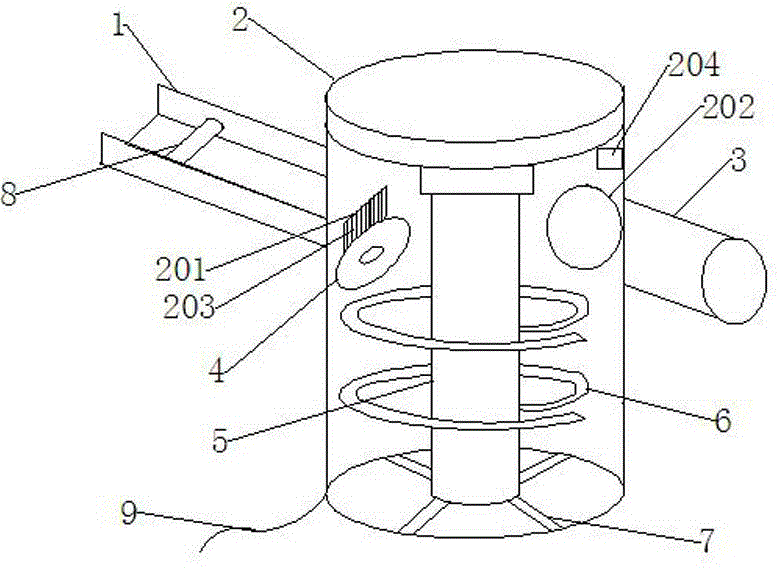

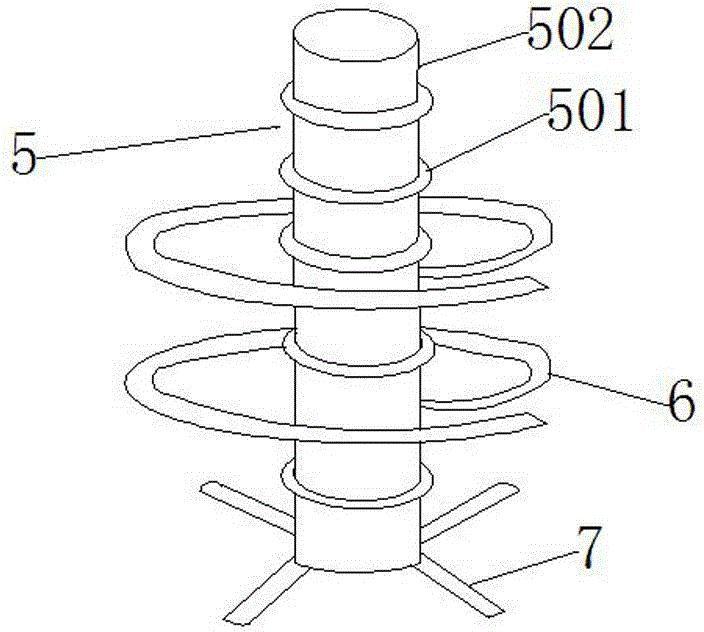

Double-cutter cotton-escape preventing fiber cutting machine

InactiveCN104153045AExcellent resistance to moisture absorptionStrong acid and alkali corrosion resistanceTows to slivers/yarnsTextile disintegration and recoveryFiberEngineering

The invention discloses a double-cutter cotton-escape preventing fiber cutting machine. The double-cutter cotton-escape preventing fiber cutting machine comprises a feed inlet cutter set (4) and a rolling cutter set (5), the feed inlet cutter set (4) is arranged below a feed inlet (201), the feed inlet cutter set (4) is driven by a first motor through a transmission mechanism, the rolling cutter set (5) is driven by a second motor through the transmission mechanism, a plurality of stirring racks are fixedly arranged on the rolling cutter set (5), a plurality of bottom stirring rods (7) are arranged at the bottom end of the rolling cutter set (5), the bottom surfaces of the bottom stirring rods (7) contact with the bottom surface of a box body (2), a cotton stop brush (203) is arranged at the position of the feed inlet (201), and a humidifier (204) is arranged on the box body (2); the box body (2) is connected with an earth lead (9). Cotton fibers can be effectively prevented from escaping out of the box body, and cotton fiber content in the environment is reduced. Meanwhile, fiber products are uniformly and finely cut.

Owner:扬中市金德纺织机械设备厂

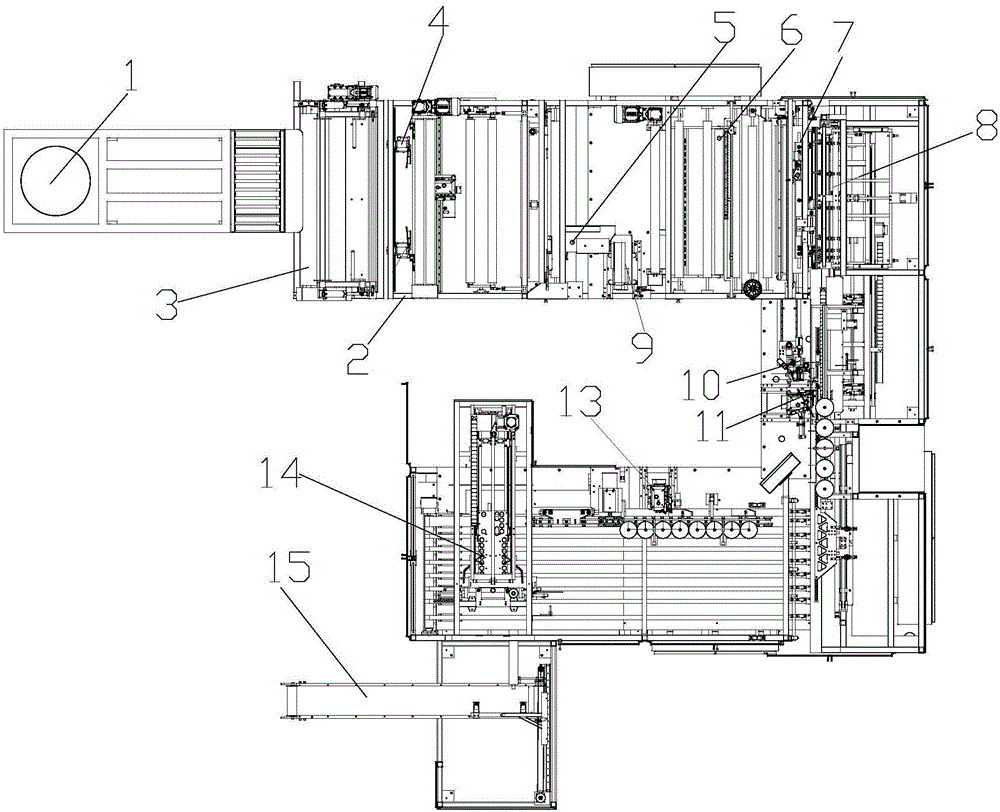

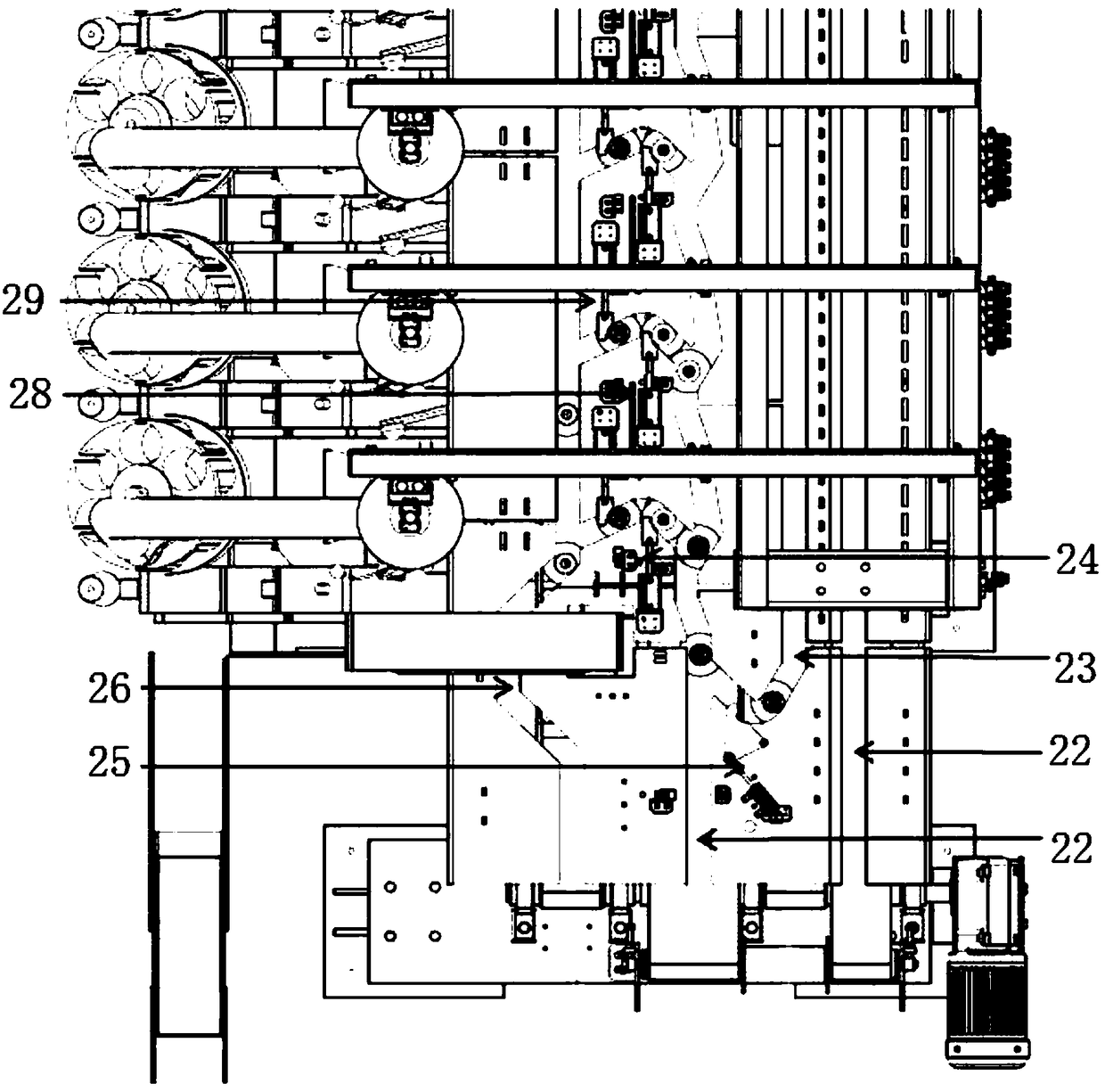

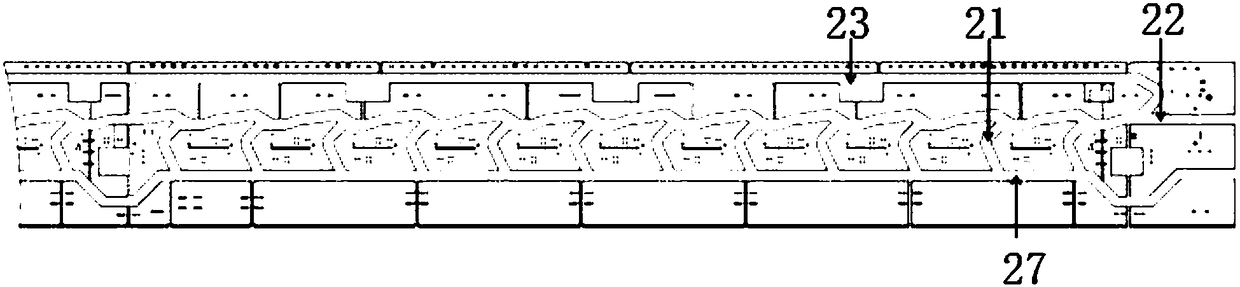

Full-automatic pillowcase machine

ActiveCN107435189AReasonable structure layoutMeet production and processing needsMechanical cleaningPressure cleaningEngineeringAssembly line

The invention relates to a full-automatic pillowcase machine. The machine comprises a feeding buffer area, a machine frame, a feeding component, a trimming device, an edge folding device, a sewing machine, a cloth slow storing mechanism, a correction device, a fixed-length cloth cutting-off mechanism, a label feeding device, a first binding-off device, a second binding-off device, a bag turning device and a collecting device, wherein the feeding component, the trimming device, the edge folding device, the sewing machine, the cloth slow storing mechanism, the correction device, the fixed-length cloth cutting-off mechanism, the label feeding device, the first binding-off device, the second binding-off device, the bag turning device and the receiving device are arranged on the machine frame; the feeding buffer area is located on one side of the machine frame; the feeding component, the trimming device, the edge folding device, the cloth slow storing mechanism, the correction device and the fixed-length cloth cutting-off mechanism are sequentially distributed on the machine frame; the label feeding device and the first binding-off device which are longitudinal distributed are arranged at the lower end of the fixed-length cloth cutting-off mechanism; the second binding-off device and the bag turning device are transversely distributed are arranged on one side of the lower end of the first binding-off device; the collecting device is arranged at the lower end of the bag turning device. The full-automatic pillowcase machine is reasonable in overall structural layout, assembly line processing of pillowcases can be automatically completed, the production efficiency is high, and the machine meets actual production and processing requirements.

