Composite cotton and polyester yarn and method for making same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012]Textile waste in the form of cuttings, trimmings and clippings is collected from manufacturing facilities around the world before it is discarded for deposit in a landfill or incinerated. The waste cotton fabric has previously been bleached and dyed, so additional treatment or dyeing is not required and therefore no additional industrial effluents which could add to the further pollution of the environment are produced.

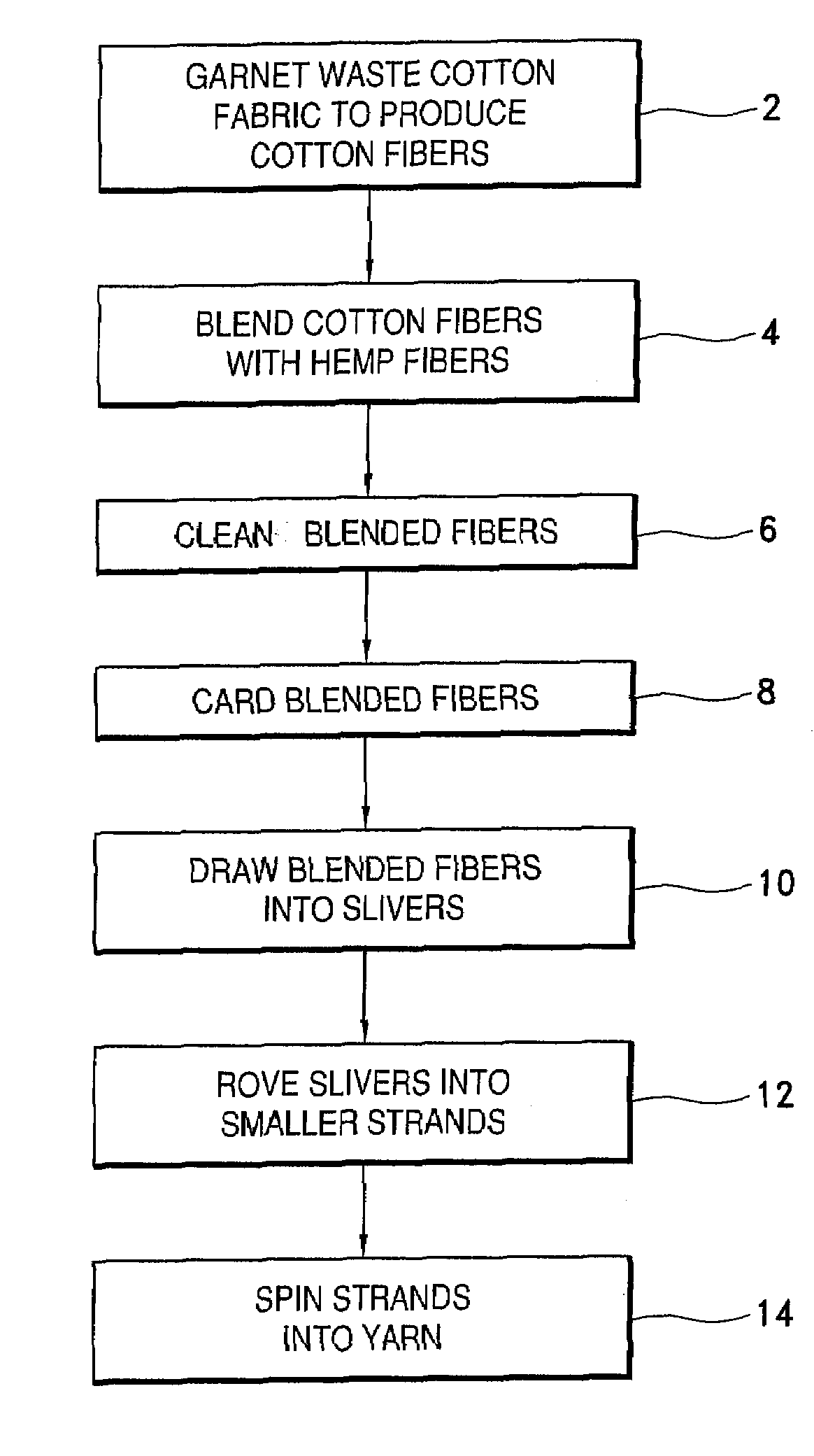

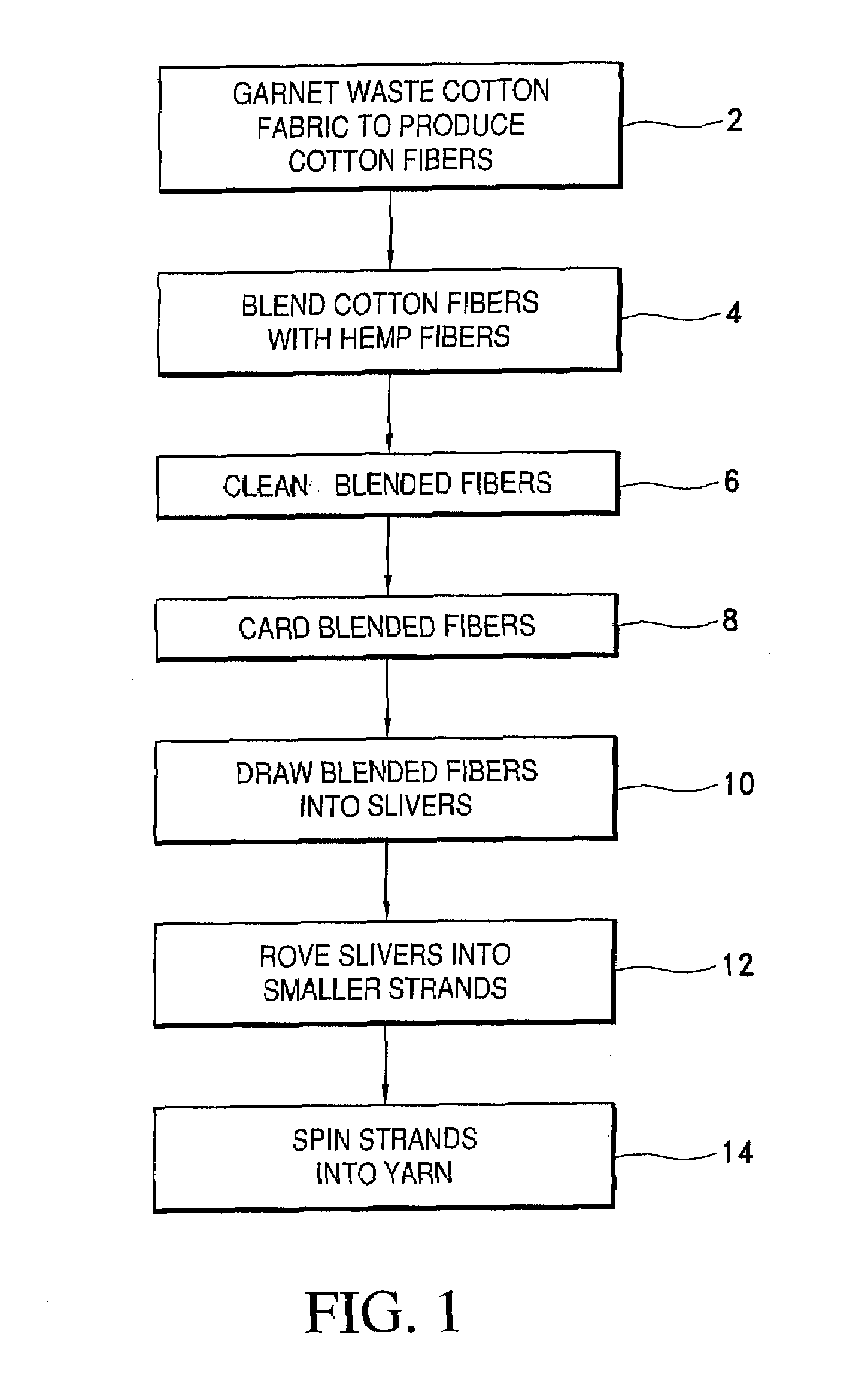

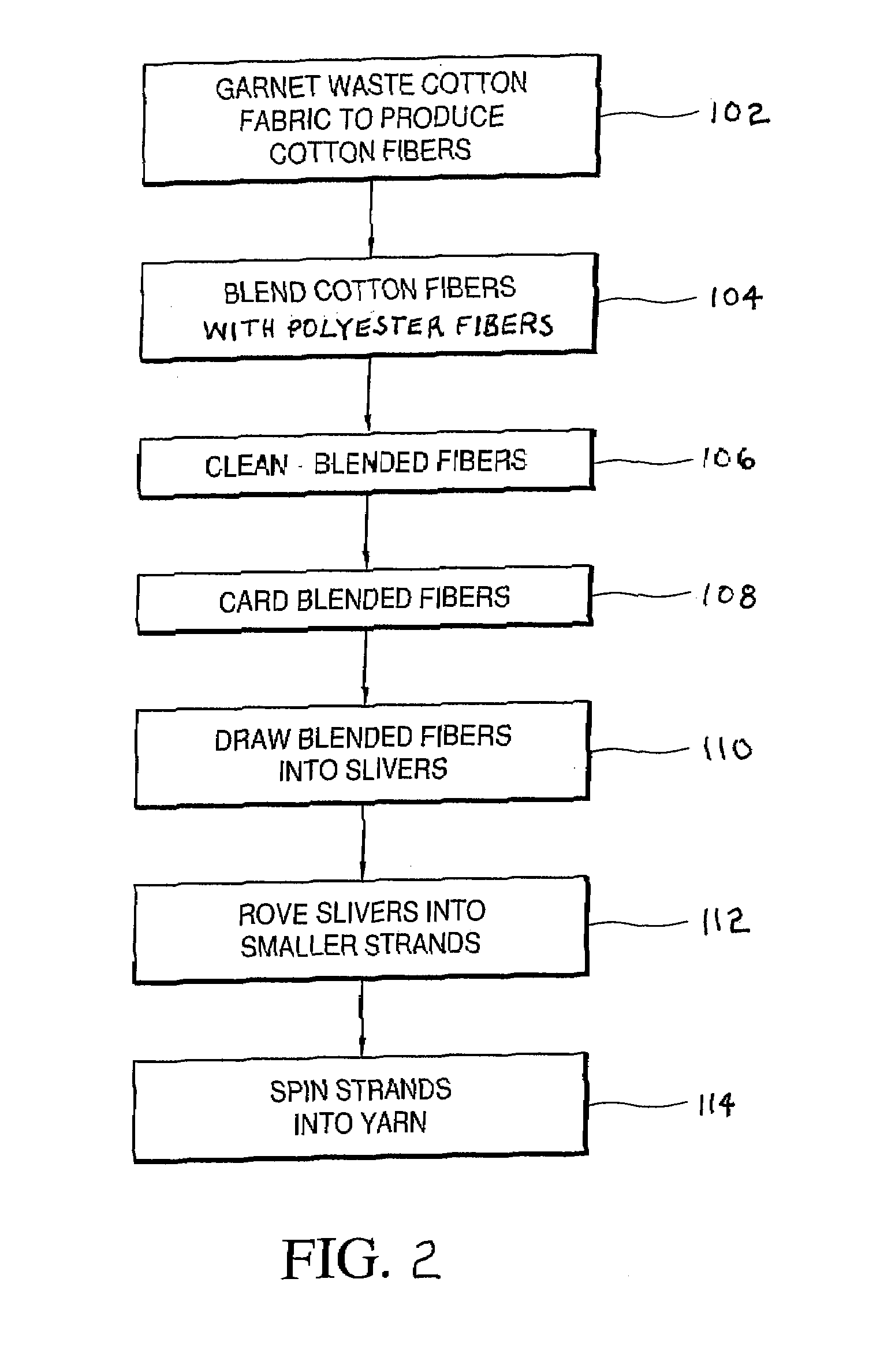

[0013]The waste materials are sorted by color range and cleaned to remove any foreign material such as paper or metal from labels, buttons, or the like. Referring to FIG. 1, the sorted waste materials are then subjected to garnetting 2 which is a process by which materials such as clippings and trimmings, threads, woven cloth scraps and the like are broken up and returned to a fluffy fibrous condition similar to the original state of the cotton. This is preferably accomplished by first cutting or chopping the waste materials into smaller pieces of approximately ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com