Production process and equipment for regenerating blend-material worn-out garments into spinnable fibers

A production process and fiber technology, which is applied in the field of production process technology and equipment for regenerated spinnable fibers from mixed-material waste clothing, can solve problems such as environmental pollution, small size of production equipment, and low output, and achieve no environmental pollution, large production scale, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

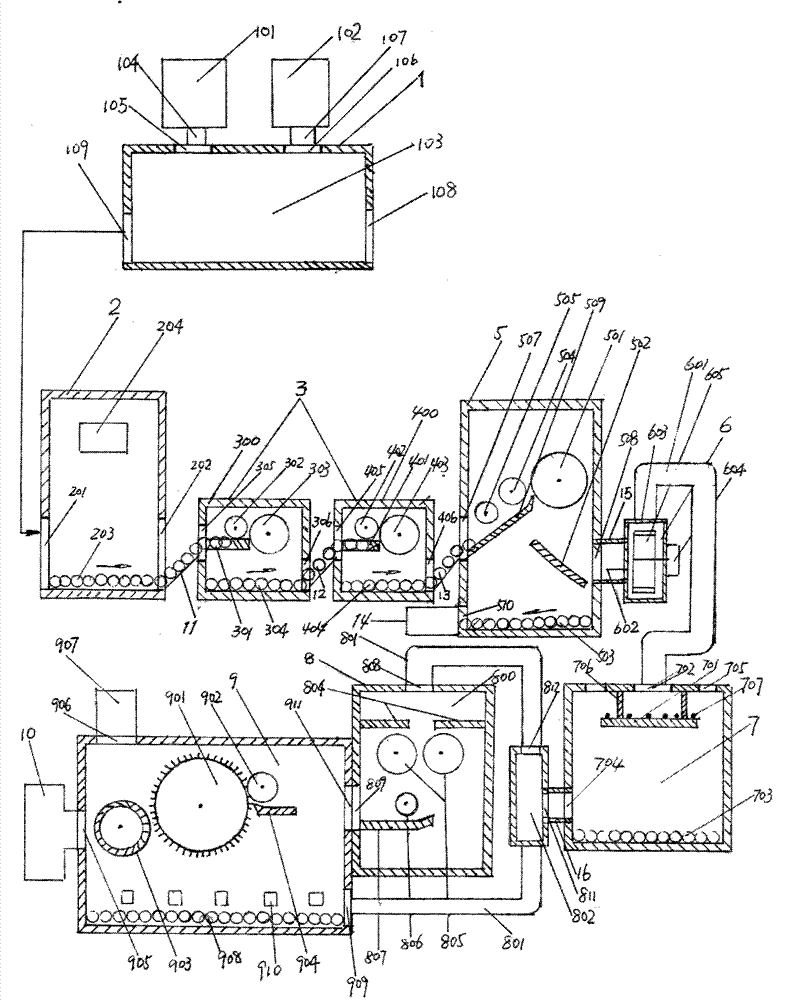

[0041] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

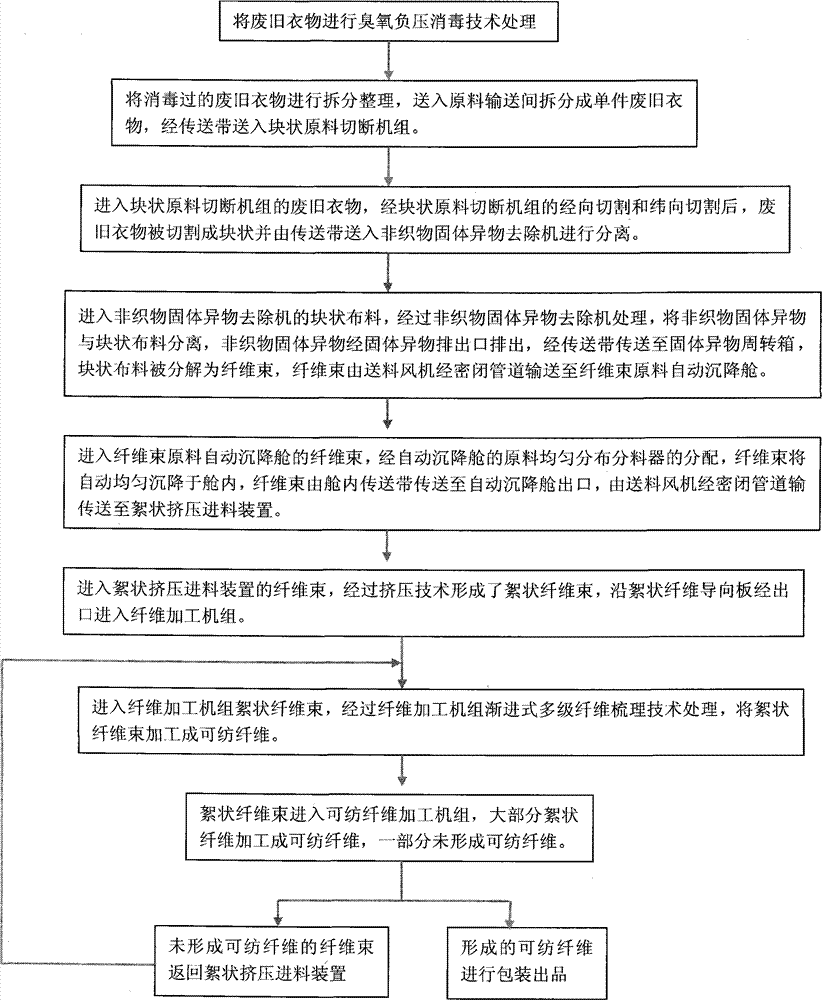

[0042] Such as figure 1 As shown, the production process of regenerated spinnable fibers from waste clothes with mixed materials adopts the following process: firstly, the process technology is to put the waste clothes into the disinfection machine for disinfection, and the disinfection technology is to penetrate the whole waste clothes through the negative pressure disinfection method of ozone , to achieve the disinfection effect. The sterilized waste and old clothes are put into the raw material sorting room for sorting, and then sent to the strip-shaped and block-shaped cutting machine for cutting through the conveyor belt, thus forming block-shaped raw materials. The bulk raw material enters the non-woven foreign matter processing machine for solid foreign matter separation and decomposes into block fiber bundles; the non-woven foreign matter produced by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com