Owner:SUZHOU TRANSPARENT TECH CO LTD

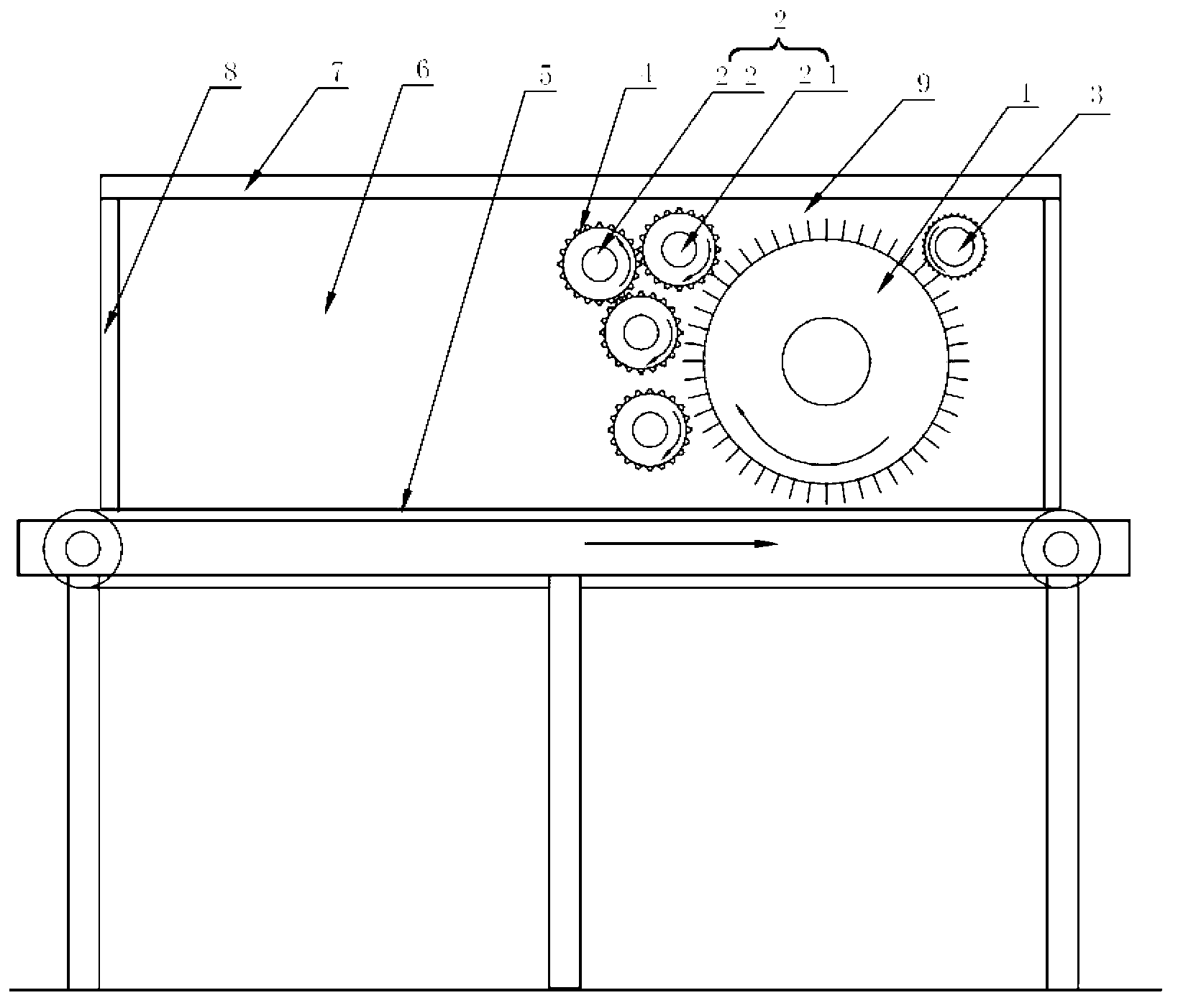

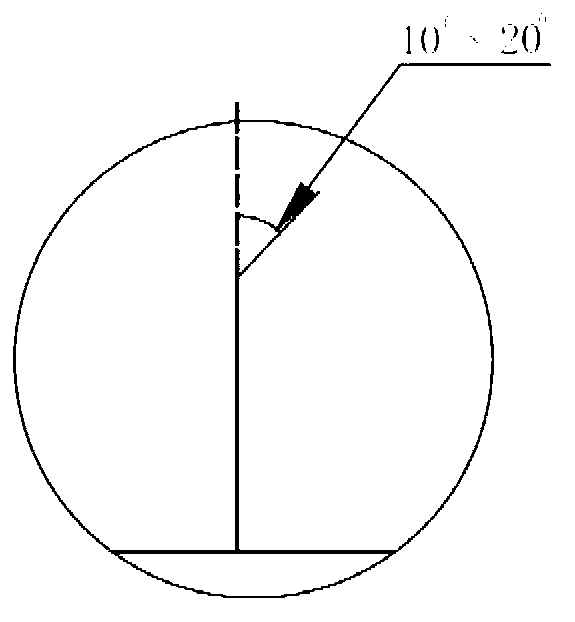

Leather material defibrating machine

The invention discloses a leather material defibrating machine, which comprises a cylinder pin cloth roll, wherein one side of the cylinder pin cloth roll is provided with a plurality of work rolls, the other side of the cylinder pin cloth roll is provided with a hairbrush roller, the work rolls comprise main work rolls and auxiliary work rolls, a plurality of main work rolls are covered and surrounded nearby the cylinder pin cloth roll, in addition, the outer surface of the main work rolls and the outer surface of the cylinder pin cloth roll gradually approach from bottom to top, the outer surface of the auxiliary work rolls and the outer surface of the main work rolls are in tangential structure arrangement, the surfaces of the work rolls are provided with tilting sheets or hook knives, the cylinder pin cloth roll, the work rolls and the hairbrush roll are respectively in horizontal arrangement and are mutually parallel, and a leather material conveying belt is arranged under the cylinder pin cloth roll. The equipment has the advantages that the structure is simple, the defibration effect is good, the defibrating efficiency is high, and pulverized leather materials can be resolved into fibrous leather materials.

Owner:JIANGYIN JUNHUA TEXTILE TECH

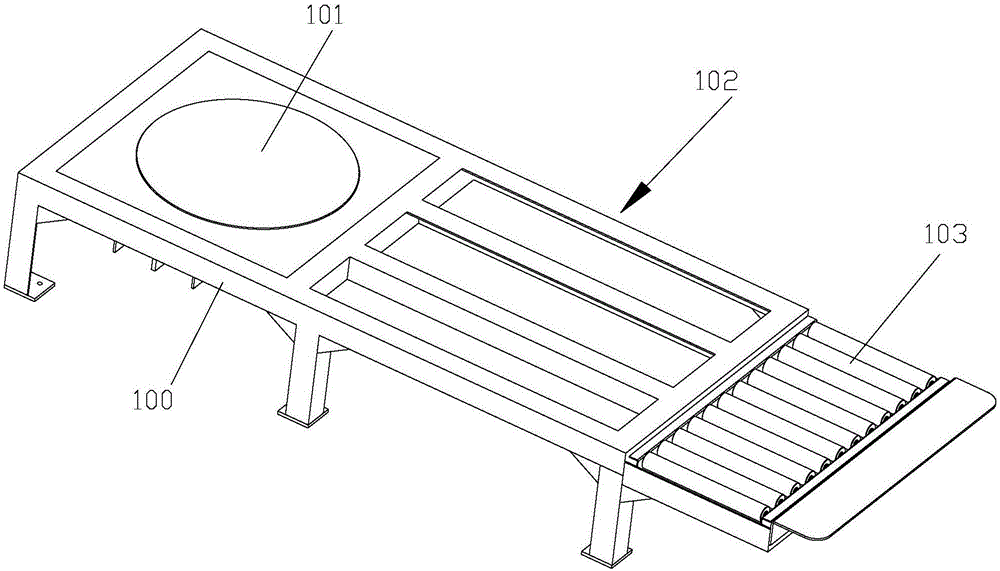

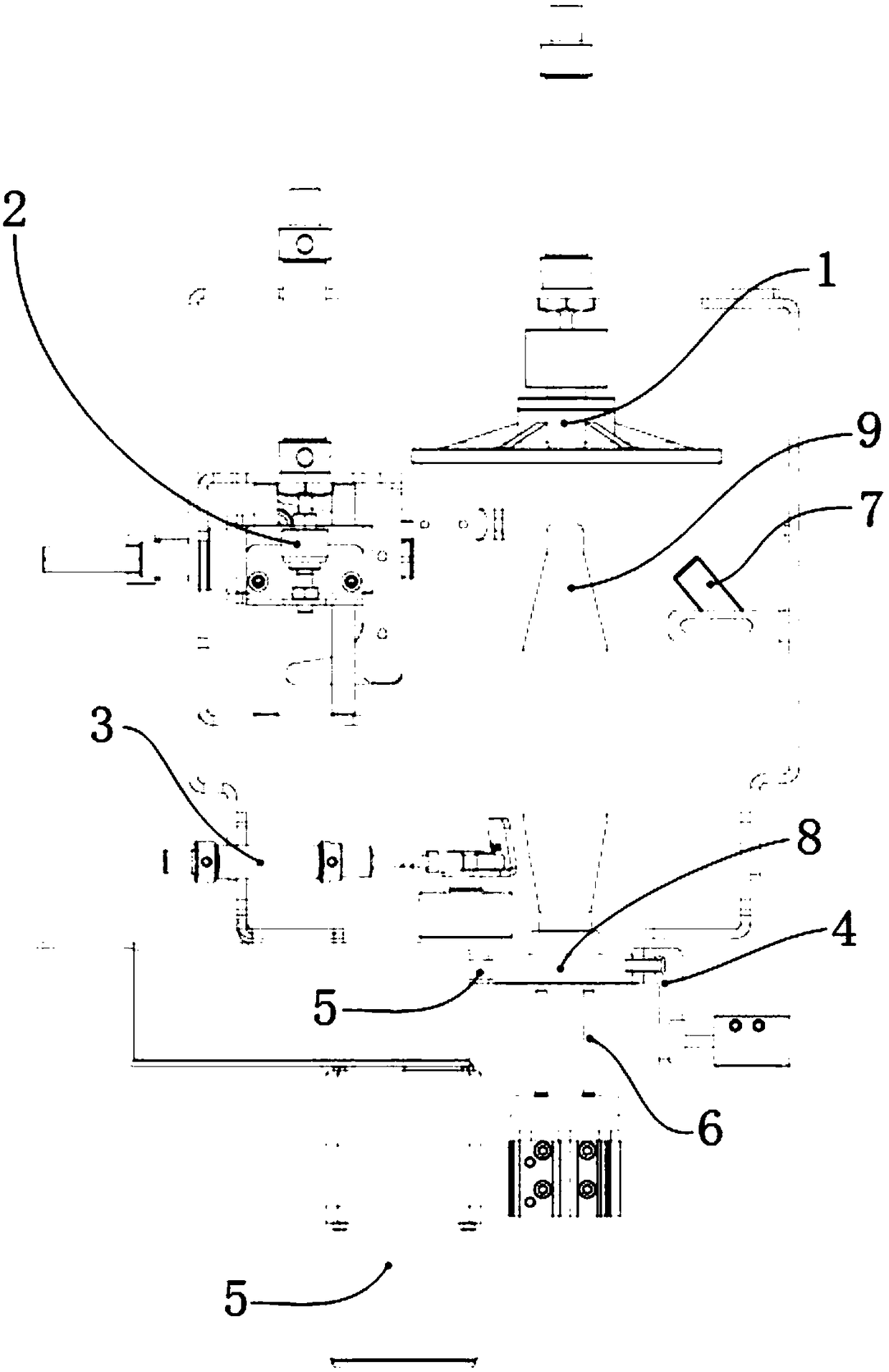

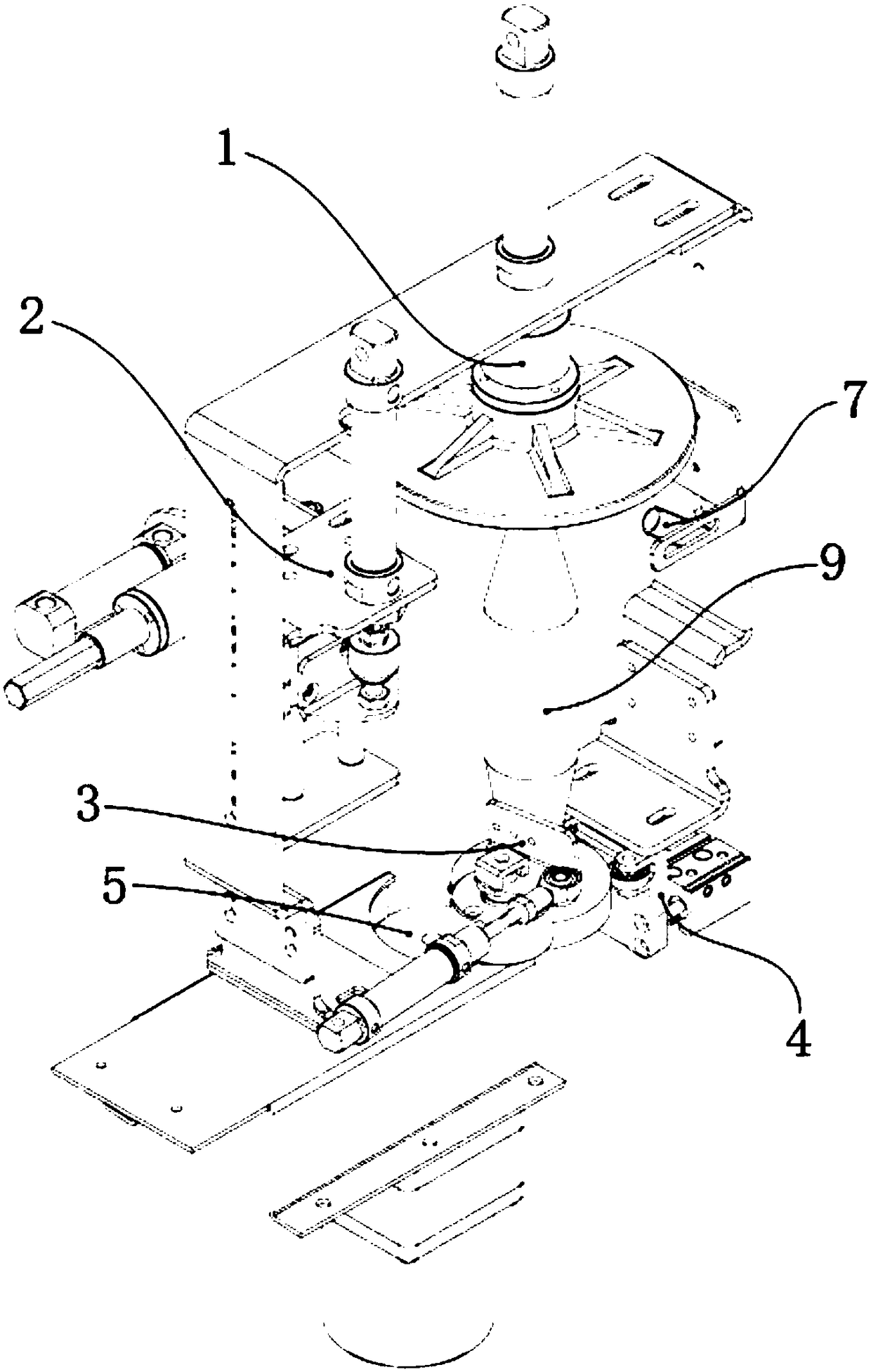

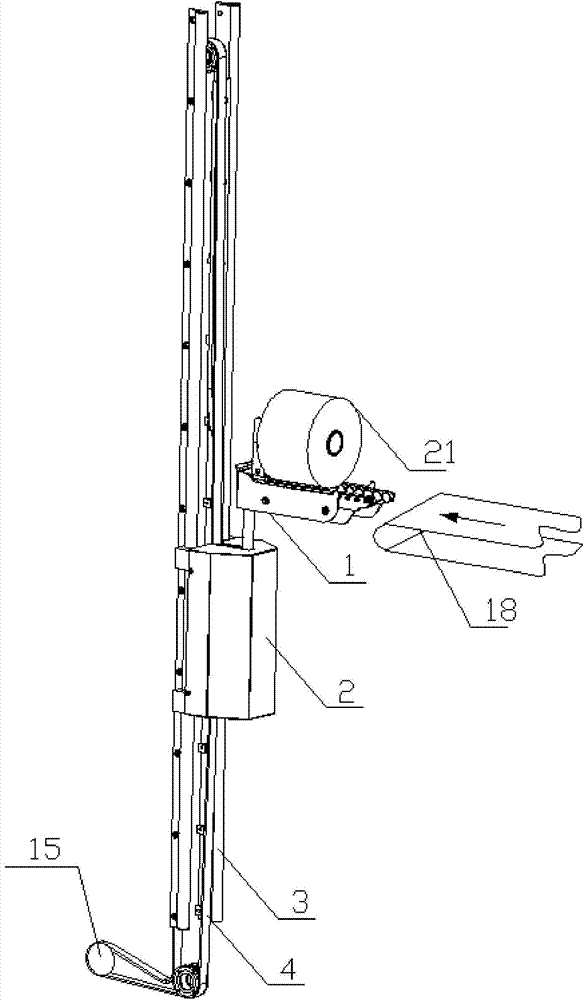

Automatic yarn feeding device for automatic bobbin winder

PendingCN108423495AWith automatic sorting and feedingFunctionalFilament handlingTextile disintegration and recoveryYarnBobbin

The invention provides an automatic yarn feeding device for an automatic bobbin winder. An existing device is remolded by constructing a conveying platform. The automatic sorting and positioning of cop is realized through an up-mounted automatic circulation channel. After a grabbing mechanism grabs the cop, the cop is dropped into a doffing channel and arrives at the specified position of a magazine. And then a suction head action to the cop is completed by an automatic suction head device. The structure of the original device does not need to be changed. Man power is replaced by cooperation of an additional platform and action with the original device, which makes the device become automatic.

Owner:江阴市凯业纺织机械制造有限公司

Waste clothing recycling pre-treatment technology

ActiveCN104532409AImprove toughnessHigh strengthTextile disintegration and recoveryFibre disintegrationFiberPre treatment

The invention discloses a waste clothing recycling pre-treatment technology, and belongs to the technical field of renewable resources of textile. According to the technology, recycled waste clothing is disinfected, cleaned, decolorized and modified, and then the treated waste clothing capable of be applied to production of new materials directly is obtained, and efficient recycling of plant fiber resources is achieved.

Owner:民勤县家兴节能服务有限公司

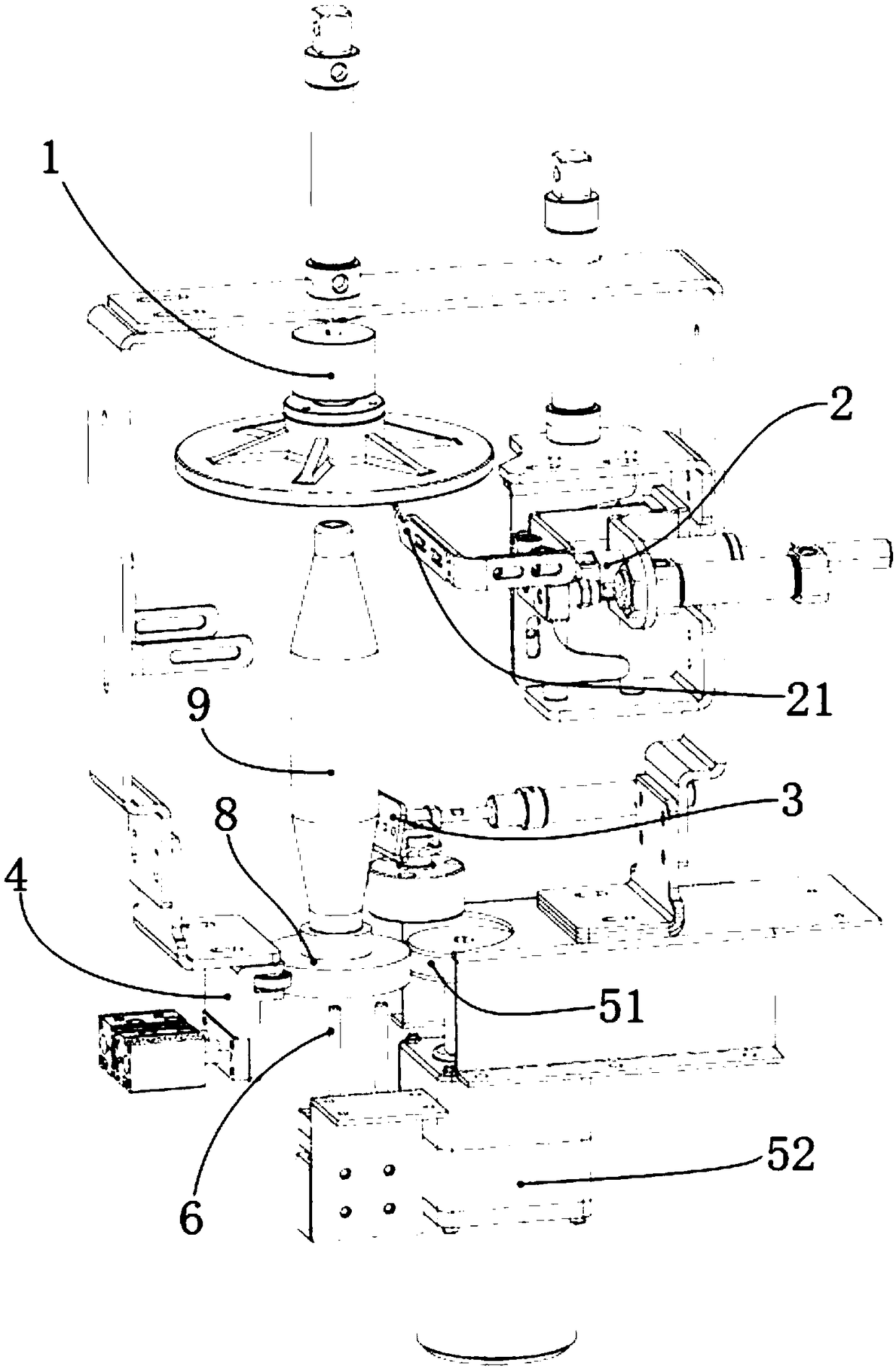

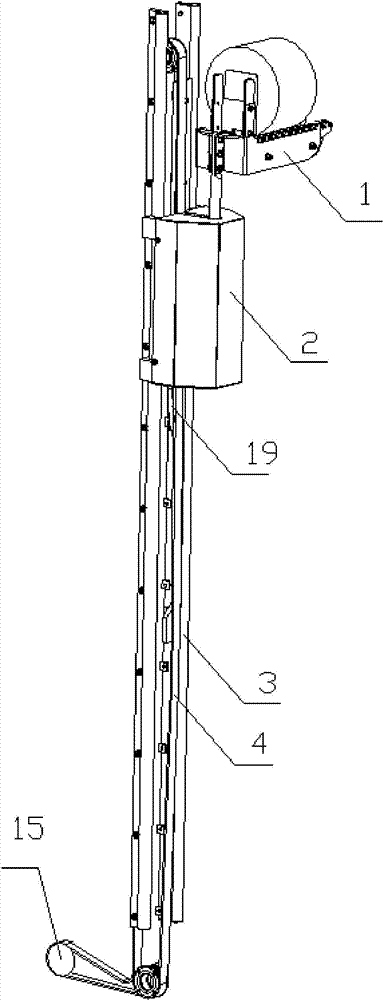

Thread end finding arrangement system for automatic thread end finding equipment of automatic bobbin winder

PendingCN108423494AImprove operational efficiencyFilament handlingTextile disintegration and recoveryYarnEngineering

The invention provides a thread end finding arrangement system for automatic thread end finding equipment of an automatic bobbin winder. When a cop reaches the portion below a thread end pressing rod,a limit rod rises to prevent the forward movement of a cop bottom support, the thread end pressing rod extends out and presses the head of a cop, and a rotary driving mechanism and a pressing mechanism press the cop bottom support and then rotate. A thread end picking mechanism extends into the surface of the cop and picks off knotted thread ends, a cutter of a thread loosening mechanism extendsto the surface of the cop and moves up and down to loosen the cop thread ends in combination with the rotation of the cop, a blowing nozzle mounted on a blowing nozzle bracket blows the thread ends from top to bottom to make the thread ends wind the top of the cop, and then the limit rod descends to discharge the cop out of a station. Thus, the subsequent thread end suction at the thread end sucking and hiding station is facilitated, and the running efficiency of the equipment is greatly improved.

Owner:江阴市凯业纺织机械制造有限公司

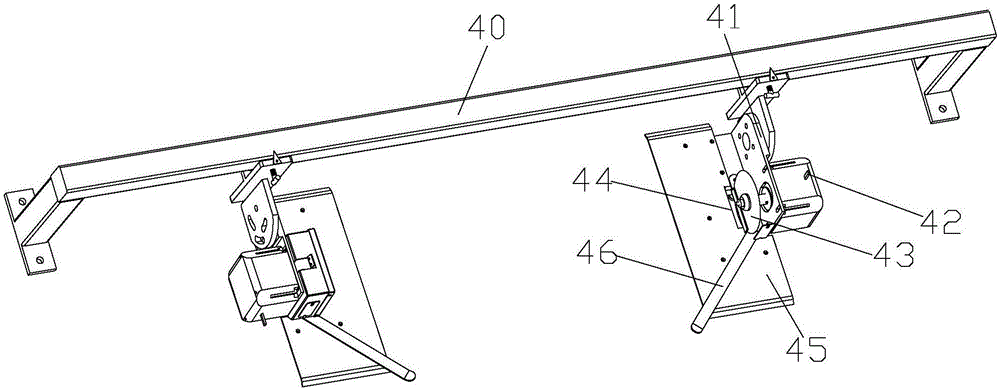

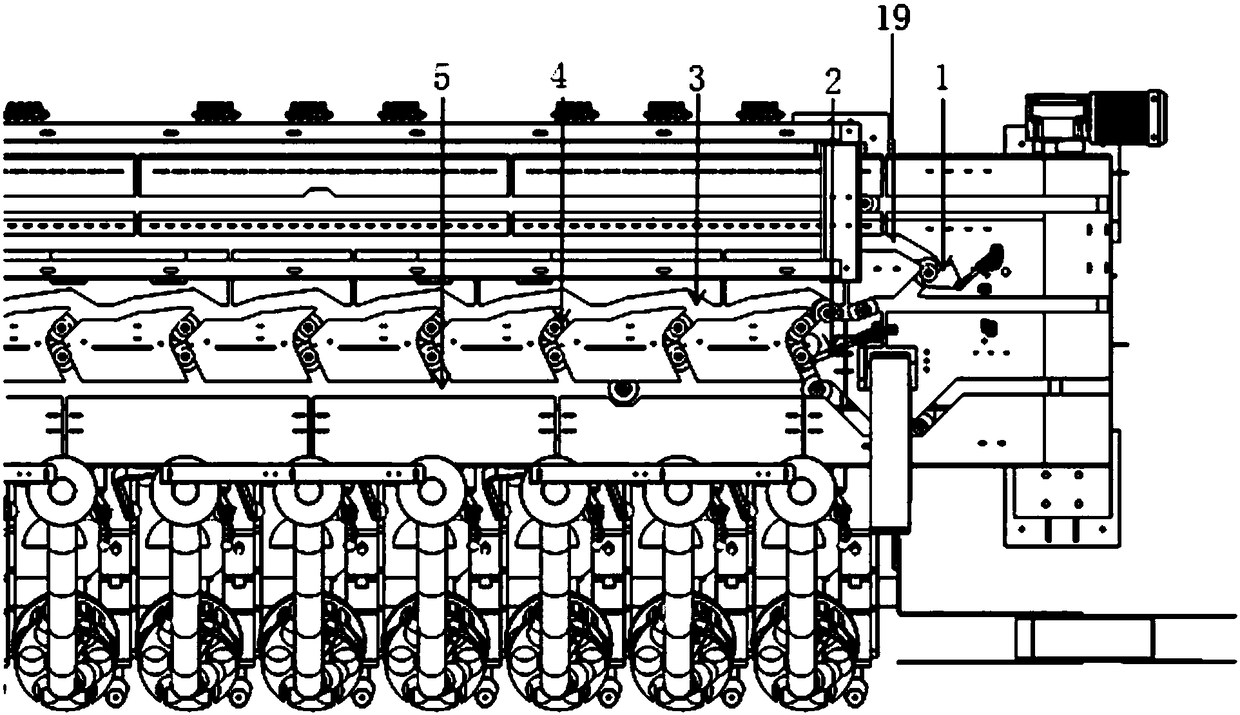

Conveying system of automatic yarn feeding equipment

PendingCN108529337AWith automatic sortingFunctionalFilament handlingTextile disintegration and recoveryYarnBobbin

The invention provides a conveying system of automatic yarn feeding equipment. According to the conveying system of the automatic yarn feeding equipment, the bobbin yarn distribution way of an original magazine-type automatic winder is improved; a frame platform structure is mainly adopted by the conveying system, and a whole bobbin yarn conveying platform is erected above original equipment; anda belt is adopted by a conveying platform for transmission, and channel movement formed by a guiding-type cover plate is used for achieving bobbin yarn distribution. In this way, the conveying systemhas the functions of automatically sorting and feeding bobbin yarn; and the production efficiency is improved, and the labor cost is reduced.

Owner:江阴市凯业纺织机械制造有限公司

High precision thread trimming device and method for embroidery machine

PendingCN106012362AHigh precision controlAvoid spindle speed fluctuationsEmbroidering machines apparatusTextile disintegration and recoveryEngineeringPosition sensor

The invention discloses a high precision thread trimming device and a high precision thread trimming method for an embroidery machine. The device comprises a plastic cutter driving device and a thread trimming device, wherein the plastic cutter driving device is arranged at the upper side of a faller; the thread trimming device is arranged at the lower side of the faller; the plastic cutter driving device comprises a plastic cutter motor; a position sensor and an eccentric wheel are respectively arranged on the periphery of a drive shaft of the plastic cutter motor; the eccentric wheel is connected with a swing rod with a sliding chute at one end by a pin roller; a stationary shaft connected with a motor base is arranged in the middle of the swing rod; the other end of the swing rod is connected with a pull rod driving a plastic cutter by a connecting rod. The device has the beneficial effects that the exact position of the plastic cutter when going back is determined via the position sensor on the periphery of the drive shaft of the plastic cutter motor, thus achieving high precision control of the thread trimming length and avoiding technical defects caused by main shaft speed fluctuation.

Owner:ZHEJIANG YUELONG SEWING EQUIP

Method of separation and cleaning of post consumer carpet face yarn from carpet backing yarn product produced therefrom

A process for producing a synthetic fiber composition with reclaimed post consumer carpet yam, wherein face yam is shaved from post consumer carpet using a shaving device to provide shaved face yam, the shaved face yam is reduced in size, contaminants are removed using mechanical screeners, the shave face yam is melt filtered, and then fiber spun.

Owner:UNIVERSAL FIBERS INC

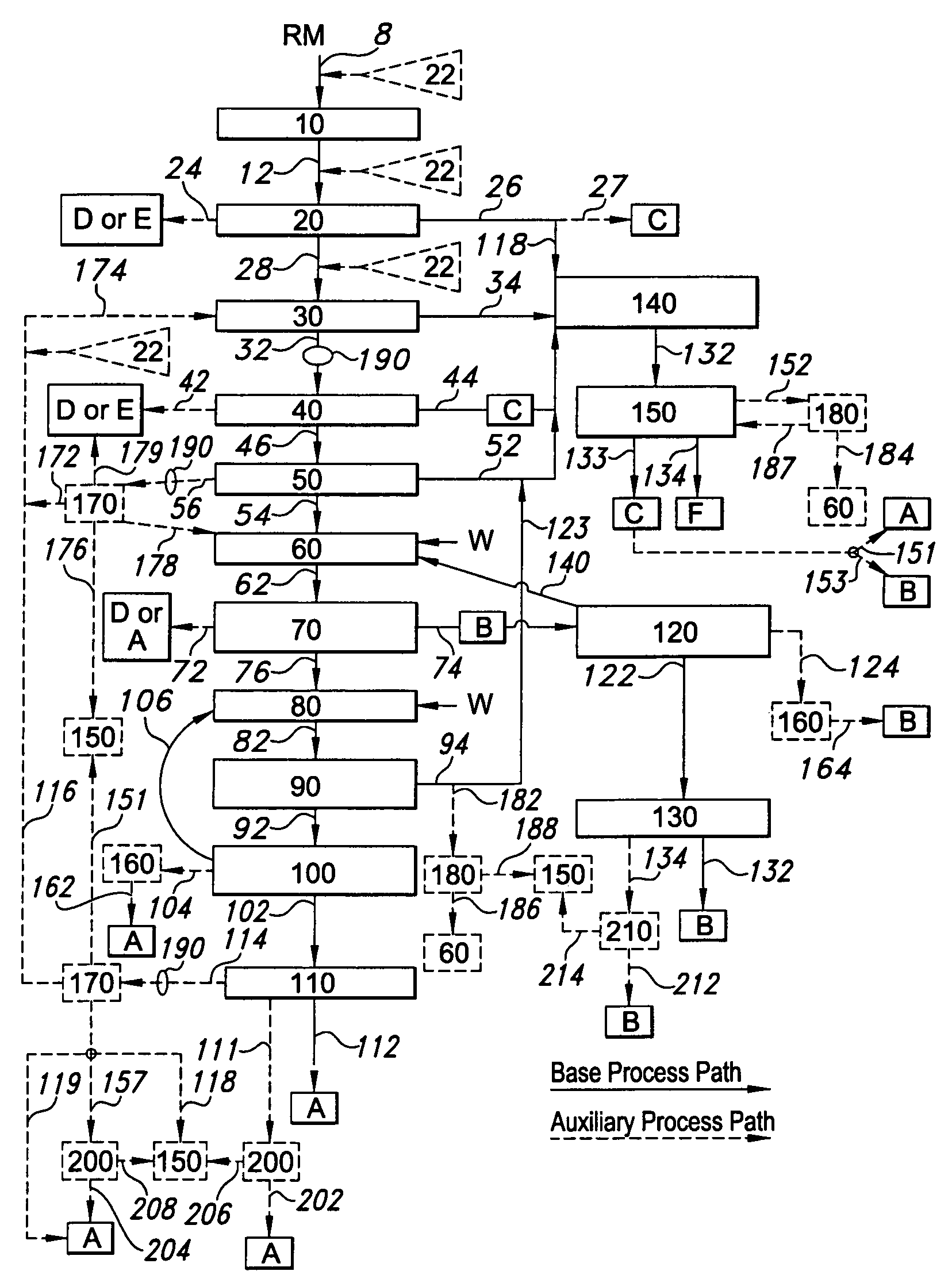

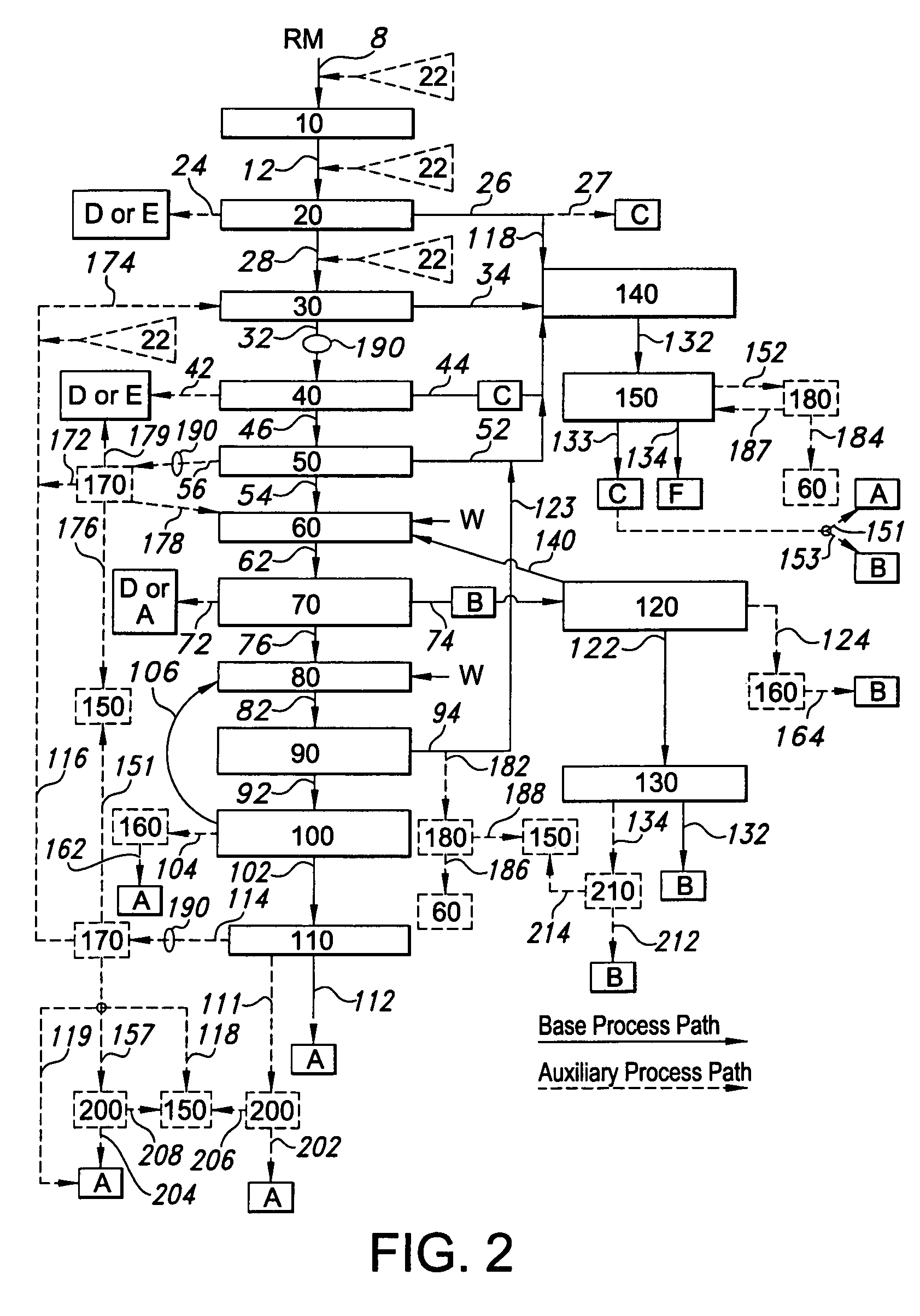

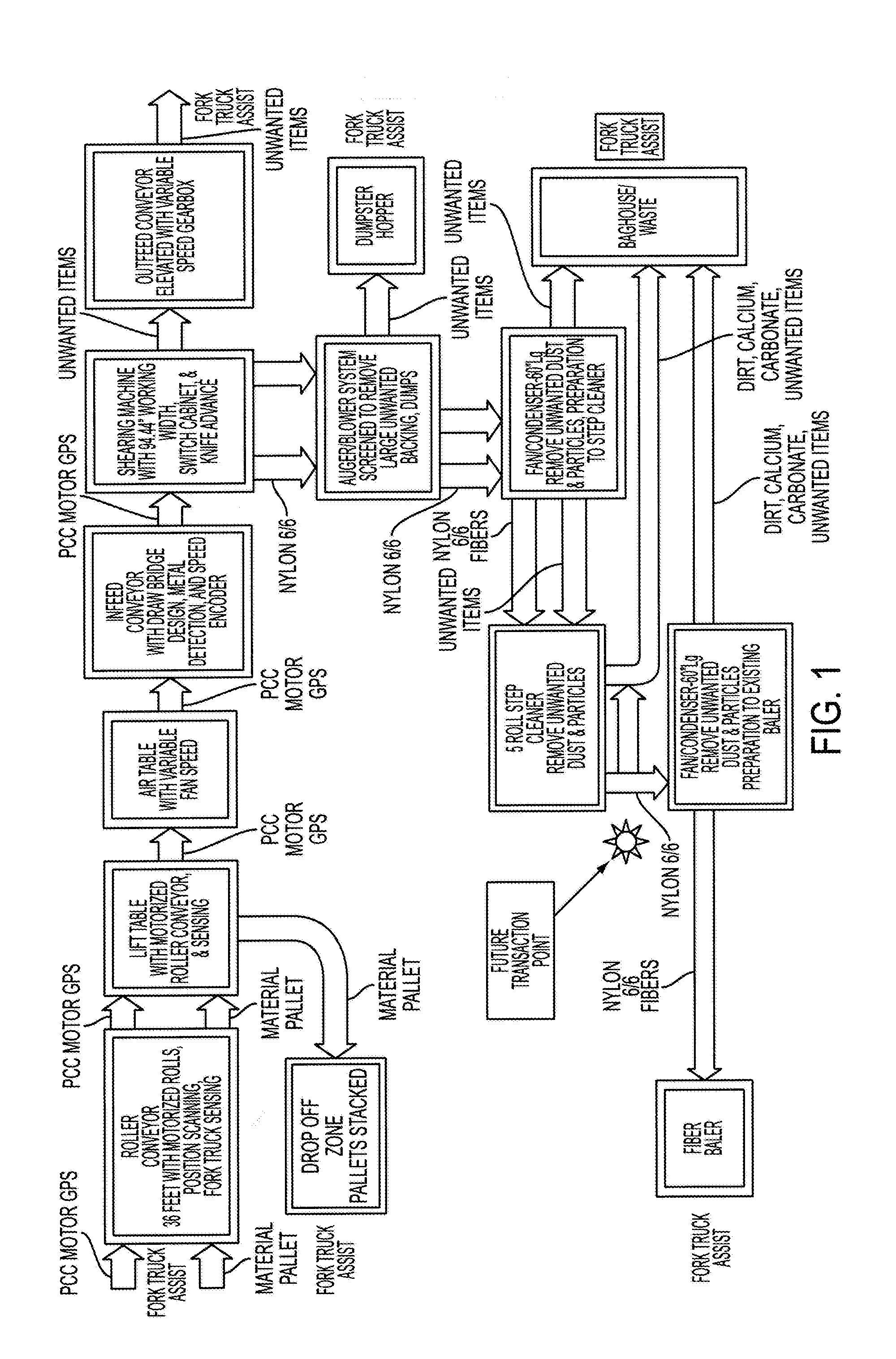

System and method for reclaiming waste carpet materials

ActiveUS20130327858A1Improve efficiencyLow level of contaminationPlastic recyclingTextile disintegration and recoveryYarnContinuous flow

The present invention relates generally to the reclaiming of carpet waste material. More particularly, the invention relates to a method and system for reclaiming carpet components such as yarn, tufting primary, binder, and secondary backing from post-industrial and post-consumer carpet waste in a substantially continuous flow process.

Owner:COLUMBIA INSURANCE CO

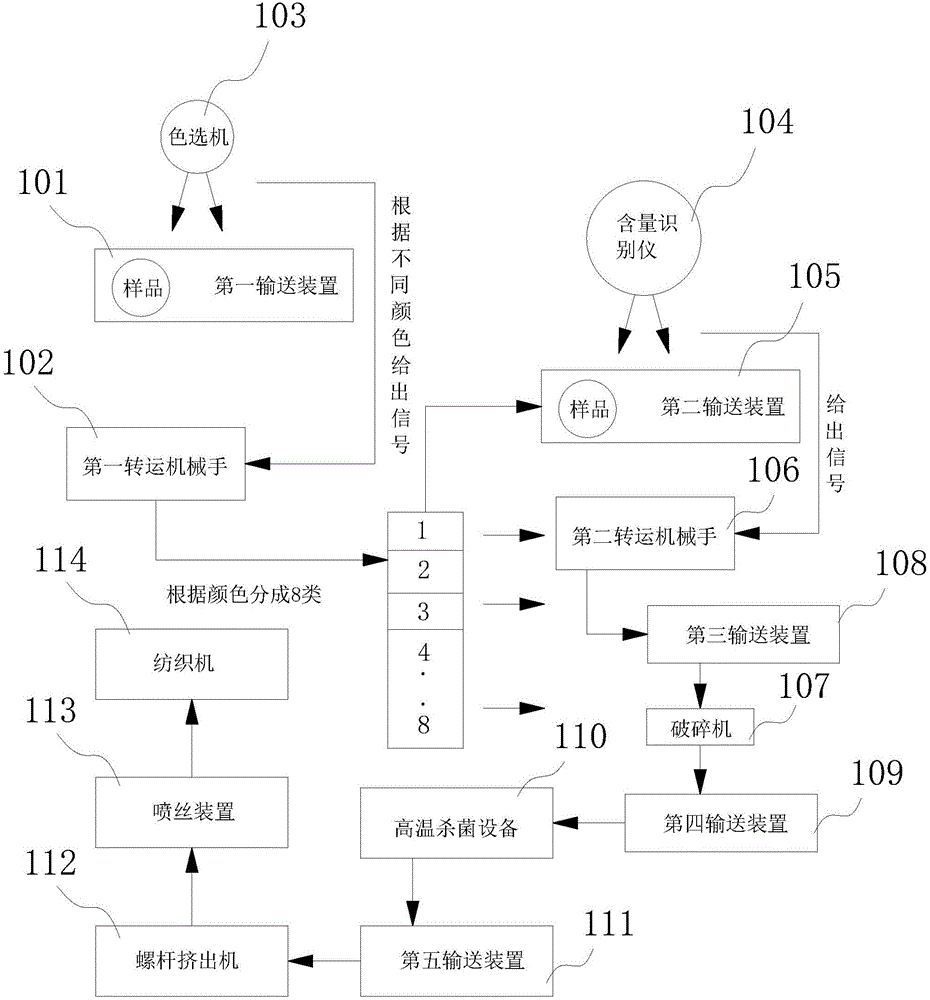

Environment-friendly and efficient waste clothes regeneration system and environment-friendly and efficient waste clothes regeneration method

ActiveCN106245125AWide range of usesImprove performanceArtificial thread manufacturing machinesTextile disintegration and recoveryFiberColor recognition

The invention provides an environment-friendly and efficient waste clothes regeneration system. The system is characterized by comprising a color sorting system, a component recognition and sorting system, a crushing system, a sterilization and disinfection system, a melt silk drawing system and a textile machine. The system has the beneficial effects that a waste fiber product intelligent recognition and sorting system can be built by introducing waste fiber product color recognition, component and content recognition components on the basis of current industrial sorting equipment, can be used for effectively sorting different colors and contents of waste fiber products, has sorting accuracy rate of more than 98% and actual content errors of less than 2% and is beneficial to subsequent recycling.

Owner:南京启宏云技术有限公司

Polyester-containing waste textile recycling technology

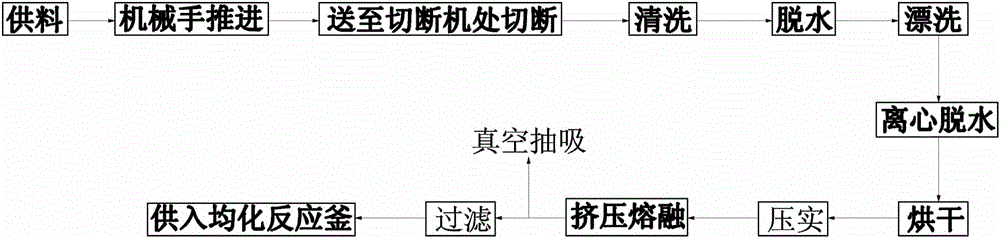

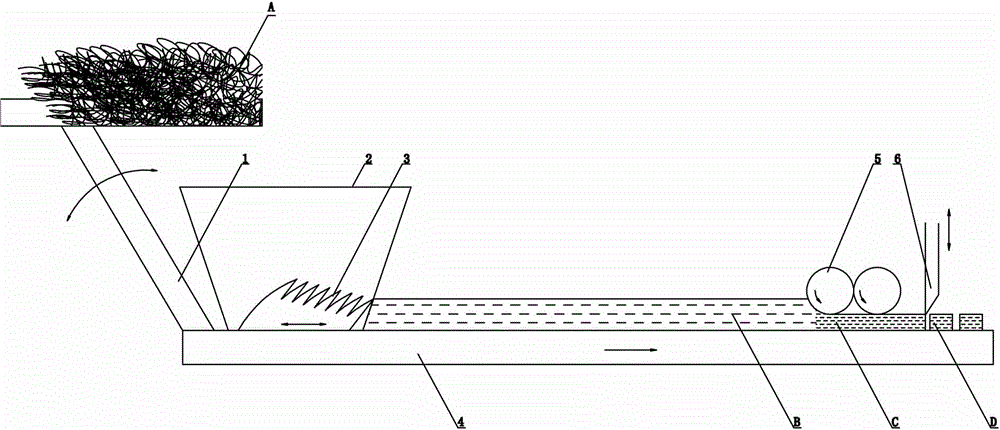

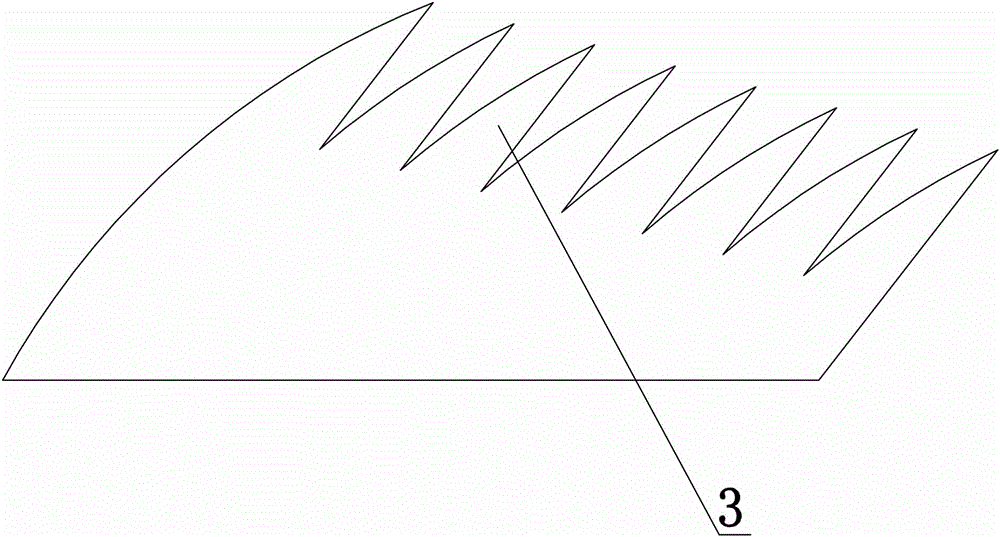

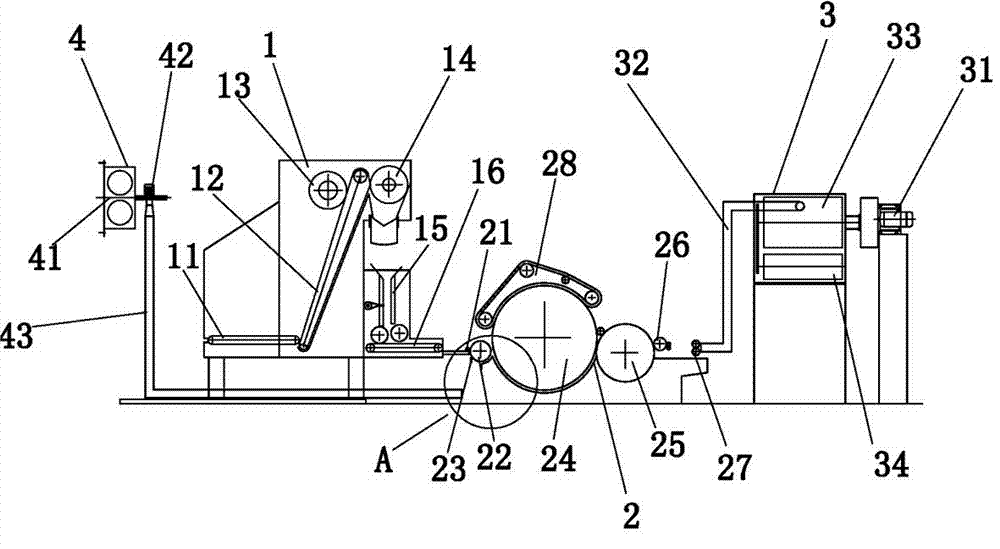

ActiveCN105803585AOrderly rowsAvoid defects such as windingTextile disintegration and recoveryFibre disintegrationPolyesterPlasticulture

The invention relates to a polyester-containing waste textile recycling technology, and belongs to the technical field of waste material recycling or processing. The polyester-containing waste textile recycling technology comprises the steps of cutting off, cleaning, drying, cutting and compacting and tackifying in sequence, wherein according to the cutting off step, waste filaments are carded with fingers of a cutting off machine and then cut off by a reciprocating cutter, after the waste filaments are cut into set length, cleaning and dewatering and drying are carried out in a fragment mode, the moisture content is controlled to be 0.5% or lower, and the waste filaments are fed into the compacting procedure, extruded, heated, plastified and then tackified. The polyester-containing waste textile recycling technology is applied to recycling of polyester products, and has the advantages that production is stable, multiple varieties of raw materials are used, the product quality is reliable, and energy consumption is low.

Owner:湖北绿宇环保有限公司

Waste cotton recycling and utilizing device

InactiveCN102758274AIncrease profitReduce wasteTextile disintegration and recoveryFibre disintegrationCardingPulp and paper industry

Owner:ZHEJIANG ZHONGXIN TEXTILE TECH

Method and system of processing waste fabrics to rejuvenated fibrous materials

ActiveUS20160283917A1Low costWithout loss of efficiencySolid waste disposalTextile disintegration and recoveryFiberProcess engineering

The present invention discloses a method and corresponding system of processing waste fabrics to rejuvenated fibrous materials that will maintain their original quality in downstream production without a loss of downstream manufacturing efficiencies. The method comprises the steps of (a) obtaining fabric data for each bale of incoming waste fabrics and storing the fabric data in a database; (b) obtaining target data relating to target product requirements; (c) processing the fabric data stored in the database and the target data according to predetermined algorithms to generate a rejuvenation processing recipe which specifies bales information relating to bales of incoming waste fabrics selected for further rejuvenation processing, and rejuvenation processes information relating to a series of processes and corresponding process parameters for each of the series of processes for processing the selected bales of incoming waste fabrics to obtain rejuvenated fibrous materials specific to the target product requirements; (d) selecting, according to the bales information of the rejuvenation processing recipe, corresponding bales of incoming waste fabrics for further rejuvenation processing; and (e) subjecting the selected bales of incoming waste fabrics to processes specified by the rejuvenation processes information of the rejuvenation processing recipe to obtain rejuvenated fibrous materials specific to the target product requirements.

Owner:PSIL HLDG LLC

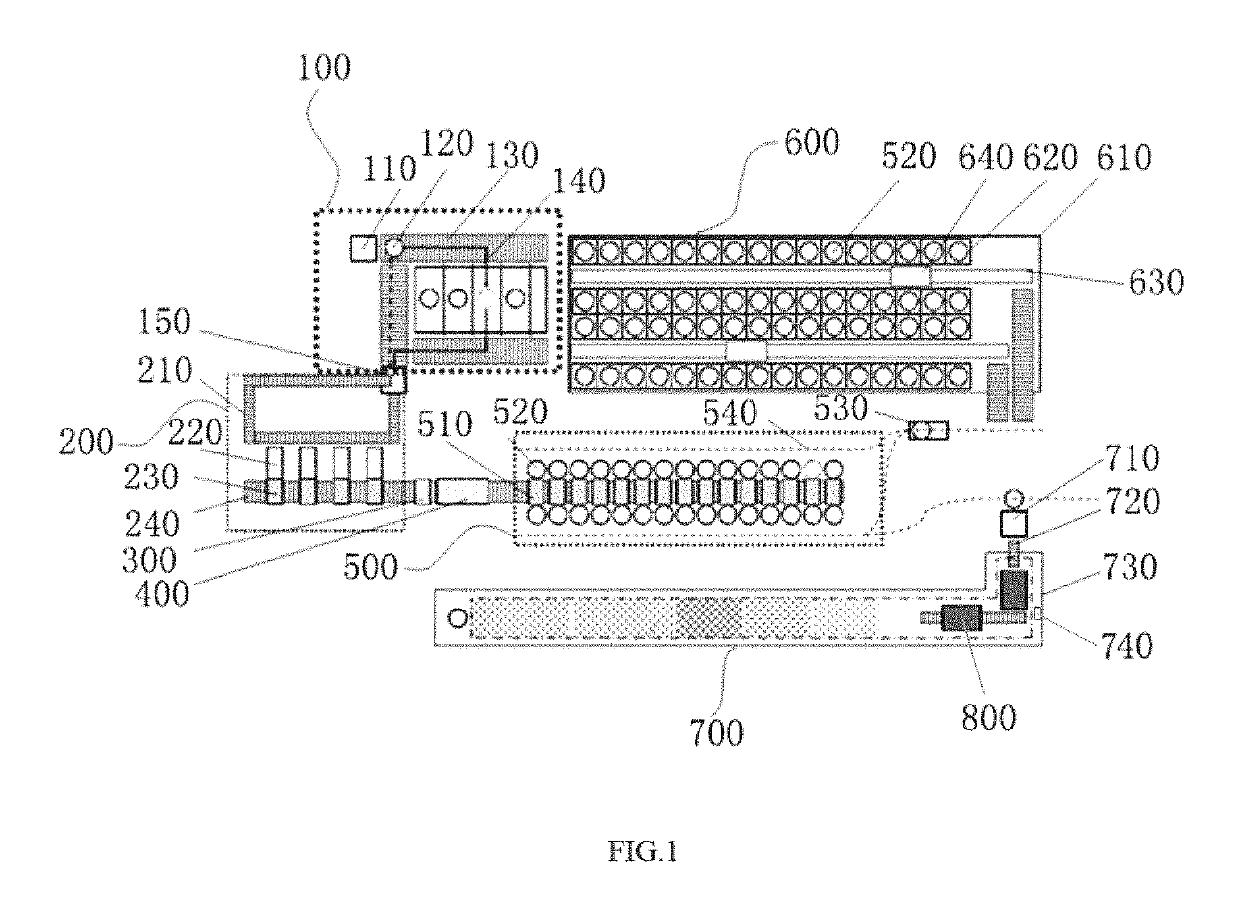

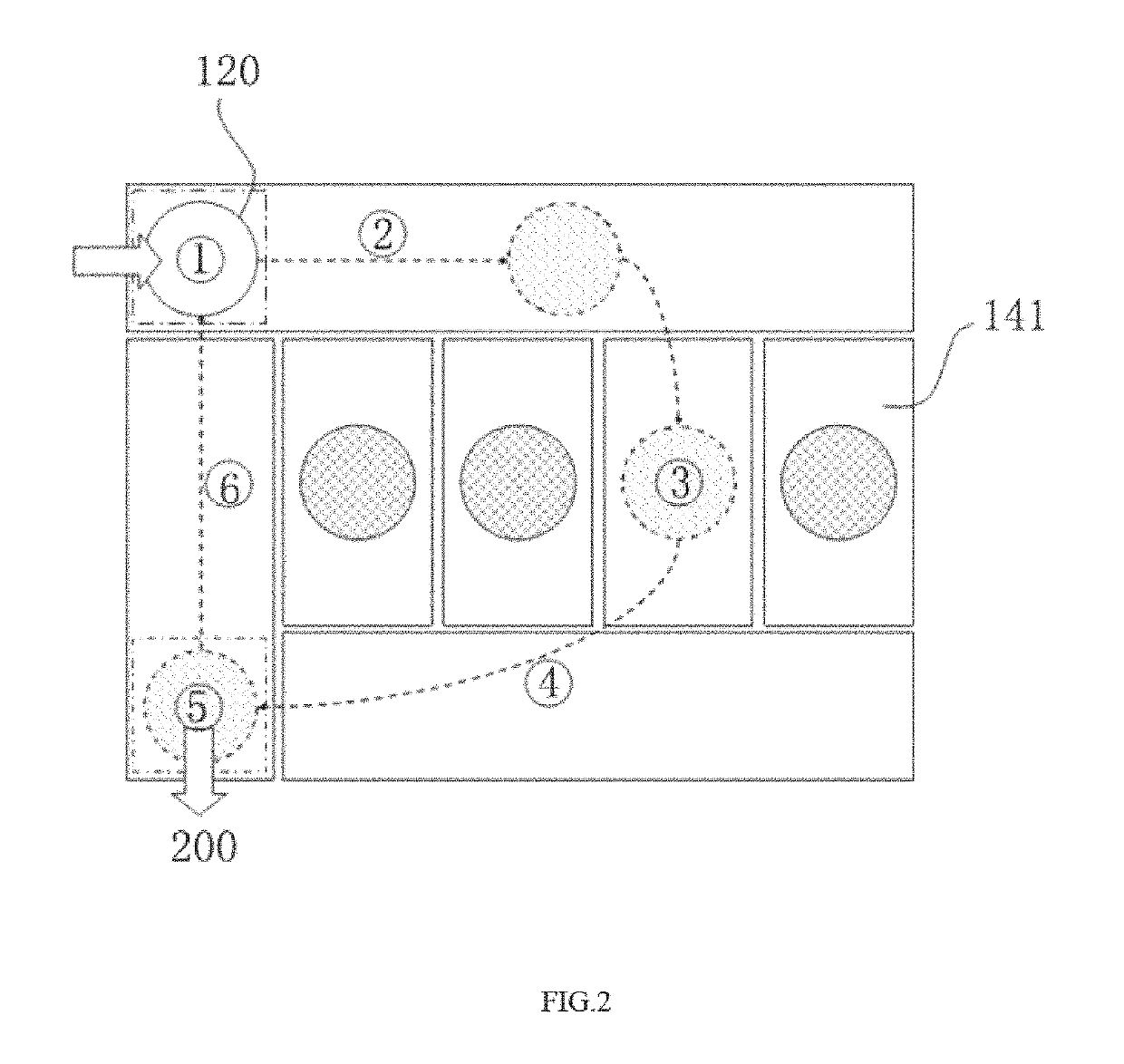

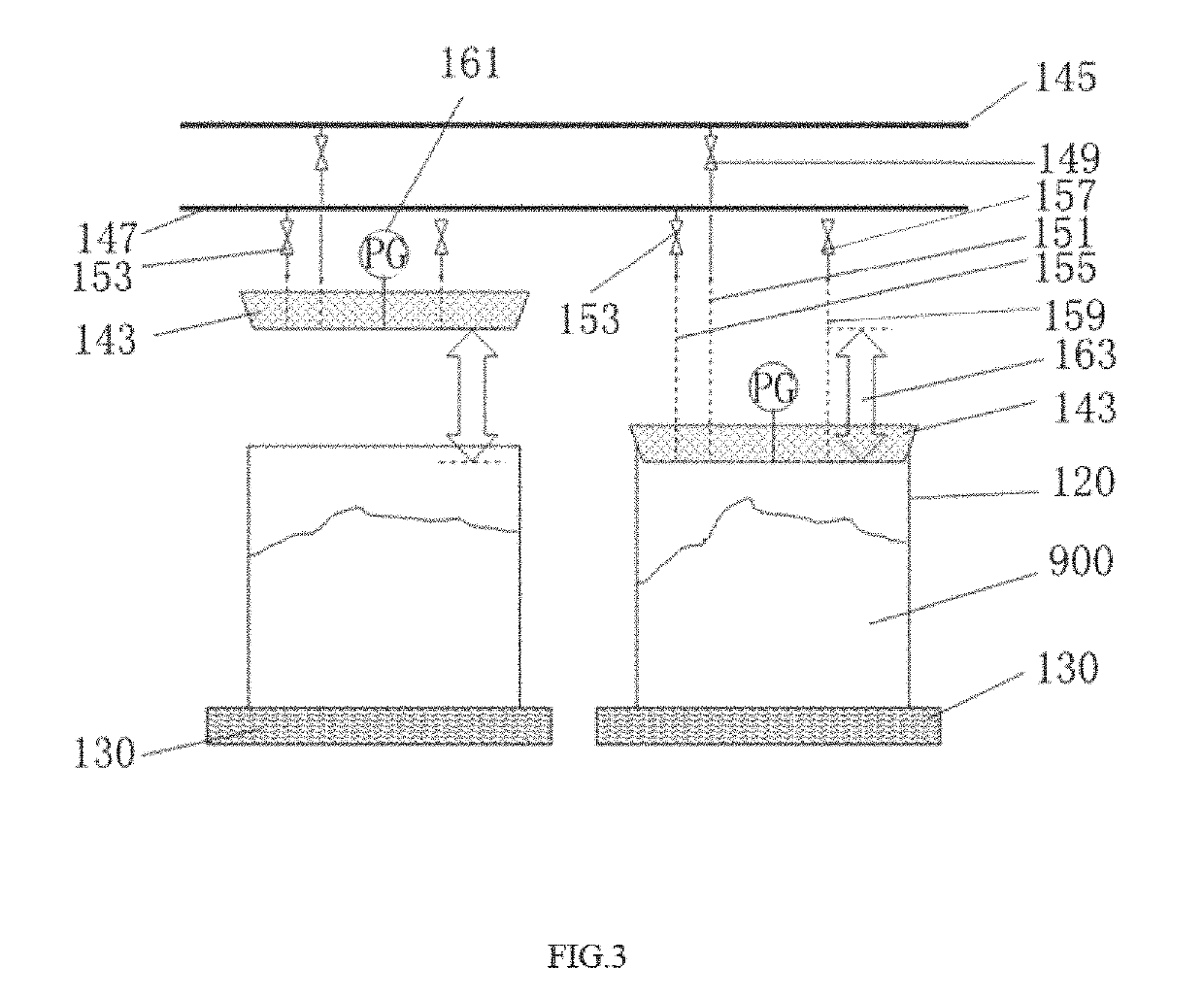

System and method for recycling fibers from textiles waste

ActiveUS10458047B2Fibre cleaning and opening machine combinationsSolid waste disposalFiberPre treatment

The present disclosure related to a system and method for recycling fibers from textiles waste. The system includes a first sanitization device; a pre-processing device; a fabric sorting device; a storage device; a fiber processing device; and a second sanitization device mounted in the fiber processing device. The first sanitization device, the pre-processing device, the fabric sorting device, the storage device and the fiber processing device are arranged along a transmission path of the textiles waste.

Owner:NOVETEX TEXTILES LTD

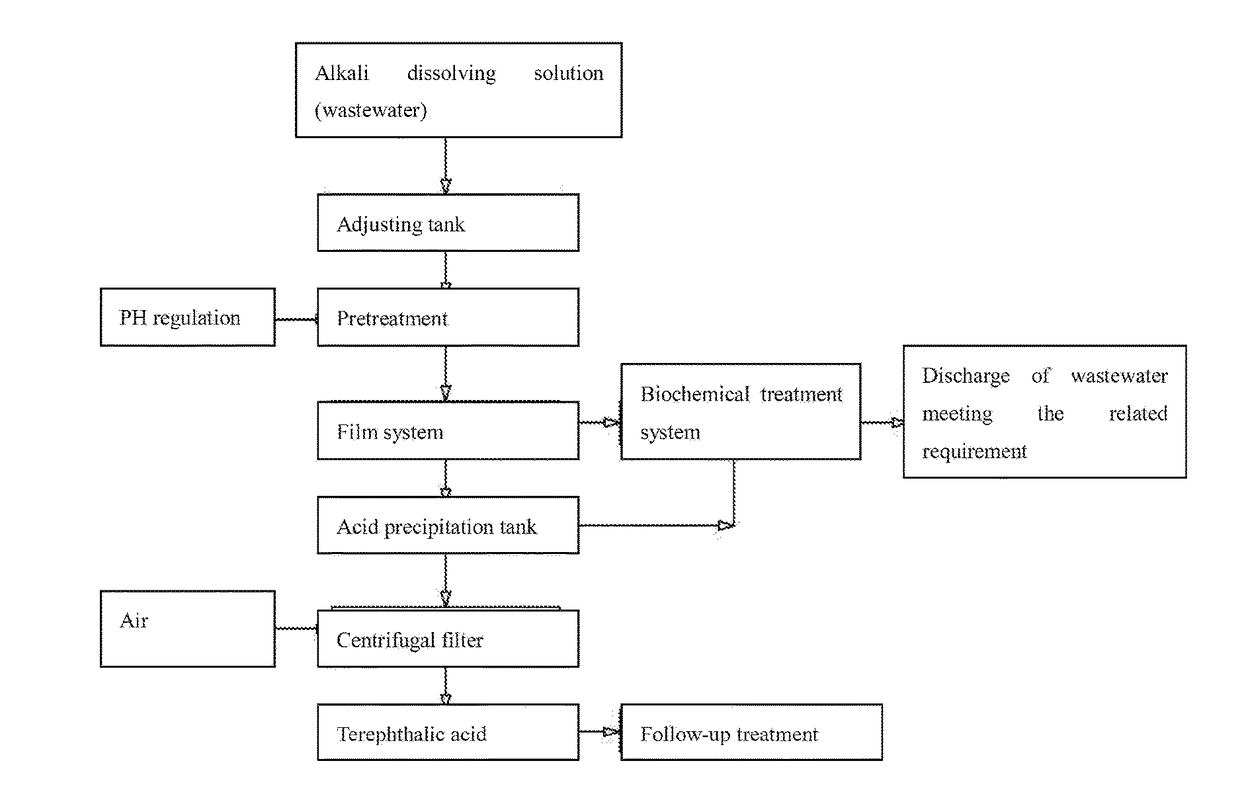

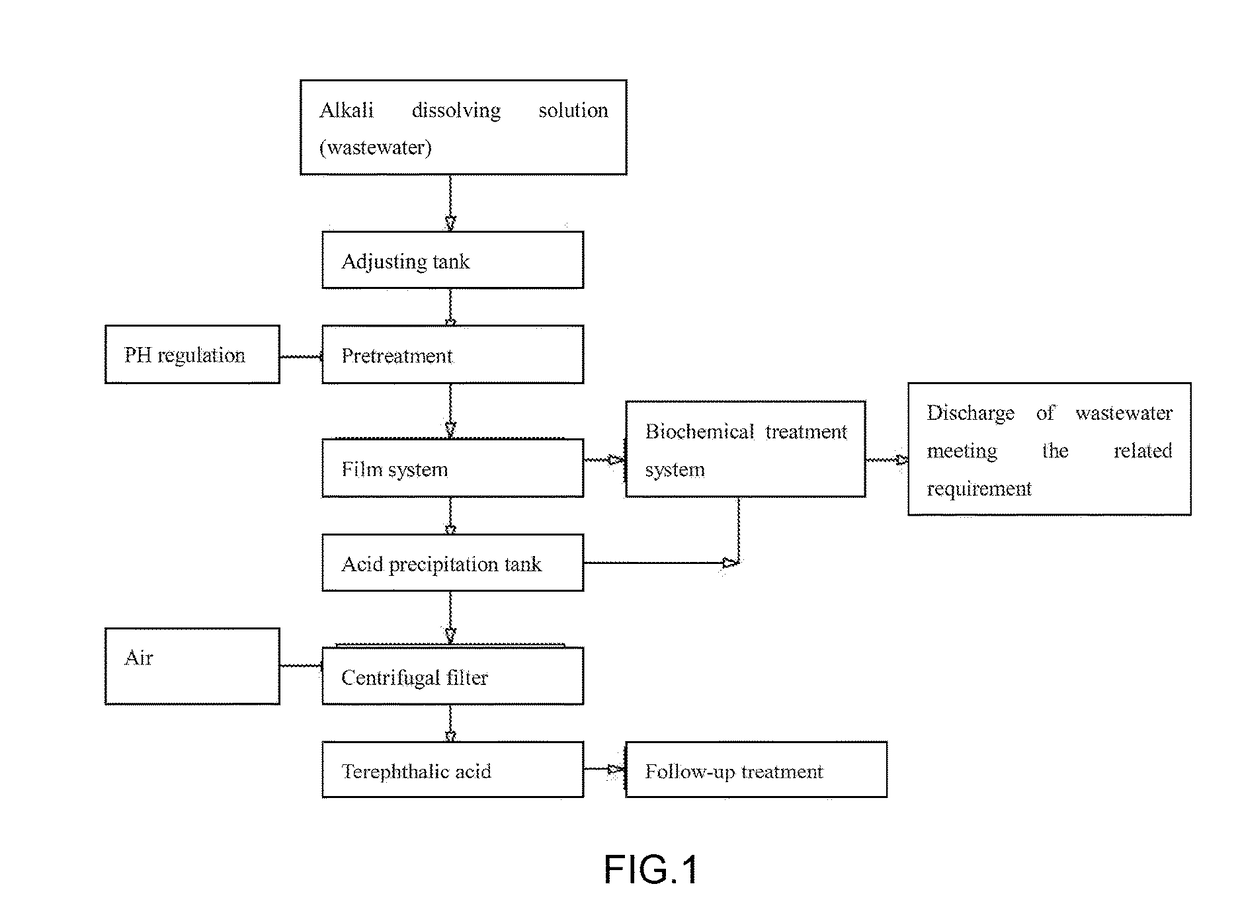

Technology for Recovery, Regeneration and Reuse of Soluble Textiles

InactiveUS20180002837A1Ensures spinnabilityEnsure wear performanceProductsReagentsTextile fiberDissolution

The invention discloses a technology for recovery, regeneration and reuse of soluble textiles. The technology comprises the steps of: the dissolution-controlled soluble polyester fibres are processed into soluble apparel accessories through conventional weaving, dyeing, finishing and tailoring or injection molding; the apparels or the soluble apparel accessories are dissolved under a certain condition, on one hand, the dissolving solution is filtered and solutes are recovered to obtain a high purity of terephthalic acid and ethylene glycol, which are reused to the polymerization of the soluble polyester, and the slices of the soluble polyester are obtained to be re-spun into the soluble fibres for reuse; on the other hand, the incompact and undissolved textiles are treated into an incompact fibre aggregation with good qualities by processes including disinfection, decolourization or redyeing, which are processed into high-quality textile fibres for reuse after drying or softly carding.

Owner:YU YANPING +3

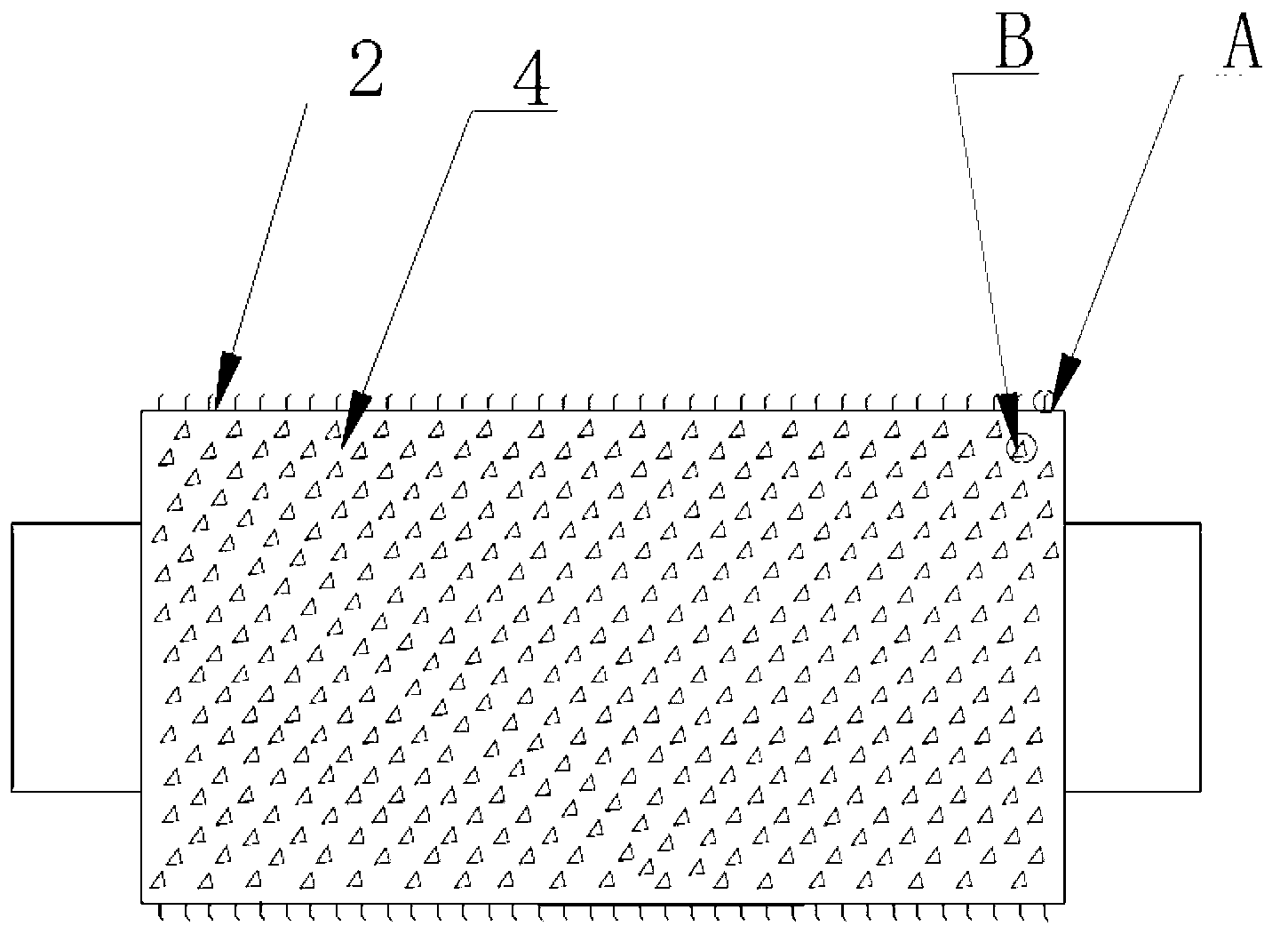

Waste fiber leftover pre-opener

ActiveCN103147172AMeet reuse requirementsReduce manufacturing costFibre cleaning/opening machinesTextile disintegration and recoveryFiberCircular economy

The invention relates to a waste fiber leftover pre-opener, belonging to the field of non-woven fabric machines. The waste fiber leftover pre-opener comprises a pre-opening roller rack, a waste fiber leftover conveying mechanism, a pre-opening roller, a pressing mechanism, a feeding mechanism, a pre-opening roller driving mechanism, a power transmission mechanism and a fiber leading-out mechanism, wherein a first wallboard is fixedly arranged above one side of the pre-opening roller rack and a second wallboard is fixedly arranged above the other side of the pre-opening roller rack; the waste fiber leftover conveying mechanism is connected with one end of the pre-opening roller rack; the pre-opening roller is supported between the first wallboard and the second wallboard; the pressing mechanism is arranged on the waste fiber leftover conveying mechanism; the feeding mechanism is arranged on the pre-opening roller rack and is arranged between the pre-opening roller and the pressing mechanism; the pre-opening roller driving mechanism is arranged on the pre-opening roller rack and is connected with the pre-opening roller; the power transmission mechanism is arranged on the pre-opening roller rack and is connected with the waste fiber leftover conveying mechanism, the pressing mechanism and the feeding mechanism; and the fiber leading-out mechanism is fixedly arranged on the pre-opening roller rack. The waste fiber leftover pre-opener has the advantages that the opening effect is good, the opening efficiency is ideal, the requirement on reuse of waste fibers can be satisfied, the resources are saved, the environment is protected, the circular economy is reflected and the manufacturing cost of automobile interior ornaments is reduced.

Owner:江苏常盛无纺设备有限公司

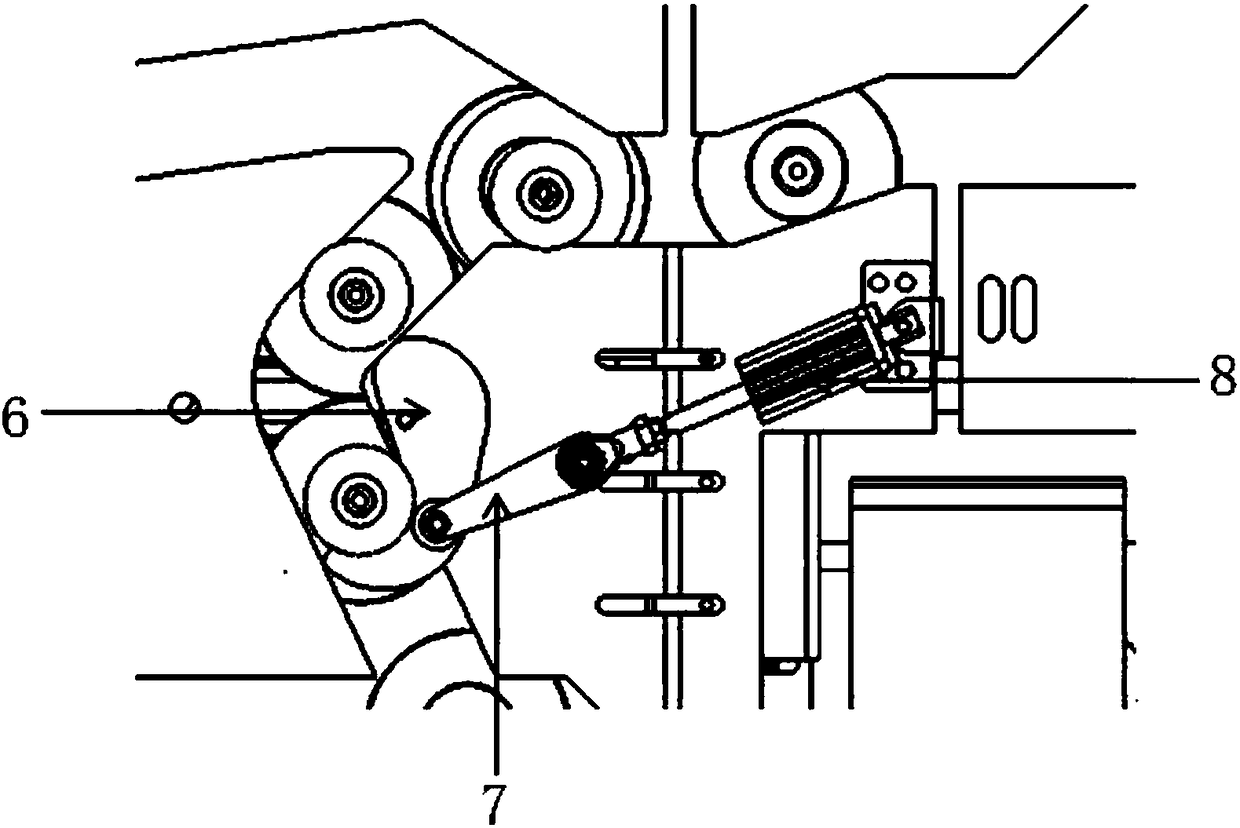

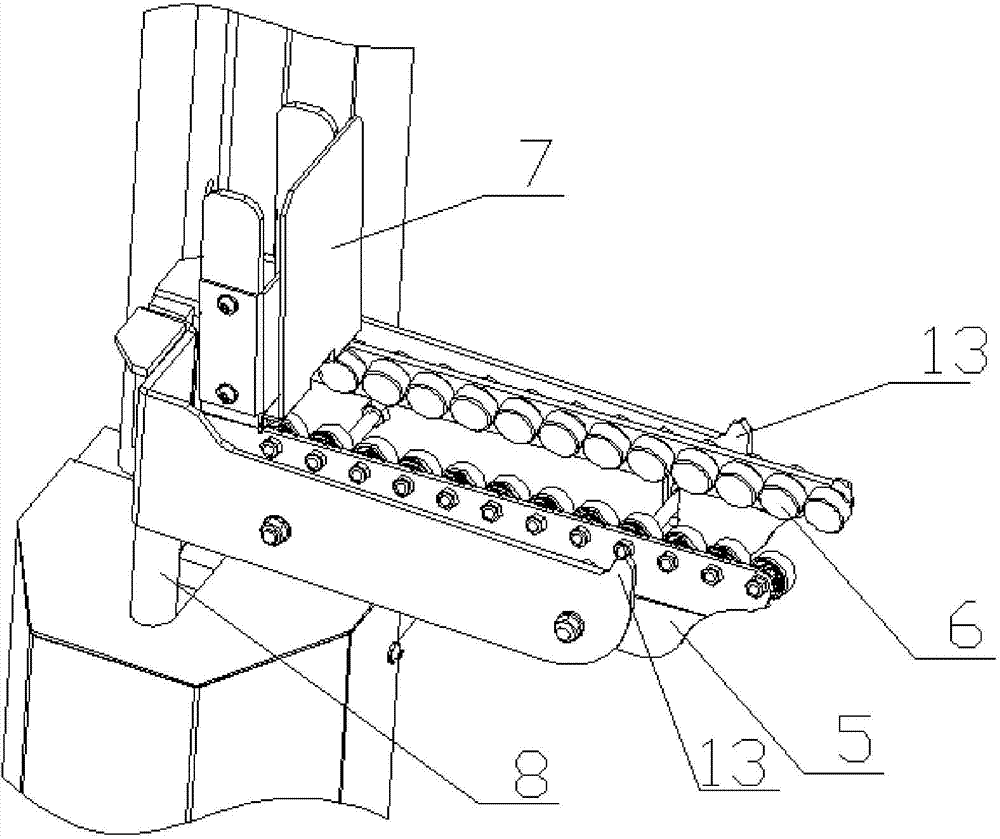

Cone yarn carrying steering mechanism

ActiveCN104762706AAvoid damageIncrease productivityTextile disintegration and recoveryTextiles and paperYarnConveyor belt

The invention discloses a cone yarn carrying steering mechanism which comprises a frame, a cone yarn supporting mechanism, a steering transmission mechanism and a driving mechanism. A supporting portion which can just contain cone yarn is formed on the cone yarn supporting mechanism and can be just in corresponding linkage with the tail end of a conveyor belt of cone yarn outputting equipment. A steering shaft is fixedly connected to the lower end of the cone yarn supporting mechanism and can rotate around a vertical shaft to be inserted into the steering transmission mechanism. The steering transmission mechanism can be installed on the frame in a lifting mode in the longitudinal direction. The driving mechanism drives the steering transmission mechanism to ascend or descend. The steering transmission mechanism ascends and descends to drive the steering shaft to rotate forwards or reversely by 90 degrees in a reciprocating mode. The cone yarn carrying steering mechanism is simple in structure and ingenious and does not occupy large space, ascending, steering and conveying of the cone yarn to the next working procedure can be automatically achieved at the same time, the production efficiency of the spinning technology is effectively improved, manual operation is avoided, damage to the cone yarn is avoided, and the spinning quality is ensured.

Owner:苏州智尊智能科技有限公司

Process for regenerating post-consumer and post-industrial fibers

InactiveUS20110094691A1Uniform colorImprove product performanceGlass making apparatusTextile disintegration and recoveryFiberPolymer science

Processes for producing regenerated fibers from post-consumer and post-industrial waste are disclosed. The process generally involves obtaining a source of post-industrial and / or post-consumer scrap material comprising fibers, cutting the material into a desirable size in the range of from one square inch to thirty square inches, detangling the fibers, removing any finish from the fibers, if present, combing and / or picking the fibers to convert any threads into fibers, humidifying the fibers, and intimately blending the fibers. These regenerated fibers can be blended with other fibers, and intimately blended to provide a uniform blend of fibers. The fibers can then be subjected to a carding process to orient the fibers. The regenerated fibers can be used in any application that would otherwise use virgin fibers, including their use to form woven or non-woven materials.

Owner:PSIL HLDG LLC

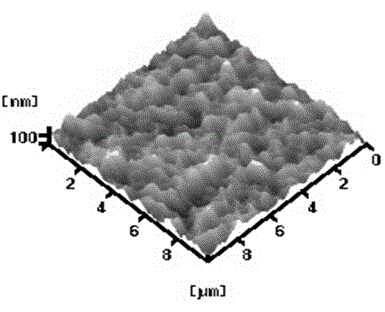

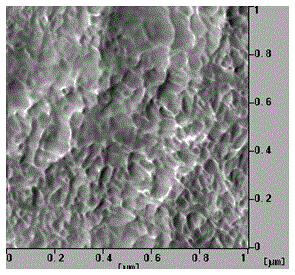

Collagen fiber capable of being directly used for spinning and dermal fiber leather prepared by the same

ActiveCN104894695AStrong and effective playI can improve the effect of the soft processingUltrasonic/sonic fibre treatmentTextile disintegration and recoveryElectrical impulseSolvent

The invention discloses a collagen fiber capable of being directly used for spinning and dermal fiber leather prepared by the same. The collagen fiber is obtained by utilizing the strong effect of a polar solvent rich in hydroxyl groups and the combination of an ultrasonic treatment mode to achieve dissociation of intermolecular high-crystallized hydrogen bonds on the conditions of great mildness, obtaining raw material loosed in structure, performing drum treatment softening, liquid fiber separation and fiber drying, and then performing treatment on the dried collagen fiber in a single fiber state in combination with electrical impulse of an appropriate strength on the conditions of nitrogen protection. The preparation process is clean and free of pollution, and the manufactured collagen fiber can be directly spun through an existing spinning process without needing graft modification or compounding.

Owner:浙江圣禾纤维科技有限公司

Method and apparatus for recycling carpet

The present invention is directed to an apparatus and method for separating carpet fibers from a backing material to which said fibers are secured. The apparatus includes a belt for driving a carpet strip having one or more backings and one or more fibers secured on a face of said backing into the operative part of the device. There are a pair of rollers that are adapted to receive the carpet strip from said belt, and pass the carpet strip to a dish plate. The dish plate has an edge extending upwardly from the dish plate. The face of the carpet having the fibers contacts the edge after the carpet passes through the rollers. The edge of the blade holds the carpet presenting it to the main drum. The main drum rotates downwards and has a plurality of pins that shred the carpet backing and tear apart and free the face carpet fibers from the backing fibers. The face fibers pass to a receptacle for recycling. The torn backing fibers, being usually longer and lighter than the face fibers, remain within the pins of the drum and are transported towards the back end of the machine and fall in a different receptacle for recycling.

Owner:LEVY FRANK +1

Production line of regenerated spinnable fiber from waste textile of general life clothes

ActiveCN107237011ASolve social stockNo emissionsSolid waste disposalTextile disintegration and recoveryFiberEnvironmental resistance

The invention discloses a production line of regenerated spinnable fiber from waste textile of general life clothes. According to the process, the production line comprises a disinfection device, a sorting device, a cutting device, a button removing device, an opening device and a carding device; the sorting device performs sorting according to colors; the button removing device and the opening device use a steel chain tearing strip and a tearing wheel for mutual tearing; there are multiple choices for the disinfection device, the opening device, the sorting device and the carding device. The invention is suitable for processing recovered regenerated fiber of life clothing, which solves environmental protection problems and livelihood issues in the current society; the production power of each production line reaches 1 to 3 tons and the processing capability is large.

Owner:林雁 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com